Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

348results about How to "Continuous preparation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Slicing method

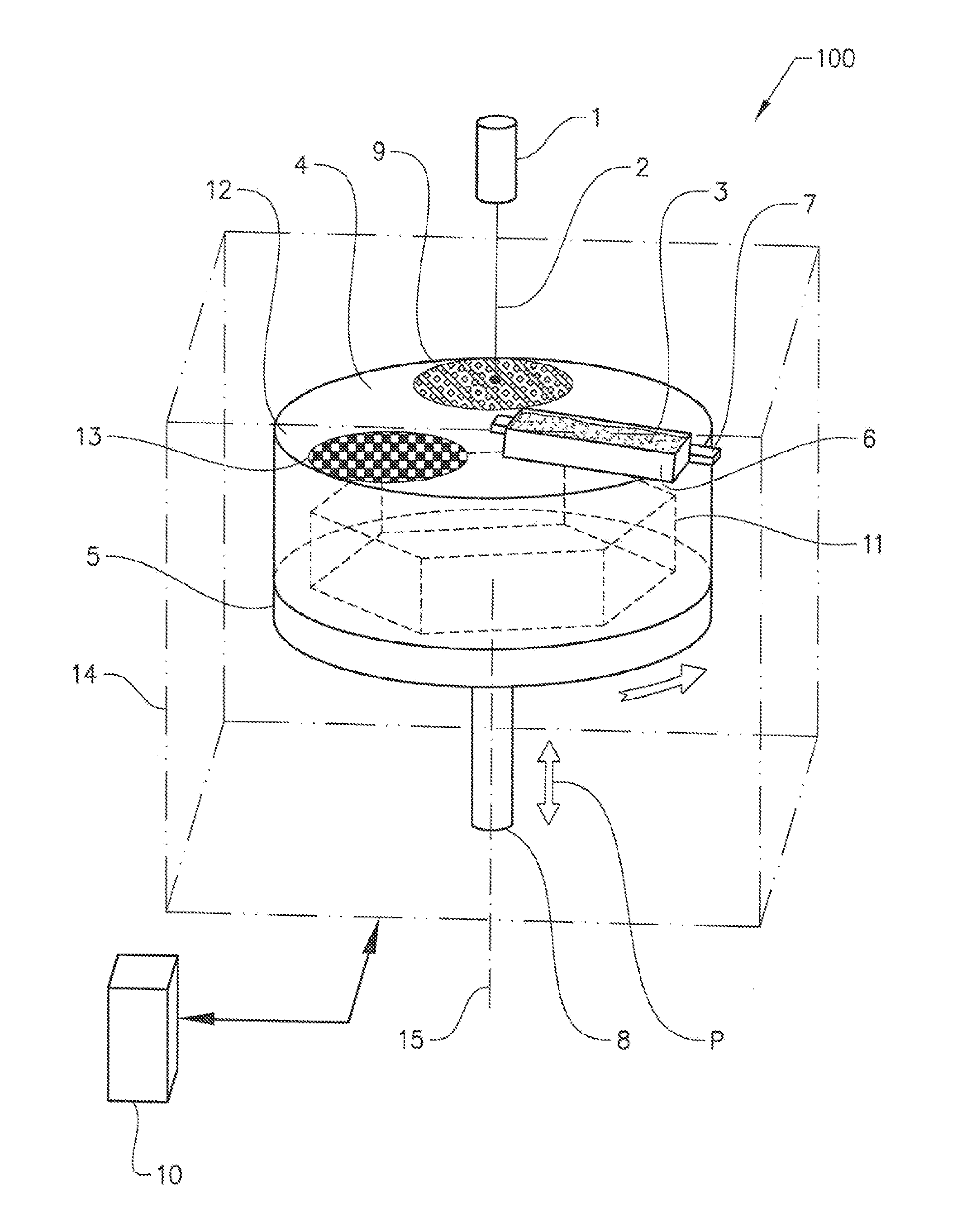

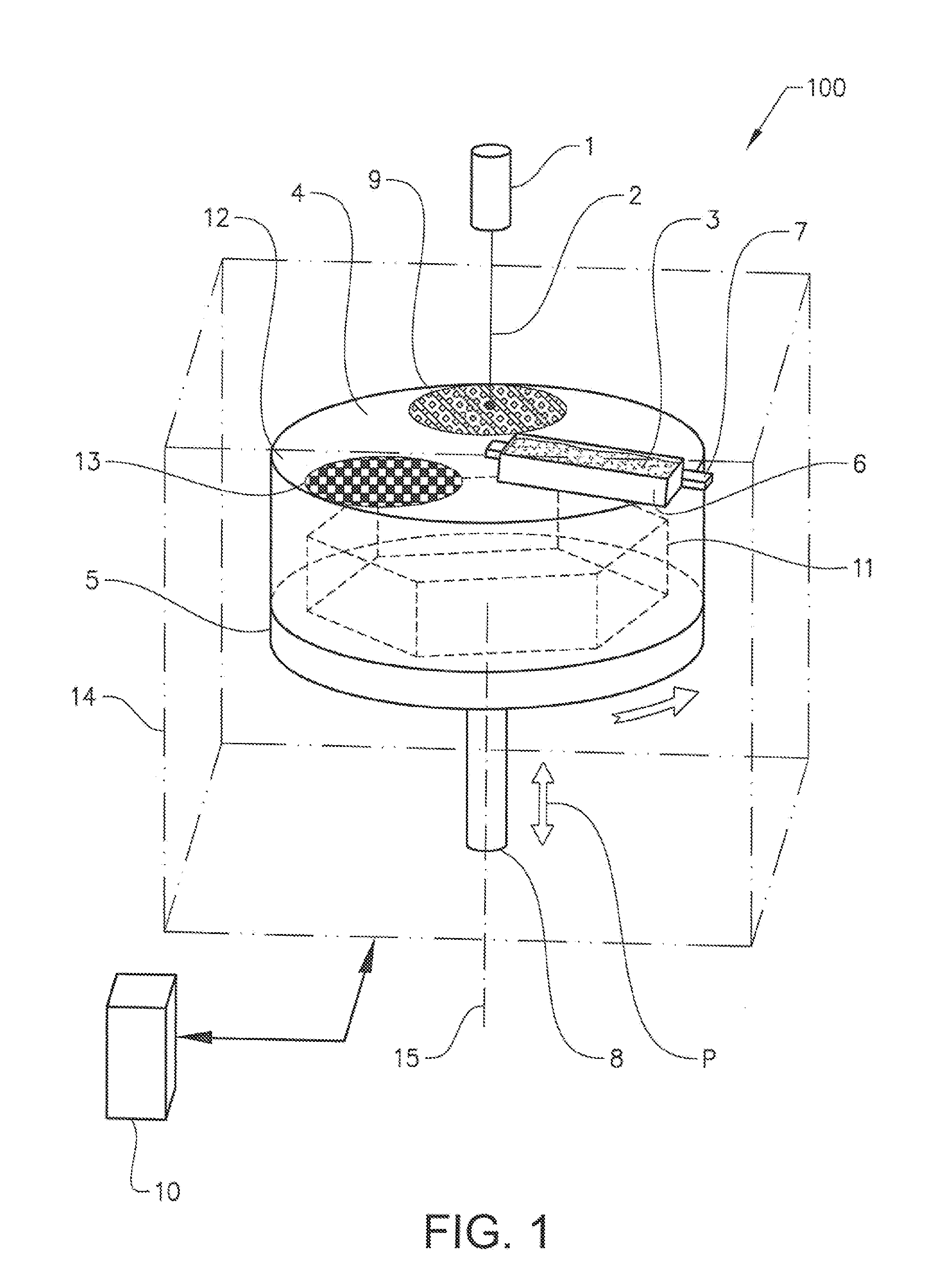

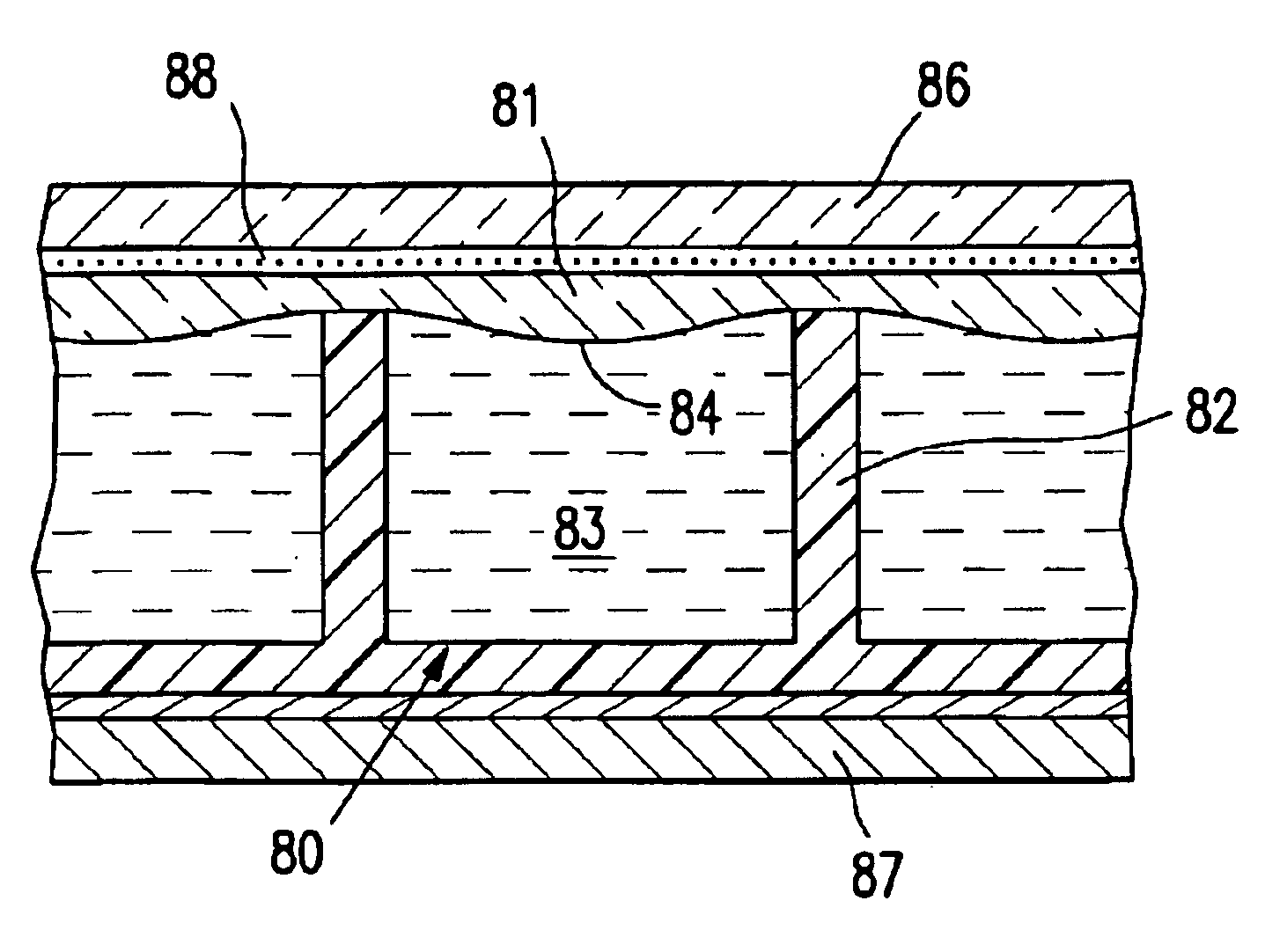

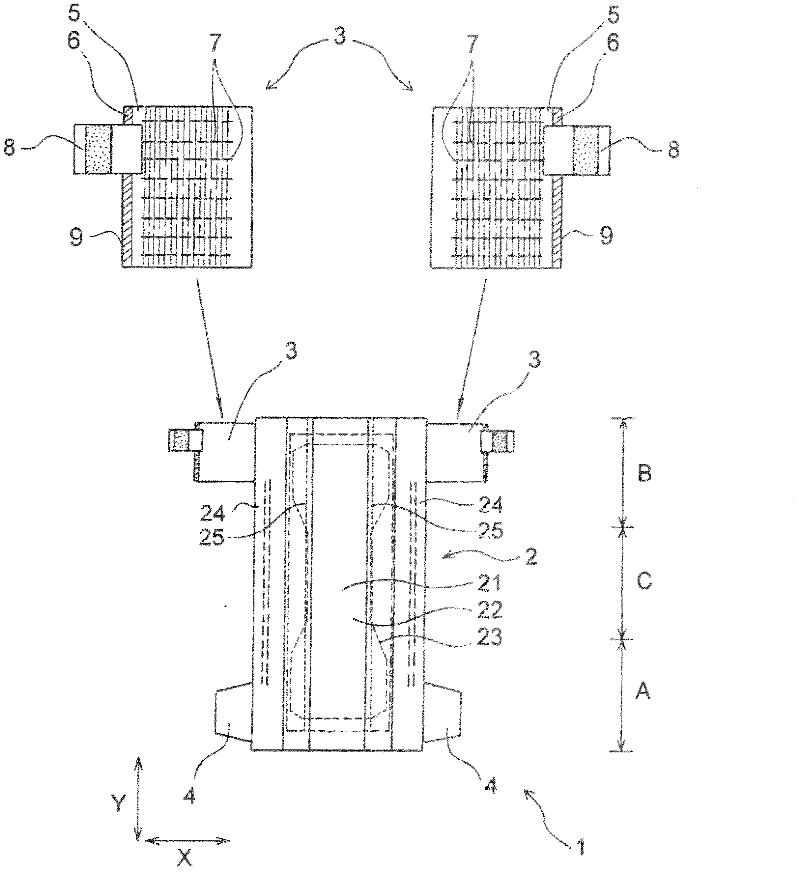

InactiveUS20160167303A1Increase the lengthSynchronization is simpleManufacturing platforms/substratesArc welding apparatusRotational axisBeam source

A method for forming at least one three-dimensional article through successive fusion of parts of a powder bed, which parts correspond to successive portions of the three-dimensional article, said method comprising the steps of: providing at least one model of said three-dimensional article, wherein said model of said three-dimensional article is described in a 2-dimensional angular coordinate system; applying a powder layer on a support structure; directing at least one energy beam from at least one energy beam source over said powder layer causing said powder layer to fuse in first selected locations according to said model to form a first portion of said three-dimensional article, providing a first portion of said powder layer simultaneous as fusing a second portion of said powder layer, wherein said second portion of the powder layer is fused along a line perpendicular to a rotational axis of said support structure.

