Machine tool with friction welding function

A technology of friction welding and machine tools, which is applied in the field of machine tools, can solve the problems of reducing the machining accuracy of workpieces, increasing the number of times of workpiece clamping, and high cost, and achieves the effects of improving welding efficiency, welding firmness, and smooth and smooth circumferential surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings.

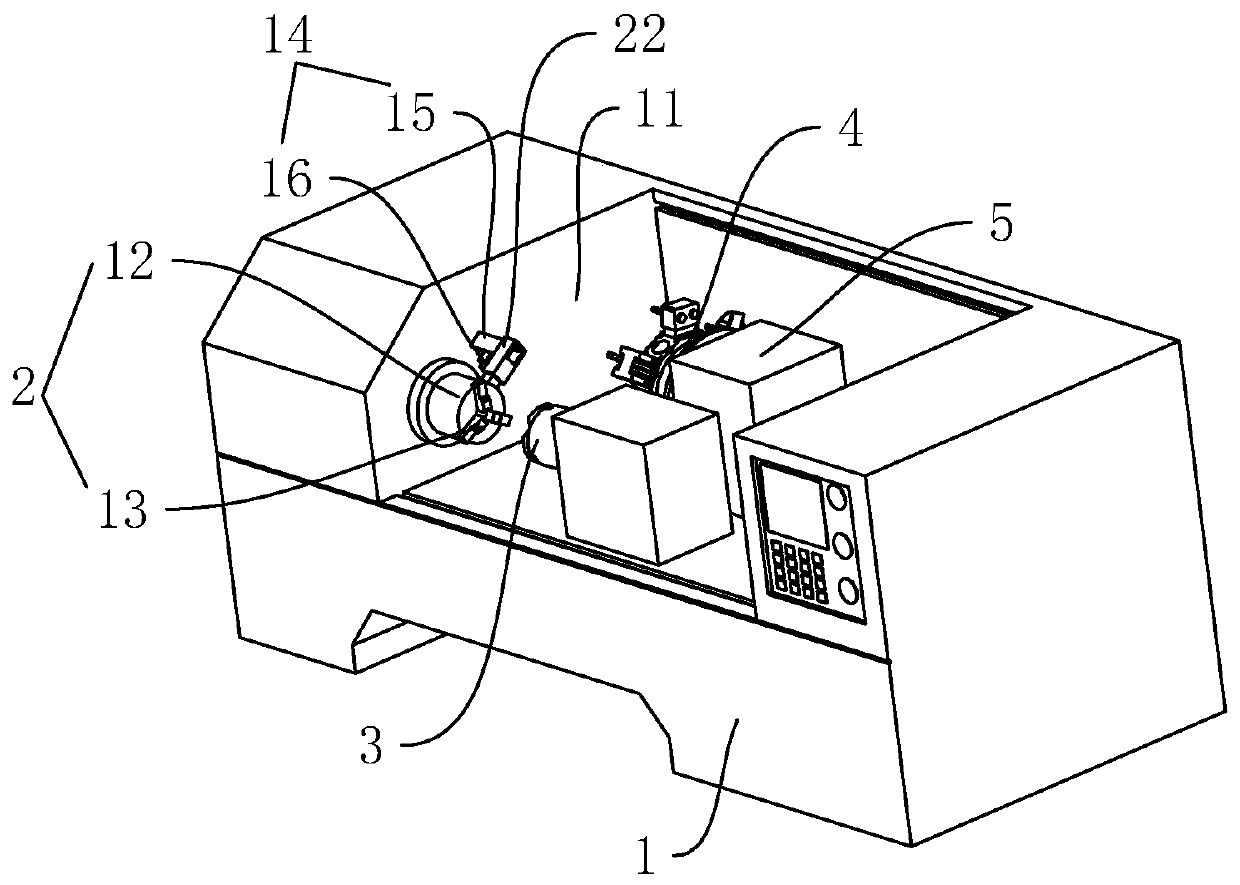

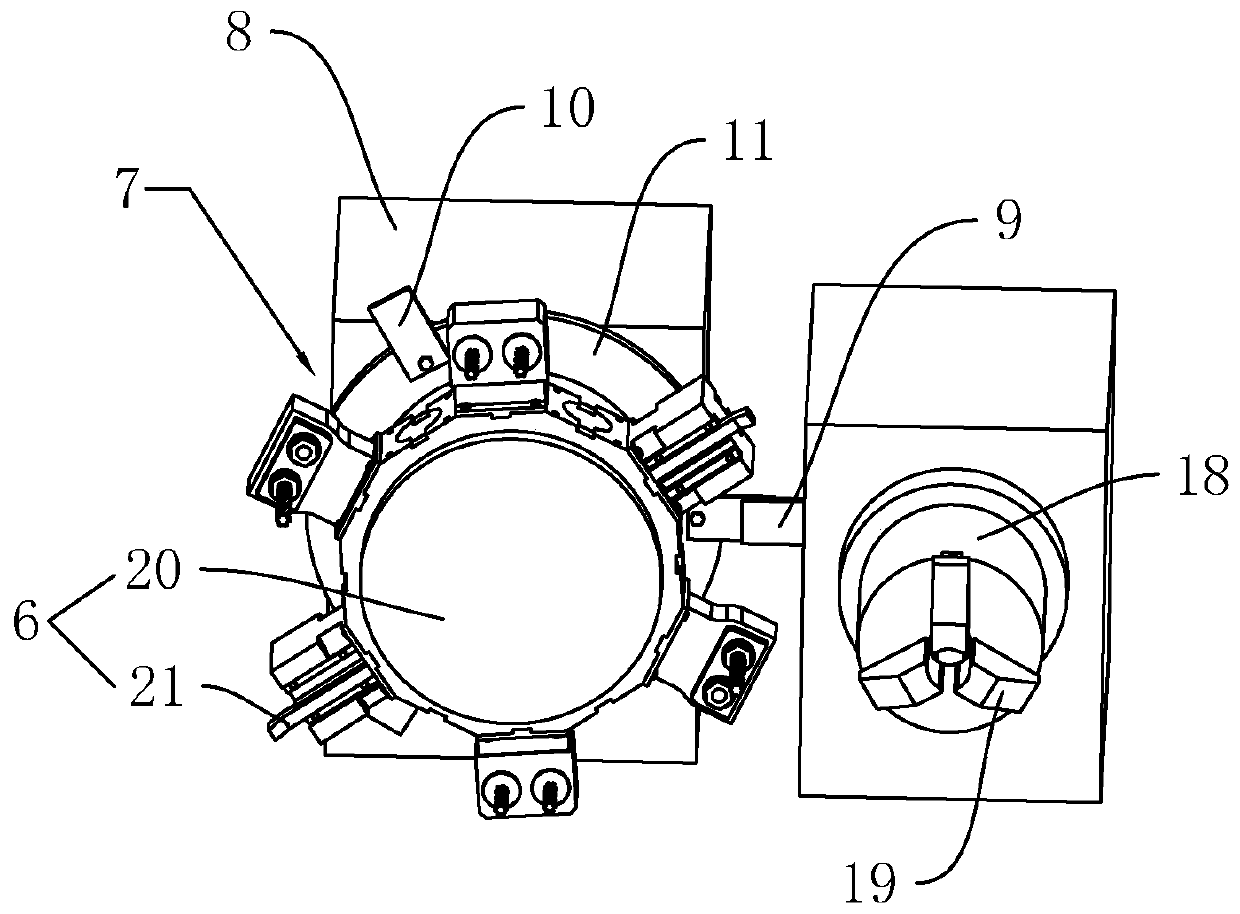

[0032] refer to figure 1 and figure 2 , is a kind of machine tool with friction welding function disclosed by the present invention, comprising a machine tool body 1, a first clamping device 2, a second clamping device 3 and an auxiliary device 4 are arranged on the machine tool body 1, and the auxiliary device 4 includes a sliding The auxiliary table 5 arranged on the surface of the machine tool body 1, the cutting assembly 6 arranged on the auxiliary table 5, and the pressure compensation assembly 7 arranged on the auxiliary table 5; when two weldments are welded, one of the weldments is clamped On the first clamping device 2, another weldment is clamped on the second clamping device 3, and the second clamping device 3 drives the weldment to move toward the first clamping device 2, and the first clamping device 2 drives The first weldment rotates at a hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com