Thermal annealing method for manufacturing hydrogen end group conducting channel on diamond face

A technology of surface fabrication and conductive channel, applied in circuits, electrical components, semiconductor/solid-state device manufacturing, etc., can solve the problems of rough diamond surface, high etchability, and great influence of conductive properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

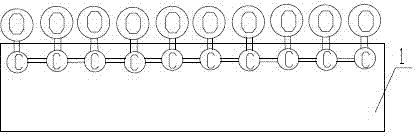

[0030] Embodiment 1, (1) Use acetone, trichloroethane, isopropanol and other organic solvents to clean the polycrystalline diamond substrate; put the cleaned polycrystalline diamond substrate into the chemical vapor deposition equipment reaction chamber, and place The reaction chamber was evacuated to 10 -6 mbar, the structure of polycrystalline diamond is as figure 1 shown;

[0031] (2) Raise the temperature of the reaction chamber to 600°C to remove impurities and organic residues on the surface of the polycrystalline diamond substrate;

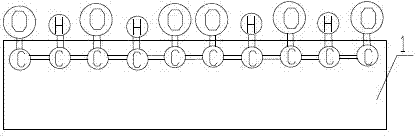

[0032] (3) Introduce hydrogen gas into the reaction chamber, the gas flow rate is 40L / min, the pressure of the reaction chamber is maintained at 80mbar, the temperature of the reaction chamber is raised, the polycrystalline diamond substrate is heated to 800°C, and kept in the hydrogen atmosphere for 30 minutes, the polycrystalline diamond The structure is as figure 2 shown

[0033] (4) Turn off the heating power supply of the reaction...

Embodiment 2

[0034] Embodiment two, (1) polycrystalline diamond substrates are cleaned with organic solvents such as acetone, trichloroethane, and isopropanol; the polycrystalline diamond substrates after cleaning are placed in the chemical vapor deposition equipment reaction chamber, and The reaction chamber was evacuated to 10 -6 mbar, the structure of polycrystalline diamond is as figure 1 shown;

[0035] (2) Raise the temperature of the reaction chamber to 600°C to remove impurities and organic residues on the surface of the polycrystalline diamond substrate;

[0036] (3) Introduce hydrogen into the reaction chamber, the gas flow rate is 40L / min, the pressure of the reaction chamber is maintained at 500mbar, the temperature of the reaction chamber is raised, the polycrystalline diamond substrate is heated to 800°C, and kept in the hydrogen atmosphere for 20 minutes, the polycrystalline diamond The structure is as figure 2 shown

[0037] (4) Turn off the heating power supply of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com