Light filling material for mines

A filling material and lightweight technology, applied in the field of mine filling materials, can solve the problems of poor air foam stability of inorganic materials, non-flammability of organic foam filling materials, unsatisfactory filling effect, etc., to achieve convenient and fast on-site construction, improve Fire extinguishing level, high reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

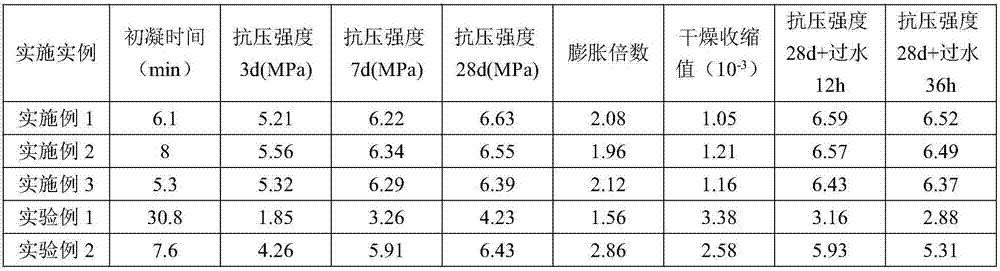

Examples

preparation example Construction

[0052] Another specific embodiment of the present invention discloses a method for preparing lightweight filling materials, the method comprising: mechanically mixing the base material, coagulant, activator, and coagulation regulator, adding an appropriate amount of water and mixing uniformly to obtain a slurry ; Add foaming agent and foam stabilizer to the above slurry and mix evenly, carry out grouting and coagulate to obtain light-weight filling material for mines.

[0053] In a preferred embodiment, the amount of water added is 0.5-5 times the mass sum of the base material, coagulant, activator, and coagulant regulator. More preferably, the amount of water added is the mass of the base material, coagulant, activator, and coagulant regulator. 0.5-2 times of the sum.

[0054] In addition, the present invention discloses the application of the above-mentioned light-weight filling material for mines, and the application includes being used in mine drilling sites, filling in up...

Embodiment 1

[0057] A lightweight filling material for mining, the components are calculated in parts by mass, 75 parts of sulfoaluminate cement, 15 parts of raw gypsum powder, 3 parts of calcium hydroxide, 3 parts of sodium gluconate, 5 parts of sodium carbonate, triterpene 0.5 part of saponin, 0.5 part of sodium lauryl sulfate, 0.5 part of calcium stearate, and 0.5 part of hydroxypropyl methylcellulose.

[0058] Mechanically mix sulfoaluminate cement, raw gypsum powder, calcium hydroxide, sodium gluconate, and sodium carbonate, add 100 parts of water (parts by mass) and stir rapidly at room temperature for 3 minutes, and mix uniformly to obtain a slurry; Alkyl sodium sulfate, calcium stearate, and hydroxypropyl methylcellulose are added to the above slurry and mixed evenly, pumped with a grouting pump, injected into the filling bag through a foaming mixer and condensed to obtain a lightweight filling material for mining .

Embodiment 2

[0060] A lightweight filling material for mines, the components are calculated in parts by mass, 75 parts of sulphoaluminate cement, 12 parts of desulfurized gypsum powder, 3 parts of calcium hydroxide, 3 parts of sodium gluconate, 3 parts of sodium carbonate, three parts 0.1 part of terpene saponin, 0.3 part of sodium lauryl sulfate, 0.2 part of calcium stearate, and 0.2 part of hydroxypropyl methylcellulose.

[0061] Mechanically mix sulfoaluminate cement, desulfurized gypsum powder, calcium hydroxide, sodium gluconate, and sodium carbonate, add 100 parts of water (parts by mass) and stir rapidly at room temperature for 3 minutes, and mix uniformly to obtain a slurry; Sodium dialkyl sulfate, calcium stearate, and hydroxypropyl methylcellulose are added to the above slurry and mixed evenly, pumped with a grouting pump, injected into the filling bag through a foaming mixer and condensed to obtain light filling for mine Material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com