Composite retarder braking orbit

A compound brake and retarder technology, which is applied in the direction of track brakes, railway car body parts, transportation and packaging, etc., can solve problems such as the inability to meet the function and performance of the retarder, and the poor effect, so as to change the quality of the working environment and reduce The effect of equipment maintenance personnel and engineering quantity and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] 1. Synthesis of noise reduction board materials:

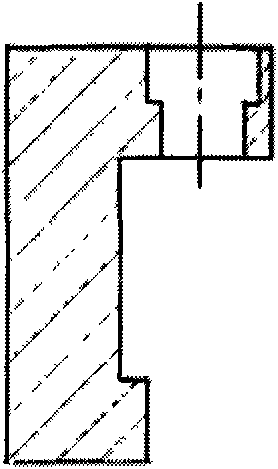

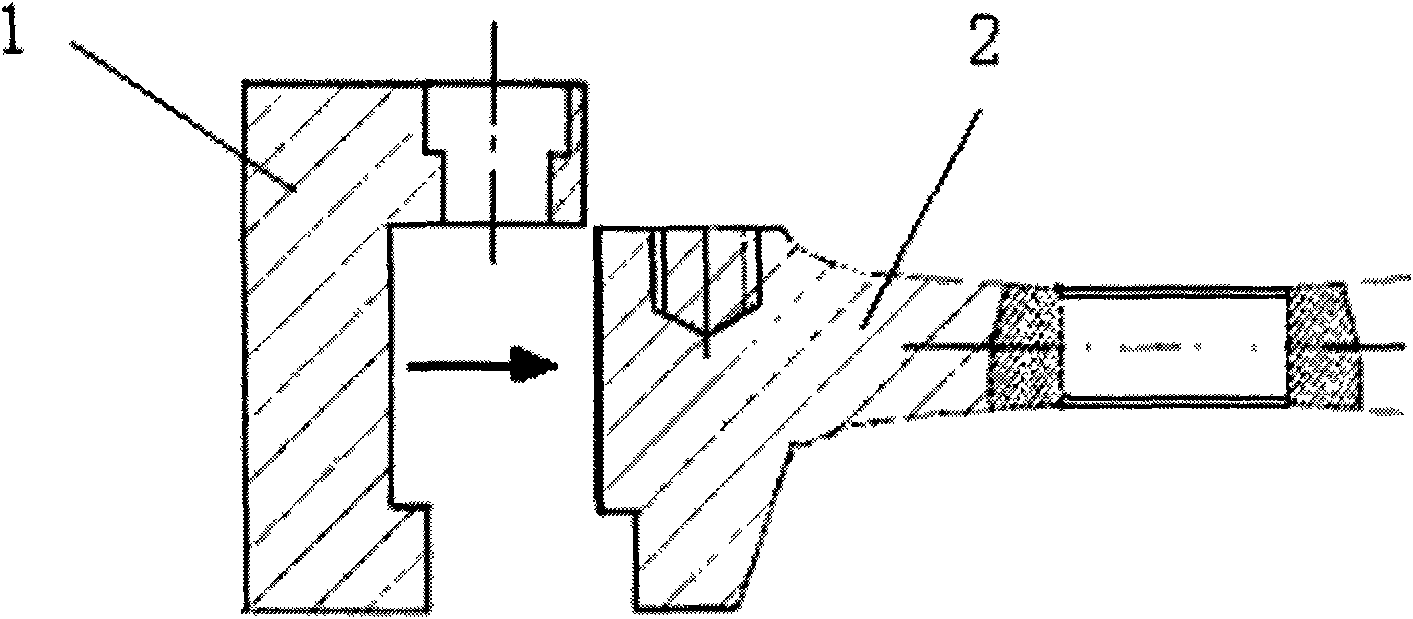

[0016] Since the brake rail of the retarder is the main brake force component, and it works in the open air without any lubrication, it belongs to the heavy-duty dry friction type. Judging from the classification of traditional friction materials, the selection range of brake materials should be mainly composite metal materials. Since its dual friction part is the wheel that must be protected, it is absolutely impossible to choose a material that will damage the wheel after friction with the wheel. From the perspective of the force characteristics, the new composite metal material must be able to withstand the impact force at the entrance of the brake caliper and the alternating stress generated during the friction process with the rotating wheel. In addition to mechanical strength, it must also have a good noise reduction effect. The coefficient of friction between it and the wheel must be reasonable. If the coeffici...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com