Device for continuous preparation of Grignard reagent and method for continuous preparation of Grignard reagent through using device

A Grignard reagent and solvent technology, applied in the direction of magnesium organic compounds, etc., can solve the problems of increasing the cost of Grignard reagents, slow reaction speed, and non-continuous production, so as to solve the problems of initiation and heat dissipation, prevent valves and pipelines from being blocked, and avoid Impact or explosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

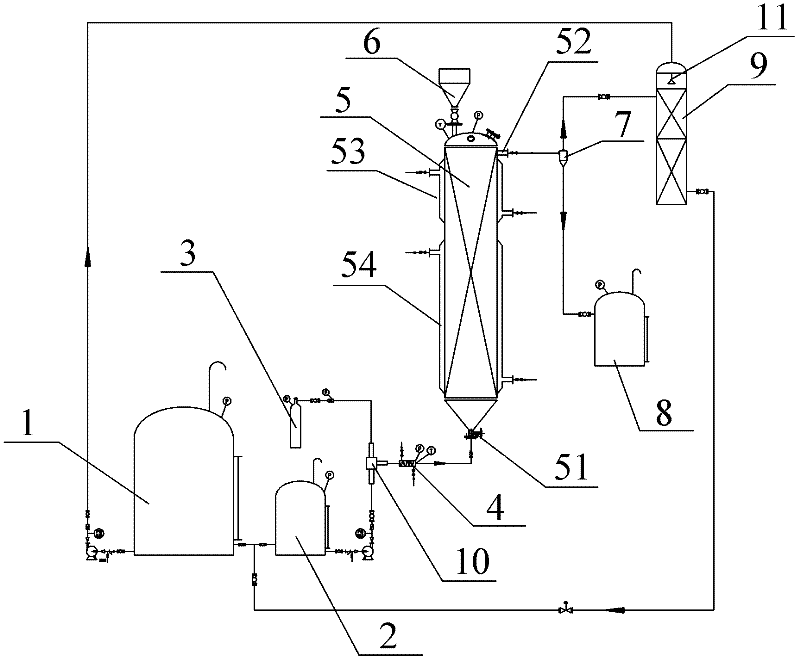

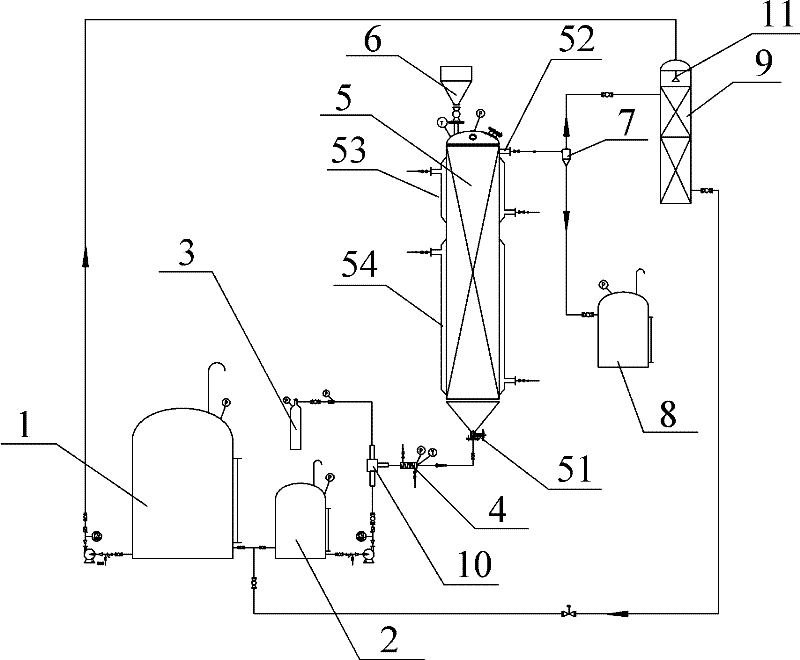

[0065] use figure 1 The device shown prepares Grignard reagent, wherein the material of the bubbling sludge bed reactor used is stainless steel, with a diameter of 45cm, a length of 135cm, and a height-to-diameter ratio of 30; the length of the lower insulation layer is 105cm, and the length of the upper insulation layer is 30cm The total bed volume (effective reaction volume) measured and calculated is 1670ml, 1970g of magnesium particles can be filled, and the bed can be filled with a liquid volume of 700ml.

[0066] a) preparing a concentration of 5wt% mother liquor in a solvent-raw material mixing vessel;

[0067] b) Filling with magnesium chips

[0068] Under the protection of an inert gas, 1970g of magnesium particles are added to the inside of the bed body of the three-phase bubbling slurry bed reactor through the magnesium feeding bin;

[0069] c) Initiate a reaction

[0070] Heat the reactor so that the temperature inside the reactor reaches 50°C, keep it warm for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com