Oxide ceramic powder capable of perpetually releasing active oxygen when suffering from water

A technology of oxide ceramics and oxides, which is applied in the professional field of inorganic non-metals, can solve problems such as high energy consumption, and achieve the effect of long service life and slow hydrolysis speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Dolomite is sintered at a temperature of 800-1100° C., and the holding time is 4 hours; surface active agent aqueous solution is used for surface treatment, and hydroxymethyl cellulose is used to make a 1% aqueous solution, and the sintered powder is soaked and then dried.

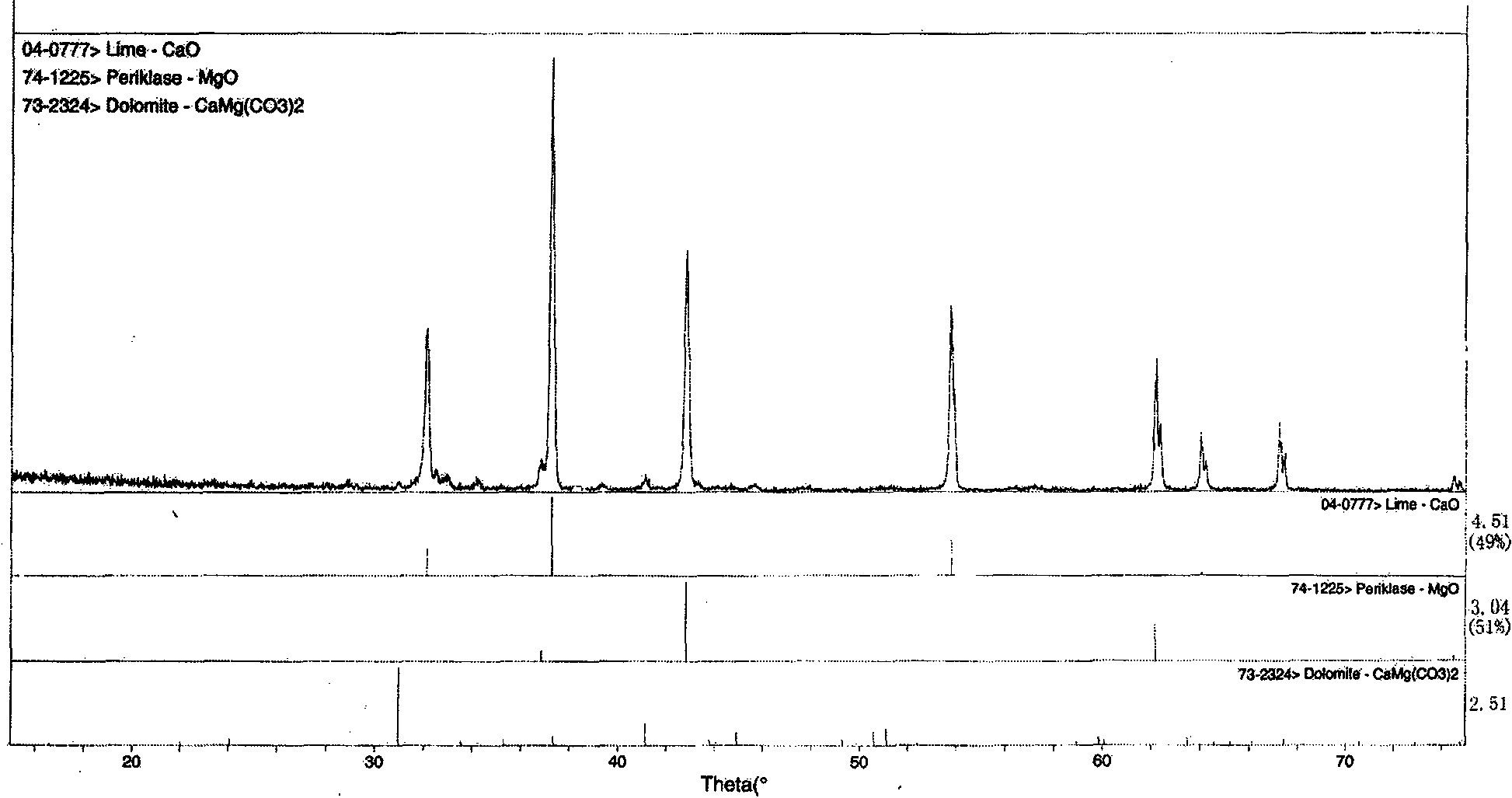

[0045] X-ray diffraction peaks see figure 2 .

[0046] The calcined powder can be quantitatively analyzed by diffraction peaks:

[0047] CaO~28%, MgO~43%, CaCO3~22%, SiO2~7%

[0048] Use 5 grams of this powder, dip into 200ml to test the pH, and get the result of pH10. After 300 days, the pH can still reach 9-10.

Embodiment 2

[0050] Sinter magnesite ore at a temperature of 700-900°C and hold for 6 hours; use acrylic resin to dissolve it in butyl acetate at a ratio of 2:8, treat the surface of the ore powder, and then bake at 260°C. After baking, the ceramic powder is placed indoors to dry.

