C45 mass concrete and preparation process thereof

A large-volume concrete and cement technology, applied in the field of concrete preparation, can solve the problems that it is difficult to ensure that the concrete does not crack, and the strength level is high, and achieve the effects of improving the heat that cannot be dissipated in time, improving the anti-cracking performance, and reducing the dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] The preparation process of paraffin microcapsules is:

[0048] 1. Dissolve 30g of polyvinyl alcohol in 400ml of distilled water and heat to dissolve the polyvinyl alcohol aqueous solution for later use.

[0049] 2. Put urea, distilled water and polyvinyl alcohol aqueous solution in 70°C constant temperature water, stir, adjust pH=2 with 0.5mol / L hydrochloric acid, add solid paraffin, stir at constant temperature for 45min, add formaldehyde solution, and react at constant temperature for 120min Then add resorcinol, react at constant temperature for 90 minutes, take out and wash 3 times with water, twice with ethanol, 3 times with ether, and dry in vacuum for 24 hours to obtain the product.

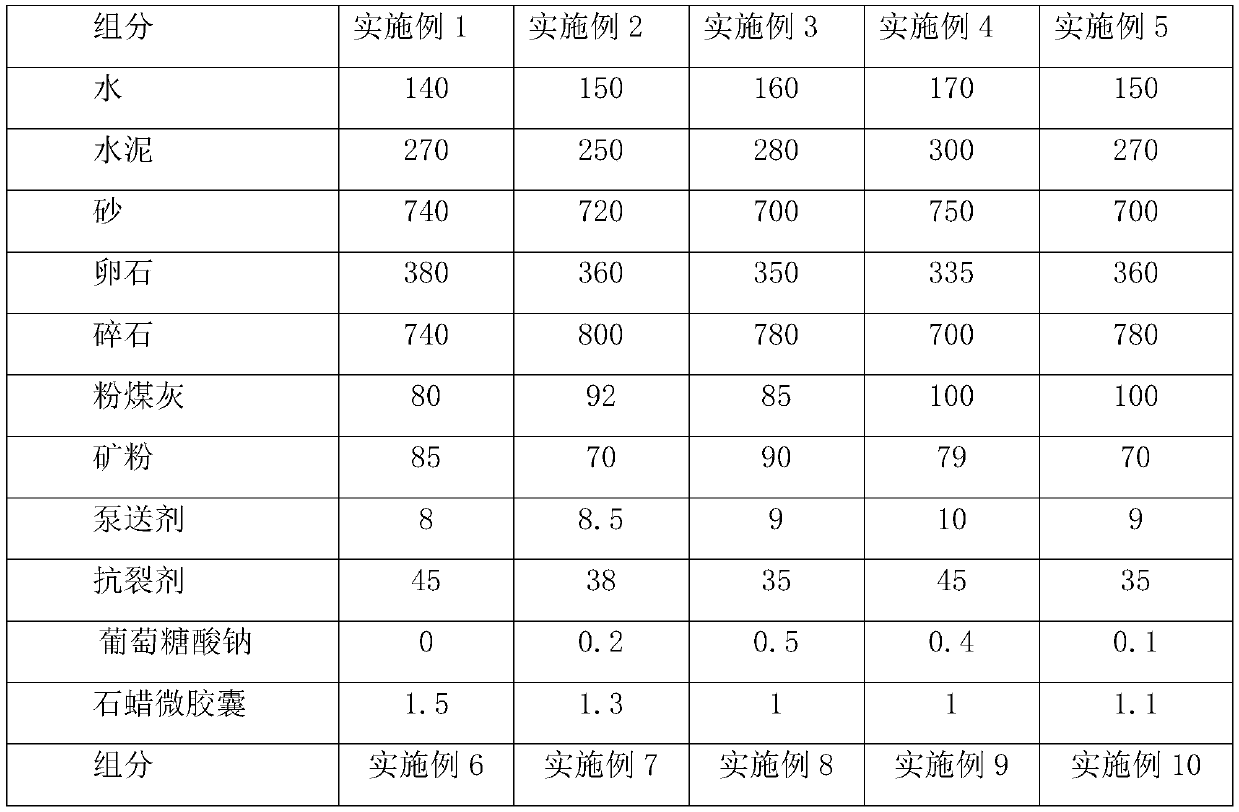

Embodiment 1

[0051]The components of C45 mass concrete: 140kg of water, 270kg of cement, 740kg of sand, 380kg of pebbles, 740kg of gravel, 80kg of fly ash, 85kg of mineral powder, 8kg of pumping agent, 45kg of anti-cracking agent, and 1.5kg of modifier;

[0052] The modifying agent is 1.5kg of paraffin wax microcapsules.

[0053] The preparation process of C45 mass concrete includes the following steps:

[0054] Step 1: Stir sand, pebbles, crushed stones and water evenly to obtain intermediate products;

[0055] Step 2: Add cement, fly ash, slag powder, pumping agent, anti-cracking agent and modifier to the intermediate product and stir for 120 seconds to obtain concrete.

Embodiment 2

[0057] The difference between embodiment 2 and embodiment 1 lies in the difference of component distribution ratio.

[0058] The components of C45 mass concrete: 150kg of water, 250kg of cement, 720kg of sand, 360kg of pebbles, 800kg of gravel, 92kg of fly ash, 70kg of mineral powder, 8.5kg of pumping agent, 38kg of anti-cracking agent, and 1.5kg of modifier;

[0059] Described modifying agent is sodium gluconate 0.2kg and paraffin microcapsule 1.3kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com