C30 high-impermeability concrete with low cementing material consumption and preparation method thereof

A material dosage, concrete technology, applied in rayon manufacturing, textile and papermaking, fiber chemical characteristics, etc., can solve the problems of reduced structural use efficiency, insufficient impermeability, damage, etc., to reduce cracks, reduce macrocracks, inhibit separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

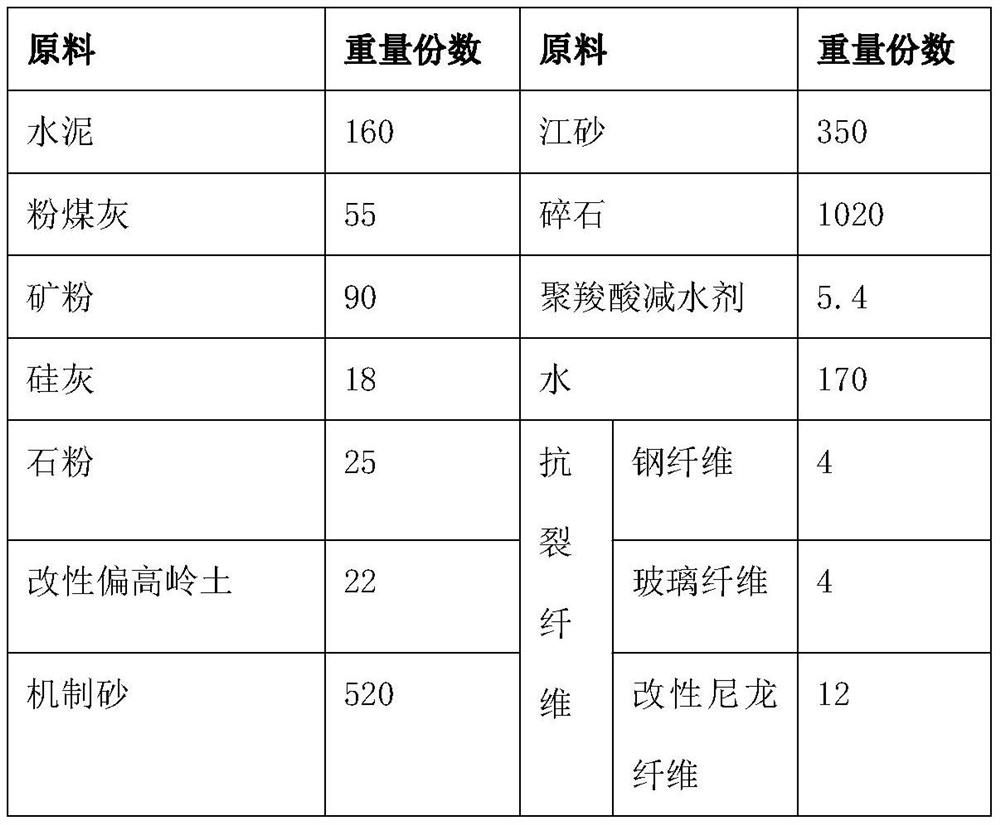

[0043] A C30 high impermeability concrete with low cementitious material content, per m 3 The raw material composition and proportion of concrete are calculated in parts by weight, as shown in the following table:

[0044] Embodiment 1 Raw material composition and parts by weight proportioning table

[0045]

[0046] Among them, the modified metakaolin is prepared by exciting modification with gypsum, epoxy silane and modified polystyrene.

[0047] Modified polystyrene is ramie fiber / polystyrene copolymer, and its preparation method comprises the steps:

[0048] 1) Stir and mix polystyrene, vinyl silane and BPO initiator evenly, then add to the torque rheometer, and blend at 170°C for 8 minutes;

[0049] 2), add the ramie fiber of polystyrene addition 30% in the torque rheometer again, continue blending;

[0050] 3), extruding the mixture in step 2) to obtain ramie fiber / polystyrene copolymer.

[0051] The preparation method of modified metakaolin comprises the steps: ...

Embodiment 2

[0065] A C30 high impermeability concrete with low cementitious material content, per m 3 The raw material composition and proportion of concrete are calculated in parts by weight, as shown in the following table:

[0066] Embodiment 2 Raw material composition and parts by weight proportioning table

[0067]

[0068] Among them, the modified metakaolin is prepared by exciting modification with gypsum, epoxy silane and modified polystyrene.

[0069] Modified polystyrene is ramie fiber / polystyrene copolymer, and its preparation method is the same as embodiment 1.

[0070] The preparation method of modified metakaolin is the same as in Example 1, and the difference from Example 1 is that the addition of epoxy silane accounts for 0.5% of the quality of metakaolin, and the addition of modified polystyrene accounts for 1% of the addition of metakaolin. %, the addition of gypsum accounts for 3% of the addition of metakaolin.

[0071] A preparation method of C30 high impermeabil...

Embodiment 3

[0073] A C30 high impermeability concrete with low cementitious material content, per m 3 The raw material composition and proportion of concrete are calculated in parts by weight, as shown in the following table:

[0074] Embodiment 3 raw material composition and parts by weight proportioning table

[0075]

[0076]

[0077] Among them, the modified metakaolin is prepared by exciting modification with gypsum, epoxy silane and modified polystyrene.

[0078] Modified polystyrene is ramie fiber / polystyrene copolymer, and its preparation method is the same as embodiment 1.

[0079] The preparation method of modified metakaolin is the same as in Example 1, and the difference from Example 1 is that the addition of epoxy silane accounts for 1.5% of the quality of metakaolin, and the addition of modified polystyrene accounts for 3% of the addition of metakaolin. %, the addition of gypsum accounts for 7% of the addition of metakaolin.

[0080] A preparation method of C30 high...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com