[0051] Use 5 grams of this powder, dip into 200ml to test the pH, and get the result of pH10. After 300 days, the pH is still above 9.

Embodiment 3

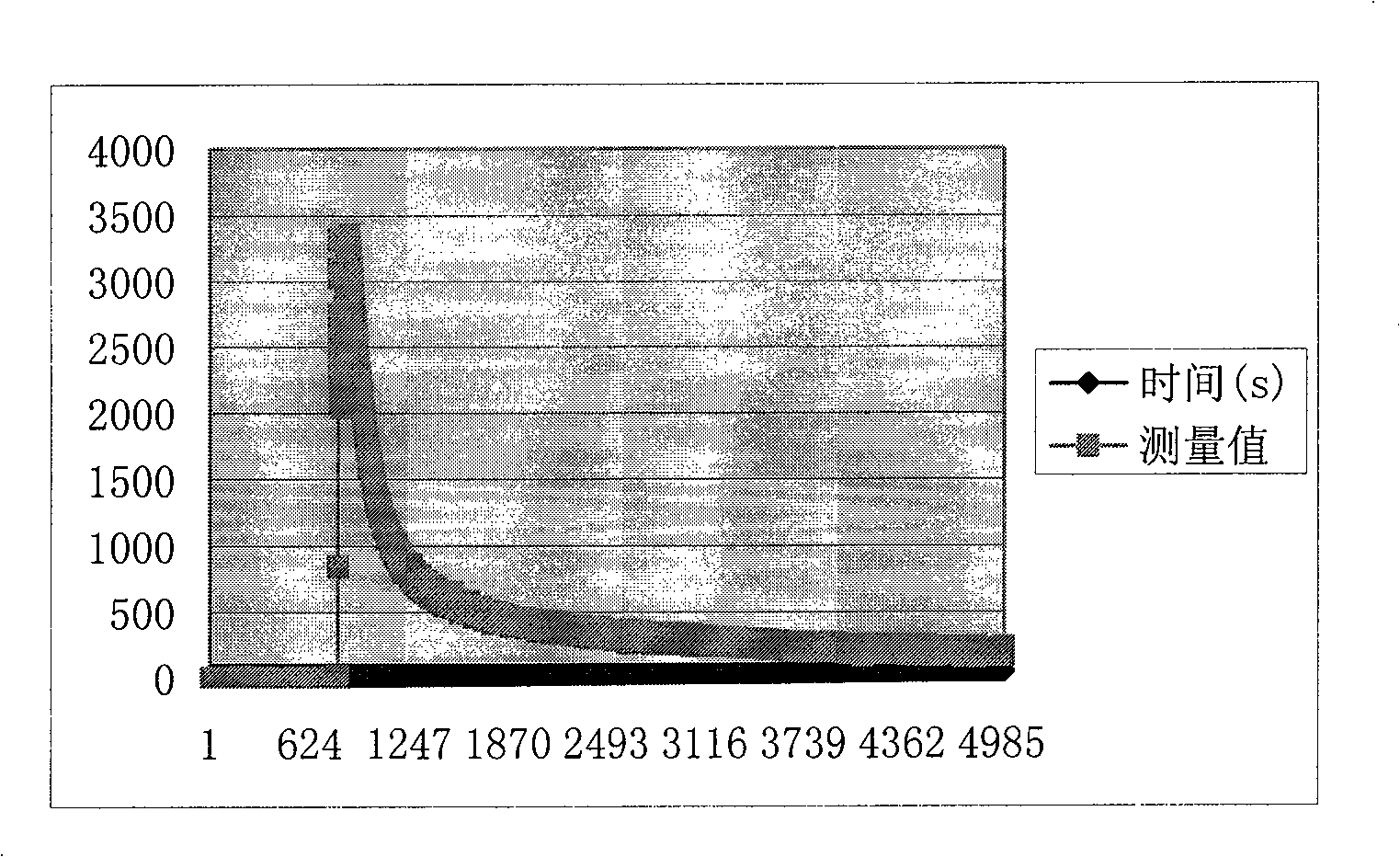

[0052] Embodiment 3 releases the inspection of active oxygen and the sterilization effect inspection

[0053] The obtained ceramic powder of the present invention is tested for releasing active oxygen, using the chemiluminescence test method provided by the chemiluminescence instrument. The test results obtained are as follows ( image 3 ):

[0054] The resulting ceramic powder of the present invention Example 1 was subjected to a bactericidal and algae-killing performance test, and the results are shown in Table 1.

[0055] Table 1 Sterilization experiment of putting ceramic powder

[0056] Numbering

Dosage (g / L)

Settling time (min)

Total number of bacteria (pcs / ml)

Coliform bacteria (unit / L)

1

0

——

>100

>100

2

5

10

0

0

3

10

10

0

0

4

5

30

0

0

5

5

600

0

0

[0057] Note: No. 1 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com