Underground structure deformation joint leaking stoppage repairing method

A repair method and underground structure technology, which is applied in the field of deformation joint repair, can solve problems such as aging of buried rubber waterstops, groundwater leakage, large differential settlement, etc., and achieve the effects of improved service life, convenient construction, and simple materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

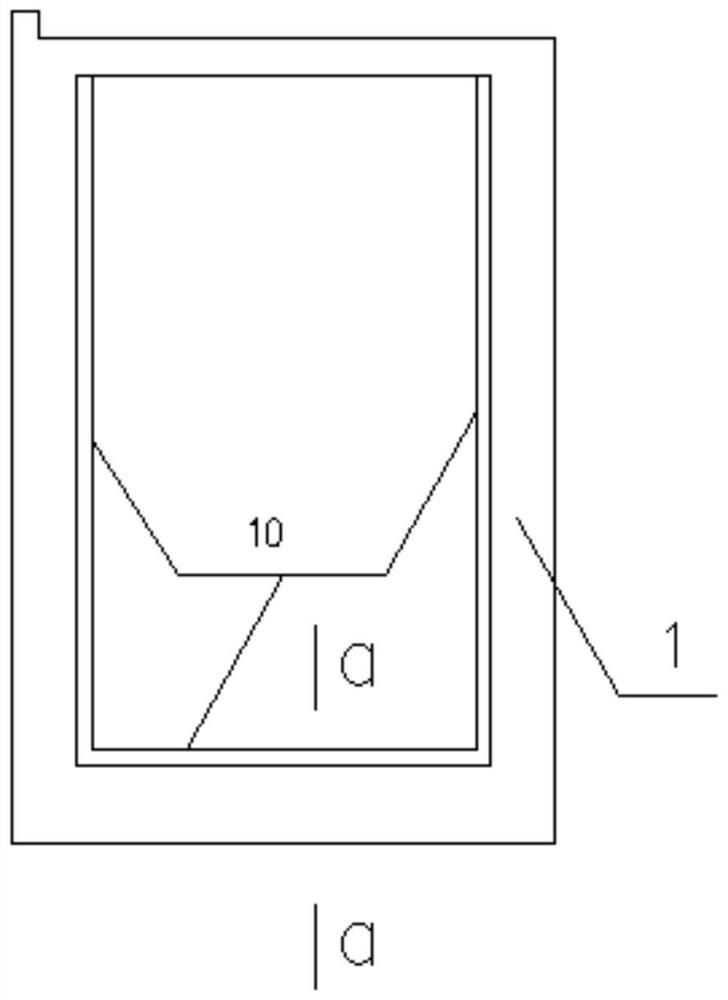

[0022] Such as Figure 1-Figure 2 As shown, a method for plugging and repairing deformation joints of underground structures comprises the following steps:

[0023] Step 1. At the place where there is a height difference between the deformation joint 2 that has undergone differential settlement and the structural member 1, level it through the fine stone concrete filling layer 4 and the waterproof mortar leveling layer 6;

[0024] Step 2, connecting the fine stone concrete filling layer 4 and the structural member 1 through nails 5;

[0025] Step 3, arrange rubber waterstop 10 on the waterproof mortar leveling layer 6, which has the waterproof ability to adapt to the subsequent further uneven settlement;

[0026] Step 4: Fix the rubber waterstop 10 on the structural member 1 through the pressure plate 7 and the expansion bolt 8 .

[0027] Specifically, in the first step, the first polysulfide sealant 3 is applied between the fine stone concrete filling layer 4 , the waterpro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com