Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

47results about How to "Self-flowing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

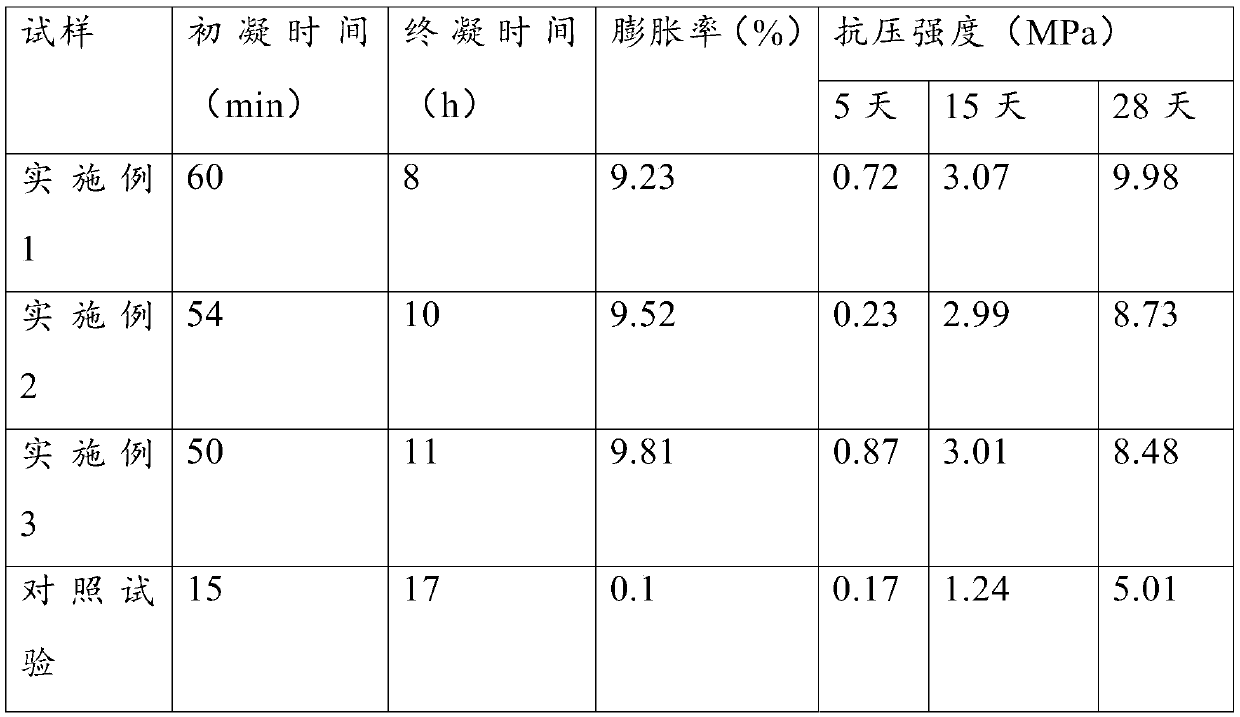

Green expansive cementing material based on salt chemical industry solid waste and building garbage, preparation method and applications thereof

InactiveCN105152553AGood expansion performanceGood affinity for mudMaterial fill-upClinker productionSteelmakingChemical industry

The present invention discloses a green expansive cementing material based on salt chemical industry solid waste and building garbage, and a preparation method thereof, wherein salt-containing chemical industry waste (salt mud, carbide slag and mirabilite), building garbage (gravel, broken bricks and concrete blocks), steelmaking plant waste residue (water residue and steel residue) and power plant desulfuration gypsum are matched with an expander, a water reducer, a soluble calcium salt and other components, and fine grinding and uniform mixing are performed to prepare the green expansive cementing material. According to the present invention, the salt mud, the carbide slag, the mirabilite and other solid waste produced by the salt chemical industry enterprise are digested while the building garbage, the desulfuration gypsum, the water residue and other solid water are subjected to the resource utilization, such that the green expansive cementing material is the green environmental protection cementing material; and the green expansive cementing material has characteristics of good expansion property, good fluidity, good consolidation property, good early strength, active tightening and effective earth's surface sinking control, is the cementing material for mine, and is particularly suitable for the filling mining of coal mines or non-coal mines.

