Metal oxide-loaded molecular sieve catalyst and preparation method thereof

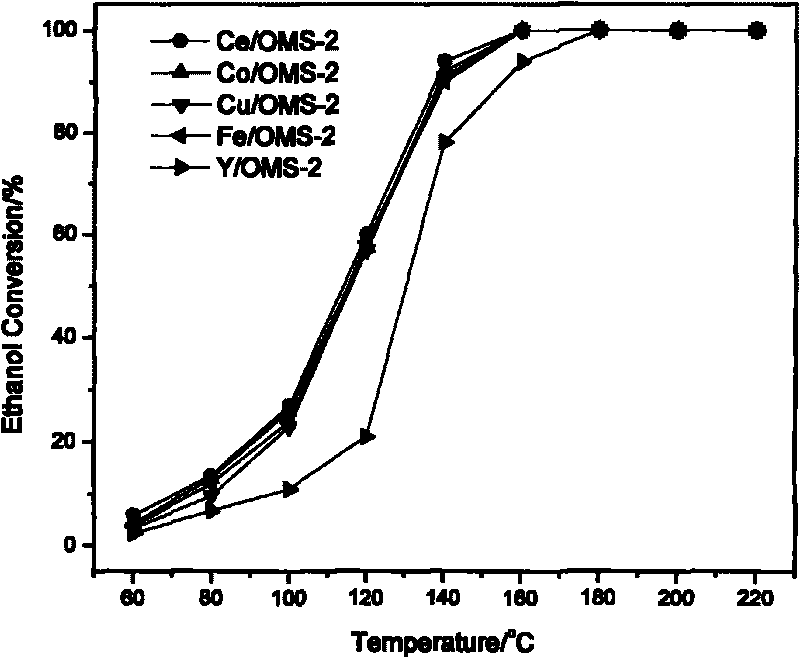

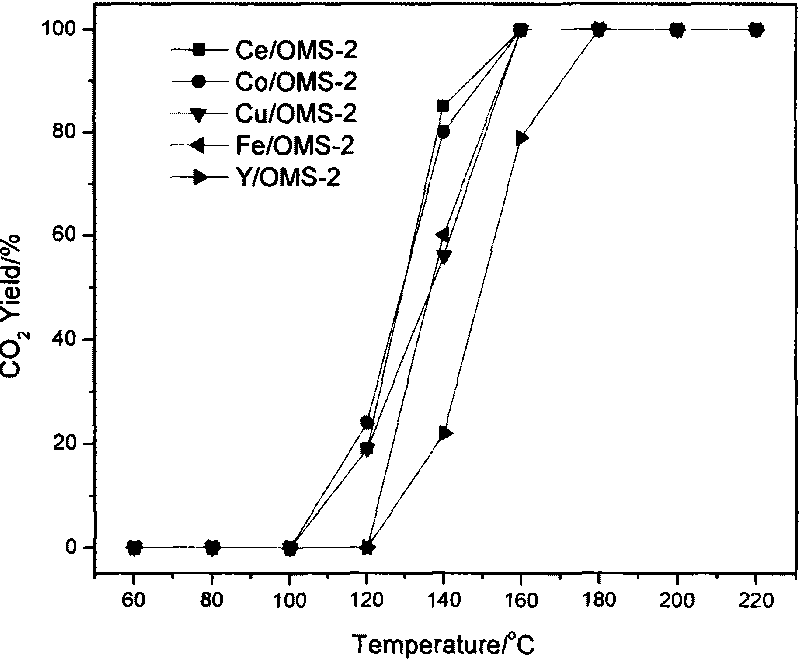

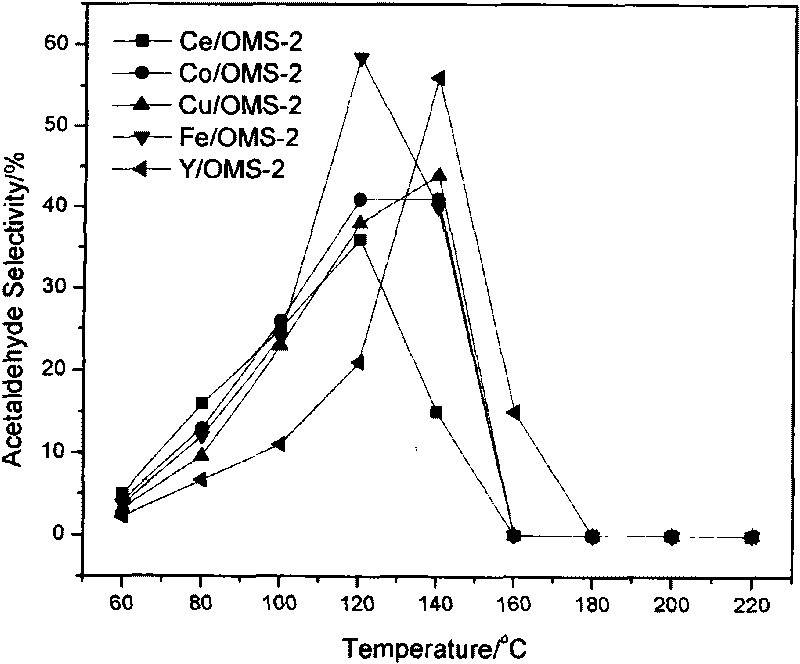

A technology for supporting metals and catalysts, applied in molecular sieve catalysts, physical/chemical process catalysts, separation methods, etc., can solve the problems of unsatisfactory purification effect and poor oxidation effect of ethanol-acetaldehyde, and achieve outstanding oxidation ability and ethanol-acetaldehyde. Excellent low temperature removal performance and low temperature activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A metal oxide-loaded molecular sieve catalyst includes the following components:

[0025] Pure cryptomelane manganese dioxide is the active component, which accounts for 94% of the total mass of the catalyst. The doped transition metal Ce component accounts for 6% of the total mass of the catalyst. The active component passes through Mn 7+ And Mn 2+ The reaction produces, the molar ratio of the two is 0.72.

[0026] A method for preparing a metal oxide-loaded molecular sieve catalyst is prepared by a reflux method, and specifically includes the following steps:

[0027] 1. Prepare 280 mL of potassium permanganate solution with a concentration of 0.38mol / L, heat and stir at 56°C to form a solution;

[0028] 2. Prepare 288mL of 0.54mol / L manganese acetate solution, heat and stir at 58℃ to form a solution;

[0029] 3. Slowly add the solution obtained in step 1 to a 1000mL three-necked flask, heat it in an oil bath at 108°C for 10 minutes, stir with an electric stirrer at a stirring ...

Embodiment 2

[0038] An octahedral manganese oxide molecular sieve catalyst includes the following components:

