Thermal expansion microspherical composition with foaming performance at low temperature, and preparation method thereof

A technology of thermal expansion microspheres and foaming performance, applied in the field of polymer materials, can solve the problems of high Tstart and limited application, and achieve the effect of improving fluidity and dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

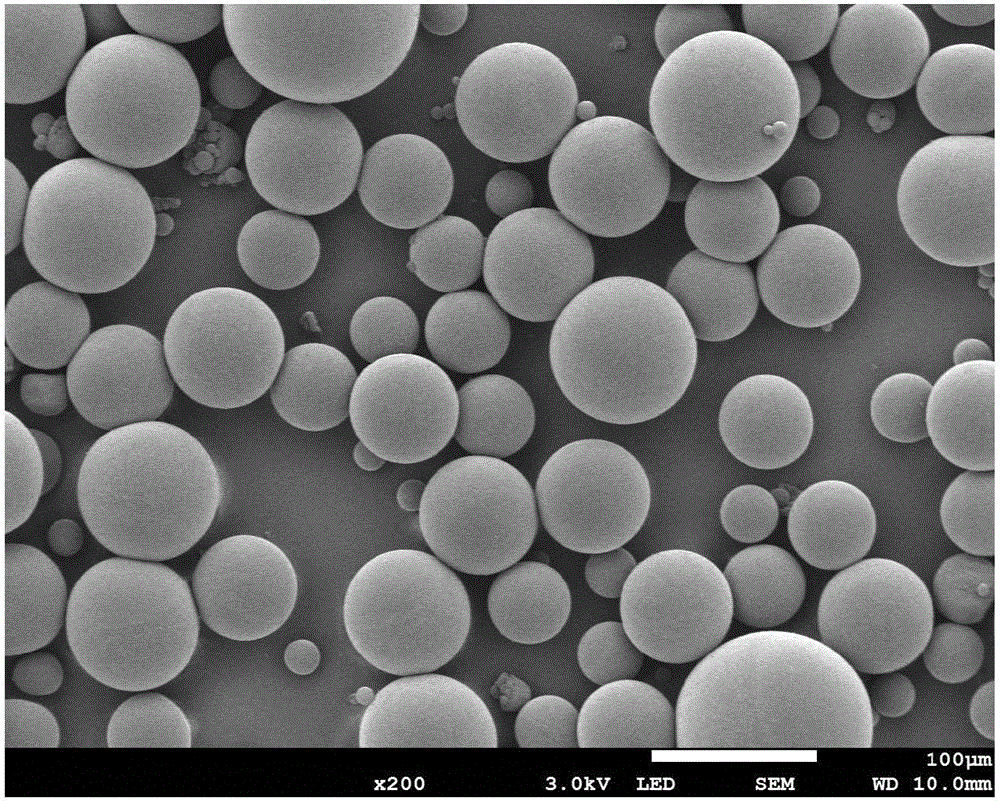

Image

Examples

Embodiment 1

[0052] This embodiment relates to a preparation method of a thermally expandable microsphere composition having foaming properties at low temperatures, comprising the following steps:

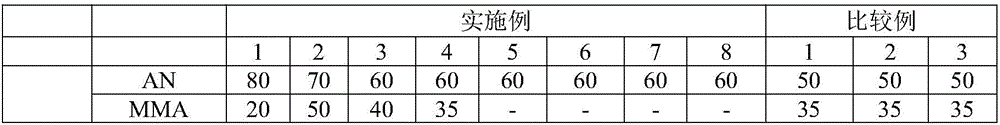

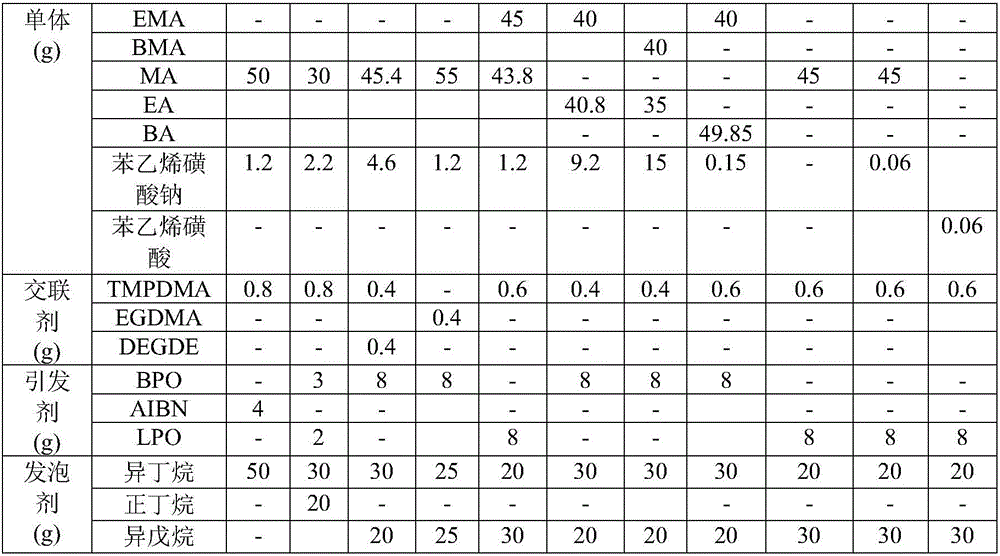

[0053] 1. By mixing 80g of acrylonitrile, 20g of methyl methacrylate, 50g of methyl acrylate, 1.2g of sodium styrene sulfonate, 0.8g of trimethylolpropane trimethacrylate, 4g of benzoyl peroxide and 50g of iso Butane obtains the oil phase of suspension polymerization;

[0054] 2. Add 280g deionized water, 30g sodium hydroxide, 40g sodium chloride and 0.2g sodium lauryl sulfate to the No. 1 beaker and fully dissolve it; add 280g deionized water and 85g magnesium chloride hexahydrate to the No. 2 flask, 30g of sodium chloride and 0.01g of sodium nitrite are fully dissolved; first pour the solution in No. 1 beaker into a 2.5L three-necked flask with a stirring paddle, and then slowly add Solution in flask No. 2. After adding, fully stir for 15 minutes to obtain the aqueous phase of suspension po...

Embodiment 2~8

[0056] Examples 2-8: Except for changing the type and amount of monomers, crosslinking agents, initiators and foaming agents used, other conditions are the same as in Example 1, and the properties of different thermally expandable microspheres prepared are shown in Table 2 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com