Owner:ARCAM AB

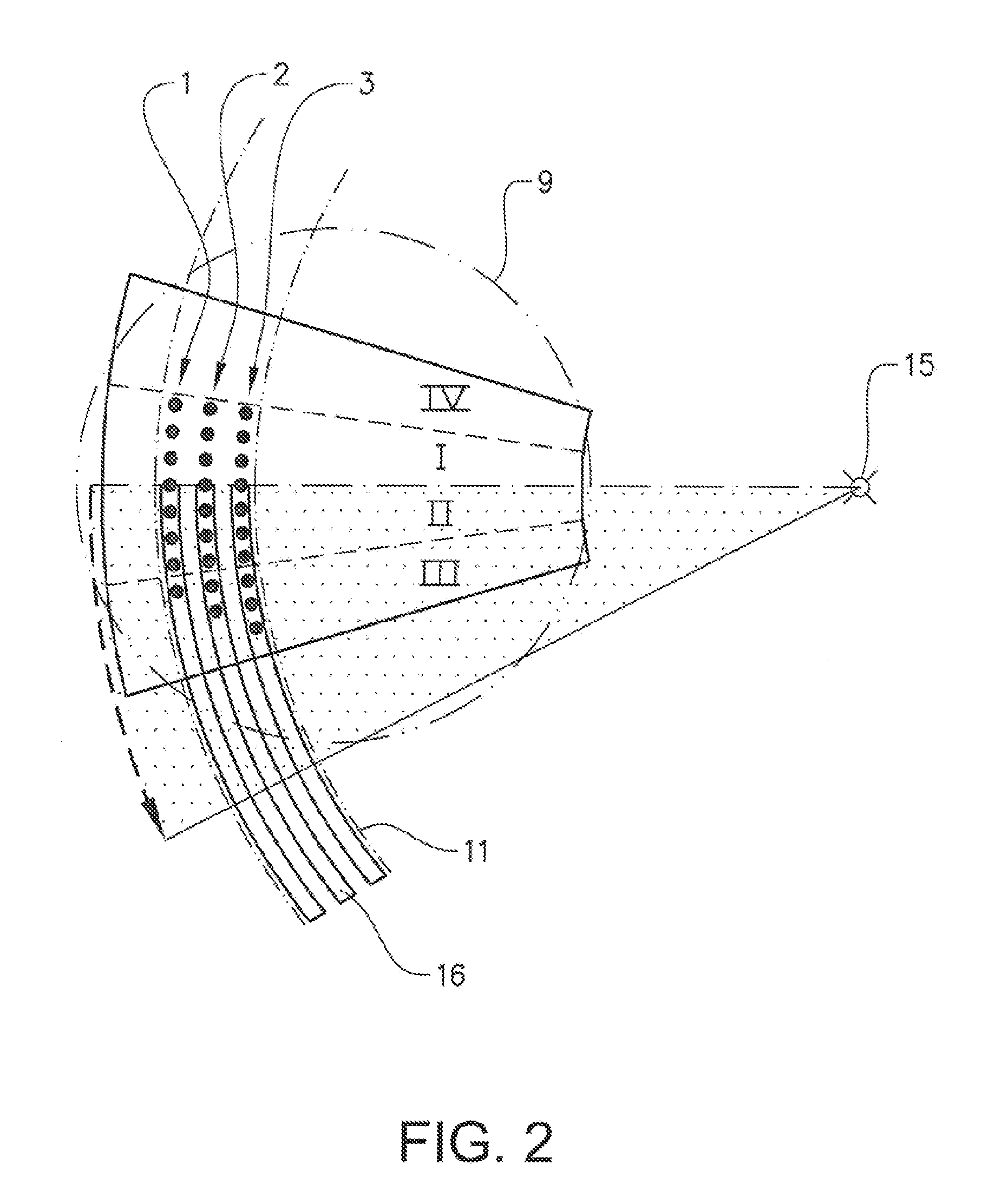

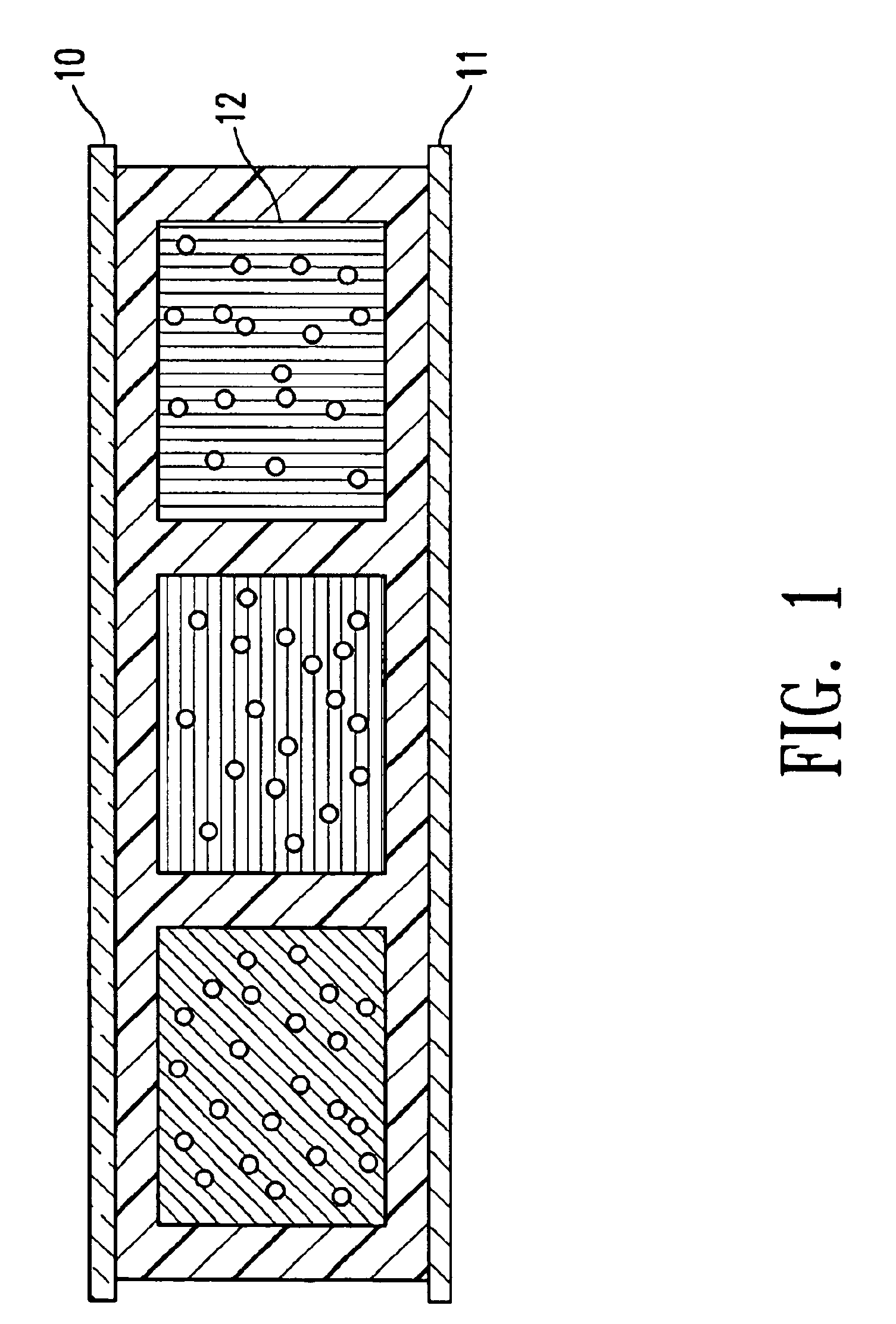

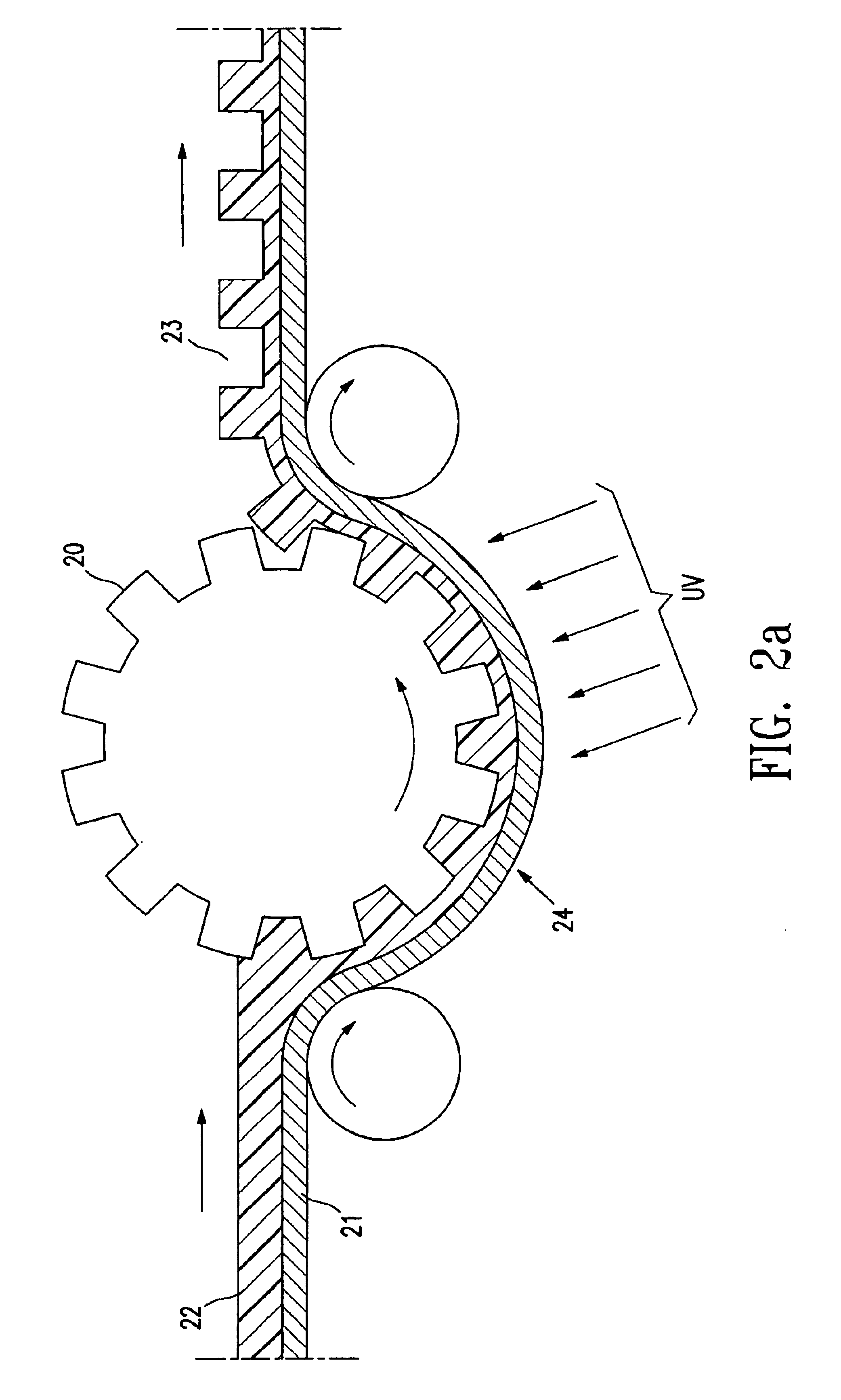

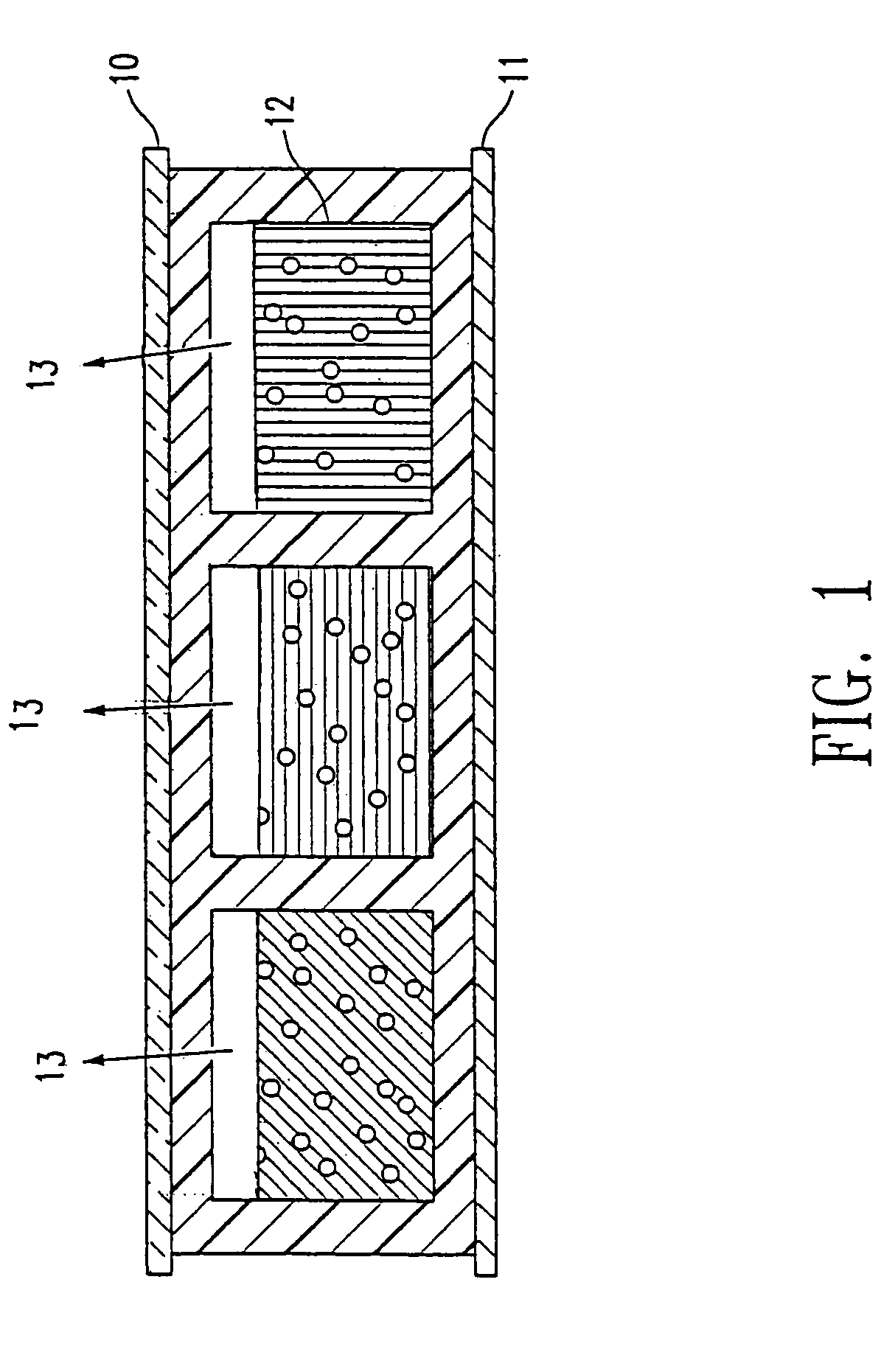

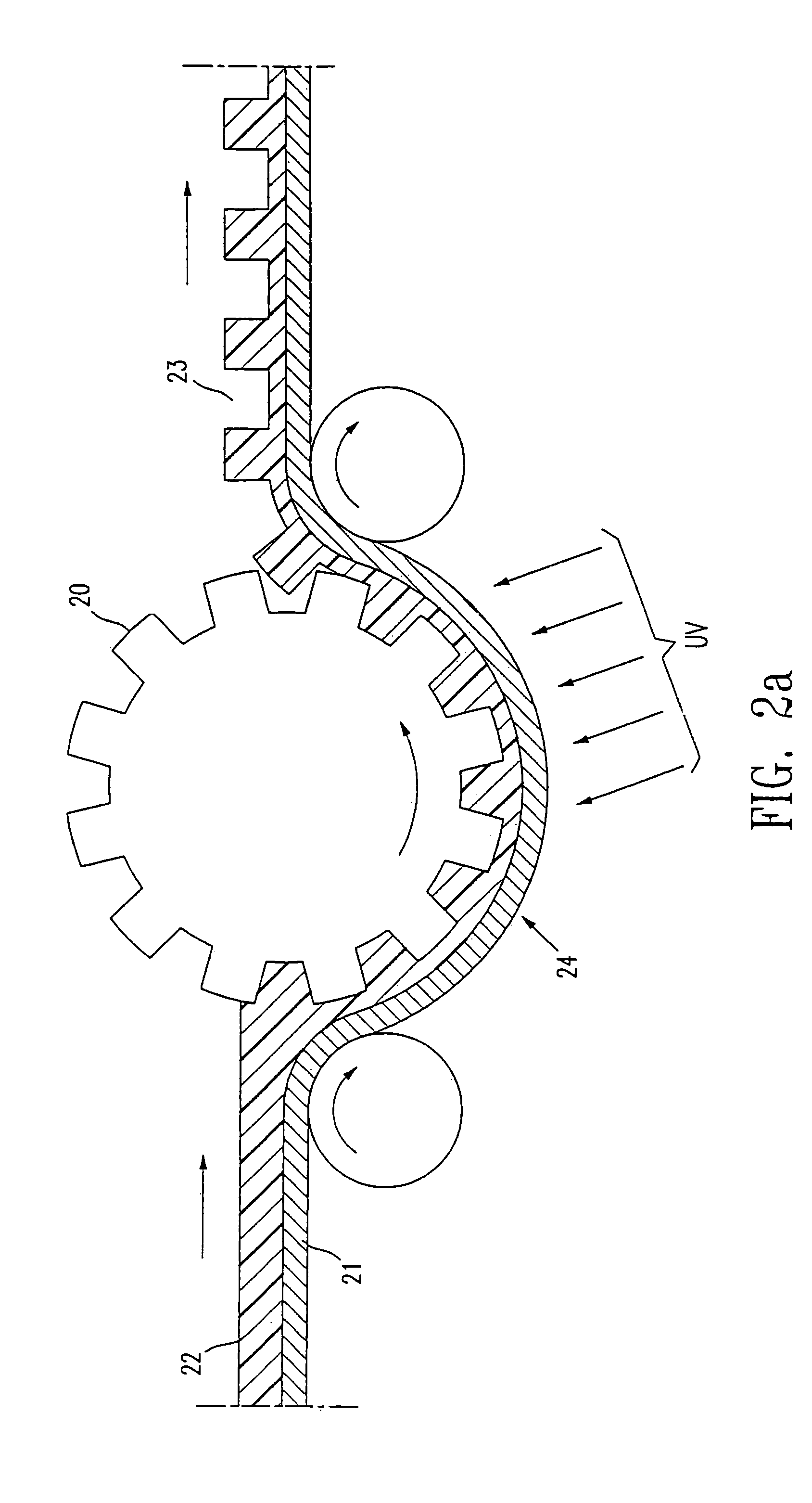

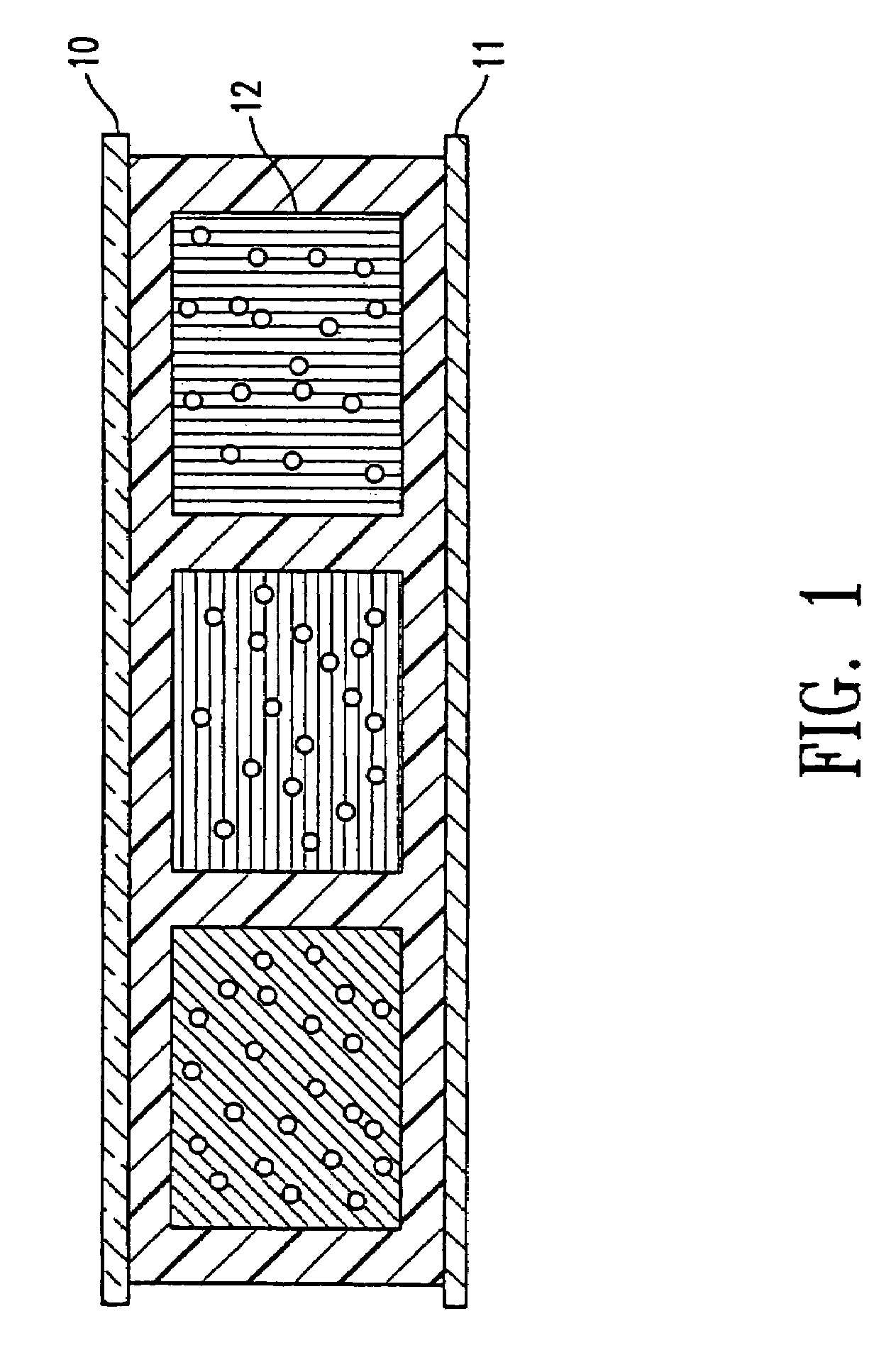

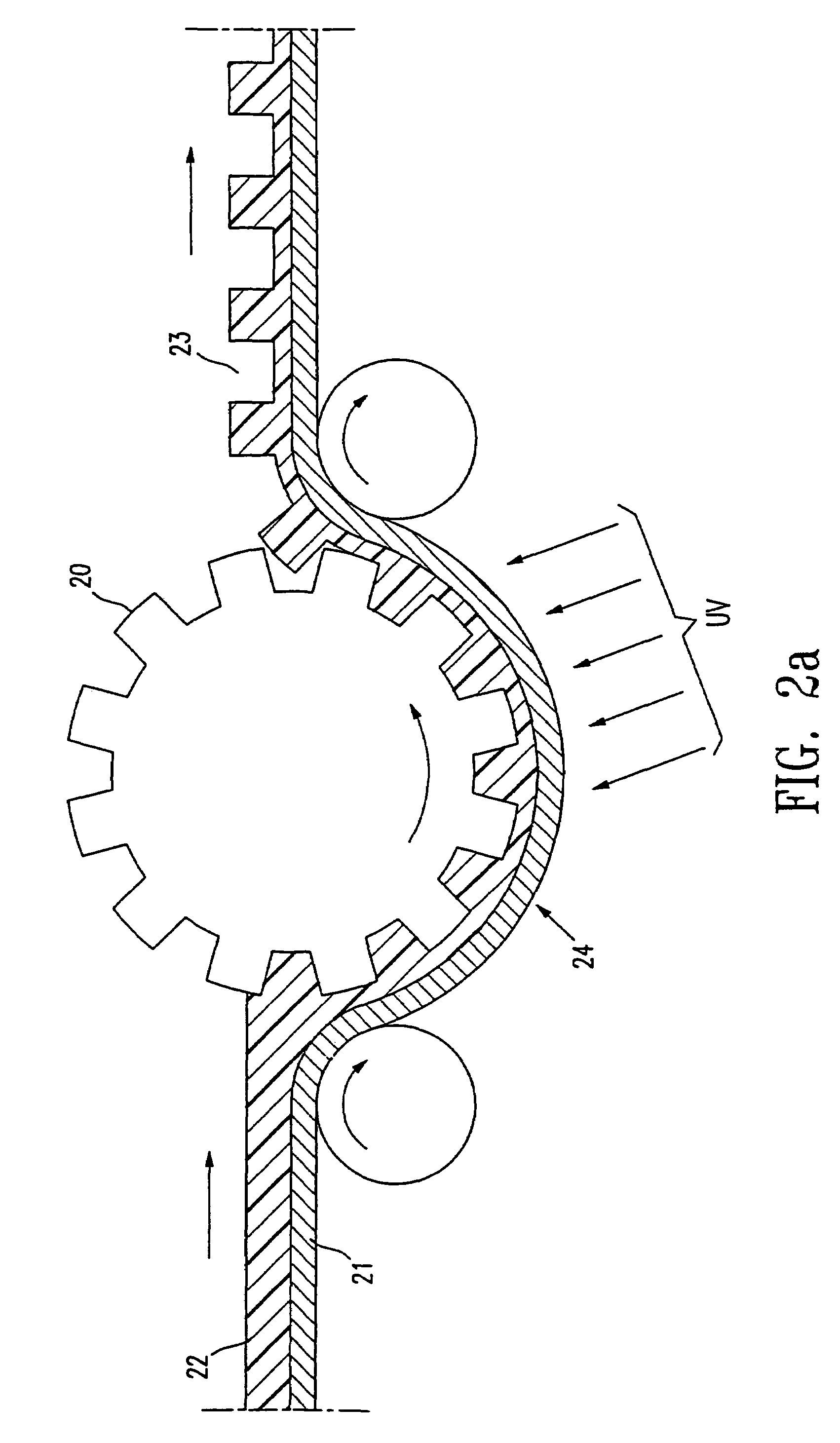

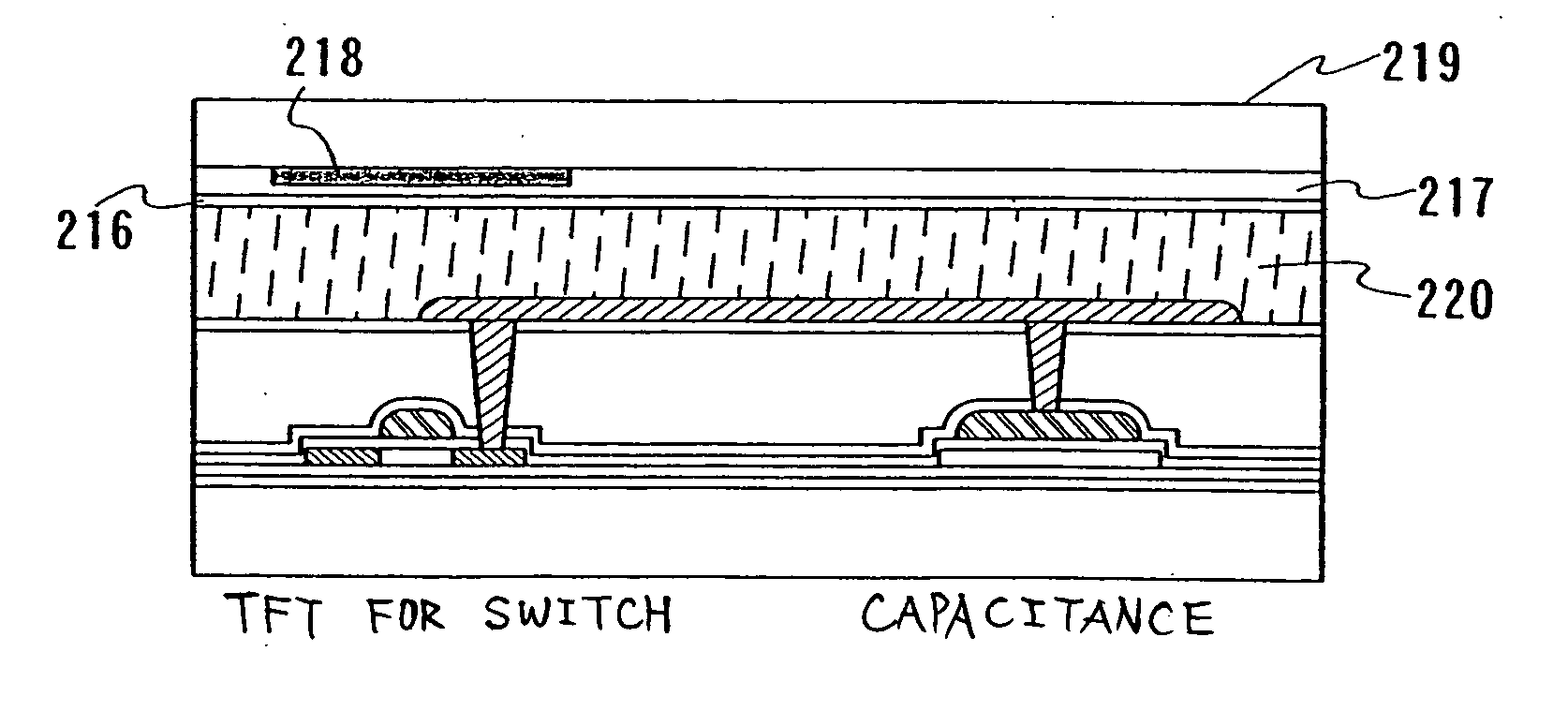

Electrophoretic display and novel process for its manufacture

InactiveUS6833943B2Improve the display effectCost effectiveStatic indicating devicesMaterial analysis by electric/magnetic meansElectrophoresisElectrical battery

This invention relates to an electrophoretic display comprising cells which are filled with charged particles dispersed in a solvent and are individually sealed with a polymeric sealing layer which is an integral part of the display and is curved.

Owner:E INK CALIFORNIA

Electrophoretic display and process for its manufacture

InactiveUS7112114B2Improve the display effectImprove optical and physicomechanical propertyMaterial analysis by electric/magnetic meansVessels or leading-in conductors manufactureElectrophoresisDisplay device

Owner:E INK CALIFORNIA

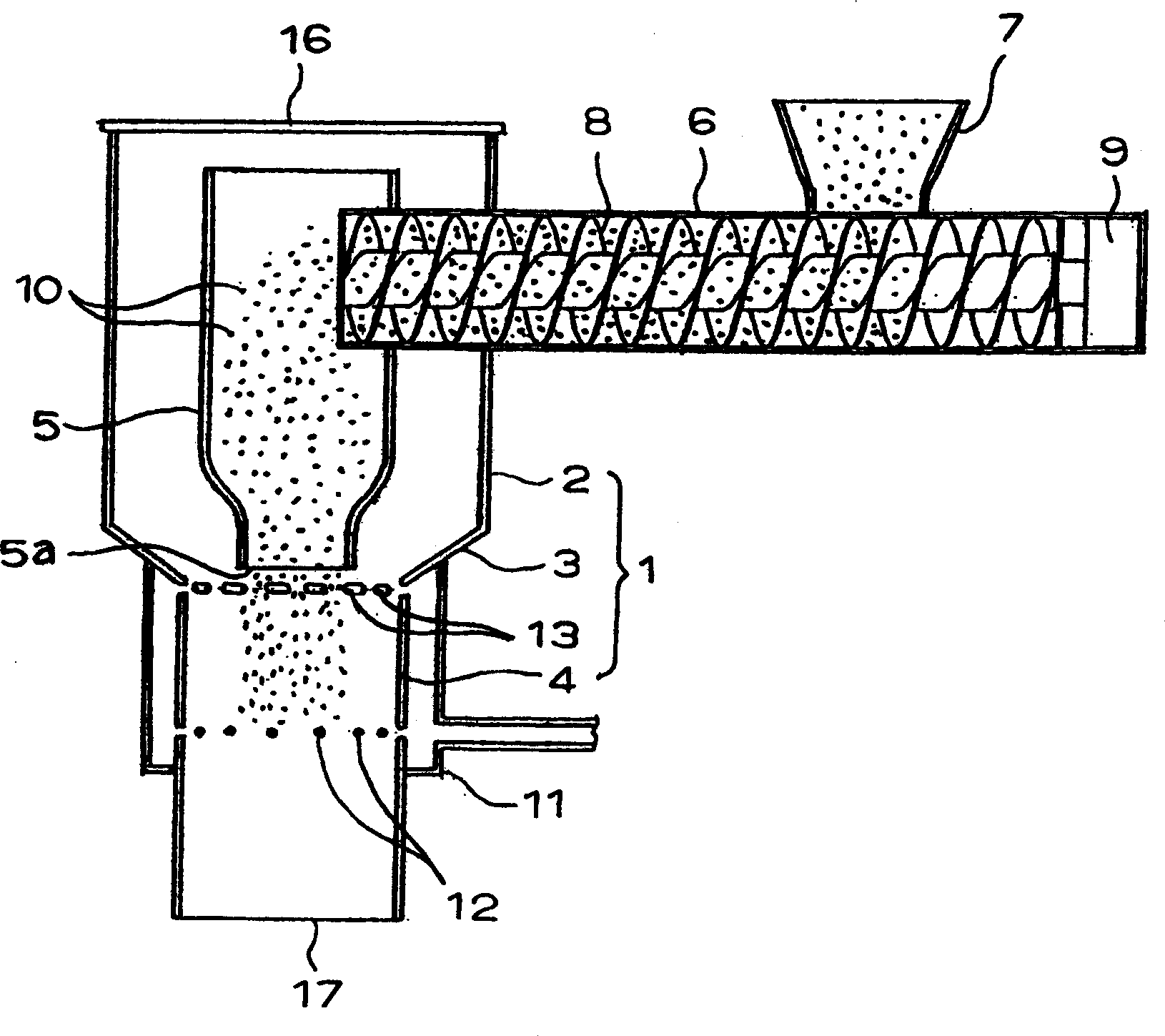

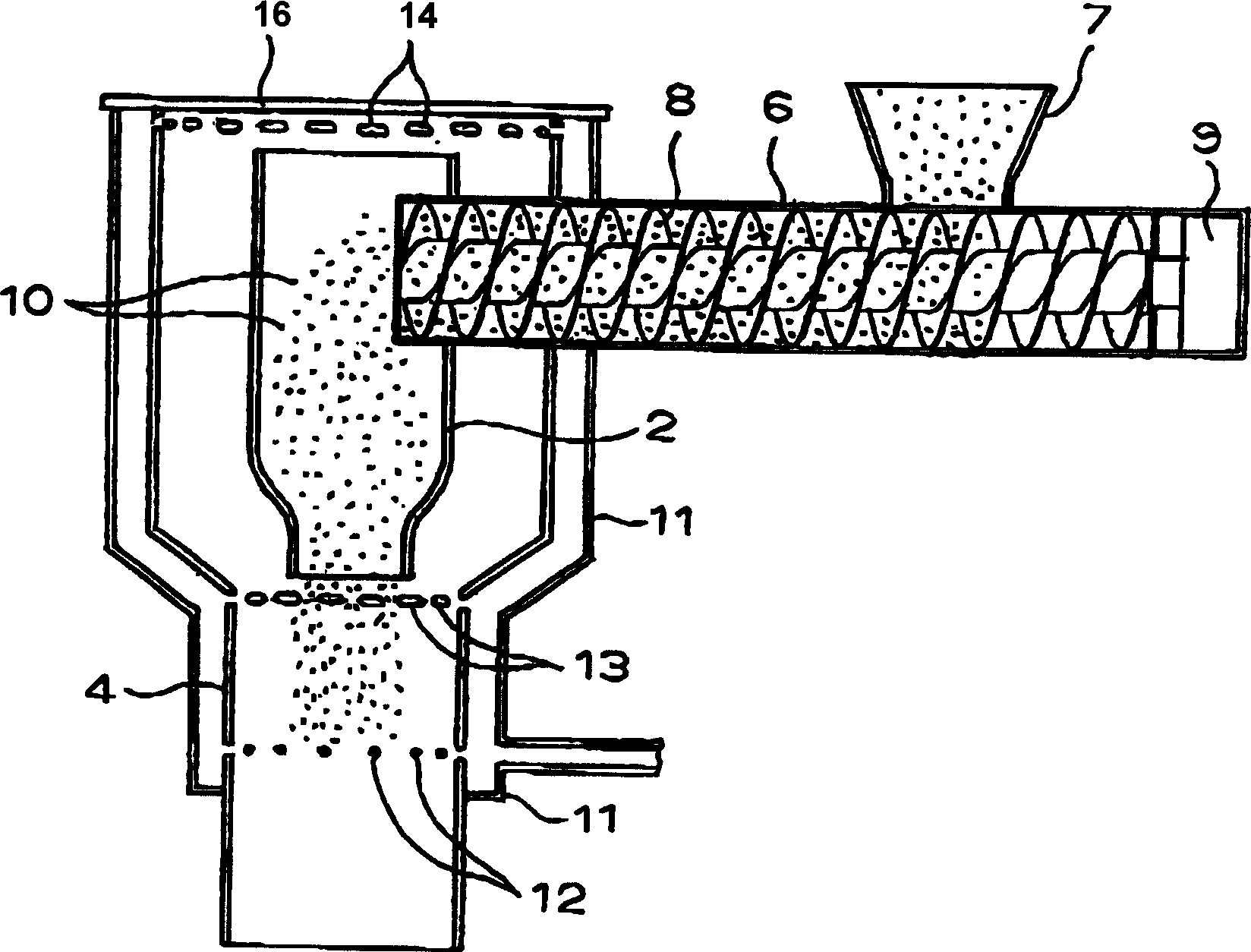

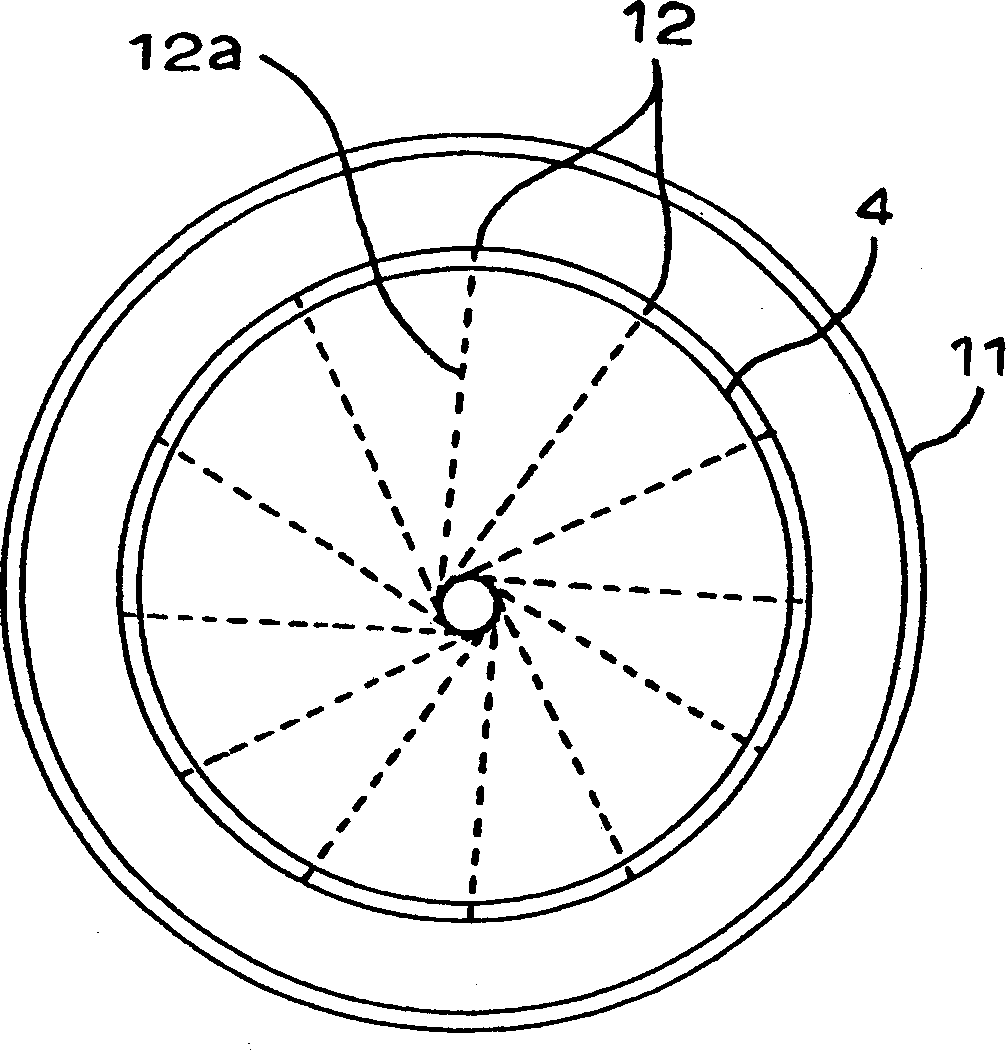

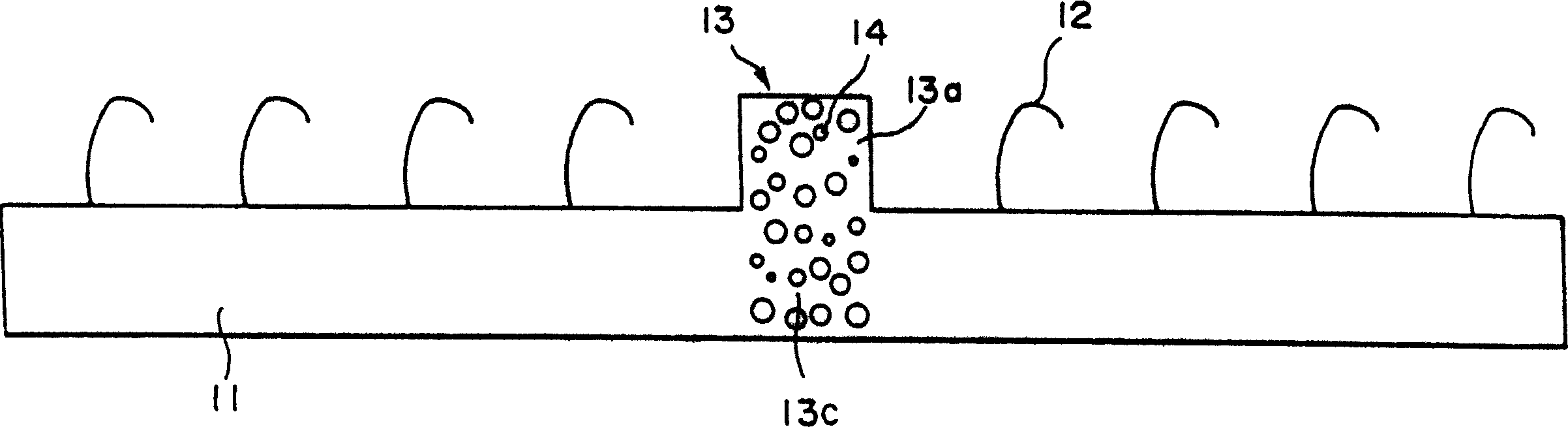

Device for mixing powder and liquid and method thereof

InactiveCN1459328AContinuous preparationUniform preparationFlow mixersMixing methodsMetallurgyMixed approach