Owner:胡相明

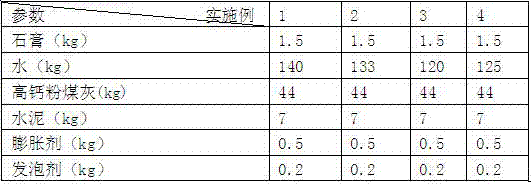

High-water-content micro-expansion filling material composition

InactiveCN102815963ALow costEasy to prepareSolid waste managementCeramicwareSodium polyacrylateGypsum

The invention relates to a high-water-content micro-expansion filling material composition, particularly a filling material for filling-process coal mining, belonging to the technical field of coal mining. The high-water-content micro-expansion filling material composition is characterized by comprising the following components in parts by weight: 100 parts of water, 55-60 parts of high-calcium fly ash, 1.5-2.0 parts of gypsum, 4-6 parts of cement, 0.15-0.20 part of sodium polyacrylate and 0.30-0.35 part of foaming agent. Compared with the prior art, the filling material provided by the invention has the advantages of low cost and great preparation convenience, is easy to transport due to high flow rate, can easily contact the roof due to expandability, and implements roof-contacted filling of the goaf by natural flow and active pressure application. The initial setting time is 5-6 hours, and the final setting time is 10-11 hours. When in use, the high-water-content micro-expansion filling material composition has sufficient preparation time, and can quickly reach a certain compression strength after filling.

Owner:ZIBO MINING GRP

Foaming filling material for alkaline residue mine and preparing method thereof

The invention provides a foaming filling material for an alkaline residue mine. The foaming filling material is characterized by being comprising a component A and a component B, wherein the componentA is prepared from, by weight, 100 parts of cement, 100-200 parts of pulverized fuel ash, 100-200 parts of alkaline residue, 150-350 parts of water and 6-10 parts of foaming agent, the component B isprepared from, by weight, 100 parts of mixture of gypsum and lime, 6-10 parts of active agent, 100-200 parts of pulverized fuel ash, 100-200 parts of alkaline residue and 50-350 parts of water, and the weight ratio of gypsum to lime is (6-7):1. The foaming filling material has the advantages of having low density, low cost, short setting time, good fluidity and the like; industrial waste residueis utilized, acetylene sludge serves as the active agent at the same time, the expansion rate of the filling material is effectively increased, and the cost is effectively lowered.

Owner:HENAN POLYTECHNIC UNIV

Automatic-flowing quick-drying pouring material for blast furnace iron runner

The invention discloses an automatic-flowing quick-drying pouring material for a blast furnace iron runner. The automatic-flowing quick-drying pouring material is composed of the following main raw materials in percentage by weight: 65-70% of dense corundum, 14-18% of black silicon carbide, 3-7% of silicon nitride, 1-2% of a composite water-reducing admixture, 1-2% of a compound anti-blasting material, 1-3% of pure aluminum silicate cement, 1-3% of ultrafine silica powder, 2-4% of reactive alumina micro powder and 2-4% of silica powder. The preparation method comprises the following steps: adding various raw materials into a mixing reactor with a powerful stirring propeller for performing strong stirring, and packaging after stirring, thereby obtaining the product, namely the automatic-flowing quick-drying pouring material for the blast furnace iron runner. The product disclosed by the invention has the advantages of being resistant to corrosion of molten iron and slag, high in erosionresistance, excellent in thermal shock resistance, excellent in flaking resistance, high in oxidation resistance, easy in construction, capable of performing rapid baking without burst and preventingproduction of harmful gases and adhesion of iron slag, and long in service life, and the like.

