Modified high carbon ferro-chrome slag aggregate for road concrete and preparation method of modified high carbon ferro-chrome slag aggregate

A high-carbon ferrochromium, concrete technology, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problem that no high-carbon ferrochromium slag aggregate has been effectively used in road concrete, concrete and workability. It can reduce the problems of aggregate crushing value and poor volume stability of concrete, so as to achieve the effect of reducing poor volume stability, reducing interfacial tension and surface free energy, and improving applicability and safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The ferrochromium slag and basalt are crushed, shaped and screened, and the gradation is manually adjusted according to the proportion. Spray the modifier evenly on the surface of the aggregate. The dosage of the modifier is 3.4% of the aggregate mass until the surface is wet, and then send it to the finished product stack for 1 day before use. At the same time, it should be sprayed evenly. Using these two aggregates to mix concrete, the mixing mass ratio is cementitious material (cement, P.O42.5R, the same below): water: coarse aggregate: fine aggregate = 1: 0.6: 2.5: 1.83.

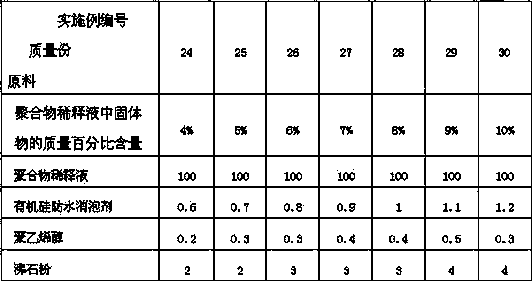

[0035] The preparation process of the modifier is as follows: firstly, the original emulsion of butadiene and styrene emulsion (45% by mass) is heated to 45°C, and tap water is added to dilute to 8% by mass, and then the admixtures and The ratio is: silicone defoamer 0.6% (based on 8% original emulsion, the same below), polyvinyl alcohol powder 0.3%, zeolite powder 3%, fully stirred and cooled to ...

Embodiment 2

[0038] Proceed as described in Example 1; except:

[0039] Its mixing ratio is cementitious material (cement: fly ash): water: coarse aggregate: fine aggregate = 1 (7.5: 2.5): 0.35: 2.1: 1.83.

[0040] After forming and curing and testing the mechanical properties of different ages, the 3d, 28d and 56d flexural / compressive strengths of the modified ferrochromium slag aggregate concrete are 7.5MPa / 46.4MPa, 8.2MPa / 63.7MPa and 9.8MPa respectively / 78.4MPa; the 3d, 28d and 56d folds / strengths of untreated carbon-chromium slag aggregate concrete are 5.8MPa / 44.9MPa and 7.6MPa / 61.5MPa and 8.3MPa / 78.2MPa, respectively.

Embodiment 3

[0042] Preparation of different grades of ordinary concrete:

[0043] The implementation process is carried out according to Example 1, and the modified carbon-chromium slag aggregate is obtained, wherein the fine aggregate modulus is 2.3, and the coarse aggregate is a continuous gradation of 5mm to 31.5mm, and its quality conforms to GBT14685-2011 "Construction Crusher". Stone and Pebble" and GB14684-2011 "Sand for Construction". Using this coarse and fine aggregate to mix concrete of different strength grades, the mixing ratio is cementitious material: water: coarse aggregate: fine aggregate = 1: (0.3, 0.4, 0.5, 0.6): 2.5: 1.83, of which 0.3 water The ash ratio is added with a polycarboxylic acid-based high-efficiency surfactant with a mass percentage of 0.3% of the cementitious material.

[0044] After forming, curing and testing, the 3d strength of the mixed concrete is 50.1MPa, 38.3MPa, 33.6MPa and 12.7MPa, the 28d strength is 64.8MPa, 48.1MPa, 40.4MPa and 22.3MPa, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com