To provide a mixing device which prevents generation of lumps and undissolved powder in mixing the powder and liquid, and can continuously mix them and uniformly at a desired concentration, and to provide a method therefor. The constant quantity of powder 10 is fallen continuously by gravity into the central part of a cylindrical vessel 1 and the falling powder is mixed with the injection-flow liquid by injecting the liquid from an injection opening 12 installed along the peripheral direction of the lower cylindrical part 4 of the cylindrical vessel 1.

Owner:MITSUBISHI CHEM CORP

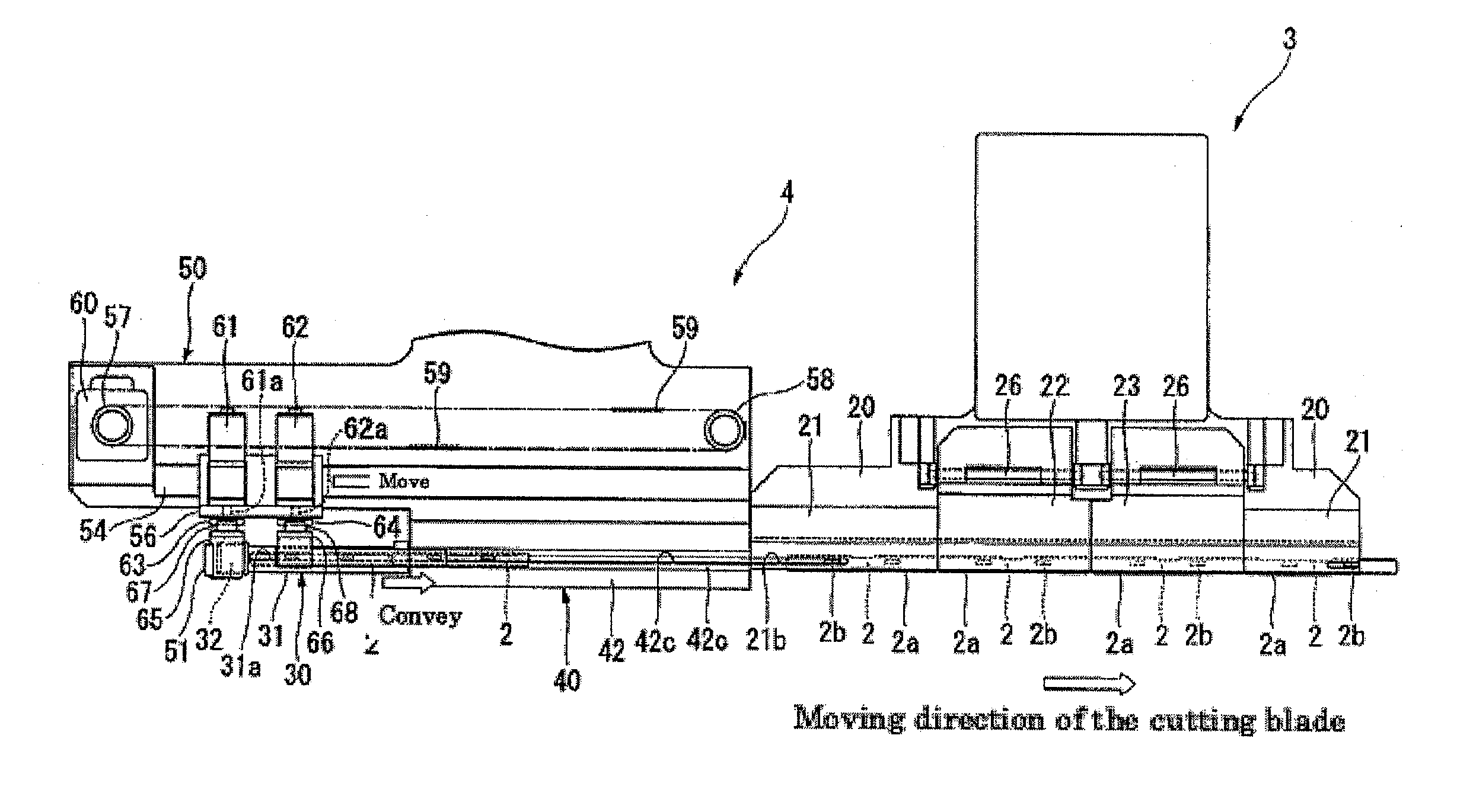

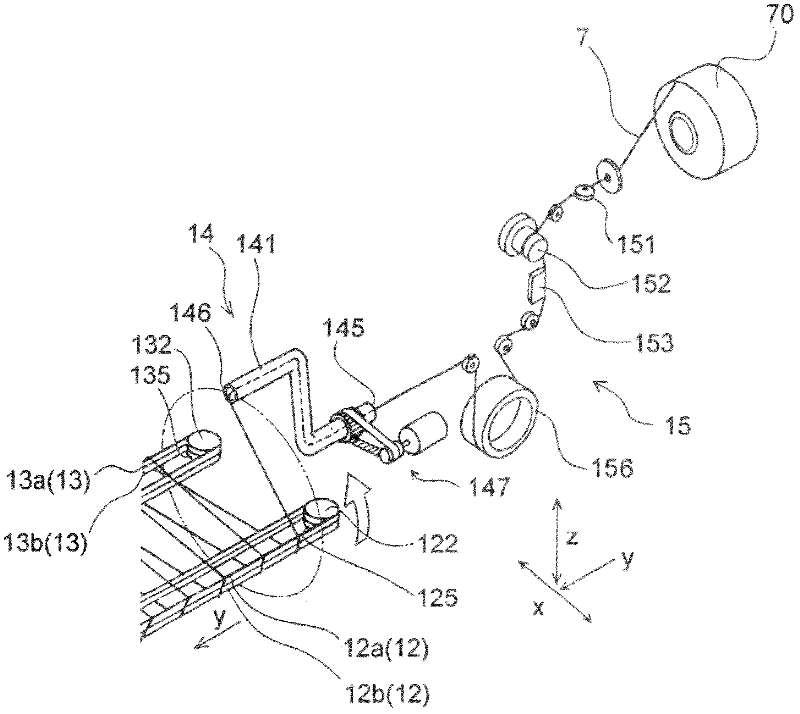

Automatic thin-section manufacturing system

ActiveUS20080202308A1Reduce the burden onThin overall sectionWithdrawing sample devicesShearing machinesEngineeringKnife blades

An automatic thin-section manufacturing system for manufacturing thin sections by thinly cutting out an embedded block having embedded therein a biological sample while setting said embedded block at a predetermined rake angle, and said system comprising: a long cutting blade having a cutting edge on one end; a holder disposed in such a manner that it makes the rake angle with respect to the surface of the embedded block; a mounting plane which is provided to the front end of the holder, on which plural cutting blades are mounted and aligned with their cutting edges exposed to the outer side; an adsorptive member provided along the mounting plane, which maintains the posture of the cutting blades by adsorbing the base end side of the cutting blades mounted on the mounting plane; a first pressing member provided to the holder, which presses, among the plural cutting blades that are mounted and aligned on the mounting plane, the cutting blade allocated to the predetermined position against the mounting plane; a conveyor unit which slides out the cutting blades that are linearly aligned on the mounting plane, by sequentially conveying the plural cutting blades to feed them one by one on the mounting plane; a transportation unit which moves the embedded block relative to the holder, such that the cutting blade pressed by the first pressing member cuts out the thin section from the embedded block; and a control unit which, after performing thin sectioning for a predetermined time, exchanging the cutting blade used for the thin sectioning by operating the conveyor unit to slide out the cutting blades.

Owner:SAKURA FINETEK JAPAN

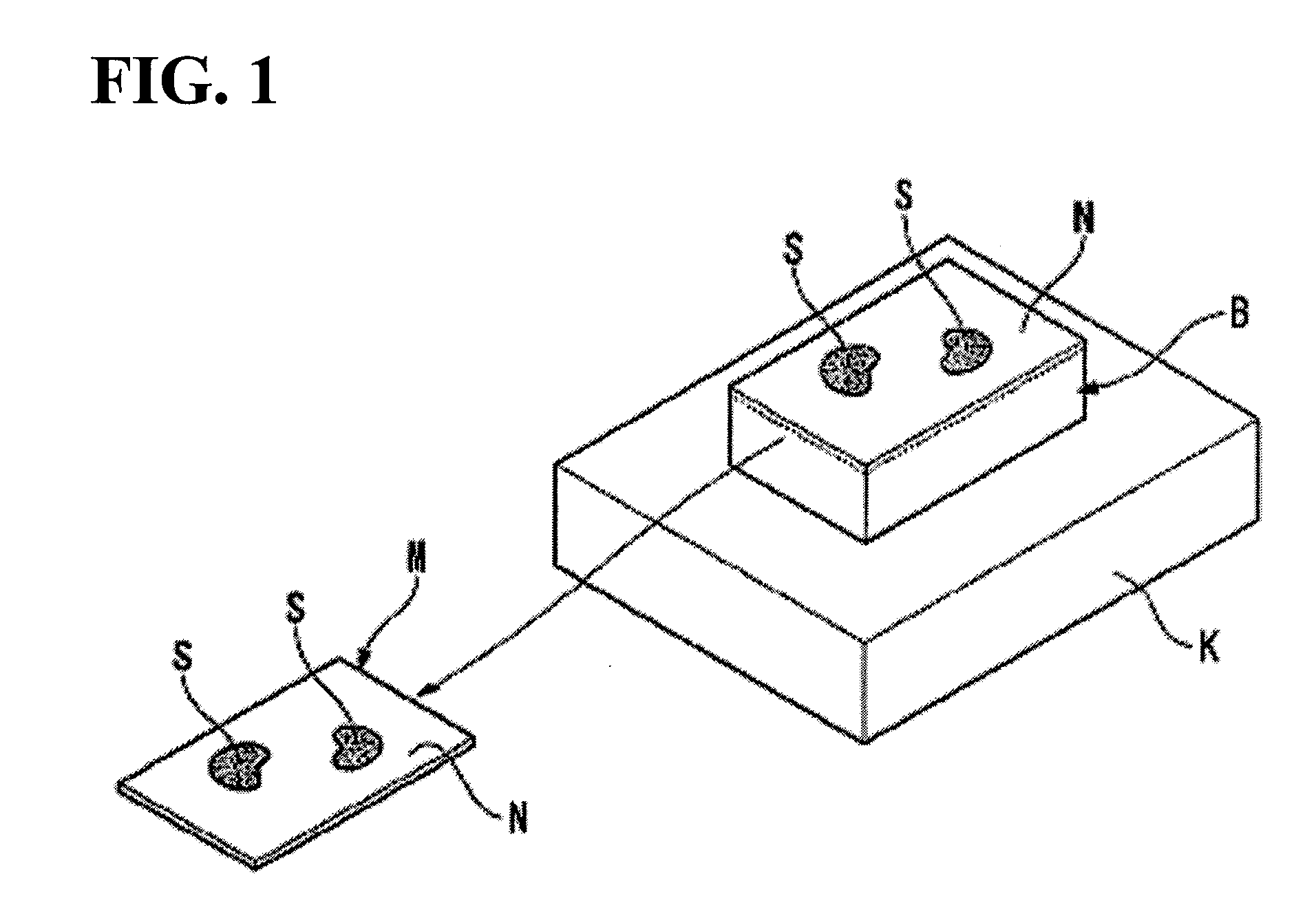

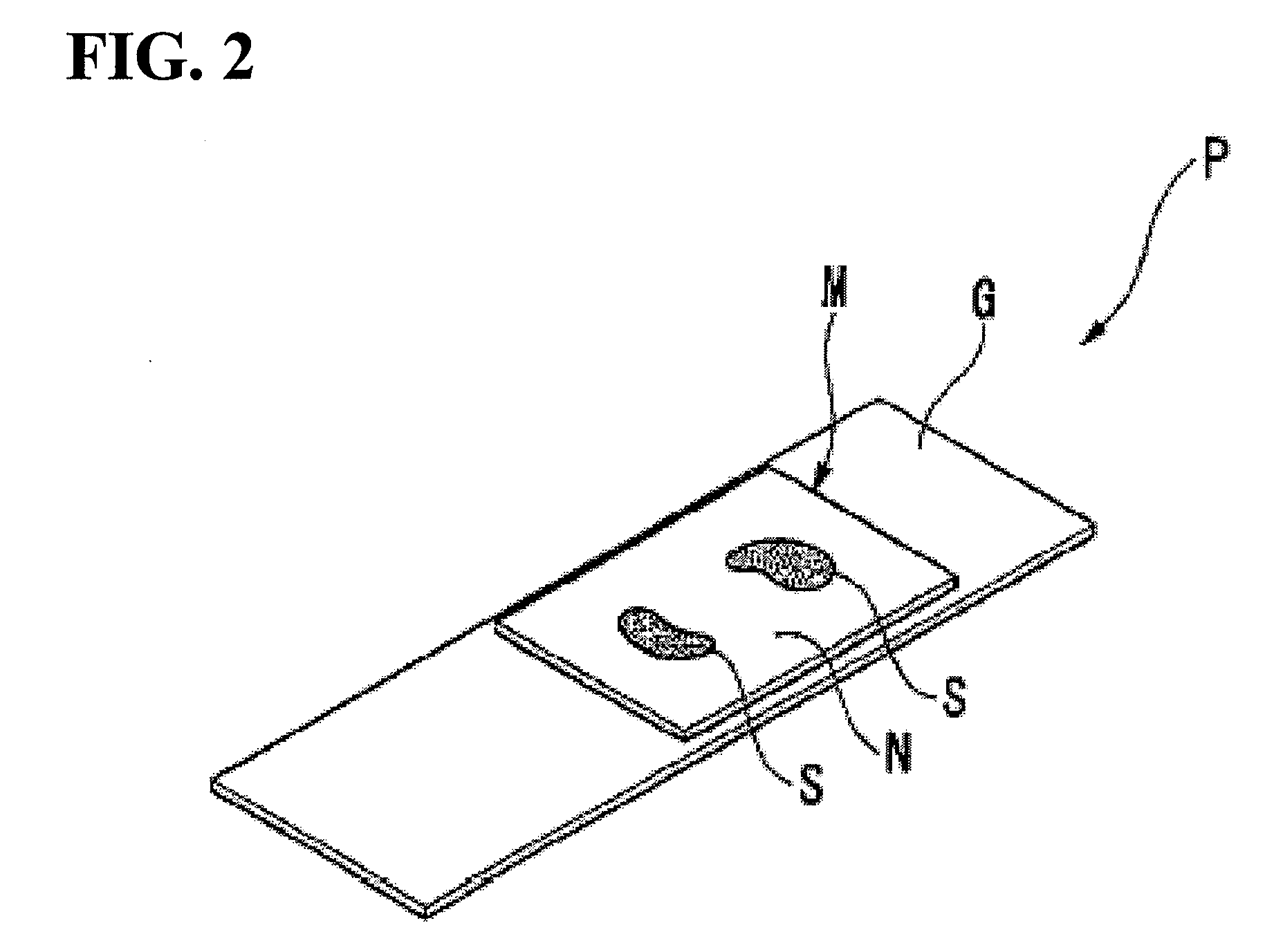

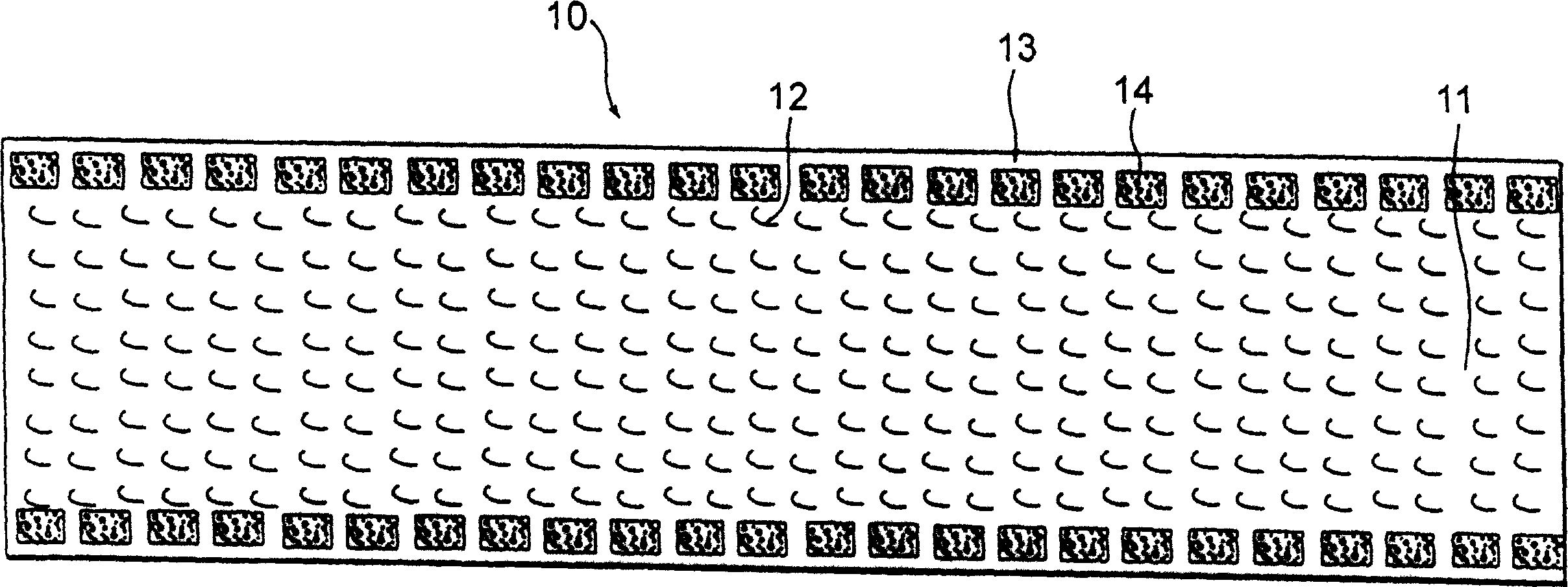

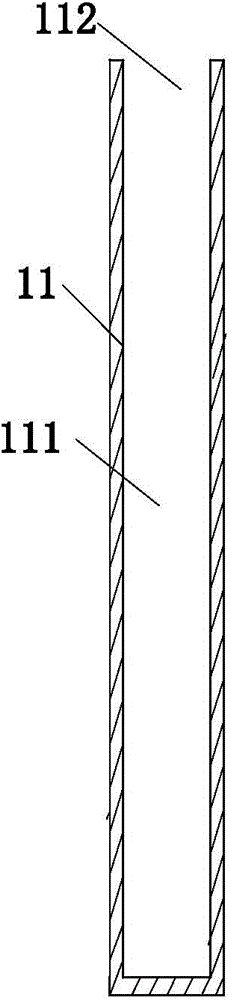

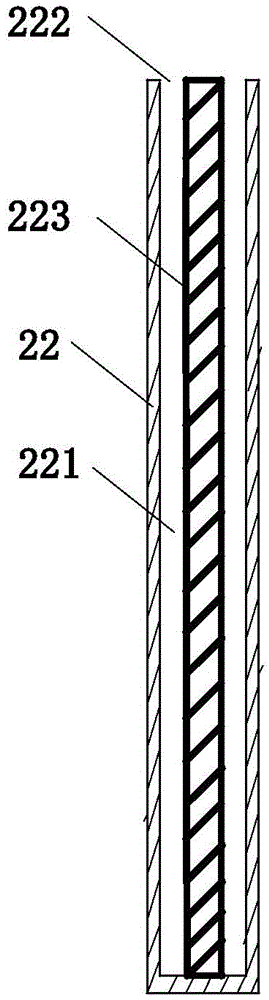

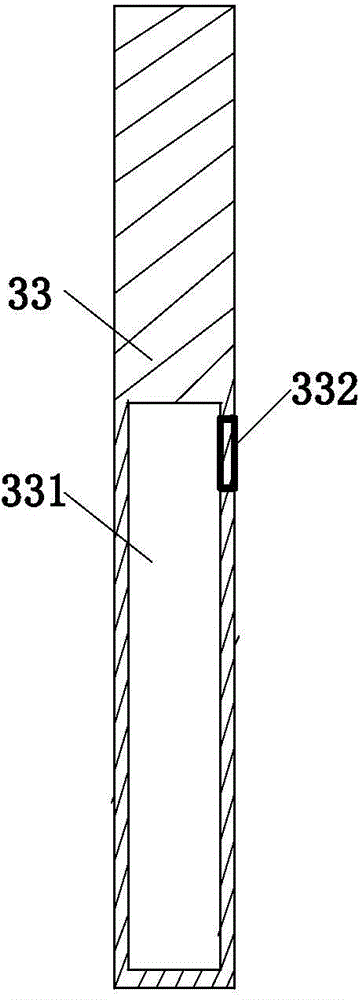

Fastener strip with magnetic body, and method and device for manufacturing the fastener strip

The present invention provides a fastener strip having magnetic powders not distributed through the entire volume thereof and contained in individual discontinuous identification areas thereof. This fastener strip has a substrate and many hook elements rising from an engaged surface of the substrate, and further has a magnetic body in a row, which rises from a surface of the substrate and is disposed below substantially a centerline and / or both lateral edges of the fastener strip. The magnetic particles are injected into the magnetic body and the substrate below the magnetic body, but, they are not dispersed through the entire substrate. The present invention also includes a manufacturing method and a manufacturing device for such a fastener strip. The present invention may function of forming an effective seal not only to accurately and suckingly position the fastener strip at a predetermined position in a metal mold but also to prevent the engaging element from being contaminated.

