Method for treating cefalexin enzyme-process synthesizing mother liquor wastewater

A cephalexin enzymatic method and a technology for synthesizing mother liquor are applied in the field of treatment of wastewater from cephalexin enzymatic synthesis of mother liquor, which can solve problems such as unsuitability for wastewater treatment, and achieve the effects of improving system operation stability, ensuring recovery rate and reducing treatment costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

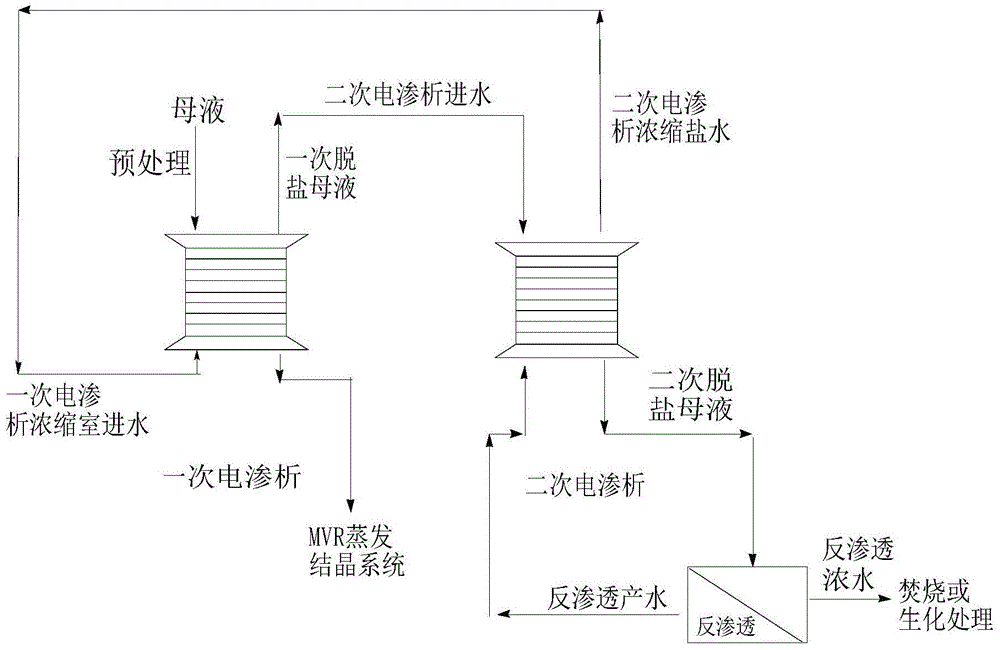

[0028] refer to figure 1 .

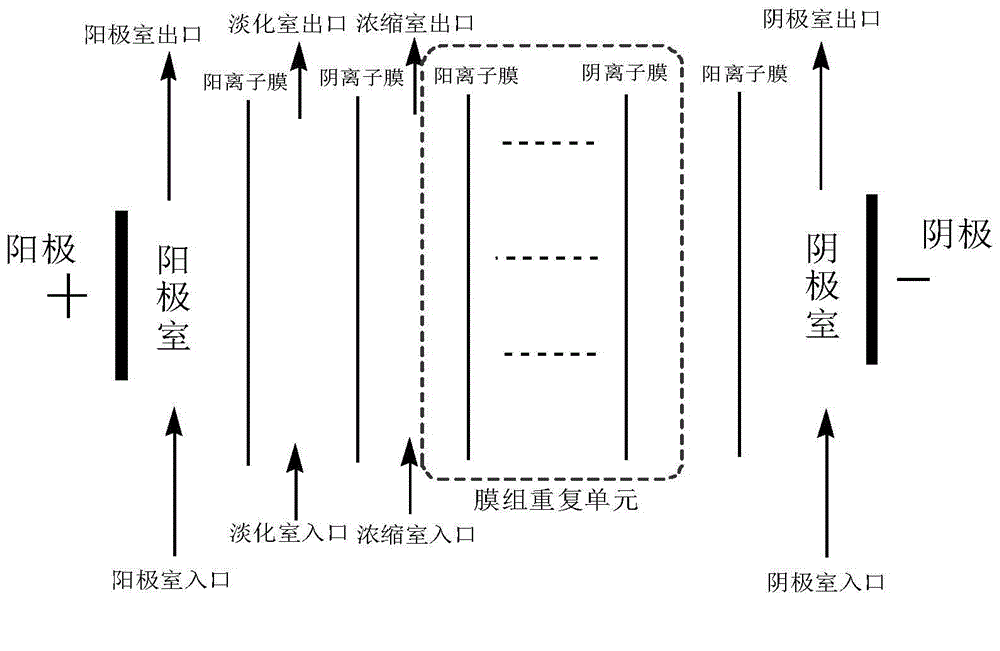

[0029] The mother liquor wastewater synthesized by cephalexin enzymatic method is treated by an electrodialysis integrated reverse osmosis system. The electrodialysis integrated reverse osmosis system is composed of primary electrodialysis equipment, secondary electrodialysis equipment, reverse osmosis device and MVR crystallization evaporator. The first-stage electrodialysis equipment is composed of anolyte chambers on both sides and an electrodialysis compartment sandwiched between the anolyte chambers on both sides. The electrodialysis compartment is composed of a concentration chamber and a desalination chamber composed of anion exchange membranes and cation exchange membranes arranged at intervals The concentrating chamber and the desalination chamber are equipped with a feed port and a liquid outlet; the electrodialysis compartment is provided with a circulation coil that can be fed into circulating frozen brine, and the anode liquid chamber ...

Embodiment 2

[0033] Taking the mother liquor wastewater produced by the process of preparing cephalexin by biological enzymatic method as the treatment object, a pilot test was carried out: the process of preparing cephalexin by biological enzymatic method mainly includes: obtaining side chains from benzaldehyde through chemical synthesis and enzymatic resolution; Through biological fermentation, chemical ring expansion, and enzymatic cleavage of the mold, the mother nucleus 7-aminodeacetoxycephalosporanic acid (7-ADCA) is obtained; the mother nucleus and the side chain are condensed by enzymes to obtain the cephalexin raw material; the acid / alkali crystallization separation method Obtain cephalexin product and mother liquor wastewater. Ammonium sulfate is about 43.31g / L, electrical conductivity is about 64.23ms / cm, biochemical oxygen consumption (COD) is about 128.00g / L, and ammonia nitrogen (NH3-N) is about 12.35 in the mother liquid waste water of described cephalexin enzymatic method. ...

Embodiment 3

[0041]Taking the mother liquor wastewater produced by the process of preparing cephalexin by biological enzyme method as the experimental object, the pilot test was carried out:

[0042] The process for preparing cephalexin by the biological enzymatic method mainly includes: obtaining side chains from benzaldehyde through chemical synthesis and enzymatic splitting; Alkanoic acid (7-ADCA); the cephalexin raw material is obtained by enzymatic condensation of the mother nucleus and the side chain; the cephalexin product and mother liquor wastewater are obtained by acid / alkali crystallization separation.

[0043] The ammonium sulfate of the mother liquor wastewater of the cephalexin enzymatic method is about 48.65g / L, the electrical conductivity is about 68.47ms / cm, the biochemical oxygen consumption (COD) is about 122.00g / L, and ammonia nitrogen (NH3-N) is about 11.72g / L.

[0044] The 40L cephalexin enzymatic mother liquor filtered through the PP cotton microporous filter eleme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com