Photo album inner core sheet double-faced gluing treatment system and treatment method

A technology of processing system and inner chip, which is applied in the direction of pretreatment surface, device for coating liquid on the surface, coating, etc. Stable paste quality, small deformation and high gluing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] In order to better understand the present invention, the implementation manner of the present invention will be explained in detail below in conjunction with the accompanying drawings.

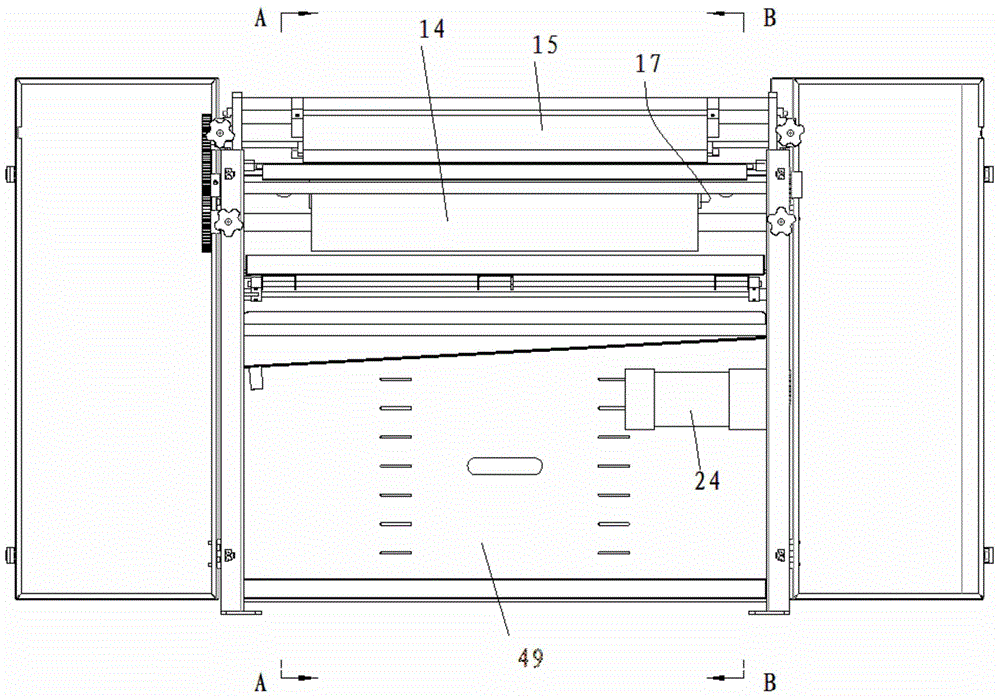

[0054] Such as Figure 1 to Figure 12 As shown in the photo album, a double-sided gluing processing system for the inner chip material includes a double-sided gluing equipment for the inner chip material 205, a double-sided gluing inner chip material drying equipment 206, and the double-sided gluing equipment for the inner chip material 205 Connected with the paper feeder 201 at the front, the feed port of the double-sided gluing inner chip material drying equipment 206 cooperates with the outlet of the inner chip material double-sided gluing equipment 205, and the double-sided gluing inner chip material is dried The discharge port of the device 206 is connected with the finishing machine 203 through the conveying device 204 , and the rear part of the finishing machine 203 is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com