Owner:YKK CORP

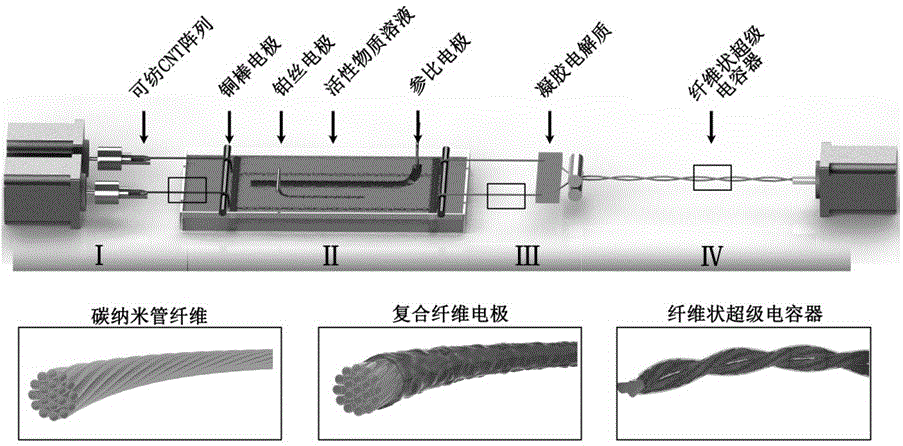

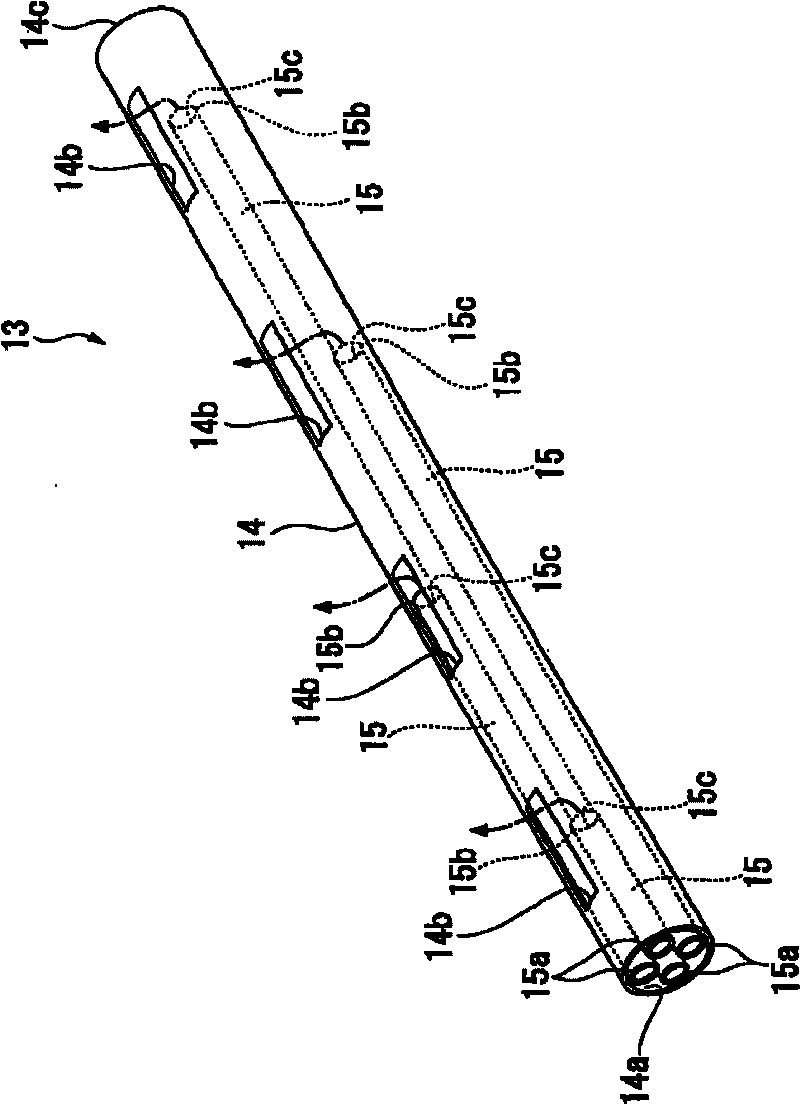

Method for preparing composite fiber-shaped capacitors continuously

InactiveCN105140048AContinuous preparationFast preparationHybrid/EDL manufactureMANGANESE ACETATEFiber

The invention belongs to the technical field of flexible energy storage and wearable devices, and specifically relates to a method for preparing composite fiber-shaped capacitors continuously. According to the invention, a spinnable carbon nanotube array serves as an initial material, and carbon nanotube fiber is obtained by means of dry spinning; the obtained carbon nanotube fiber is subjected to a solution mixed with fake capacitance active substances, such as an oxidized graphene aqueous solution, a manganese acetate aqueous solution, a aniline aqueous solution and a pyrroles aqueous solution, and a specific voltage is applied to the carbon nanotube fiber so as to enable the fake capacitance active substances to be deposited or aggregated on the surface of the carbon nanotube fiber; the continuously prepared carbon nanotube fiber is subjected to a phosphoric acid / polyvinyl alcohol gel electrolyte to obtain composite fiber electrodes; and finally two identical composite fiber electrodes are wound to obtain the fiber-shaped composite super capacitor. According to the invention, the continuous preparation of the fiber-shaped composite super capacitor is realized, the method is simple to operate and is applicable to large-scale production, and the prepared composite fiber-shaped super capacitor is good in flexibility and can be used in the field of flexible energy storage and wearable devices.

Owner:FUDAN UNIV

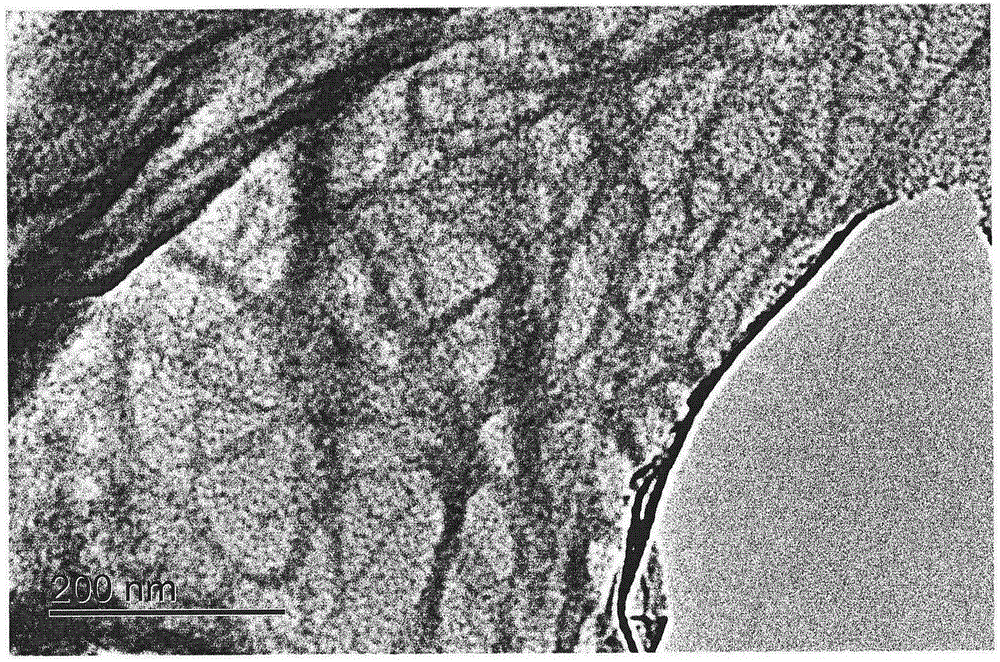

Method for rapidly and continuously preparing size and feature controllable metal nano particles

The invention belongs to the field of preparation of metal nano particles, and in particular relates to a method for rapidly and continuously preparing size and feature controllable metal nano particles. In the invention, through controlling a relative flow velocity of a continuously flowing metal complex solution or metal salt solution and a reducing agent solution, the proportion of a metal salt to a reducing agent in a reactor is strictly controlled, metal nano particle sol with required size and feature is prepared in the reactor by using a chemical reducing method, a target solution in the reactor is discharged through introducing nitrogen or air so that the influence of the generated metal nano particle sol to subsequent products is avoided, therefore, the continuous preparation of different sizes and features of metal nano particles is realized.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Electrophoretic display and process for its manufacture

InactiveUS7522332B2Improve the display effectCost effectiveElectrographic processes using photoelectrophoresisElectrographic process apparatusElectrophoresisDisplay device

This invention relates to an electrophoretic display comprising cells which are filled with charged particles dispersed in a solvent and are individually sealed with a polymeric sealing layer.

Owner:E INK CALIFORNIA

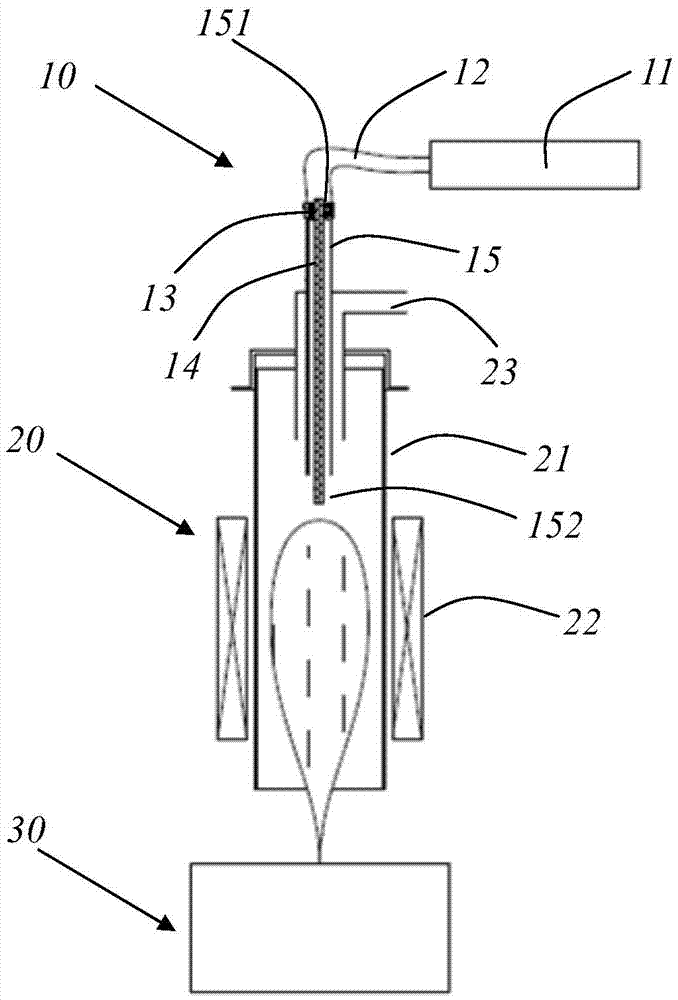

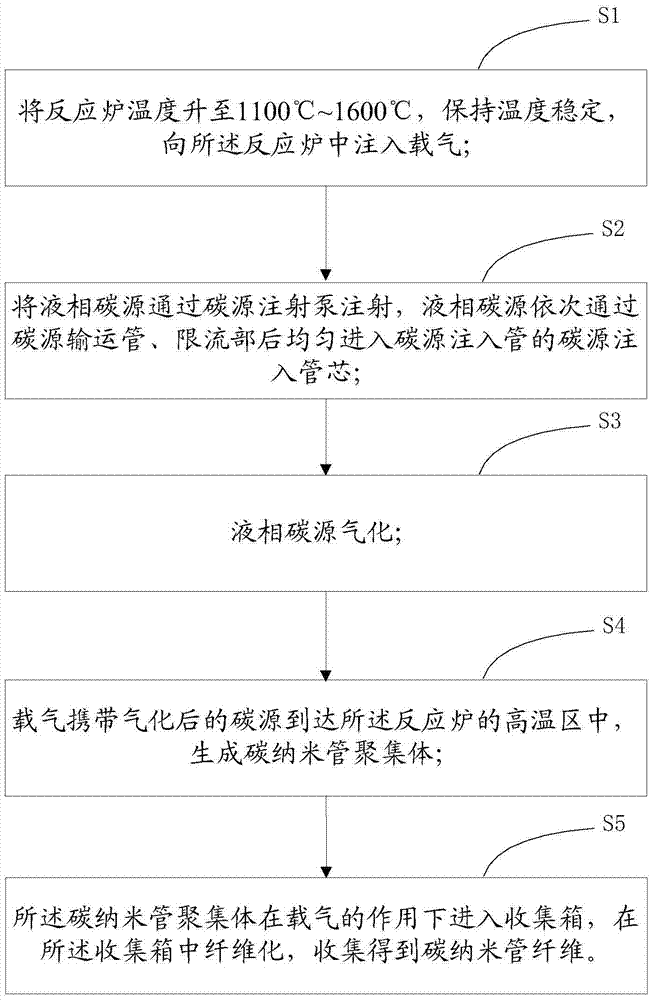

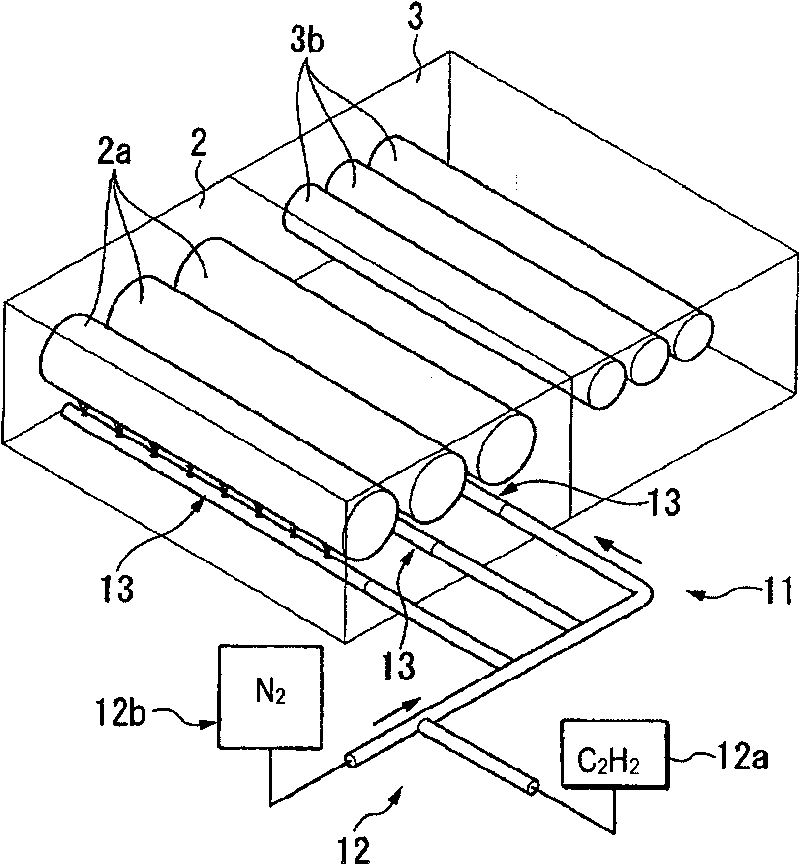

Vertical continuous preparing device for carbon nano tube fibers and preparing method

The invention provides a vertical continuous preparing device for carbon nano tube fibers. The vertical continuous preparing device comprises a carbon source injector, a tube furnace and a collecting box communicated with the tube furnace. The carbon source injector comprises a carbon source injection pump, a carbon source injection tube, a carbon source conveying tube and a flow limiting part, wherein one end of the carbon source injection tube is located in the tube furnace, the carbon source injection pump and the carbon source injection tube are communicated through the carbon source conveying tube, and the flow limiting part is arranged between the carbon source conveying tube and the carbon source injection tube. The carbon source injection pump injects a liquid-phase carbon source into the tube furnace through the carbon source conveying tube and the carbon source injection tube, a carbon source injection tube core is further arranged in the carbon source injection tube, one end of the carbon source injection tube core is arranged in the flow limiting part, and the other end of the carbon source injection tube core protrudes and stretches out of the carbon source injection tube. Compared with the prior art, the carbon source injector which is simple in structure and low in cost is adopted so that the liquid-phase carbon source can be uniformly injected and gasified, and finally the purpose of stably and continuously preparing the carbon nano tube fibers is achieved.

Owner:SUZHOU CREATIVE CARBON NANOTECH

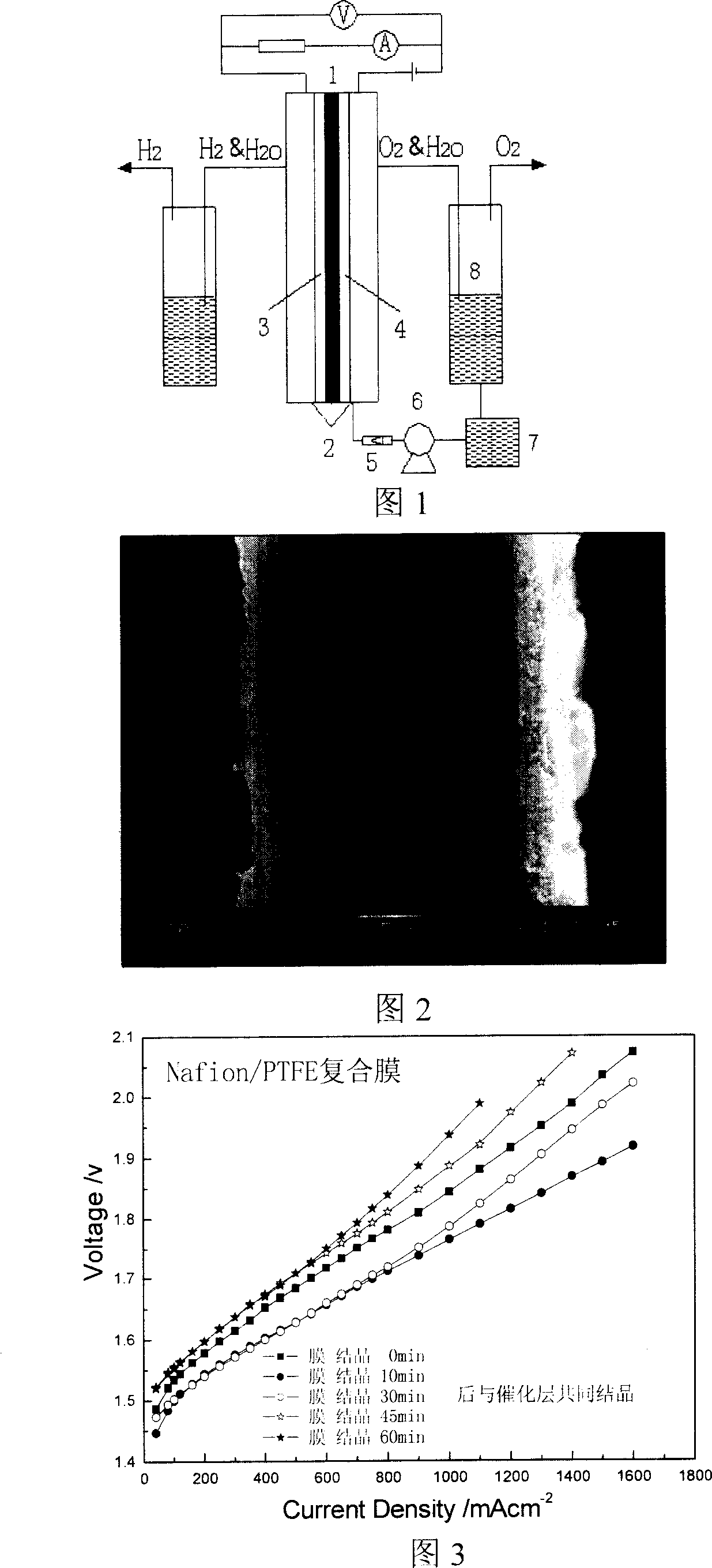

Preparation method of film electrode for solid polymer electrolyte water electrolysis

The invention relates to a method for preparing membrane electrode for solid polymer water electrolyte. It evaporates solid polymer electrolyte solution and forms film, couples catalytic layer composed of catalyst and solid polymer electrolyte on two sides to form integrated membrane electrode, then crystalizes membrane electrode to realize co-crystallization for solid polymer electrolyte. The combination between membrane and catalytic layer is tight and the stratification between membrane and electrode caused by gas evolution and wahsing during water electrolysis process is solved. The invention can produce solid polymer water electrolyte with high performance, high stability and high durability.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

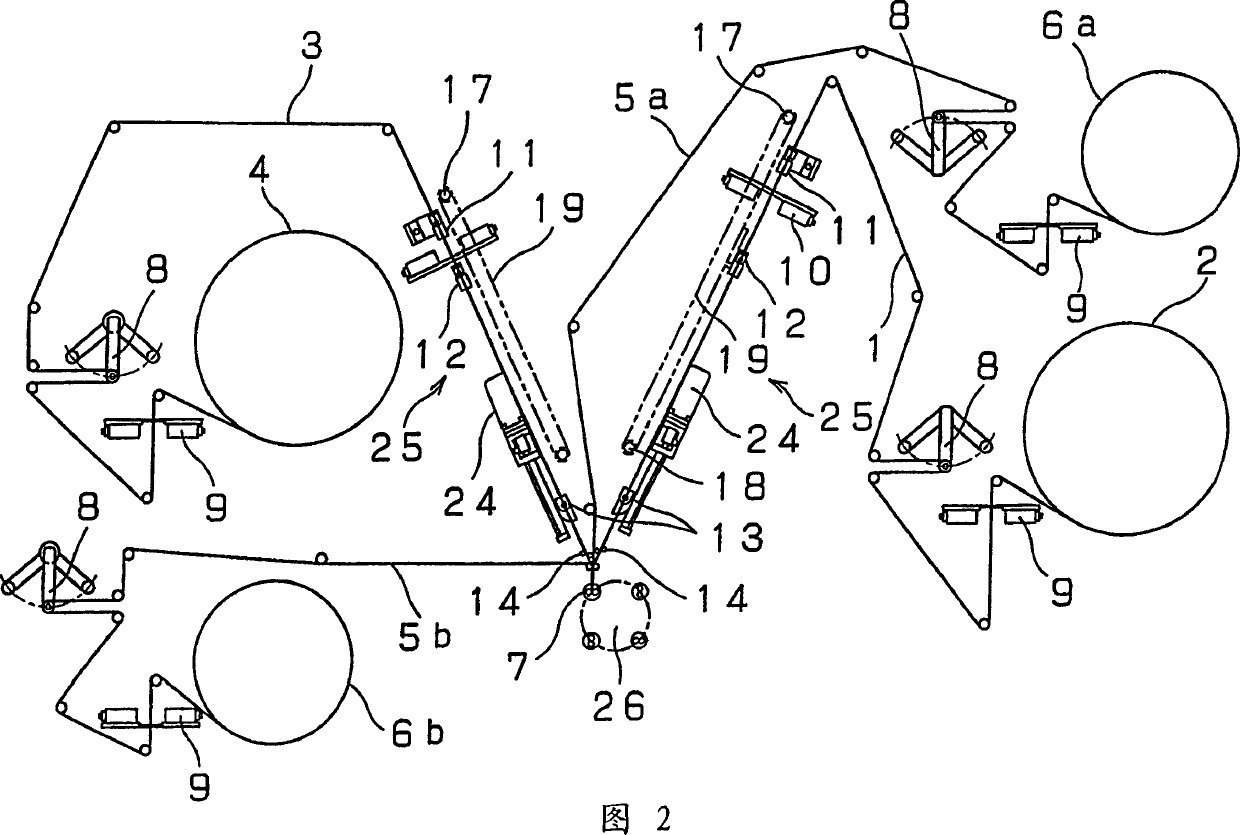

Spiral electrode group winding method and device and battery using them

InactiveCN1387683AContinuous preparationImprove performanceAssembling battery machinesFinal product manufactureElectrical batteryEngineering

The present invention provides a method and device for winding a spiral electrode group for a battery. The method and device wind a continuous strip-shaped positive electrode, negative electrode plate, and separator into a spiral electrode group through a freely rotatable winding core. The edge position of the strip-shaped electrode plate is detected by the edge position detection device at a predetermined position near the winding core, and compared with the reference position, and according to the result, it is grasped by the chuck movable from the electrode plate to the direction perpendicular to the direction of travel of the electrode plate. , after correcting the edge position of the electrode plate, the electrode plate is held by the gripper that is constrained by the guide rail to move only in the direction parallel to the transfer direction of the electrode plate, and the electrode plate is held by the third chuck, and the front end of the electrode plate is supplied to the winding core , The second chuck prevents the positional deviation of the electrode plate and winds the electrode group while applying tension to the electrode plate, thereby performing electrode plate winding with a small deviation in the winding of the electrode group. In addition, the flatness of the electrode during flat shaping can be improved by making the cross-sectional shape of the winding core at right angles to the axial direction substantially hexagonal.

