Self-compacting concrete for floor heating protection layer and preparation method thereof

A technology of self-compacting concrete and protective layer, which is applied in the field of self-compacting concrete to achieve the effect of small dry apparent density, small load and avoid shrinkage cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

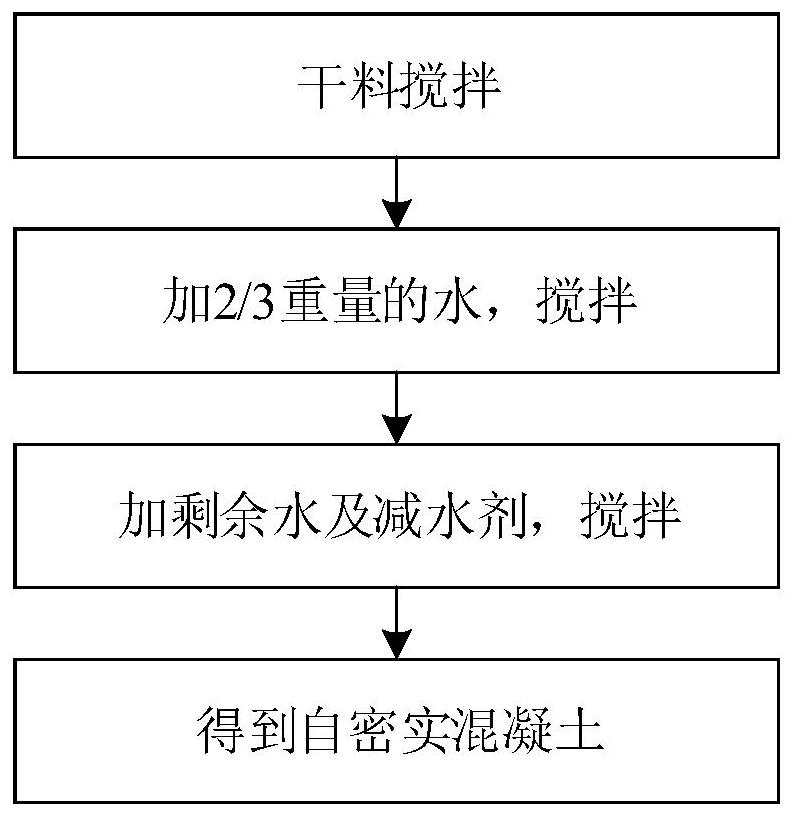

[0028] as attached figure 1 Shown, the present invention also provides a kind of preparation method for the self-compacting concrete of ground heating protective layer, comprises the following steps:

[0029] Step 1. According to the mass fraction requirements of each raw material, take sulfur-fixing ash, slag and cement, put them into a forced mixer, and stir the dry materials to obtain uniformly mixed dry materials.

[0030] Step 2. Add 2 / 3 weight of water to the uniformly mixed dry material, and stir to obtain a viscous mixture; wherein, the stirring time is 60-80s, and the stirring rate is 45r / min.

[0031] Step 3. Add the water reducer to the remaining water, mix and add to the viscous mixture in step 2, and stir to obtain the self-compacting concrete; wherein, the stirring time is 160-180s, and the stirring rate is 45r / min.

[0032] The self-compacting concrete for floor heating protective layer and its preparation method according to the present invention adopts slag...

Embodiment 1

[0035] This embodiment 1 provides a kind of self-compacting concrete that is used for floor heating protective layer, and the raw material composition of described self-compacting concrete comprises:

[0036] P.O42.5 Ordinary Portland Cement: 210kg;

[0037] Sulfur-fixing ash: 600kg;

[0038] Slag: 605kg;

[0039] Polycarboxylate high-performance water reducer: 18kg;

[0040] Water: 285kg.

[0041]Among them, the solid content of polycarboxylate high-performance water reducer is 30%; the average particle size of sulfur-fixing ash is 40μm, and the specific surface area is 425m 2 / kg, the loss on ignition is 7%; the slag is the coal-fired waste slag discharged from the coal-fired power plant, and the fineness modulus of the slag is 2.6.

[0042] making process:

[0043] Step 1. According to the mass fraction requirements of each raw material, take sulfur-fixing ash, slag and cement, put them into a single-horizontal shaft forced mixer, and stir the dry materials to obtain u...

Embodiment 2

[0048] This embodiment 2 provides a kind of self-compacting concrete that is used for floor heating protective layer, and the raw material composition of described self-compacting concrete comprises:

[0049] P.O42.5 Ordinary Portland Cement: 260kg;

[0050] Sulfur-fixing ash: 530kg;

[0051] Slag: 710kg;

[0052] Polycarboxylate high-performance water reducer: 27kg;

[0053] Water: 260kg.

[0054] Among them, the solid content of polycarboxylate high-performance water reducer is 20%; the average particle size of sulfur-fixing ash is 30μm, and the specific surface area is 450m 2 / kg, the loss on ignition is 4%; the slag is the coal-burning waste slag discharged from the boiler, and the fineness modulus of the slag is 2.7.

[0055] making process:

[0056] Step 1. According to the mass fraction requirements of each raw material, take sulfur-fixing ash, slag and cement, put them into a single-horizontal shaft forced mixer, and stir the dry materials to obtain uniformly mixe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com