Concrete filled wall and cast-in-place structure synchronous construction structure and method

A technology of simultaneous construction and filling of walls, applied in the direction of walls, building components, building structures, etc., can solve the problems of large shrinkage connection gaps, prone to common quality problems, and complicated process interspersed, so as to enhance waterproofing and reduce quality defect repair works. and temporary employment, and the effect of reducing hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

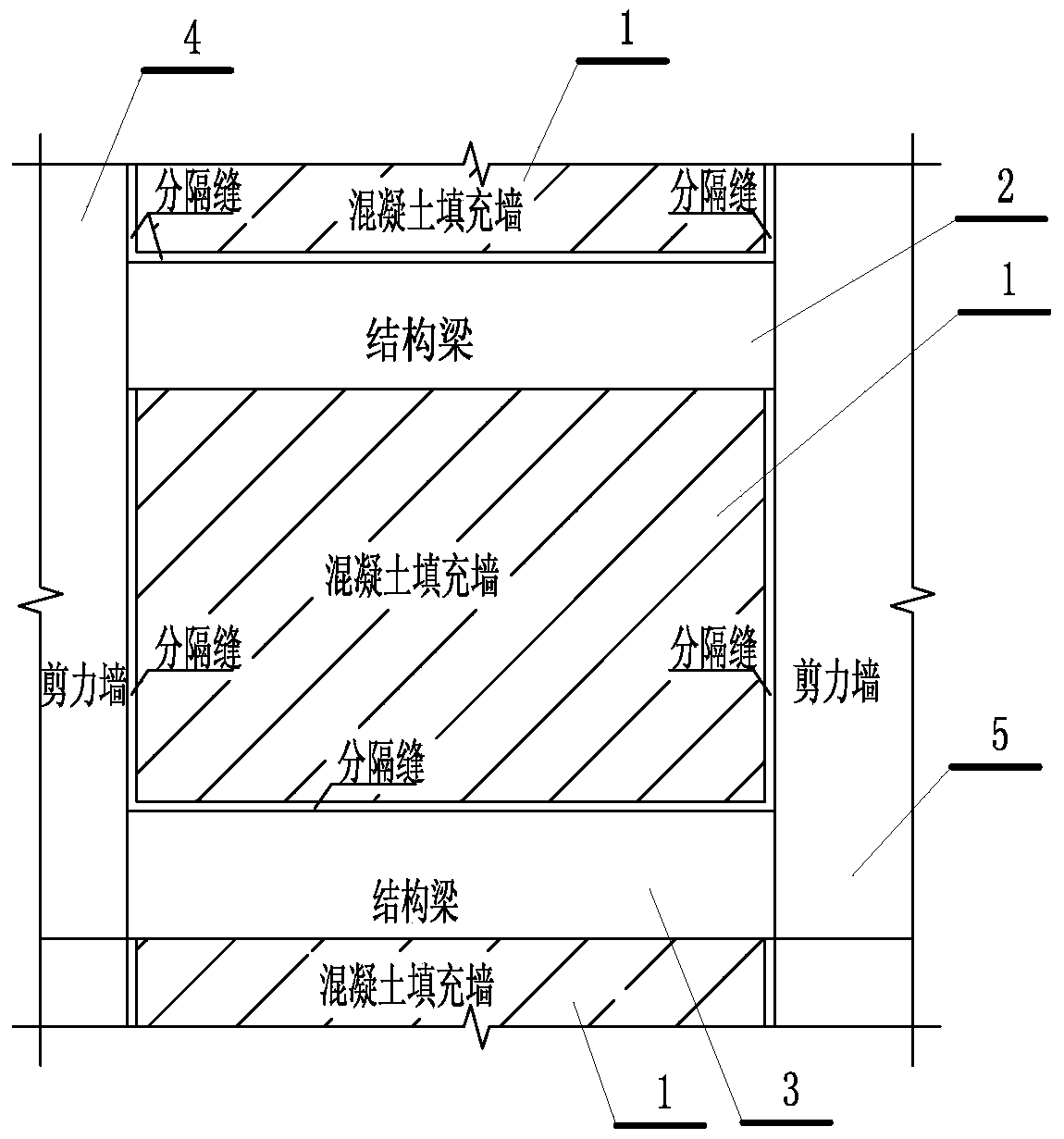

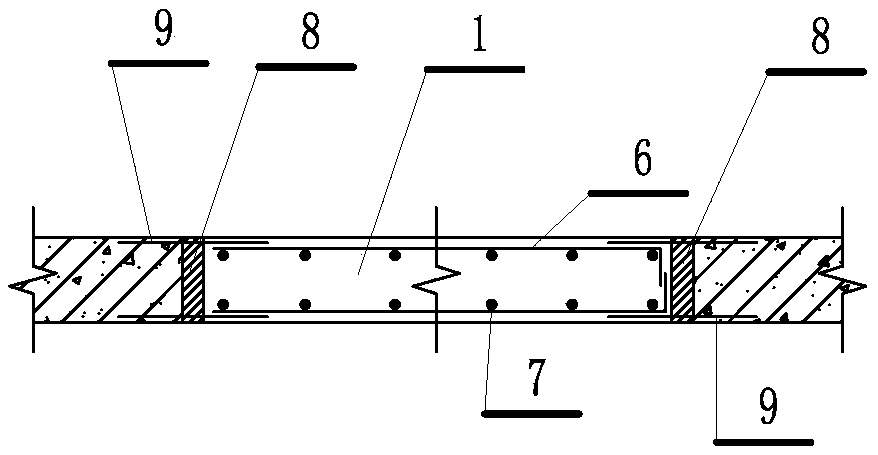

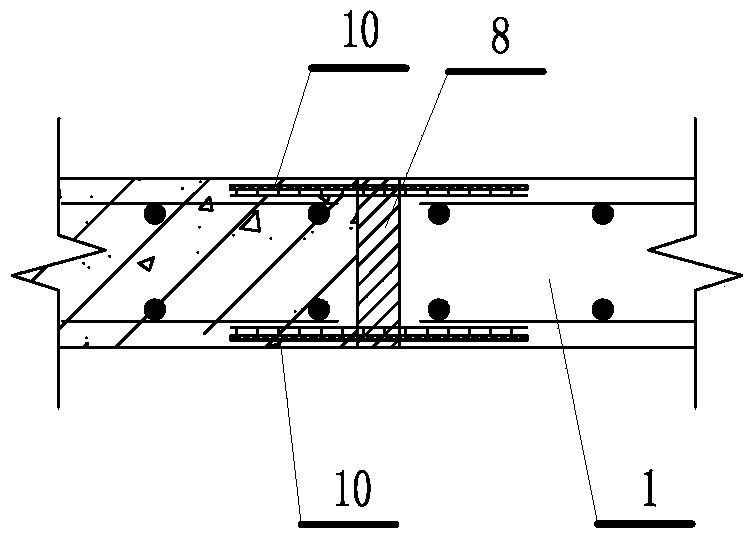

[0028] A concrete filled wall and cast-in-place structure simultaneous construction structure, such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the synchronous construction structure of the concrete filling wall and the cast-in-place structure includes an upper structural beam 2, a lower structural beam 3 surrounding the filling wall 1, and left shear walls 4 and right shear walls 5 on both sides, figure 1 It shows a three-story structure, including the upper infill wall and the lower infill wall. Here, the upper structural beam 2 and the lower structural beam 3 are relative to each floor. Therefore, as the upper structural beam of the middle layer , in the upper layer is the lower side structural beam of the upper filling wall, and the upper and lower side structural beams include the upper and lower side structural beams of the side wall and the upper and lower side structural beams in the middle of each layer. Such as figure 2 , image 3 and Figure 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com