Owner:GK BRIDGE 1

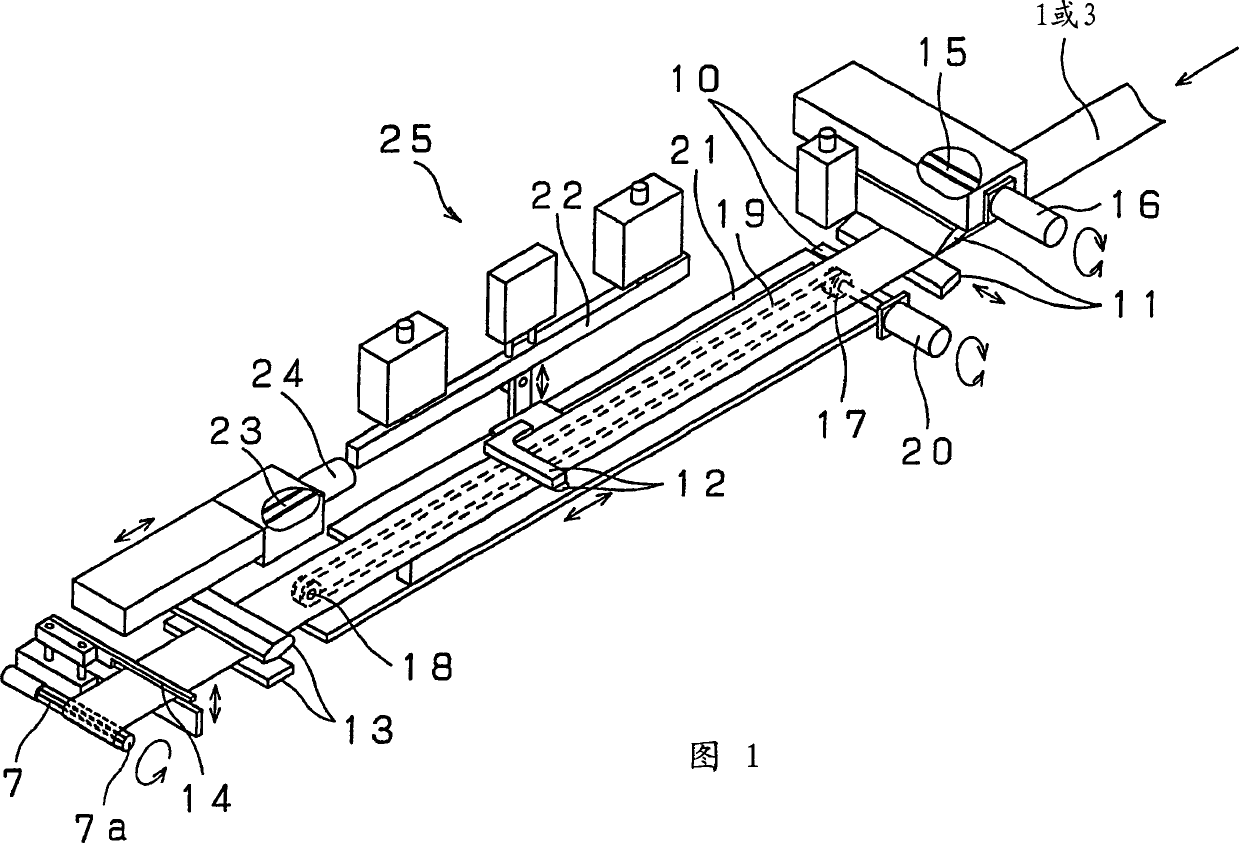

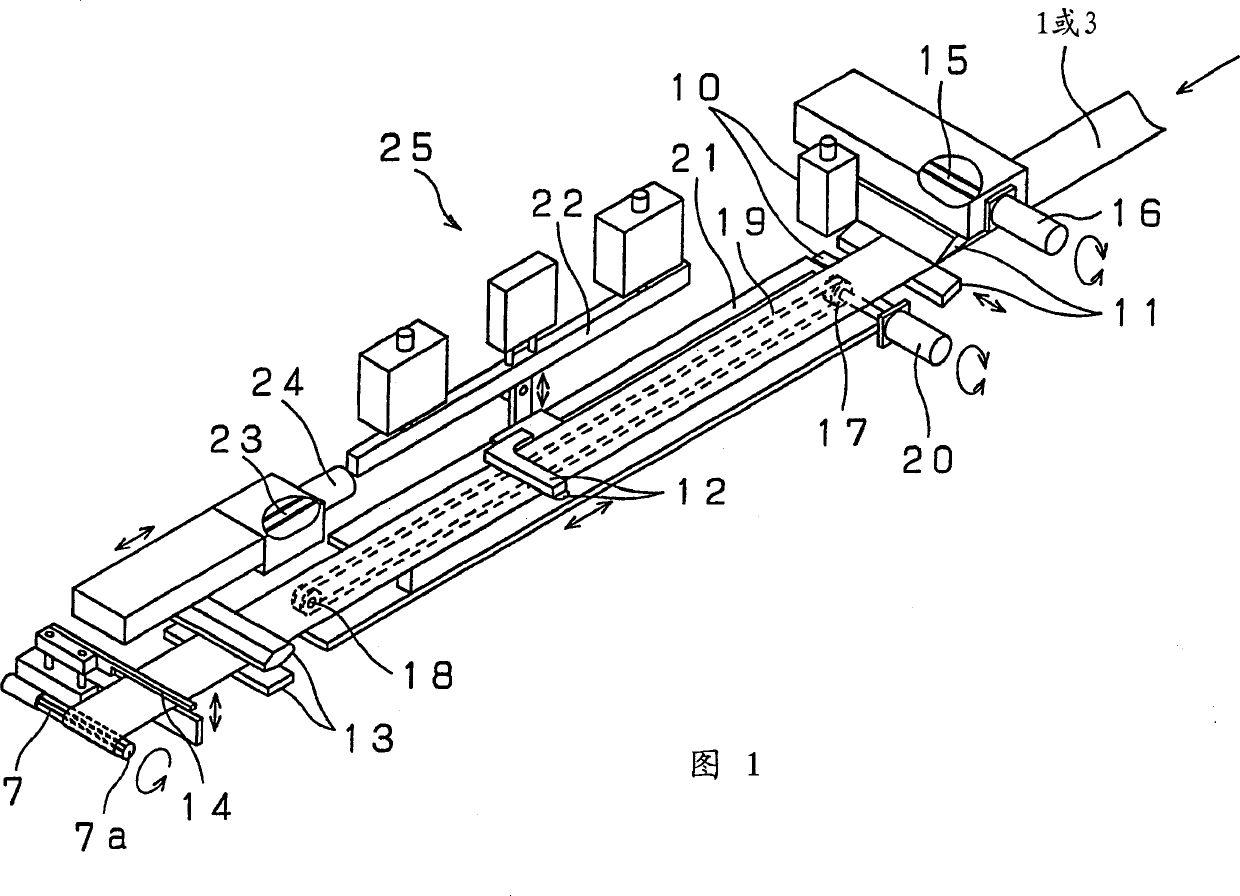

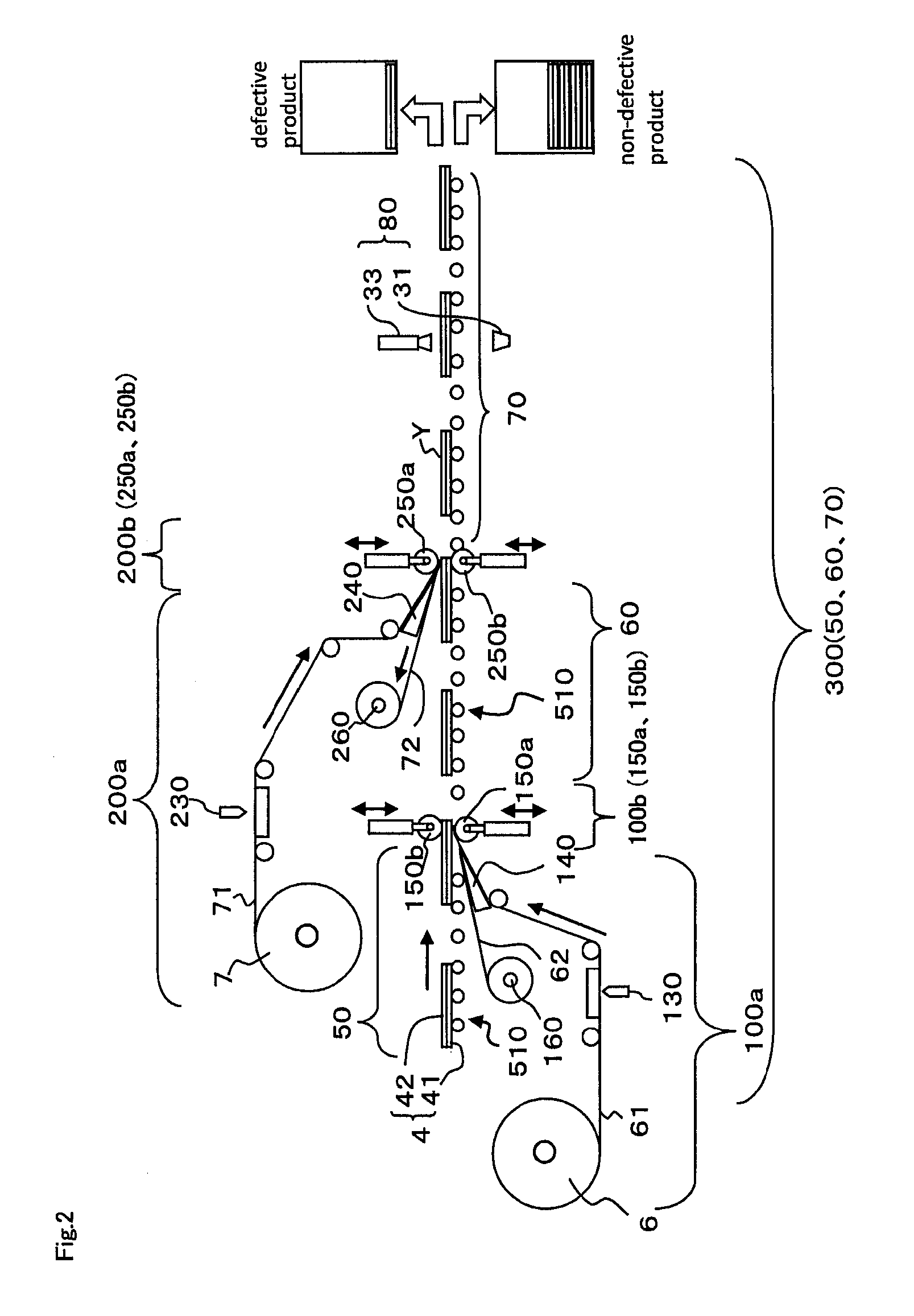

Manufacturing method of absorbent article

The present invention provides a manufacturing method of an absorbent article which is provided with waist fins (3). The fins (3) are telescopic sheets (30) which is fixed between strip-shaped sheets (50,60) through an elongation state in an X direction. The manufacturing method comprises steps of: after coiling an elastomer (7) between long structures (12,13) by an elastomer coiling mechanism (14) for line conveying, clamping the elastic member between the strip-shaped sheets (50,60); and a step of cutting off the linear elastomer (7) thereby forming the telescopic sheets (30). Besides, the manufacturing method further comprises the following steps: a dividing step of cutting off the strip-shaped sheets (50,60) at the central part; and a step of replacing the positions of the two telescopic sheets obtained through cutting, forming the waist fins (3) through cutting, jointing the waist fins (3) with an absorbent body (2) according to a mode that a cutting edge (91) extends out in an X direction of a diaper (1) for forming the diaper (1).

Owner:KAO CORP

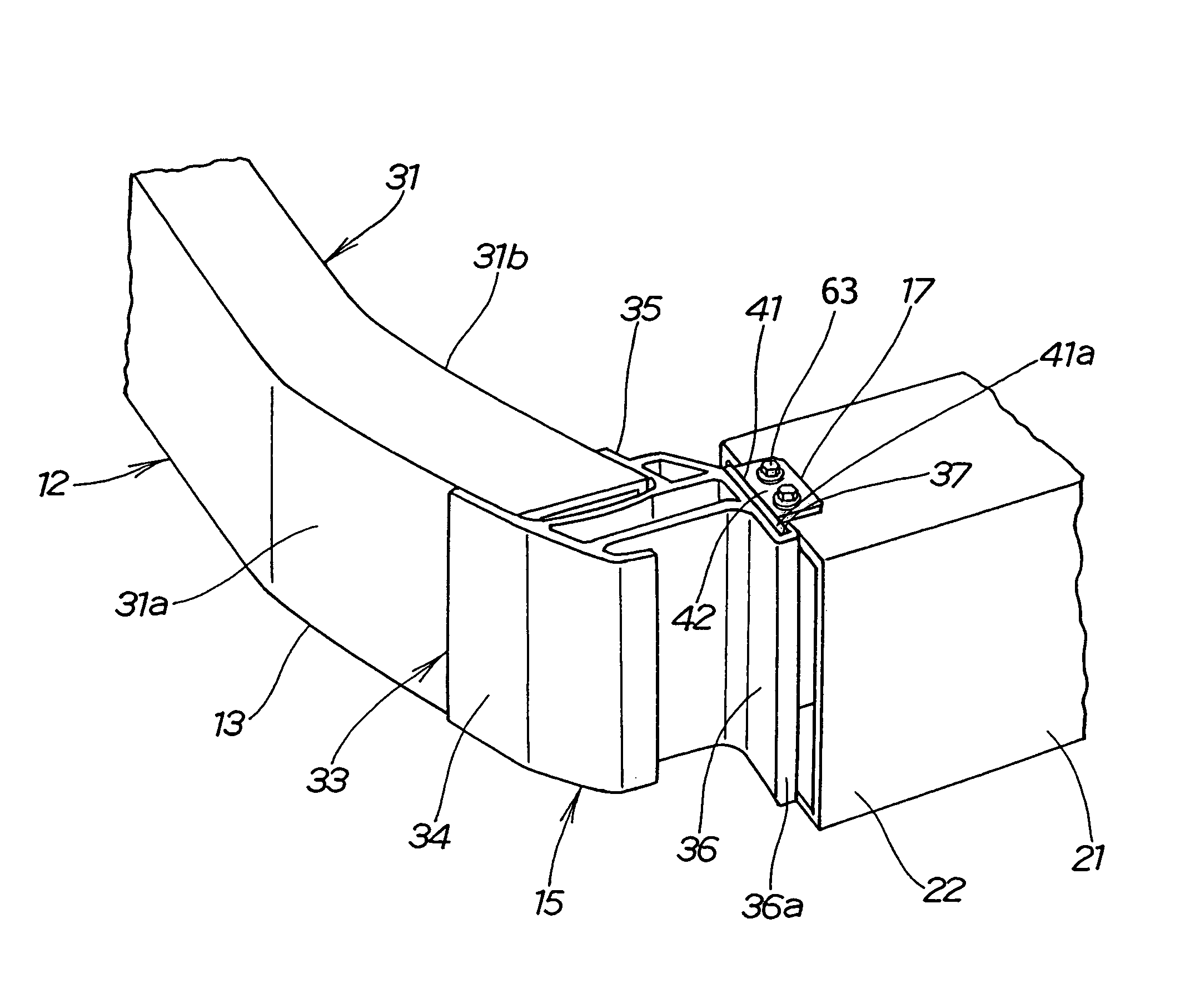

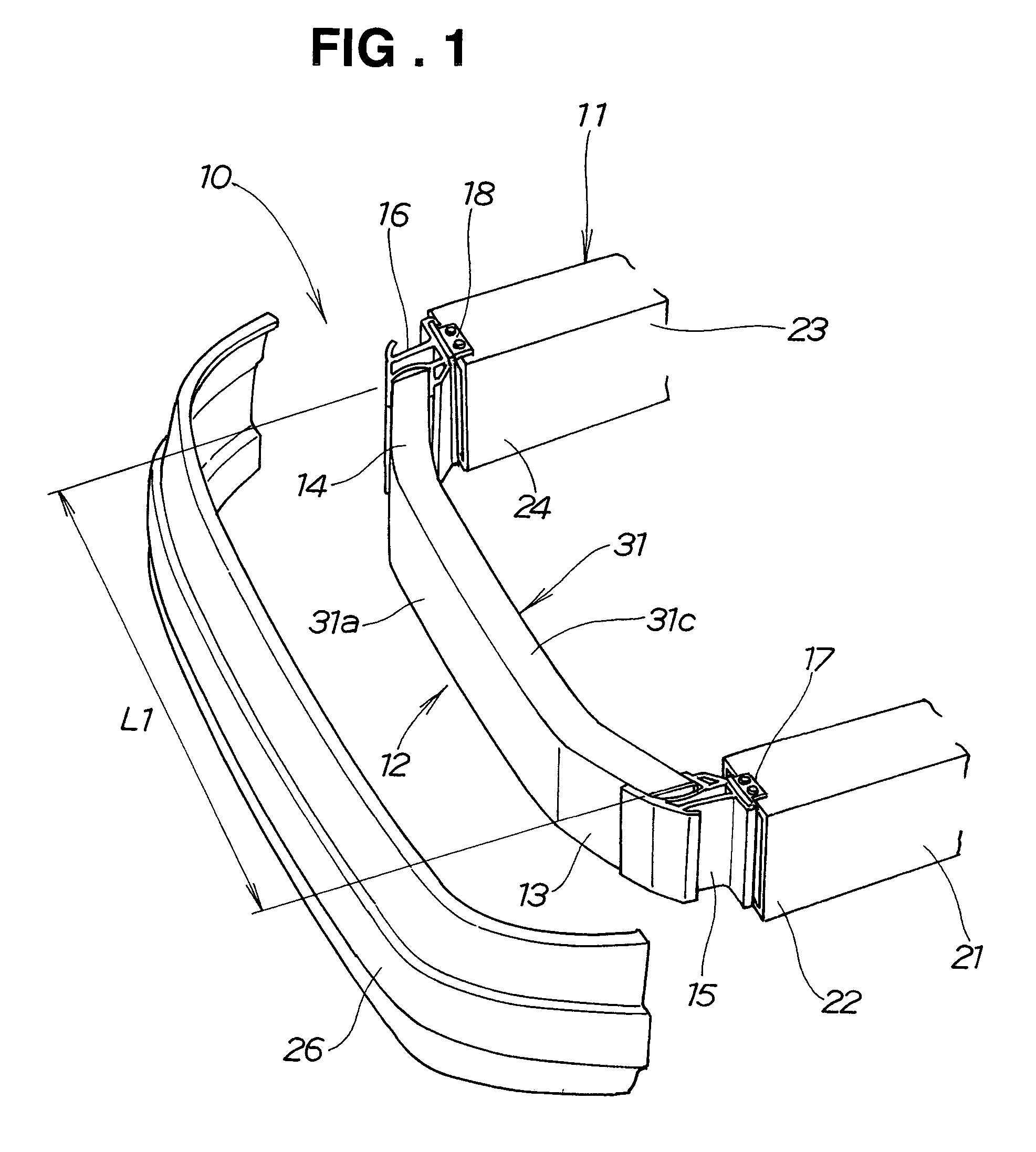

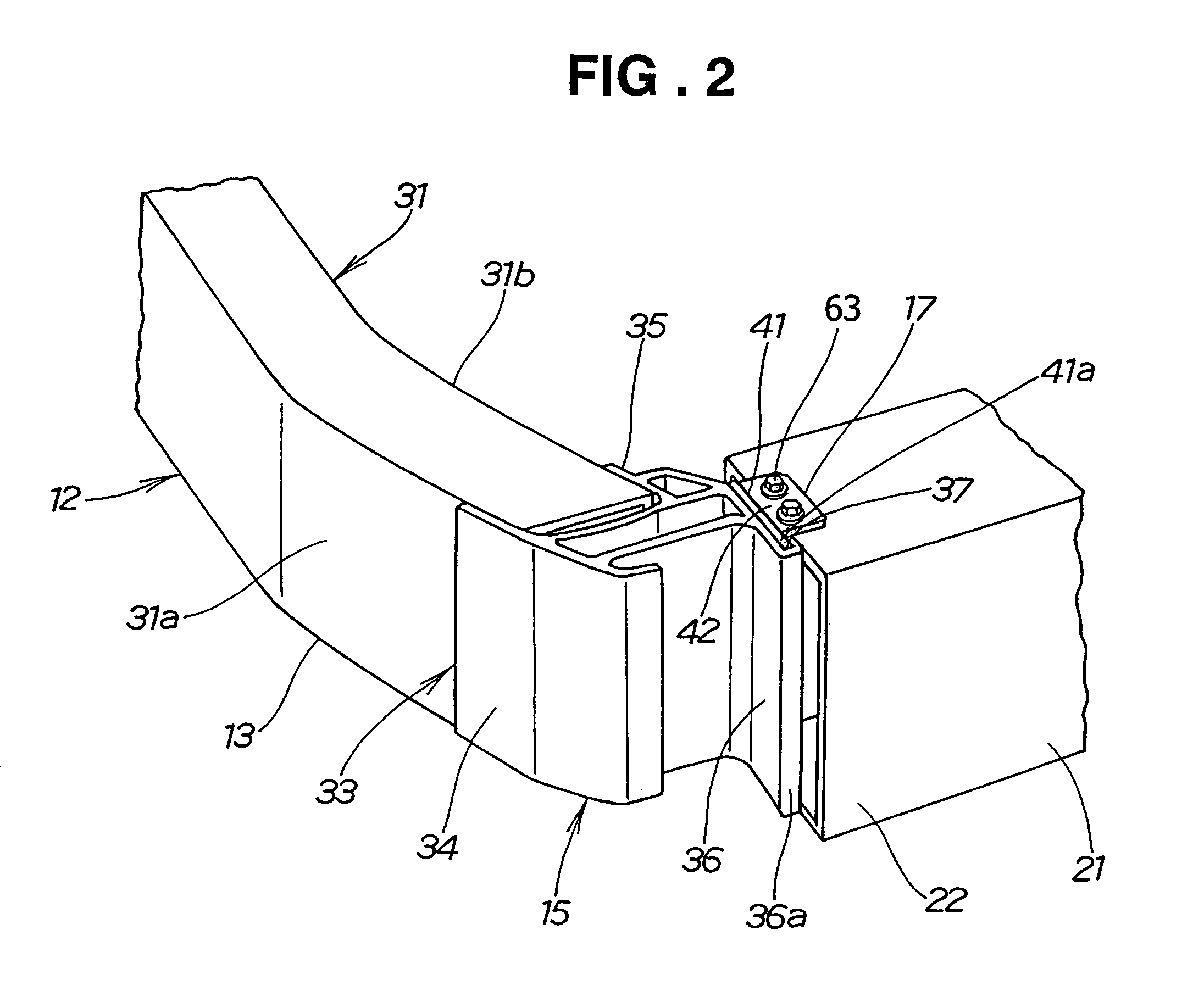

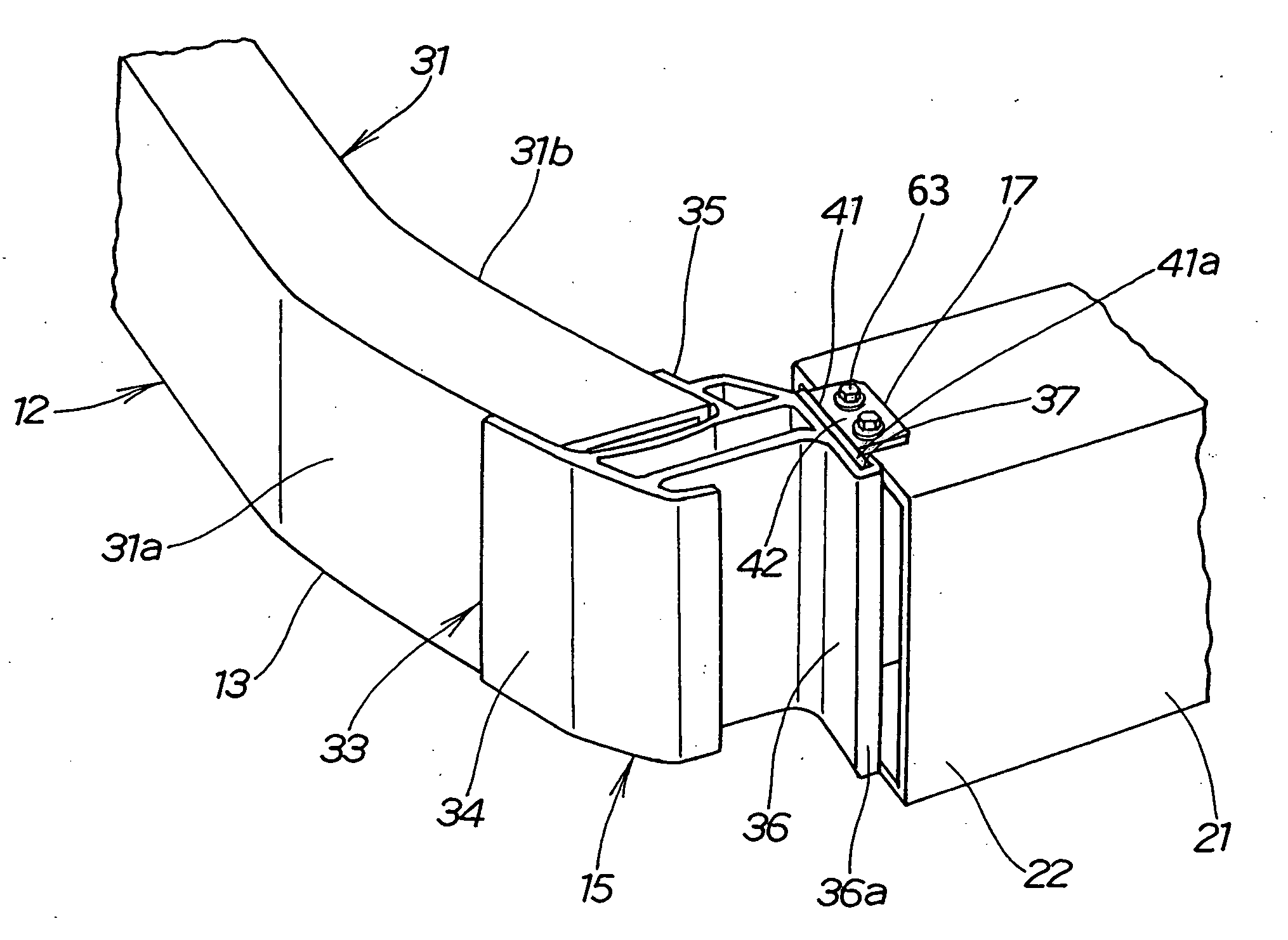

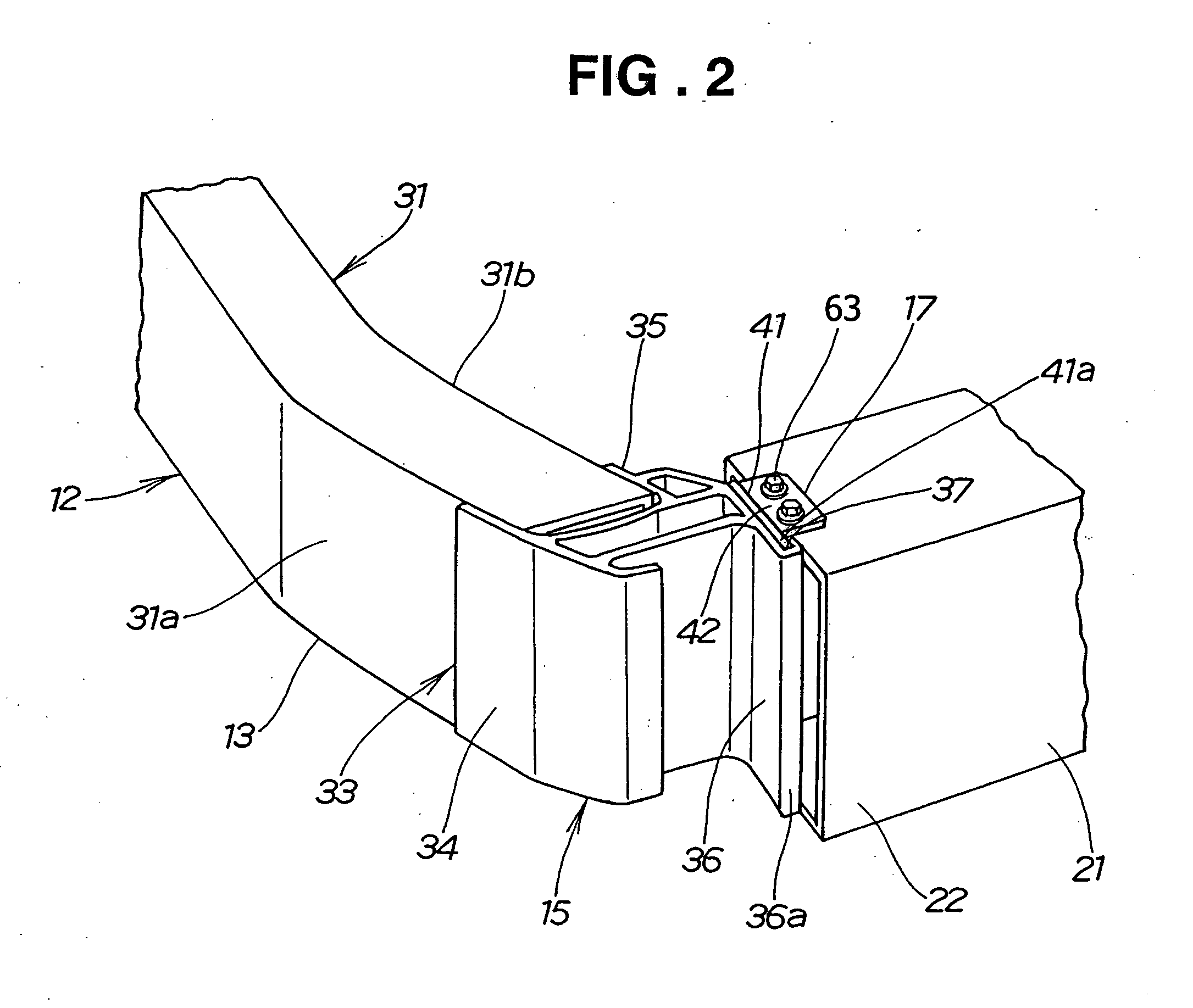

Bumper beam structure

A bumper beam structure includes a beam extending transversely of a vehicle and right and left corned members attached to right and left ends of the beam. The beam is mountable to front ends of right and left vehicle frame members via the right and left corner members. The beam and the right and left corner members are all extruded members. The beam is disposed with its axis in an extrusion direction oriented transversely of the vehicle. The right and left corner members are disposed with their axes in an extrusion direction oriented vertically of the vehicle.

