Green expansive cementing material based on salt chemical industry solid waste and building garbage, preparation method and applications thereof

A technology for cementitious materials and construction waste, which is used in fillings, mining equipment, earth-moving drilling, etc., can solve the problems of poor topping and high production costs, and achieve strong consolidation, high early strength, and good expansion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

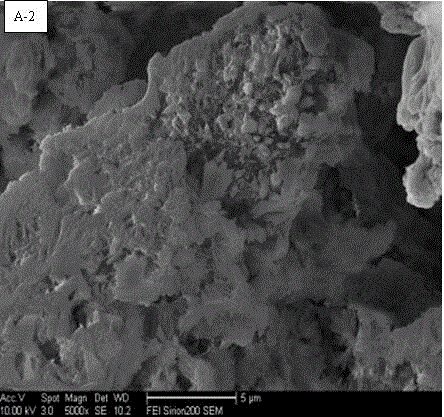

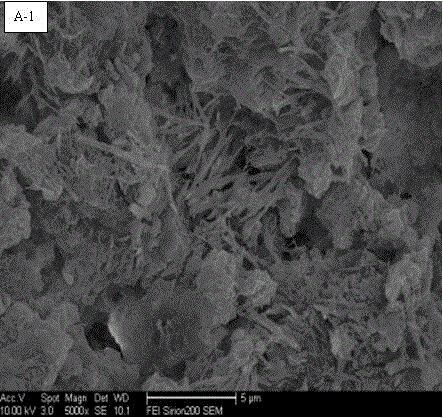

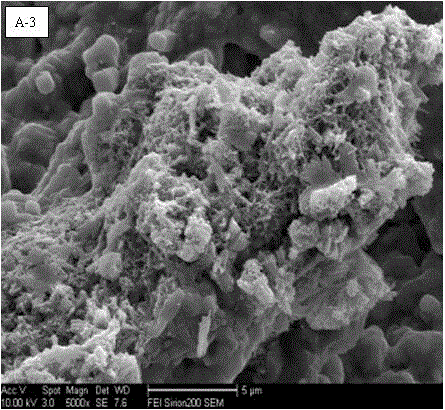

Image

Examples

Embodiment 1

[0040] 1-3 parts of calcium carbide slag, 0.5-3 parts of salt mud, 0.5-3 parts of Glauber's salt, 40 parts of crushed stone, 20 parts of blast furnace slag, 10 parts of desulfurized gypsum, 1 part of water reducing agent, 0.02 parts of expansion agent, soluble calcium Mix 2 parts of salt and 1 part of grinding aid (triethanolamine or triisopropanolamine) evenly, and grind to obtain a green expansive gelling material. Mix the above-mentioned green expansive cementitious material with water, fly ash, and sand in a mass ratio of 1:2.3:4:15 to prepare cementitious material sample 1.

Embodiment 2

[0042] 0.8-1 part of calcium carbide slag, 1 part of salt mud, 1.5 parts of Glauber's salt, 40-45 parts of crushed stone, 30-35 parts of blast furnace slag, 10-20 parts of desulfurized gypsum, 0.8 part of water reducing agent, 0.03 part of aluminum powder, soluble 2 parts of calcium salt, 1 part of grinding aid (triethanolamine or triisopropanolamine), mixed evenly, and ground to obtain green expansive gelling material. Mix the above-mentioned green expansive cementitious material with water, sand, and fly ash at a mass ratio of 1:2.1:4:15 to prepare cementitious material sample 2.

Embodiment 3

[0044] 1.2 parts of calcium carbide slag, 2 parts of salt mud, 1.5 parts of Glauber's salt, 30-40 parts of crushed stone, 20-30 parts of blast furnace slag, 10-15 parts of desulfurized gypsum, 0.05-0.1 parts of water reducing agent, and 0.01-0.03 parts of expansion agent , 2 parts of soluble calcium salt, 0.5-1.5 parts of grinding aid (triethanolamine or triisopropanolamine), mix evenly, and grind to obtain green expansive gelling material. Mix the above-mentioned green expansive cementitious material with water, fly ash, and sand according to the mass ratio of cementitious material: water: fly ash: sand in a specific ratio of 1:2:4:13, and prepare cementitious material sample 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com