High-compressive-strength recycled concrete and preparation process thereof

A technology of recycled concrete and compressive strength, applied in the field of concrete production, can solve the problems of high water absorption, rough surface, high crushing index, etc., achieve the goal of reducing porosity and water absorption, improving interface transition zone, and improving resource utilization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

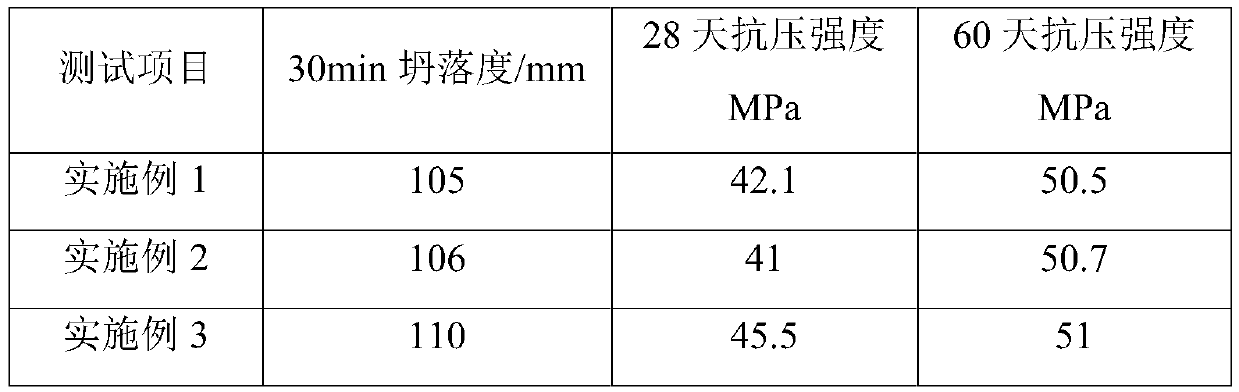

Examples

preparation example 1~5

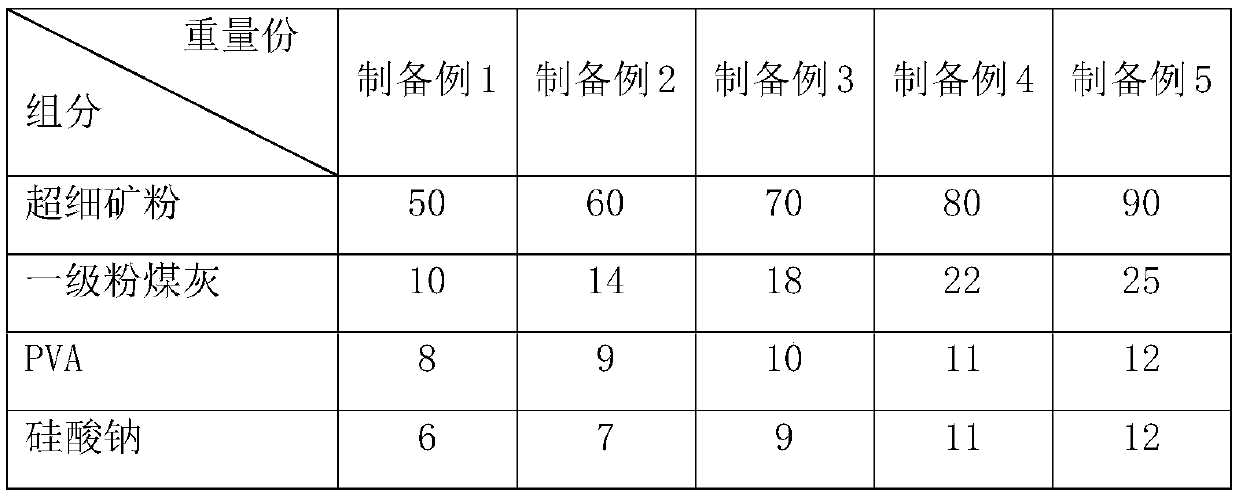

[0045] Raw material ratio of reinforcing modifier in Table 1 preparation example 1~5

[0046]

preparation example 1

[0047] Preparation Example 1: According to the ratio in Table 1, add 25 parts of ultrafine mineral powder into the mixer, then add 10 parts of fly ash, 8 parts of PVA, and 8 parts of sodium silicate into the mixer, and finally add the remaining 25 parts Superfine mineral powder, adjust the speed of the mixer to 150rpm, stir for 2 minutes, let it stand for 6 minutes, release the reinforcement modifier premix, then add the reinforcement modifier premix to the ball mill, grind for 40 minutes, and prepare the reinforcement modifier. .

preparation example 2

[0048] Preparation Example 2: According to the ratio in Table 1, add 30 parts of ultrafine mineral powder into the mixer, then add 14 parts of fly ash, 9 parts of PVA, and 7 parts of sodium silicate into the mixer, and finally add the remaining 30 parts Superfine mineral powder, adjust the speed of the mixer to 165rpm, stir for 2 minutes, let it stand for 7 minutes, release the reinforcement modifier premix, then add the reinforcement modifier premix to the ball mill, and grind for 45 minutes to prepare the reinforcement modifier. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com