Owner:HONDA MOTOR CO LTD

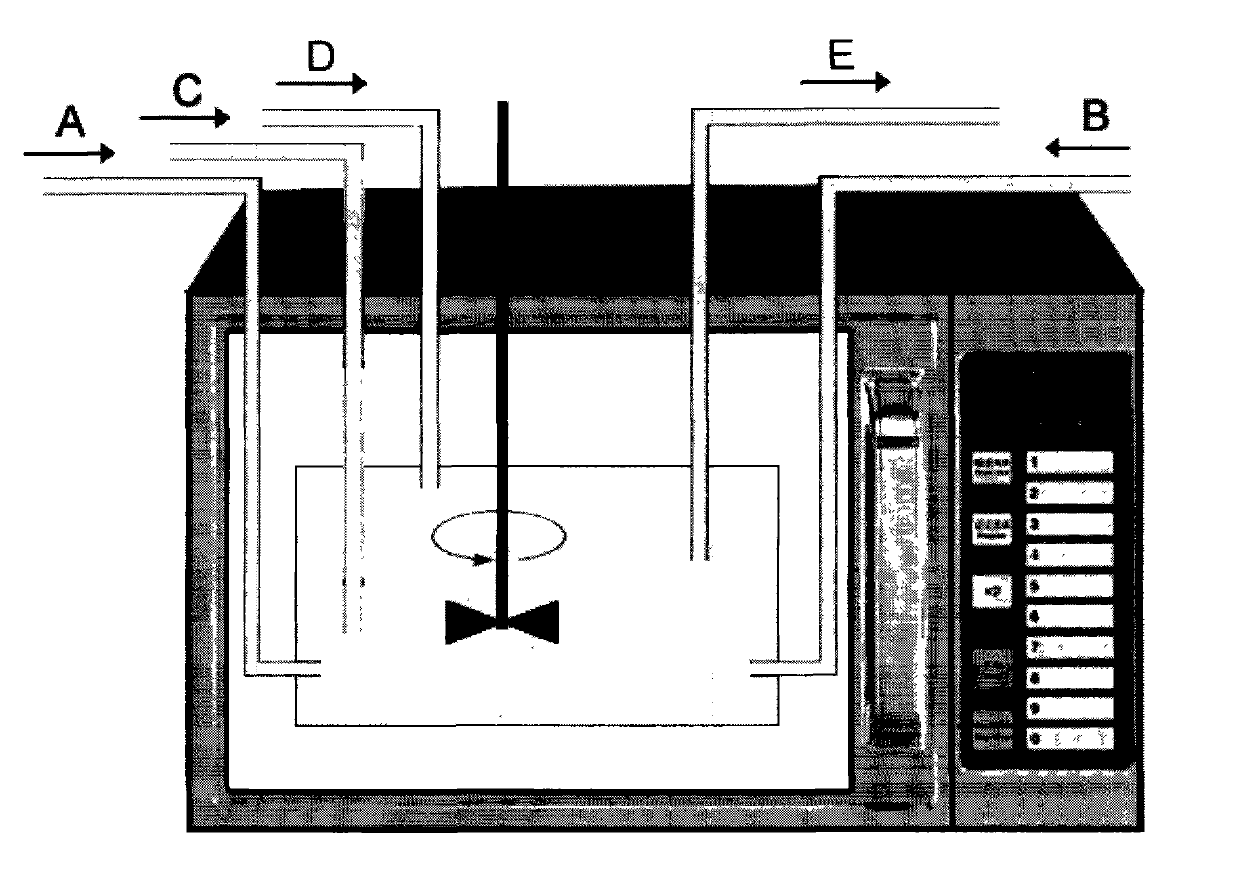

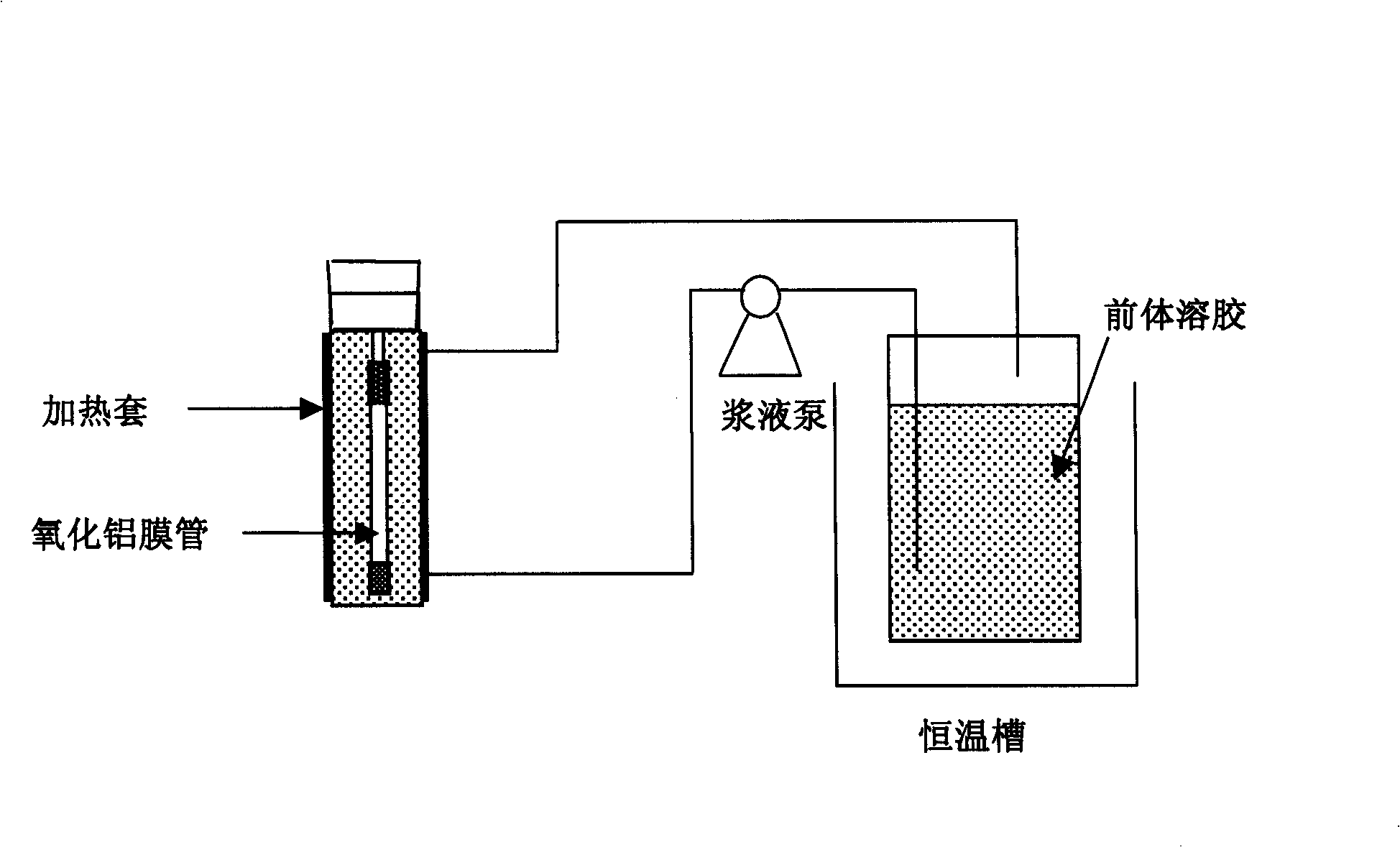

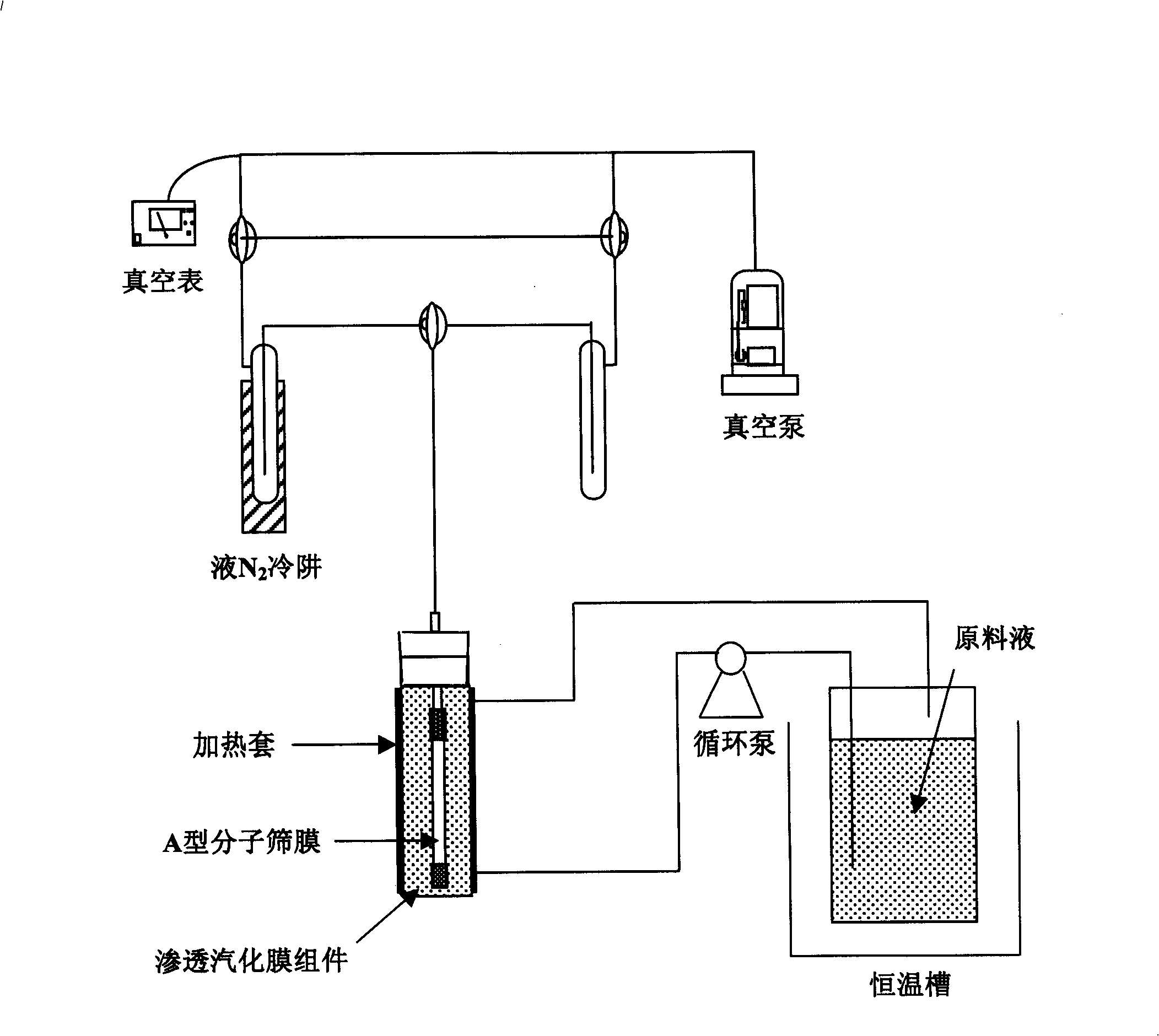

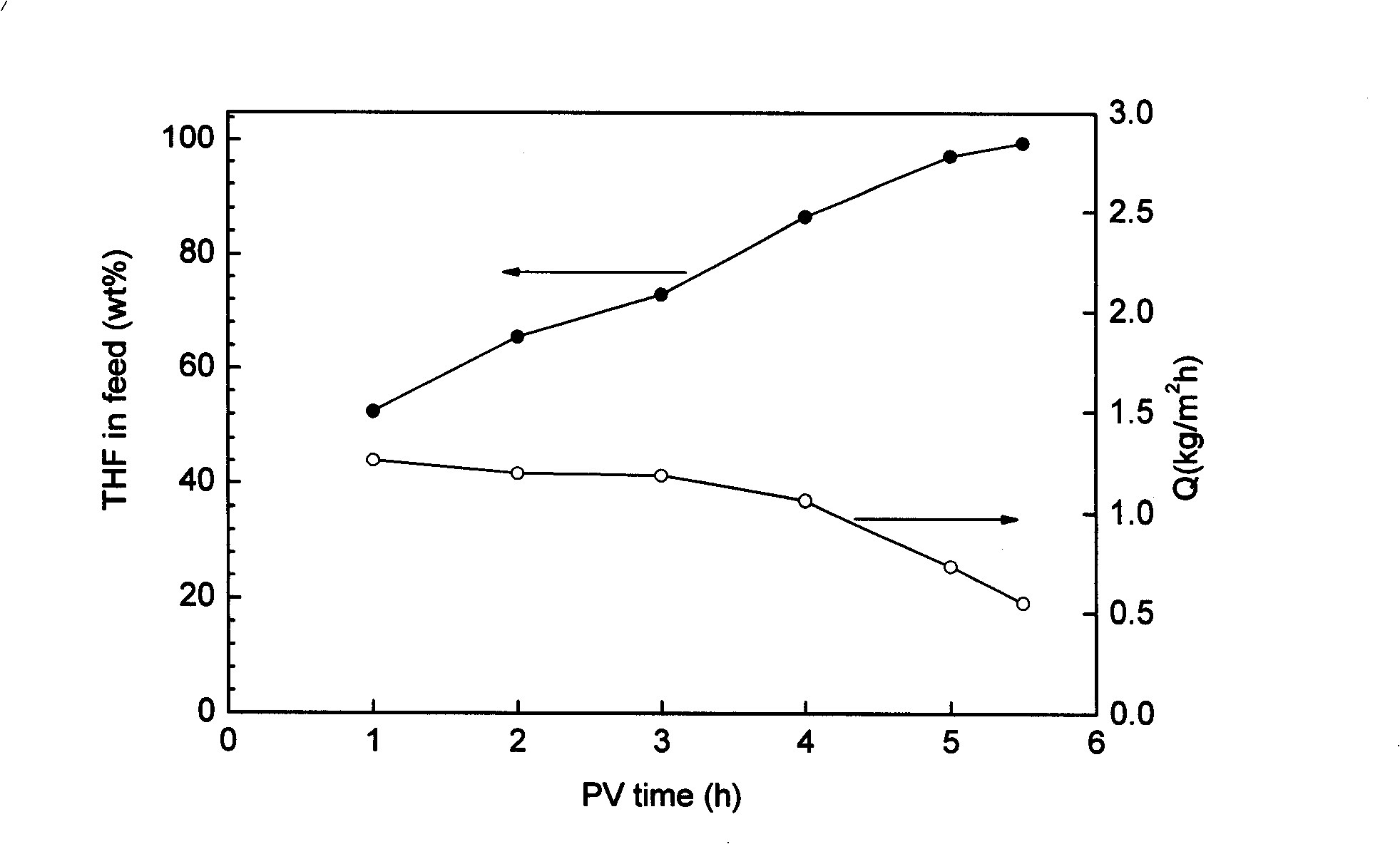

Novel methods for producing type A molecular sieve film in current system

InactiveCN101402022AUniform preparationContinuous preparationSemi-permeable membranesMolecular sieveDefinite time

The invention provides a novel method for preparing an A-type molecular sieve membrane, which adopts preparation of the molecular sieve membrane in a flow system. The method comprises the following steps: a silicon source, an aluminum source, an alkali source and deionized water are prepared into precursor sol of A-type molecular sieve according to certain proportion first; a vector membrane tube which is precoated with A-type molecular sieve crystal seeds is fixed inside a synthesis reactor; the molecular sieve precursor sol which is heated to a given temperature is conveyed into the synthesis reactor through a slurry pump, and the precursor sol is driven to flow and circulate on the surface of an outer membrane of the vector membrane tube; and the A-type molecular sieve membrane can be obtained after flowing, circulating and crystallization for a definite time at the given temperature. The preparation method provided by the invention has the advantages that the preparation method can basically solve the problem of concentration gradient during the synthetic process of he molecular sieve, is favorable to the preparation of the uniform, continuous and compact molecular sieve membrane with superior separation performance, and is particularly suitable for preparing the molecular sieve membrane for industrial application.

Owner:中科院嘉兴中心成都有机所分中心 +1

Bumper beam structure

A bumper beam structure includes a beam extending transversely of a vehicle and right and left corned members attached to right and left ends of the beam. The beam is mountable to front ends of right and left vehicle frame members via the right and left corner members. The beam and the right and left corner members are all extruded members. The beam is disposed with its axis in an extrusion direction oriented transversely of the vehicle. The right and left corner members are disposed with their axes in an extrusion direction oriented vertically of the vehicle.

Owner:HONDA MOTOR CO LTD

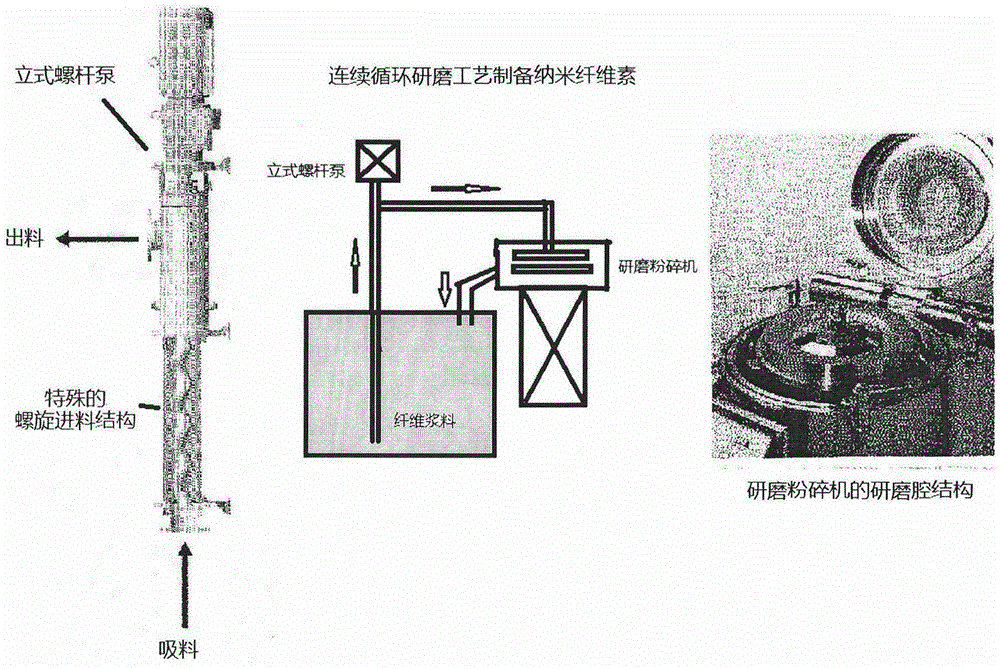

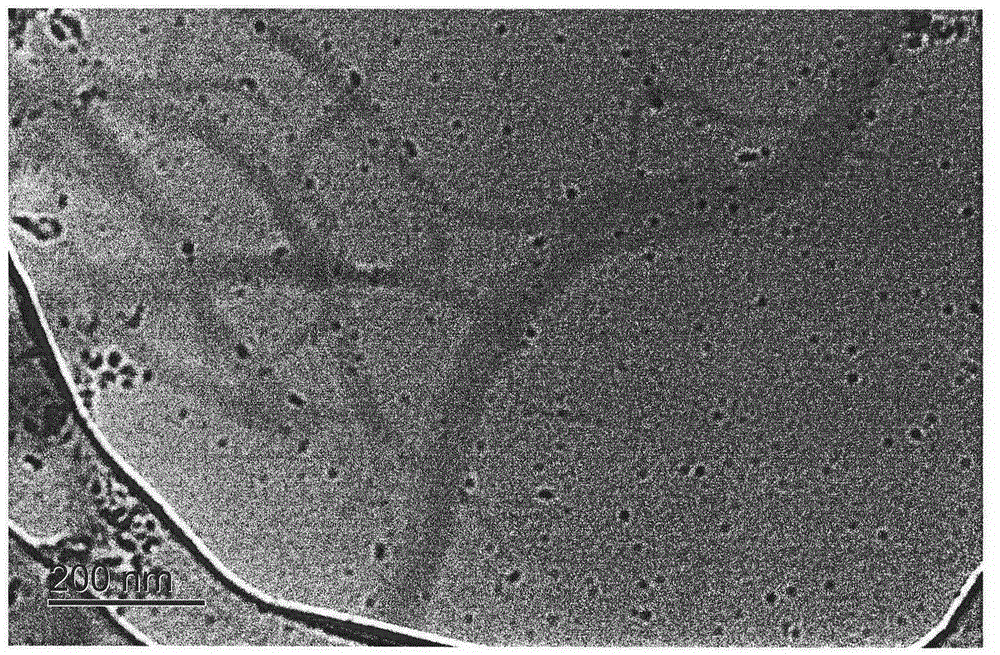

High-efficiency and low-energy-loss nanocellulose preparation method

ActiveCN105369663AReduce manufacturing costReduce energy consumptionPaper material treatmentHigh concentrationMaterials preparation

The invention discloses a high-efficiency and low-energy-loss nanocellulose preparation method, and belongs to the technical field of nanometer material preparation. The method includes the steps of firstly, preprocessing cellulosic materials; secondly, conducting washing and filter-press concentration till the concentration is 6% or above, pumping a high-concentration sizing agent into a grinding and smashing machine through a vertical screw pump, and grinding the cellulosic materials multiple times in a circulating mode under certain pumping pressure and certain grinding process conditions, and obtaining nanocellulose. Compared with the prior art, high-concentration nanocellulose gel can be continuously and rapidly prepared, the unit product preparation energy consumption is greatly lowered, the production cost is reduced, and the production efficiency is improved. The method is simple in process step and capable of being easily implemented in an industrialized mode.

Owner:CHINA NAT PULP & PAPER RES INST CO LTD

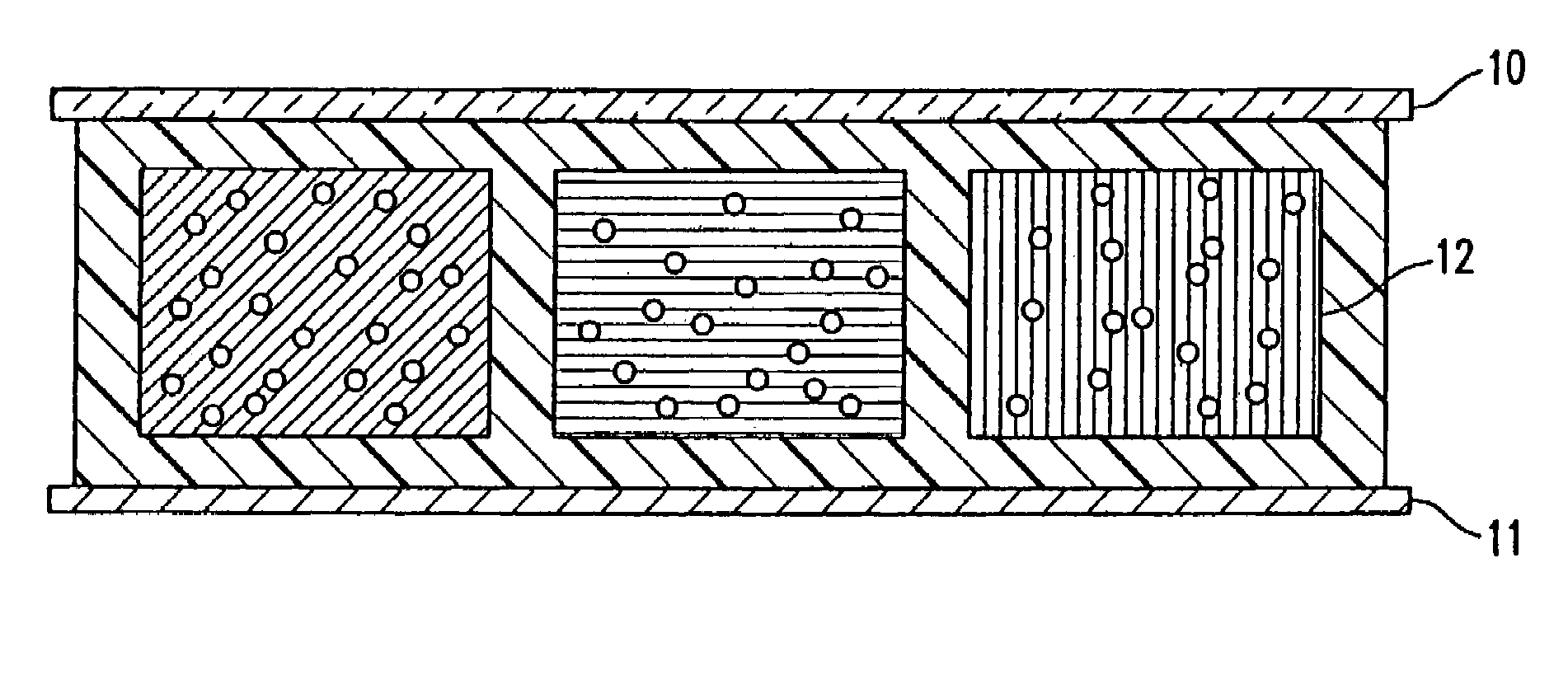

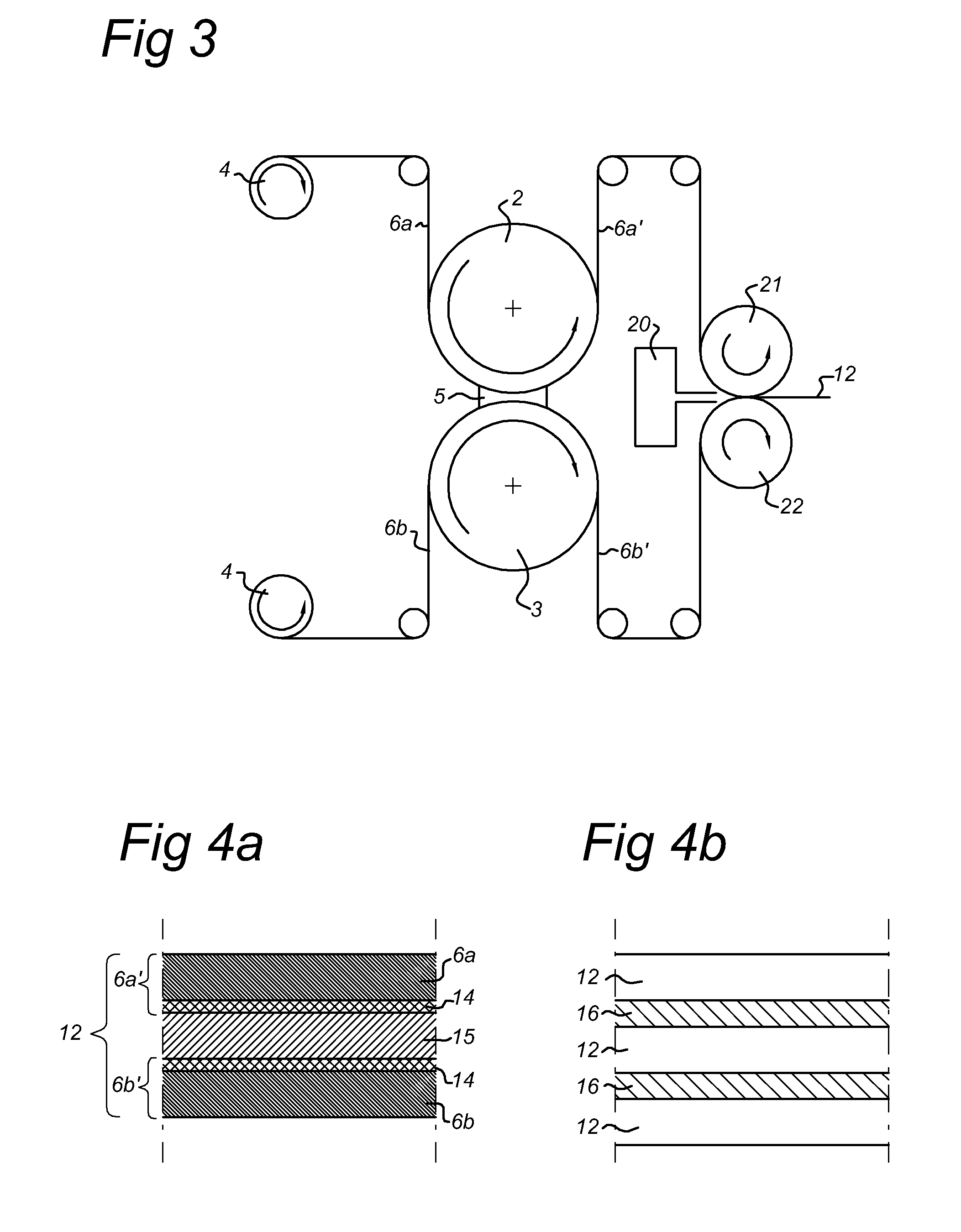

Method for manufacturing a multi-layer stack structure with improved wvtr barrier property

InactiveUS20110049491A1Effective and efficient and cheap processImprove barrier propertiesLamination ancillary operationsSolid-state devicesEngineeringAtmospheric pressure

A method and apparatus for manufacturing a multi-layer stack structure (12), the structure (12) comprising in order: a substrate (6a) a barrier layer (14) an adhesive layer (15) a barrier layer (14) a substrate (6b). The method comprises: a) providing two substrates (6a, 6b) in a single treatment space (5), the treatment space (5) comprising at least two electrodes (2, 3) for generating an atmospheric pressure glow discharge plasma in the treatment space (5); b) treating the facing surfaces of the two substrates (6a, 6b) simultaneously in the single treatment space (5); c) laminating the two treated substrates (6a, 6b) with an adhesive layer (15) in between the facing surfaces to obtain the multi-layer stack structure (12).

