High-performance and high-compactness power module

A power module and compact technology, which is applied in the field of high-performance and high-compact power modules, can solve the problems of low system compactness, low system compactness, and general module electrical performance, so as to reduce busbar stray Inductance, the effect of improving the operating current of the module and improving the electrical performance of the module

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

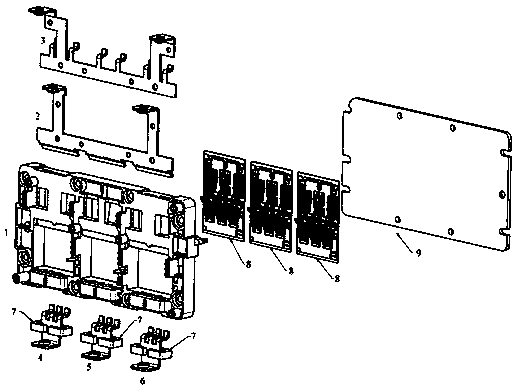

[0024] Accompanying drawing is a kind of specific embodiment of the present invention. This embodiment includes a plastic housing 1 pre-molded with a current sensor 7, a first DC copper bar 2, a second DC copper bar 3, an AC first copper bar 4, an AC second copper bar 5, and an AC third copper bar 6 , there are three insulating substrates and heat dissipation substrates 9 in the plastic shell 1, the first DC copper bar 2, the second DC copper bar 3, the first AC copper bar 4, the second AC copper bar 5 and the AC The bottom of the third copper bar 6 is combined with the front copper clad layer of the insulating substrate through ultrasonic bonding or welding, and the back copper clad layer of the insulating substrate is combined with the heat dissipation base plate through welding; the current sensor 7 is 3, set on the first AC copper bar 4, the second AC copper bar 5 and the third AC copper bar 6 respectively.

[0025] Among them, the plastic housing 1 includes a cavity for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com