A kind of dealumination method of hydrogen and ammonium y, zsm-5, beta and sapo-34 molecular sieves

A technology of ZSM-5 and molecular sieve, which is applied in the direction of molecular sieve characteristic silicoaluminophosphate, molecular sieve and alkali exchange phosphate, crystalline aluminosilicate zeolite, etc. It can solve the problems of complicated preparation process and uneven degree of dealumination of molecular sieve , to achieve the effect of a wide range of dealumination and easy control of the degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

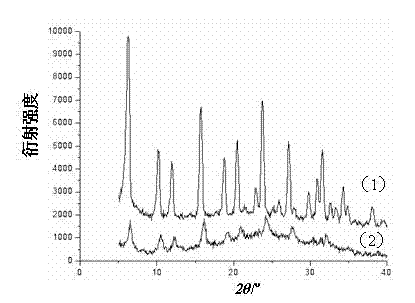

[0047] Put 1 g (tabletting sieve into 20-40 mesh) hydrogen type Y molecular sieve (HY, SiO2 / Al2O3=5) in a quartz fixed bed reactor, and pass pure N2 at 500 ℃ to pretreat the zeolite 40 min to get rid of the water. The bed temperature was reduced to 250 ℃, and at this temperature, a CCl4 / N2 mixed gas with a CCl4 concentration of 5% was passed into the reactor at a flow rate of 300 ml / min to dealumulate the hydrogen-type Y molecular sieve 12 min. Then switch the above mixed gas to pure N2, raise the bed temperature from 250 ℃ to 400 ℃, and purge the sample for 40 min at a flow rate of 300 ml / min. The XRD patterns of the molecular sieve after dealumination and the original parent hydrogen type Y molecular sieve are as follows figure 1 Shown. It is measured that the dealumination amount of the hydrogen-type Y molecular sieve caused by the dealumination process is 173.5 mg (calculated as Al2O3).

example 2

[0049] Repeat example 1, but change the mixed gas used for dealumination of hydrogen type Y molecular sieve from CCl4 / N2 with a CCl4 concentration of 5% to CHCl3 / N2 with a CHCl3 concentration of 300 ppm, and at the same time, change the flow rate of the mixed gas At 600 ml / min, the dealumination time was extended from 12 min to 1 h. The molecular sieve obtained after dealumination is similar to the XRD pattern of the original parent hydrogen-type Y molecular sieve. The dealumination amount of the hydrogen-type Y molecular sieve caused by the dealumination process was measured to be 8.9 mg (calculated as Al2O3).

example 3

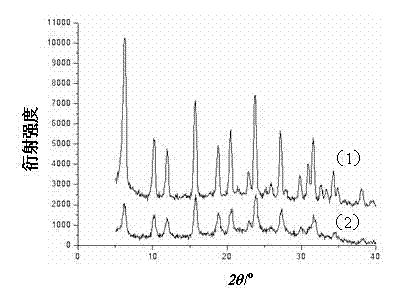

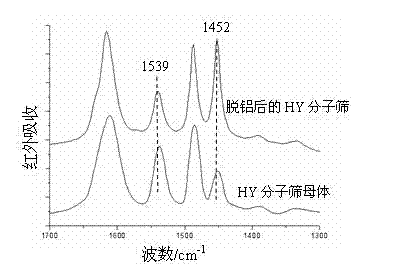

[0051] Repeat Example 1, but shorten the dealumination time of hydrogen type Y molecular sieve from 12 min to 4 min. It is measured that the dealumination amount of the hydrogen type Y molecular sieve caused by the dealumination process is 62.8 mg (calculated as Al2O3). The XRD patterns of the molecular sieve after dealumination and the original parent hydrogen type Y molecular sieve are as follows figure 2 Shown. The molecular sieve samples obtained after dealumination and the original precursor hydrogen-form Y molecular sieve samples were measured by pyridine adsorption infrared spectroscopy at 400 ℃. by image 3 It can be seen that the molecular sieve dealumed by this method has an infrared absorption at 1452 cm-1 nearly three times that of dealumination, which indicates that the molecular sieve dealumed by this method has a strong Lewis acid content that is nearly 3 times that of the original parent hydrogen type Y molecular sieve. Times. This result shows that the metho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com