Owner:FUJIFILM MFG EURO

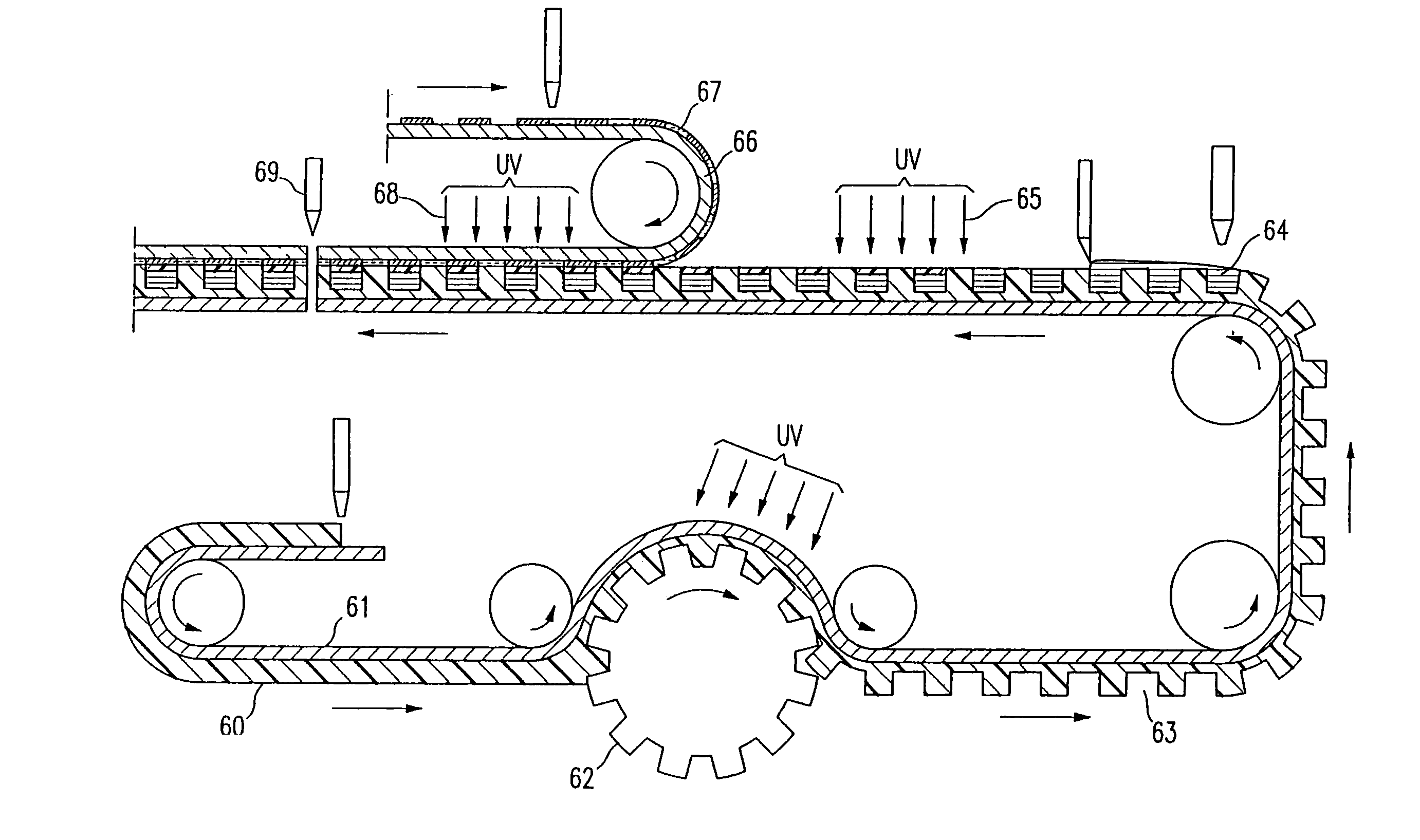

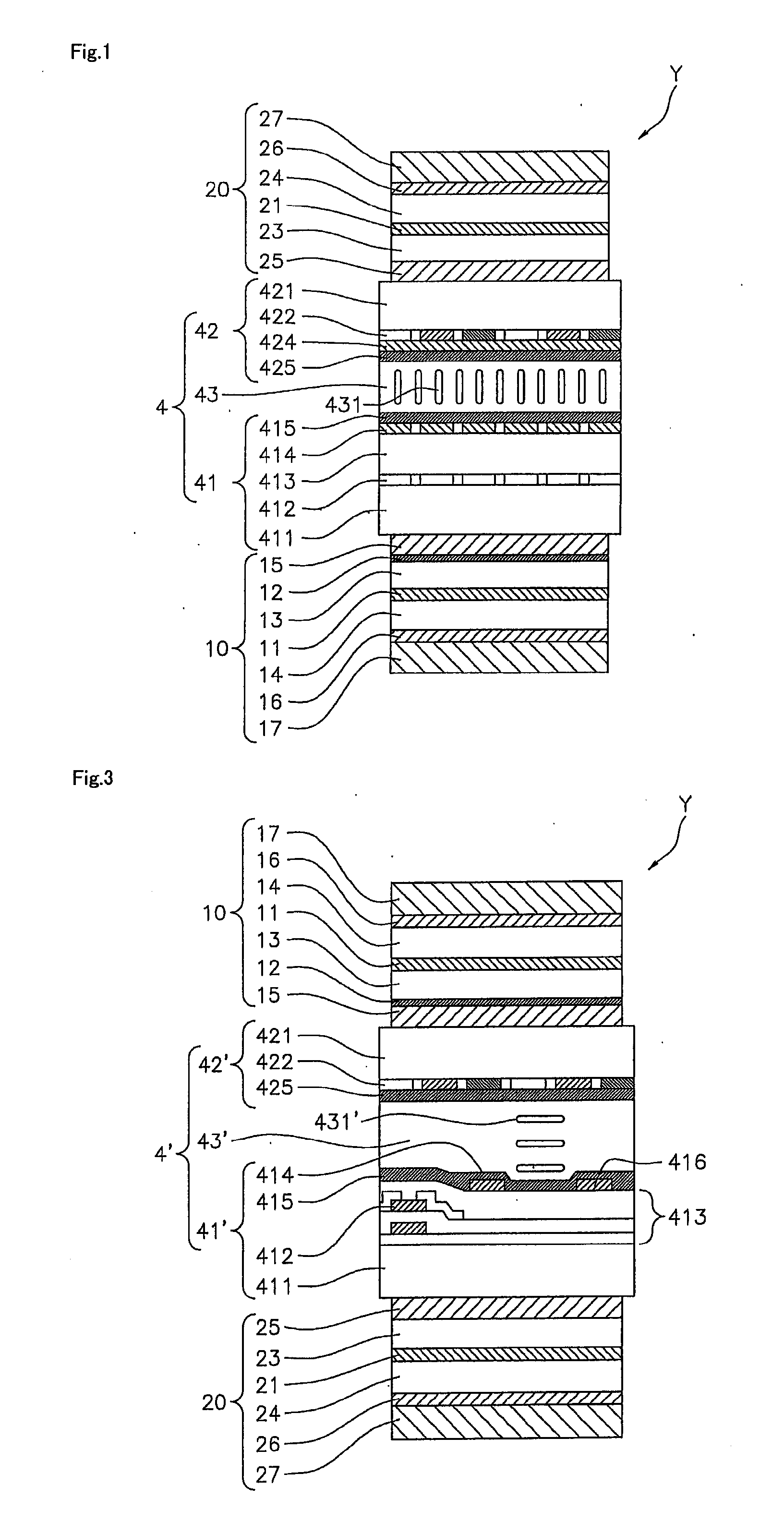

Method for manufacturing liquid crystal display panels

ActiveUS20110315297A1Fast decayLess susceptible to electrostatic decayLamination ancillary operationsLaminationPolarizerEngineering

The invention is a method for continuously manufacturing an inspected liquid crystal display panel, includes: a liquid crystal cell feeding step including feeding a liquid crystal cell having a first substrate and a second substrate; a first polarizing plate providing step including providing a first polarizing plate from a first polarizing plate roll; a first polarizing plate laminating step including laminating the first polarizing plate to the first substrate; a second polarizing plate providing step including providing a second polarizing plate from a second polarizing plate roll; a second polarizing plate laminating step including laminating the second polarizing plate to the second substrate to obtain a liquid crystal display panel after laminating the first polarizing plate to the first substrate; and an inspecting step including optically inspecting the liquid crystal display panel without applying voltage to the liquid crystal panel, wherein the first substrate is less susceptible to electrostatic decay in the liquid crystal cell than the second substrate.

Owner:NITTO DENKO CORP

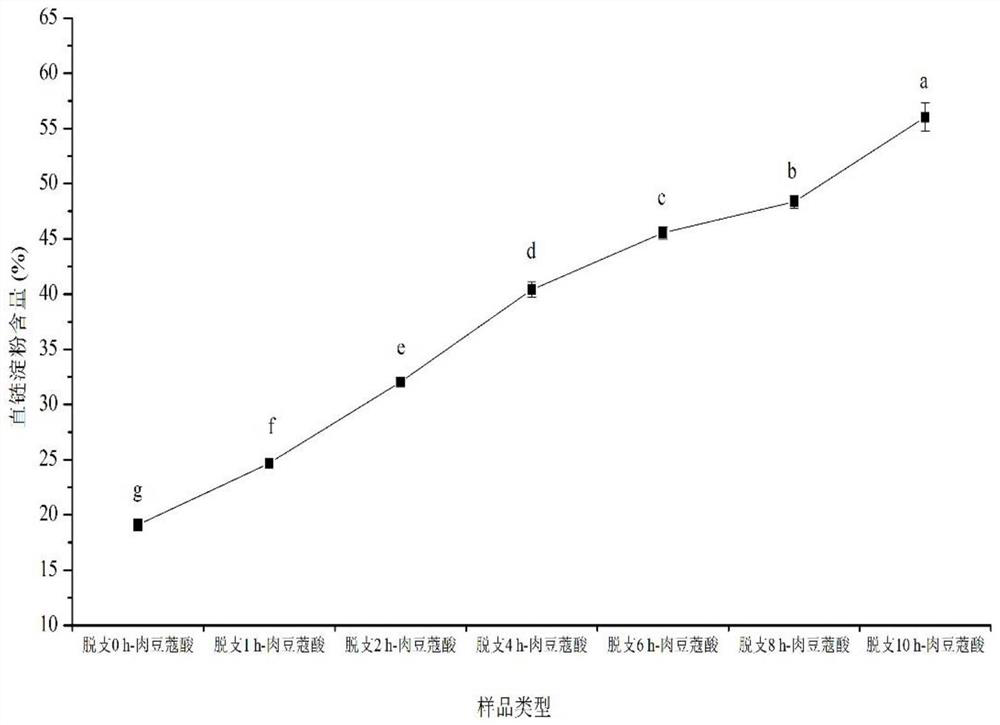

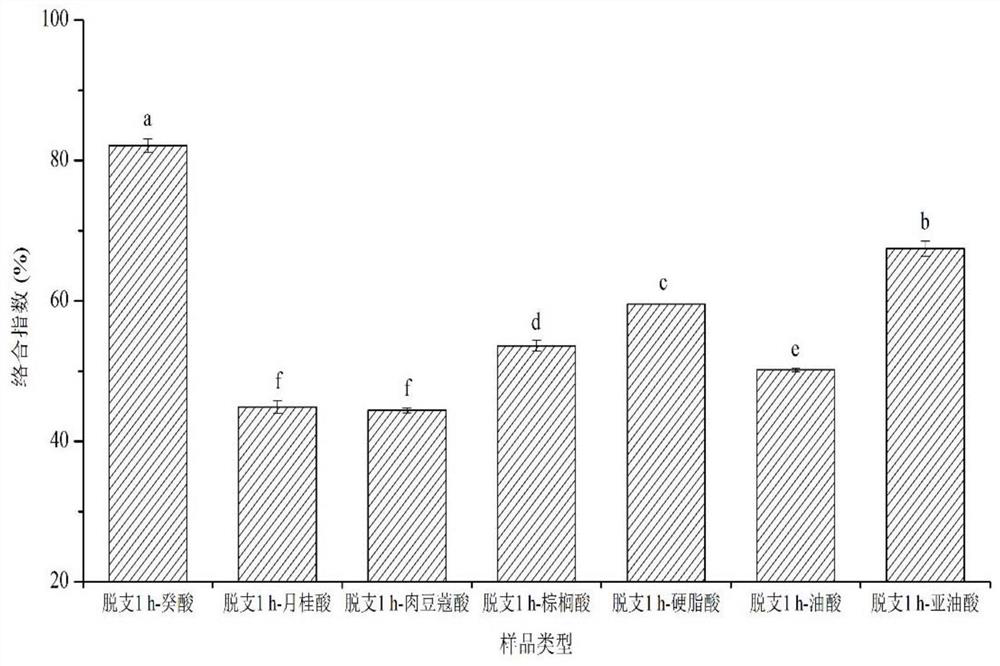

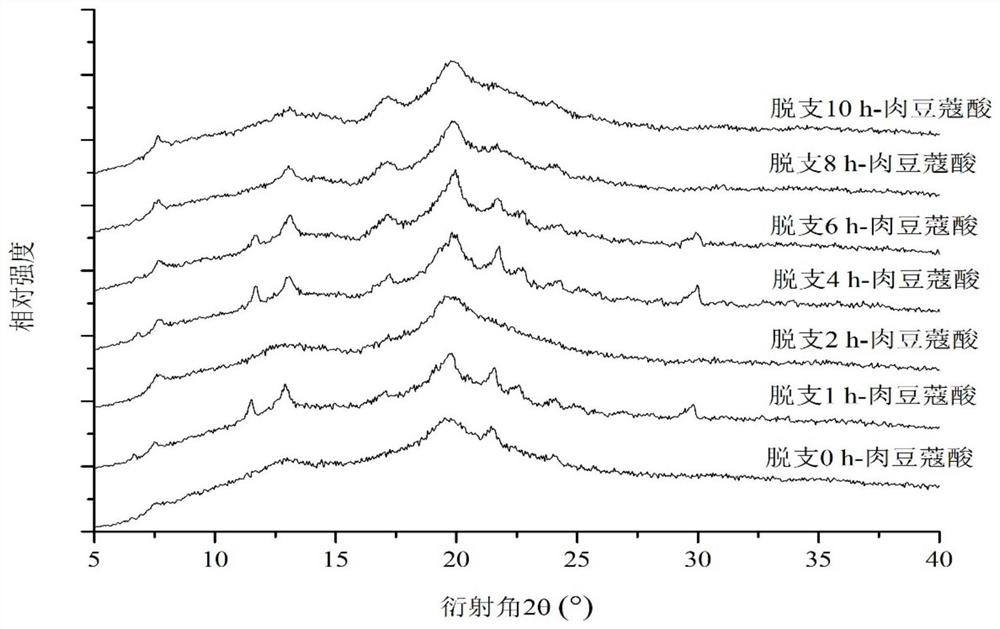

Preparation method of debranched starch-lipid compound

ActiveCN111675830AComplexation index controllableFully develop application potentialMetabolism disorderDigestive systemPolymer scienceEnzymatic hydrolysis

The invention discloses a preparation method of a debranched starch-lipid compound, and belongs to the technical field of modified starch processing. The method comprises the following steps: taking starch as a raw material, carrying out de-branching modification on the starch by adopting a de-branching enzyme, carrying out structural modification on the starch so as to improve the complexing capacity of the starch, and preparing the debranched starch-lipid compound in a water phase system by taking lipid as a ligand. Ordinary starch is used as a raw material; the debranched starch-lipid compound is prepared through enzymatic hydrolysis, de-branching modification and lipid complexing, the debranched starch-lipid compound and common starch interact with each other, the content of digestion-resistant starch in the product is greatly increased and can reach 39% at most, and the debranched starch-lipid compound has good effects of reducing blood sugar and benefiting intestinal tracts, hasa higher resistant starch content compared with that of a high-amylose corn starch-lipid compound, and is lower in cost.

Owner:JIANGNAN UNIV

Microencapsulated aluminium hypophosphite and preparation method therefor and application thereof

ActiveCN105037808AGood compatibilityImprove flame retardant performanceMicroballoon preparationMicrocapsule preparationPolymer scienceIn situ polymerization

The invention discloses microencapsulated aluminium hypophosphite and a preparation method therefor and application thereof and belongs to the field of materials. The microencapsulated aluminium hypophosphite is synthesized through in situ polymerization by taking aluminium hypophosphite as a capsule core and melamino-formaldehyde resin and a derivative of the melamino-formaldehyde resin as a capsule material. The microencapsulated aluminium hypophosphite prepared by the preparation method disclosed by the invention is good in compatibility with polyurethane rigid foam, and the damage on the mechanical property is less while the flame retardance is improved. The preparation method disclosed by the invention is continuous in process, short in reaction time, low in production cost, high in production efficiency and easy to realize industrial production. By adding the microencapsulated aluminium hypophosphite through a one-step foaming method, the prepared high performance polyurethane rigid foam has high flame retardance and mechanical properties.

Owner:国科广化(南雄)新材料研究院有限公司 +1

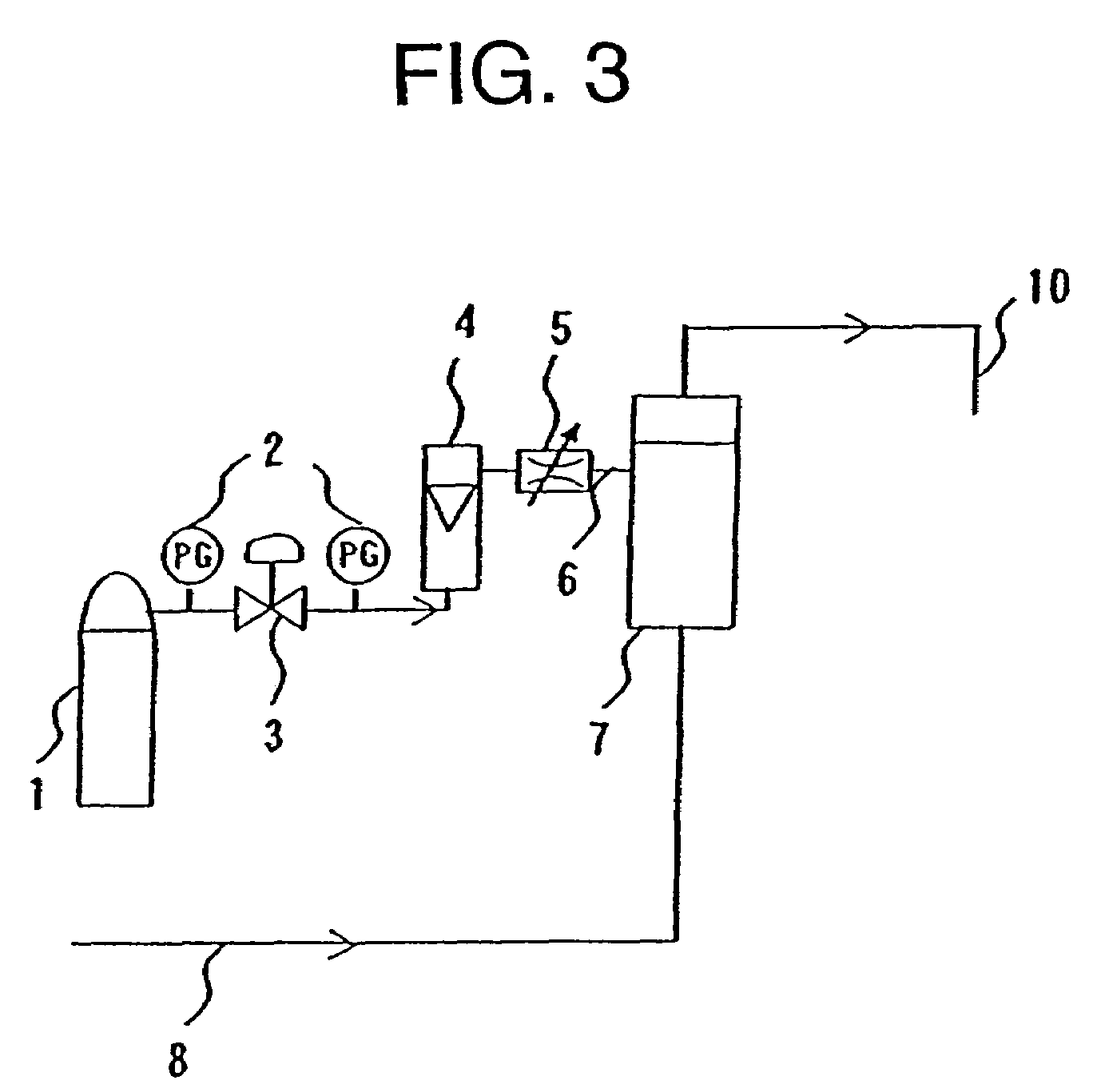

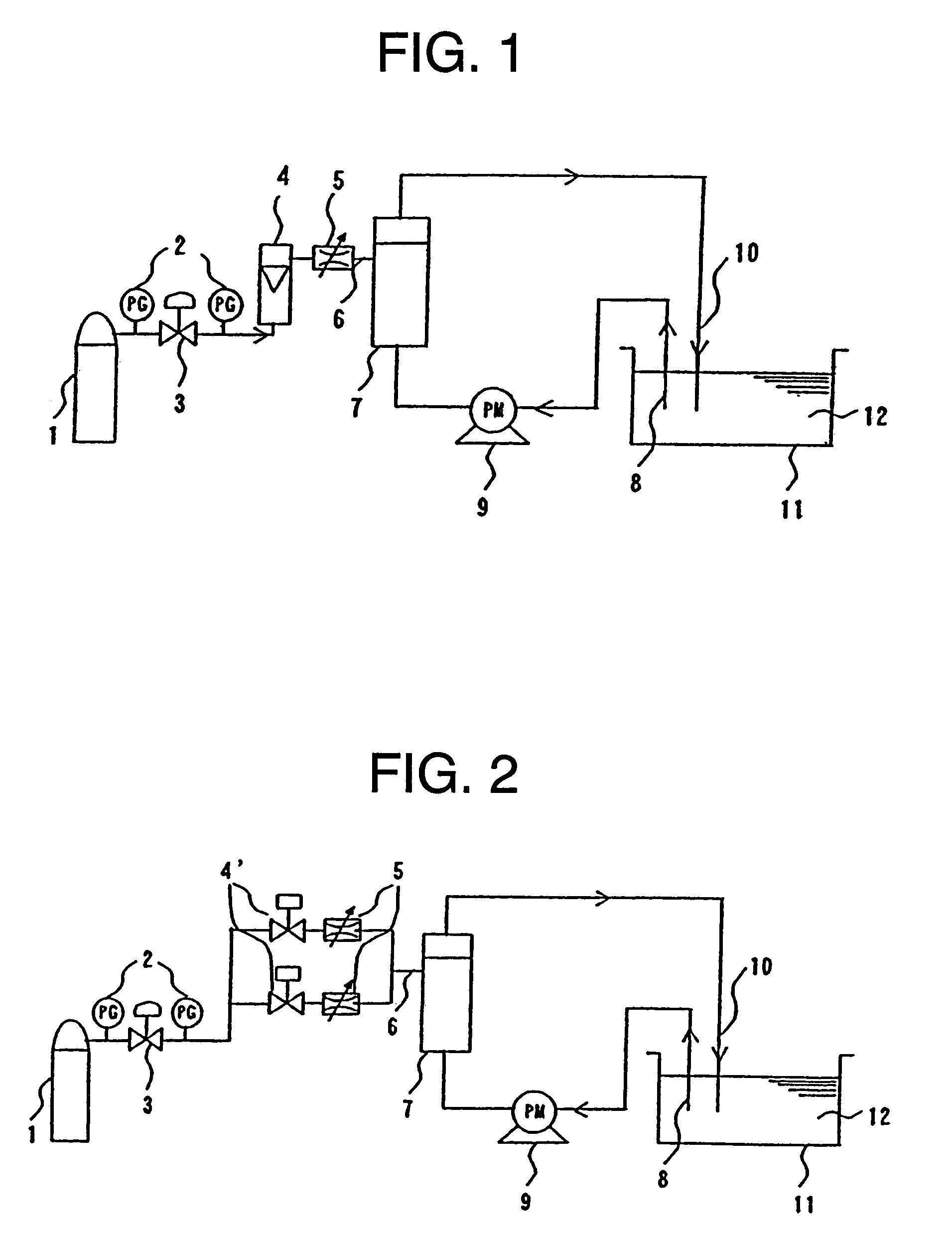

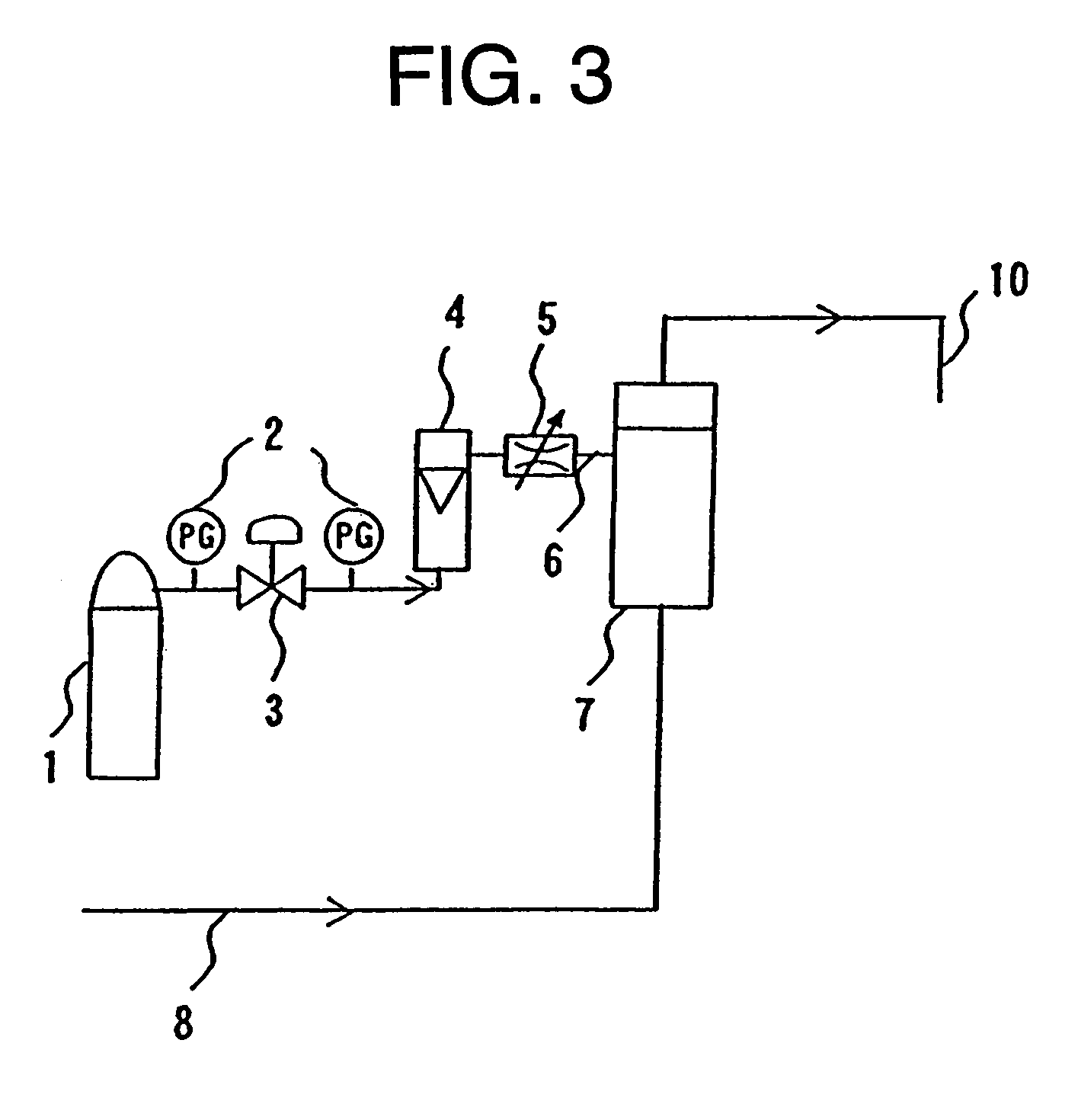

Device and method for manufacturing carbonated spring and carbonic water, control method for gas density applied thereto and membrane module

