Disc for transferring a torque transmission in torque transmission transfer device of a motor vehicle

A torque transmission device and torque transmission technology, which is applied to shaft couplings, mechanical drive clutches, mechanical equipment, etc., and can solve problems such as multiple structural spaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

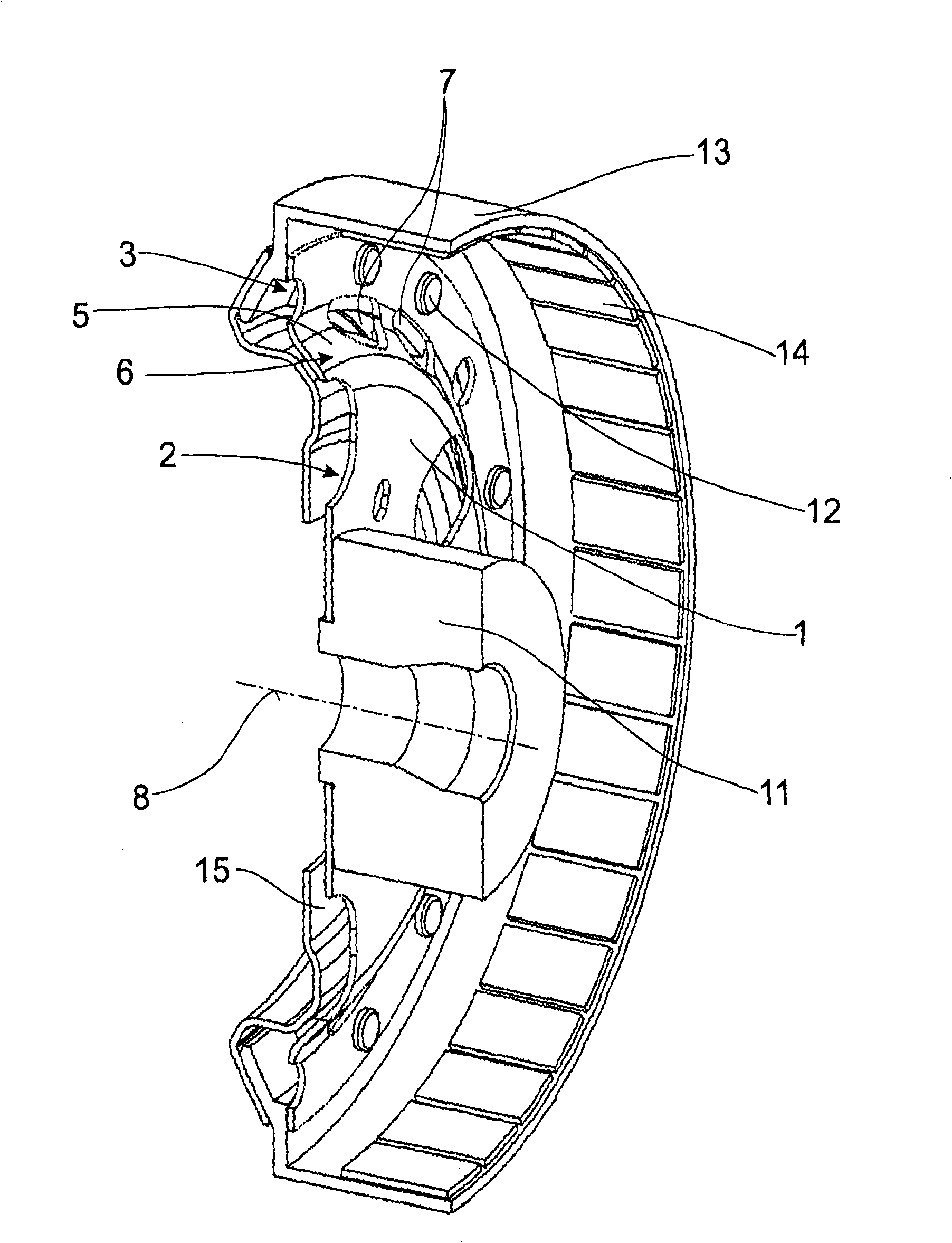

[0057] Depend on figure 1 Part of the car's drive train is visible. Shown is a torque transmission device in which a crankshaft adapter 11 is connected to a crankshaft (not shown) of an internal combustion engine. To which the crankshaft adapter 11 is non-rotatably connected is a disc body 1 ("flexible plate") consisting of a thin plate. In its radially outer region, the disk is non-rotatably connected to the adjacent component, in the exemplary embodiment, to the rotor 13 of the electric motor by means of a plurality of rivets 12 . The rotor 13 has a plurality of magnets 14 , which of course have no significance in connection with the invention.

