Preparation methods of chemical micro-corroded coral aggregate and geopolymer-based ultrahigh-strength coral concrete

A micro-corrosion and concrete technology, applied in the field of concrete, can solve the problems of adverse effects on the durability of concrete, increase the corrosion of structural concrete steel bars, etc., and achieve the effects of delaying the setting and hardening process, low porosity, and prolonging the setting time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] The invention provides a method for preparing chemically slightly corroded coral aggregate, wherein the chemically slightly corroded coral aggregate is chemically slightly corroded coral coarse aggregate or chemically slightly corroded coral sand;

[0053] Wherein, the preparation method of the chemically slightly corroded coral coarse aggregate comprises: soaking the coral coarse aggregate in a phosphoric acid solution, taking out the chemically slightly corroded coral coarse aggregate without washing and directly drying;

[0054] The preparation method of chemical microcorrosion coral sand includes: soaking coral coarse aggregate in phosphoric acid solution, taking out the chemical microcorrosion coral coarse aggregate without washing and directly drying, and then ball milling and sieving, divided into the following different particle sizes Coral fine aggregate: 0.075~0.15mm, 0.15~0.3mm, 0.3~0.6mm, 0.6~1.18mm, 1.18~2.36mm, 2.36~4.75mm, 4.75~9.5mm; the method of directi...

Embodiment 1

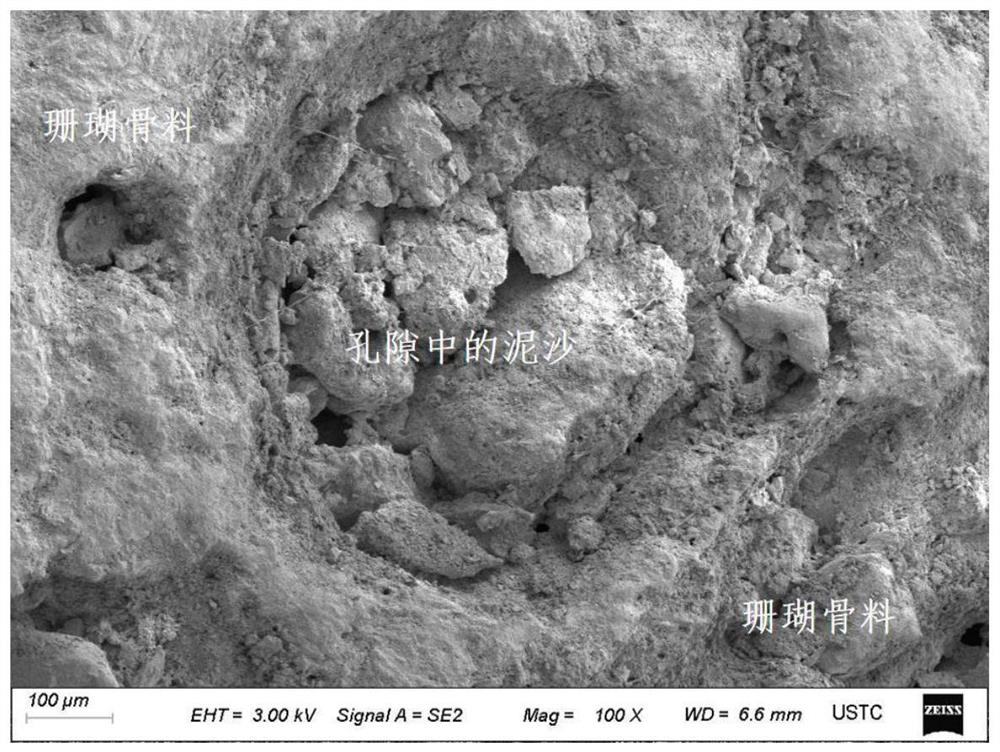

[0089] figure 1 It is the preparation flowchart of the chemical microcorrosion coral aggregate of the present embodiment;

[0090] Step 1: Soak coral coarse aggregate in 0.68mol / L phosphoric acid solution for 60 minutes (volume ratio of coral aggregate to phosphoric acid aqueous solution is about 1:2);

[0091] Step 2: After soaking, filter and dry, remove, and dry at 50°C for 24 hours without washing to obtain chemically corroded coral coarse aggregate;

[0092] Step 3: Ball-mill the chemically micro-corroded coral coarse aggregate and sieve it into the following chemically micro-corroded coral fine aggregates of different particle sizes: 0.075-0.15mm, 0.15-0.3mm, 0.3-0.6mm, 0.6-1.18mm , 1.18~2.36mm, 2.36~4.75mm, 4.75~9.5mm;

[0093] Step 4: Composite chemically micro-corroded coral fine aggregates of different particle sizes according to directional gradation to obtain the required gradation of chemically micro-corroded coral sand. The mass fraction is calculated. For spec...

Embodiment 2

[0097] The chemical micro-corrosion coral coarse aggregate prepared in Example 1 is used as aggregate to prepare concrete, and the concrete steps are as follows:

[0098] Raw materials: 9 parts of active powder (a mixture of slag and fly ash with a mass ratio of 3:1), 4 parts of alkali activator (sodium hydroxide modified water glass, modulus of 1.2), 7 parts of aggregate; The active powder and the alkali activator are stirred to prepare the geopolymer slurry, and then the aggregate is stirred to prepare the concrete. Then carry out the fresh mix performance test, and shape 40×40×160mm 3 Prismatic specimens are used for compressive strength tests.

[0099] The initial and final setting times were tested to be 56min and 100min respectively; the 3-day compressive strength was tested to be 34.2MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com