[0039] Pure cryptomelane manganese dioxide is the active component, which accounts for 90% of the total mass of the catalyst. The doped transition metal Co component accounts for 10% of the total mass of the catalyst. The active component passes through Mn 7+ And Mn 2+ The reaction produced, the molar ratio of the two was 0.72.

[0040] A method for preparing a metal oxide-loaded molecular sieve catalyst is prepared by a reflux method, and specifically includes the following steps:

[0041] 1. Prepare 150 mL of potassium permanganate solution with a concentration of 0.30mol / L, heat and stir at 40°C to form a solution;

[0042] 2. Prepare 150mL of 0.45mol / L manganese acetate solution, heat and stir at 40℃ to form a solution;

[0043] 3. Slowly add the solution obtained in step 1 to a 1000mL three-necked flask, heat it in an oil bath at 80°C for 15 minutes, stir with an electric stirrer at a...

Embodiment 3

[0052] An octahedral manganese oxide molecular sieve catalyst includes the following components:

[0053] Pure cryptoknite manganese dioxide is the active component, which accounts for 95% of the total mass of the catalyst. The doped transition metal Cu component accounts for 5% of the total mass of the catalyst. The active component passes through Mn 7+ And Mn 2+ The reaction produced, the molar ratio of the two was 0.72.

[0054] A method for preparing a metal oxide-loaded molecular sieve catalyst is prepared by a reflux method, and specifically includes the following steps:

[0055] 1. Prepare 300mL of 0.40mol / L potassium permanganate solution, heat and stir at 60℃ to form a solution;

[0056] 2. Prepare 300mL of 0.55mol / L manganese acetate solution and heat and stir at 60℃ to form a solution;

[0057] 3. Slowly add the solution obtained in step 1 to a 1000mL three-necked flask, heat it in an oil bath at 110°C for 20 minutes, stir with an electric stirrer at a stirring speed of 450r / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com