InactiveUS7237767B2Easy to adjustEasy to manufactureFlow mixersSpace heating and ventilationHigh concentrationGas cylinder

Hot water (12) in a bath (11) is pumped up by a suction pump (9) and introduced into a carbon dioxide gas dissolver (7) through solution flow rate adjusting means (14) and then, poured into the bath (11). Carbon dioxide gas supplied from a carbon dioxide gas cylinder (1) is introduced into the carbon dioxide gas dissolver (7) through gas flow rate adjusting means (5). At this time, the quantity of bubbles existing in artificial carbonated spring in a take-out pipe (15) is measured with a measuring device (13), and the solution flow rate adjusting means (14), gas flow rate adjusting means (5) and the like are controlled by means of a control device (16) using a relational expression between a preliminarily set quantity of bubbles and carbon dioxide concentration to obtain a desired concentration of carbon dioxide gas in carbonated spring. Because the carbon dioxide gas flow control means (5) is provided between the carbon dioxide gas dissolver (7) and a carbon dioxide gas supply source, carbonated spring of a high concentration can be always manufactured even if the pressure of supplied carbon dioxide gas changes or the permeating performance of a membrane changes.

Owner:MITSUBISHI RAYON CO LTD

Environment-friendly biomass material and preparation method thereof

The invention relates to a process method for continuously producing an environment-friendly biomass material by using an extruding method, and belongs to degradable environment-friendly biomass materials and the related technical field thereof. The environment-friendly biomass material is prepared by taking biomass fibers as main materials and starch as an auxiliary material; the materials are sufficiently agitated and mixed, and then are heated by a water bath; a semi-fluid state of the biomass fiber raw material is realized under a flow aiding effect after starch pasting; then the materials are continuously extruded by a screw-rod extruder and then is molded by a mould with the shape which is the same as that of an opening mould, so as to realize continuous production of the biomass materials; after being extruded, the materials are processed by processes of drying, compressing or foaming to prepare materials and products with different densities, sizes and mechanical properties. By virtue of adopting the process method provided by the invention, a continuous automatic production process of the biomass materials can be finished and the process method can be used as a former procedure for the biomass materials or the products and can also be used as a final procedure. Therefore, the cost can be saved and the production efficiency is improved.

Owner:JIANGNAN UNIV

Device and method for manufacturing carbonated spring and carbonic water, control method for gas density applied thereto, and membrane module

InactiveUS7152850B2Easy to adjustEasy to manufactureFlow mixersLighting and heating apparatusHigh concentrationGas cylinder

Owner:MITSUBISHI RAYON CO LTD

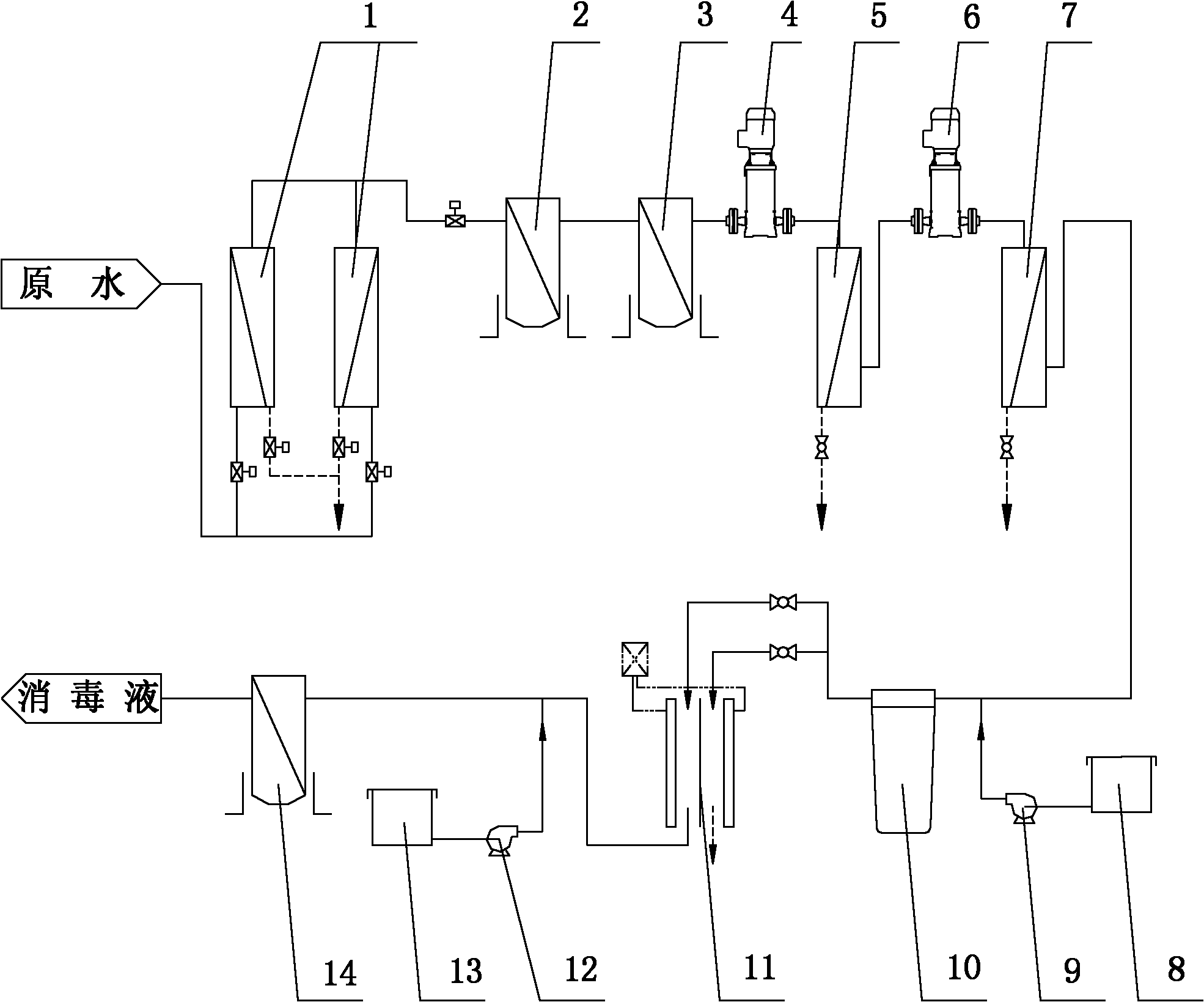

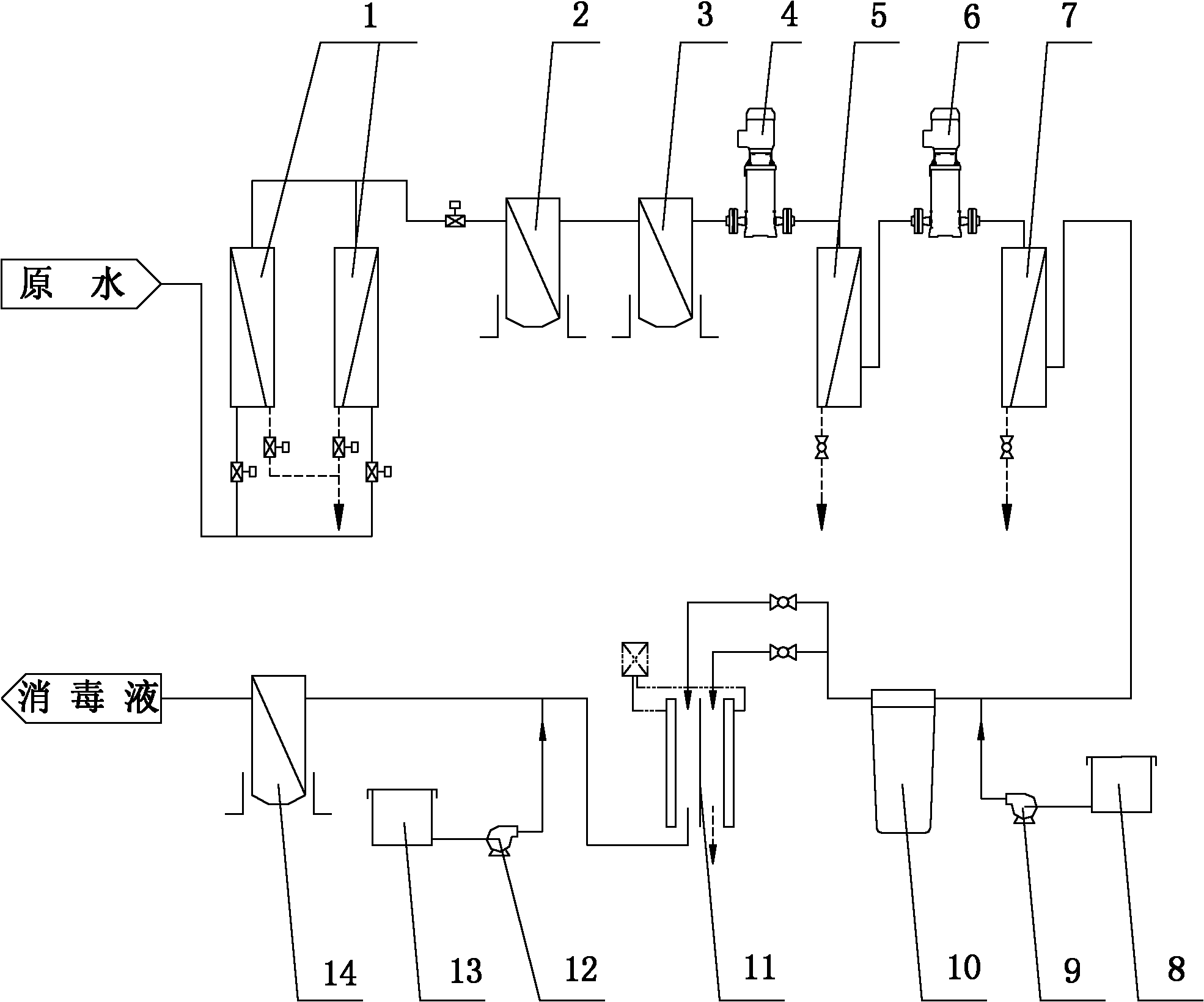

Method and equipment for preparing isosmotic disinfection cleaning solution

ActiveCN102138568AAvoid pollutionGuarantee the quality of produced waterBiocideFungicidesElectrolysisFiltration

The invention discloses a method and equipment for preparing an isosmotic disinfection cleaning solution. The method for preparing the isosmotic disinfection cleaning solution comprises the following steps of: performing ultrafiltration, active carbon filtering, micro-filtration and reverse osmosis treatment on raw water to obtain purified water; mixing the purified water with an NaCl aqueous solution to obtain electrolyte, feeding the electrolyte into an anode chamber and a cathode chamber of an electrolysis unit and continually applying direct current to the anode and the cathode of the electrolysis unit to electrolyze, wherein water with the pH value of greater than 7 is produced in the cathode chamber, and a disinfection cleaning solution with the pH value of smaller than 7 is produced in the anode chamber; and mixing the disinfection cleaning solution produced in the anode chamber with the NaCl aqueous solution and filtering with a terminal to obtain the isosmotic disinfection cleaning solution. The preparation method disclosed by the invention is scientific and reasonable, various defects existing in the prior art are overcome, continuous, stable, quick and efficient preparation of the isosmotic disinfection cleaning solution is realized, and the isosmotic disinfection cleaning solution can be applied to cleaning, disinfection and the like of medical instruments and environments such as wounds, wound surfaces, sickrooms, sick beds, clothes, endoscopes, dialysis machines and the like.

Owner:SANITARY EQUIP INST ACAD OF MILITARY MEDICAL SCI PLA

Semisolid metal slurry preparation device and method

The invention discloses a semisolid metal slurry preparation device and method. The semisolid metal slurry preparation device comprises an air supplying device body, an air guiding pipe, a stirring rod and a bearing container used for containing a metal melt. The end, stretching into the metal melt in the bearing container, of the stirring rod is a stirring end. The stirring end is internally provided with a cavity. The air supplying device body is used for injecting cooling gas into the cavity inside the stirring end through the air guiding pipe when the metal melt is stirred by the stirring rod, and a processing mode of cooling and stirring is formed, so that in the stirring and flowing processes of the metal melt, the internal temperature field is uniformly distributed basically, obvious too cold gradients are avoided, the dendritic crystal growth environment is destroyed, and thus semisolid slurry with a certain proportion of near-spheroidal primary solid phase uniformly distributed in a liquid phase matrix is obtained. According to the semisolid metal slurry preparation device and method, the semisolid slurry is continuously and rapidly prepared, and continuous working is stable and reliable; the process can be simplified, the cost is reduced, and the efficiency is improved; and the industrialized application of the semisolid metal processing technology is promoted.

Owner:ZTE CORP

Liquid drop jetting apparatus using charged beam and method for manufacturing a pattern using the apparatus

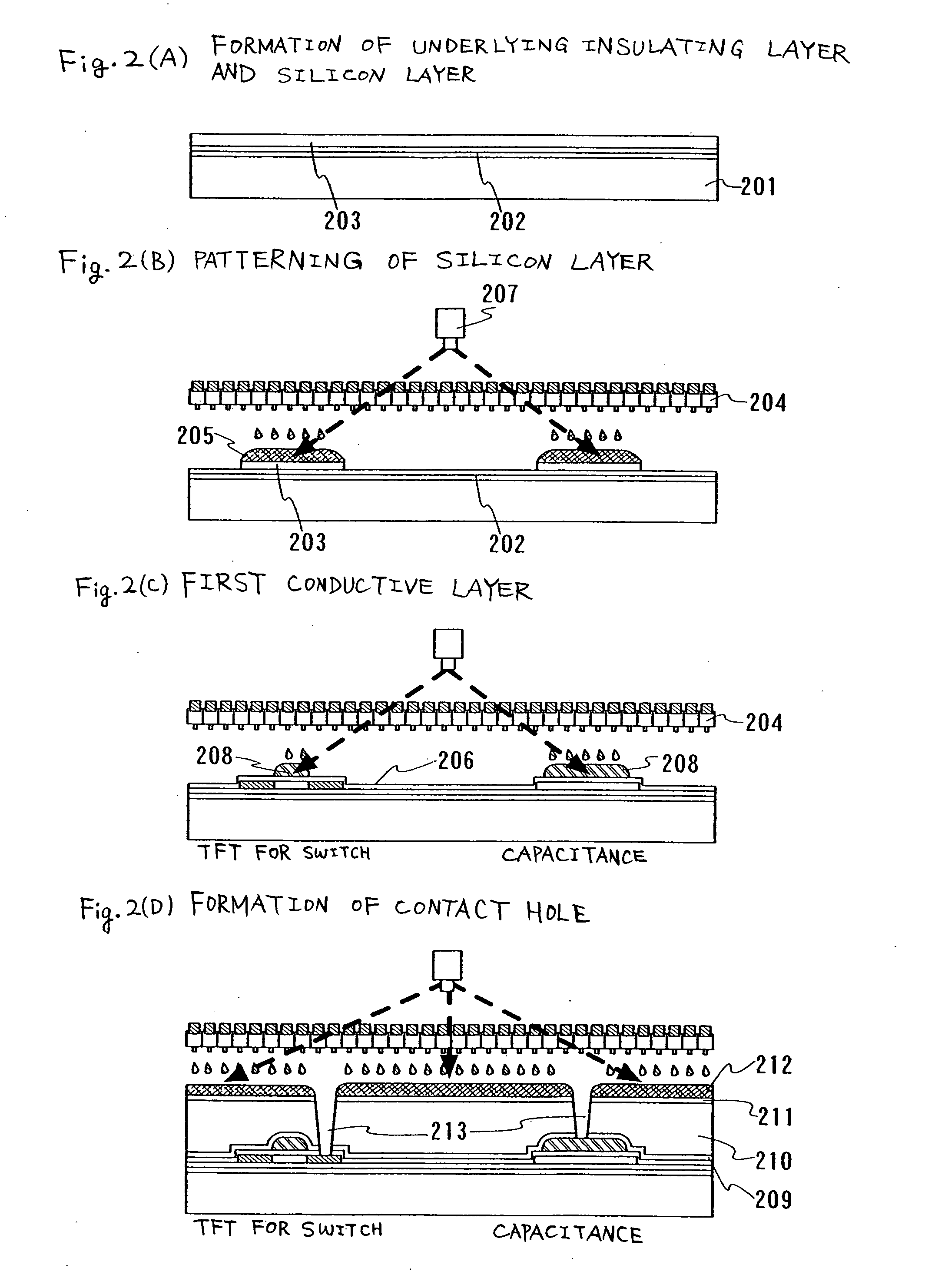

InactiveUS20050142896A1Reduce impactEfficient arrangementLiquid surface applicatorsSpraying power supplyResistDisplay device

The invention drastically improves the accuracy of adhesion position of a liquid drop discharged by a liquid drop discharge method and makes it possible to form a fine and highly accurate pattern directly on a substrate. Therefore, one object of the invention is to provide a method for manufacturing a wiring, a conductive layer and a display device that can respond to upsizing of a substrate. Moreover, another object of the invention is to provide a method for manufacturing a wiring, a conductive layer and a display device that can improve throughput and the efficiency of use of material. The invention can improve the accuracy of adhesion position of a liquid drop drastically at the time of patterning a resist material, a wiring material, or the like directly by the liquid drop discharge method mainly on a substrate having an insulating surface. To be more specific, the invention is characterized in that: a liquid adhesion position on the surface of the substrate is scanned with a charged beam in accordance with a desired pattern immediately before a liquid drop is discharged by the liquid drop discharge method; and immediately thereafter, the liquid drop is charged with an electric charge of a polarity opposite to the charged beam and is discharged to improve the controllability of the adhesion position of the liquid drop to a great extent.

Owner:SEMICON ENERGY LAB CO LTD

Float glass making process and float glass making equipment

ActiveCN101754937APrevent adhesionContinuous preparationGlass transportation apparatusCarbon filmMultiple delivery

A float glass making process and float glass making equipment devised to prevent any occurrence of stain or flaw. There is disclosed a float glass making process through continuously feeding a molten glass onto a horizontal surface of molten metal bath wherein a molten metal is accommodated to thereby form a glass ribbon, drawing up the glass ribbon from the bath surface and delivering the same by means of multiple delivery rolls to a slow cooling furnace, characterized in that the forming, drawing up and delivery of the glass ribbon are carried out under the condition of having a carbon film formed on the surface of the delivery rolls.

Owner:ASAHI GLASS CO LTD

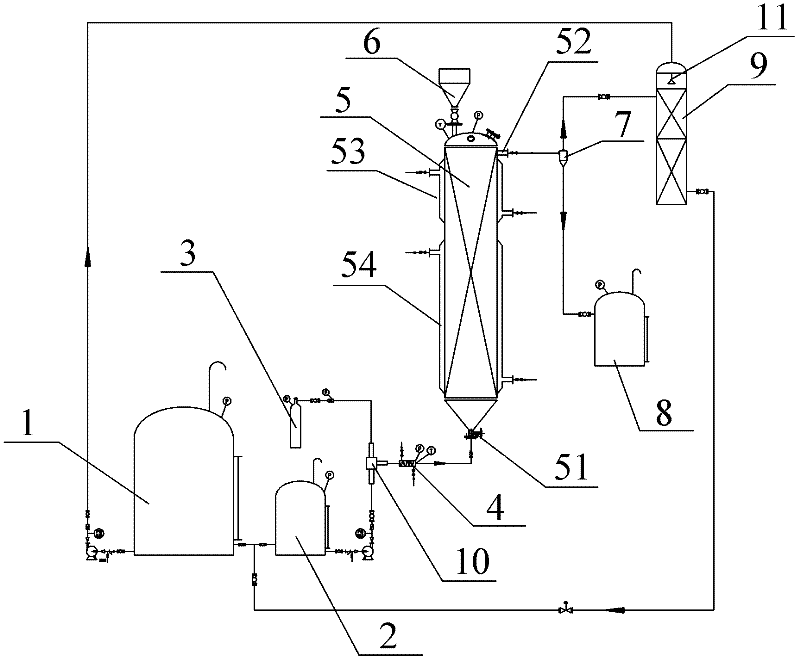

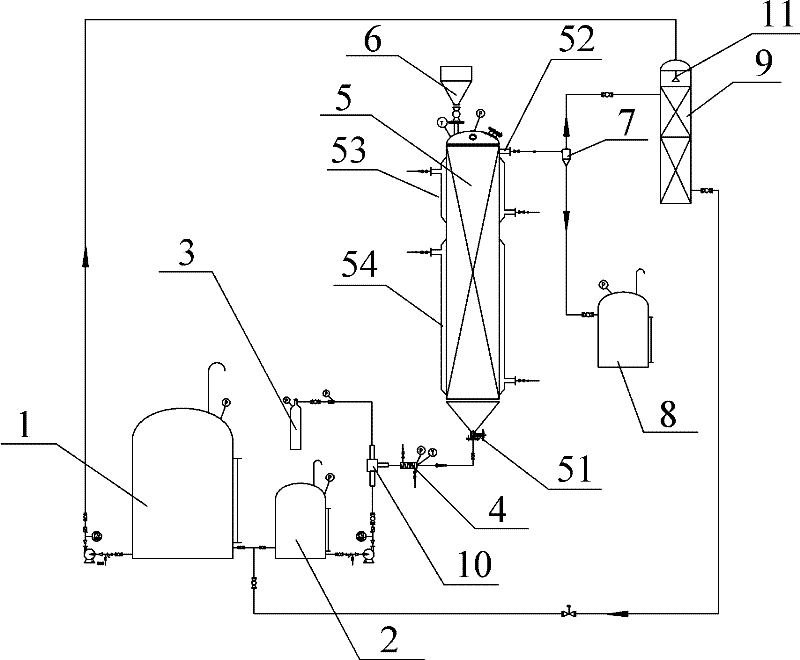

Device for continuous preparation of Grignard reagent and method for continuous preparation of Grignard reagent through using device

ActiveCN102603775ANot prone to valve cloggingLess prone to plumbing problemsMagnesium organic compoundsEnvironmental resistanceVapor–liquid separator

The invention discloses a device for the continuous preparation of a Grignard reagent and a method for the continuous preparation of the Grignard reagent through using the device. The device comprises a solvent storage container, a solvent-raw material mixing container, a raw gas storage container, a preheater, a reactor, a magnesium adding bin, a gas-liquid separator, a Grignard reagent reception container and a tail gas recovery apparatus, wherein the reactor adopts a three-phase bubble slurry column reactor. A purpose of the continuous preparation of the Grignard reagent can be realized through using the device of the invention, and initiation and heat radiation problems of a Grignard reaction can be effectively solved through adopting the three-phase bubble slurry column reactor, so potential safety hazards of material rush-out, explosion and the like caused by the severe temperature rise of the Grignard reaction can be effectively avoided, the obstruction of valves and pipelines by magnesium shreds can be prevented, and the high purity Grignard reagent can be obtained; and the tail gas recovery apparatus is arranged in the invention to absorb and recycle tail gases, so the cost is saved, and the environmental pollution is reduced, thereby cleaning and environmental protection requirements of the preparation of the Grignard reagent are realized.

Owner:SHANGHAI HEGNO PHARMA HLDG +1

Method for preparing metal sizing agent by a compelling, equal-freezing and continuous method

The invention relates to a method for forced uniform solidified continuous preparing metal slurry, comprising that (1) melting overheat metal with the temperature more than the liquidus temperature about 0-100deg.C is poured into upper guide flow pipe; (2) the liquid metal flows into the melting deconcentrator and the liquid metal is injected on the inner round wall of melting deconcentrator; the temperature control system out of pulping room make the wall temperature of pulping room be controlled lower than the liquidus temperature about 0-100deg.C; the liquid metal is collected at the cone bottom to obtain the metal slurry with solid fraction smaller than 30%; the metal slurry flows out through the lower guide flow pipe and the temperature is controlled in -10-10deg.C of liquidus temperature; (3) the metal slurry flows into the collector or is sent into the common equipment such as die-casting, rolling and forging so on directly to carry rheological forming out and or is cast into the mould continuously to produce semi-solid continuous casting slab. The merit of invention is that the preparation of metal slurry is uniform, mass and continuous, and it can satisfy the demand of huge industrial production easily.

Owner:有研金属复材技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com