[0058] Also of no further importance for the invention is the disk 15 ("drive plate") which is non-rotatably connected to the rotor 13 . The disk 15 is non-rotatably connected to the torque transducer, which is not shown.

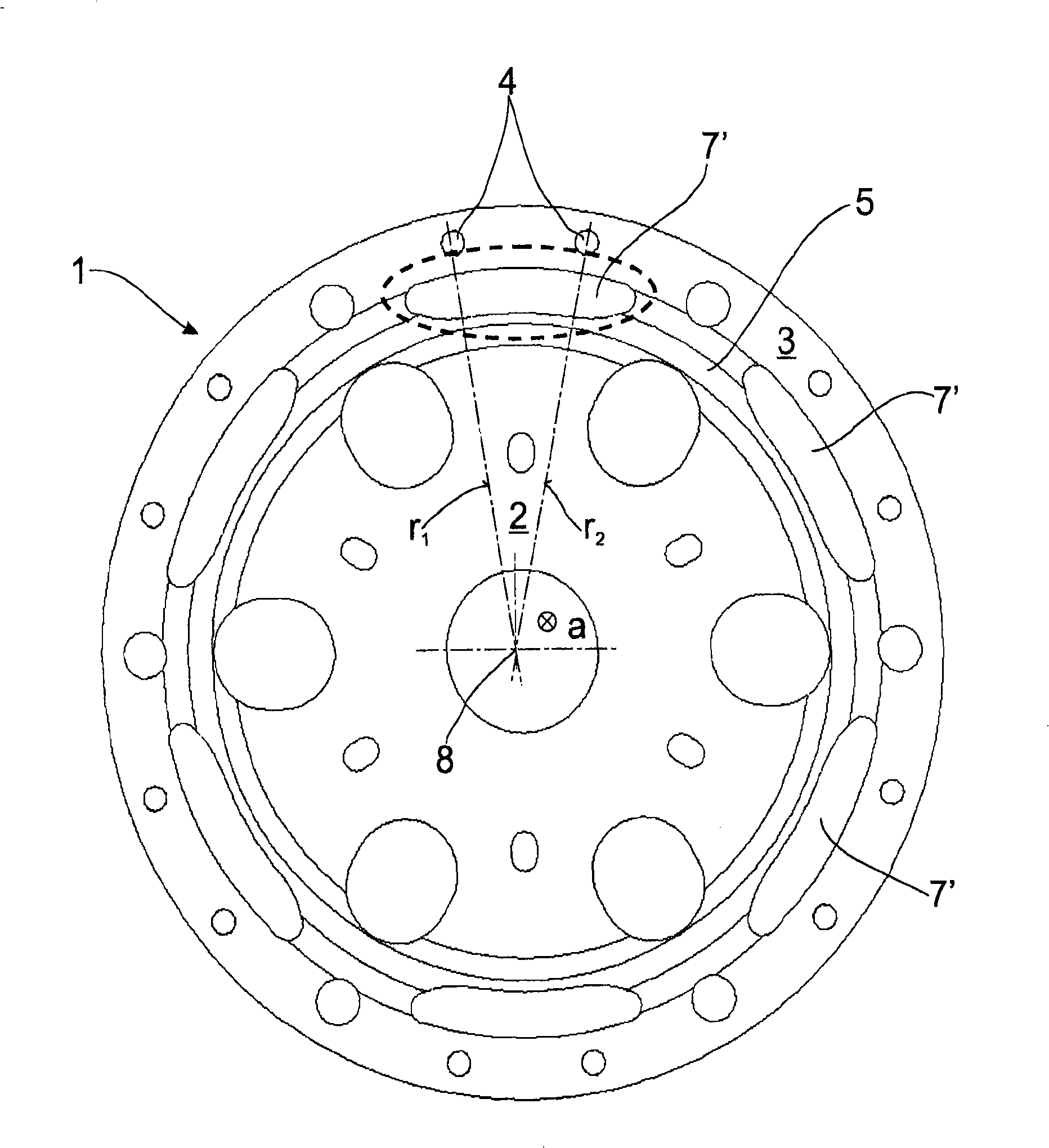

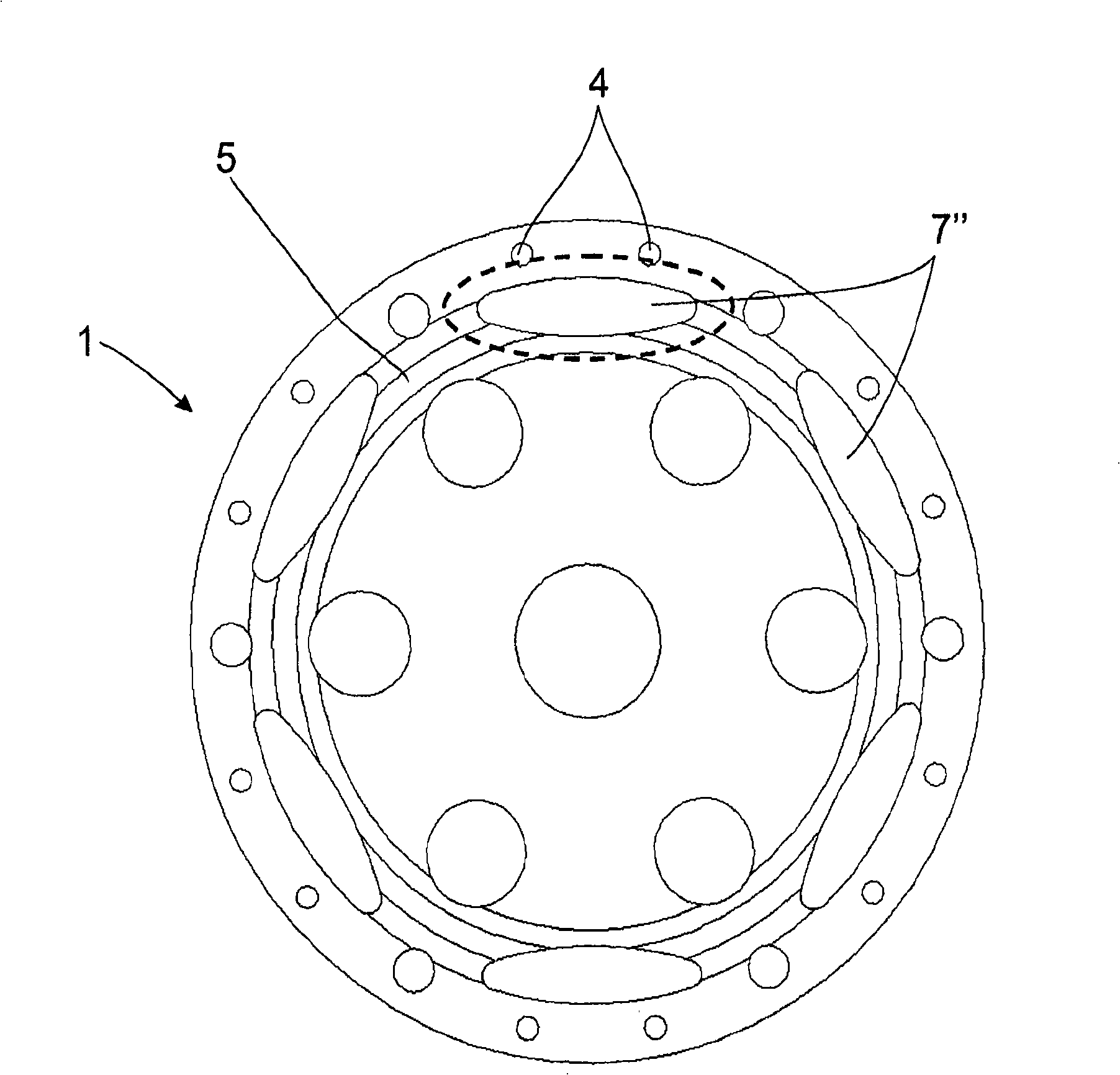

[0059] as by figure 1 It can also be seen that the radially inner region 2 of the disk 1 is arranged offs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com