Owner:河南欣昌耐材股份有限公司

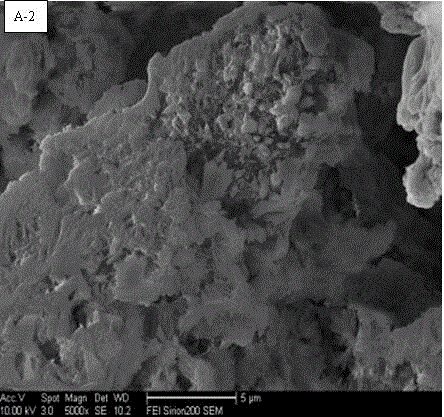

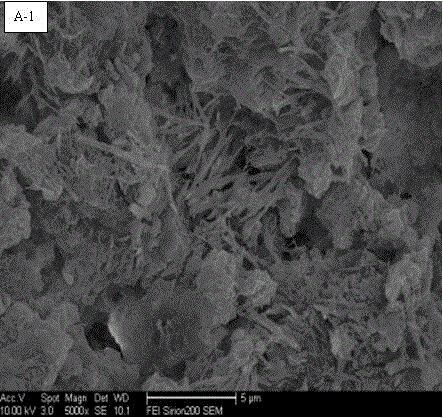

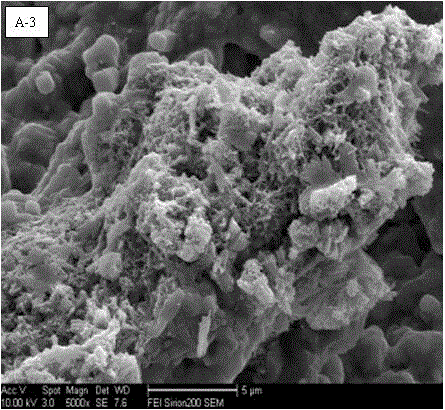

Crushing system for iron mine underground mill and crushing process

The invention relates to a crushing system for an iron mine underground mill and a crushing process. The crushing system for the iron mine underground mill is characterized in that the crushing system is mainly composed of a coarse crushing plant, a medium crushing plant, a screening plant, a fine crushing plant and an overhaul system; and the coarse crushing plant, the medium crushing plant, the screening plant and the fine crushing plant are arranged in a stair-step mode from top to bottom in the vertical direction of a mining factory travelling roadway according to the operation sequence. The crushing process includes the steps that after mined lump ore with the particle size being 600mm-1000mm is crushed by a coarse crushing machine, a medium crushing machine and a fine crushing machine, the ore grain size is turned to be 20mm-30mm; and then the undersize product of a vibrating screen is fed into roughing flotation operation of a grinding flotation system through a pump. The crushing system is low in energy consumption, no earth surface land is occupied, environmental protection is achieved, and qualified raw materials can be provided for the subsequent grinding flotation system.

Owner:MCC NORTH (DALIAN) ENG TECH CO LTD

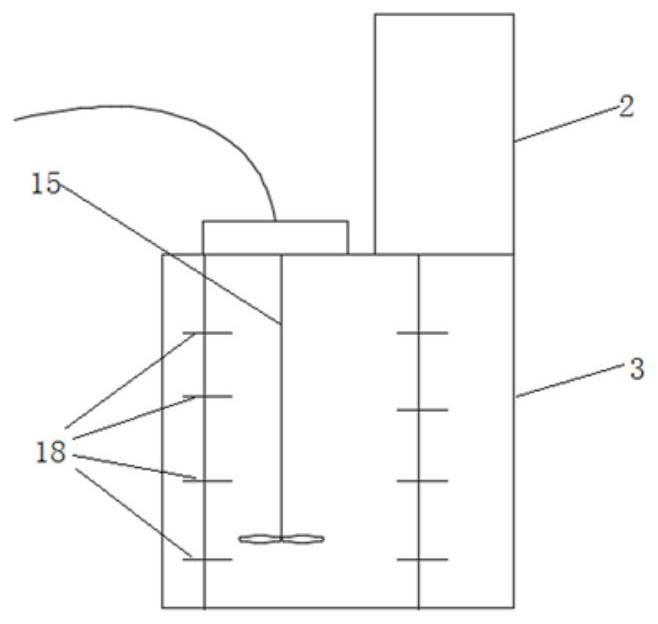

Dynamic bottom aeration system and aeration method thereof

PendingCN106517498AEliminate oxygenation blind spotsEvenly oxygenatedSustainable biological treatmentBiological water/sewage treatmentAeration systemNozzle

The invention provides a dynamic bottom aeration system and an aeration method. The system comprises two trusses, a truss moving unit, an aeration component, a scraper, a fan, a blow-brushing unit and a second driving device, wherein a bridge is arranged between the two trusses; the truss moving unit comprises a guide rail, truss rollers, a first driving device and limiting devices; the first driving device drives the truss to move on the guide rail; the aeration component comprises an aeration air supply pipe, aeration air supply branch pipes, a fixed support and aerators; the aeration air supply branch pipes are radially connected on the aeration air supply pipe; the aerators are communicated with the aeration air supply branch pipes; the scraper is arranged below the fixed support; the fan is communicated with the aeration air supply pipe and a blow-brushing air supply pipe; the blow-brushing unit comprises the blow-brushing air supply pipe, a blow-brushing air supply branch pipe and air nozzles; the blow-brushing air supply pipe and the aeration air supply branch pipes are concentric; one end of the blow-brushing air supply pipe is communicated with an air outlet of the fan and the other end is connected with the blow-brushing air supply branch pipe; the blow-brushing air supply branch pipe is installed on the fixed support; the air nozzles are arranged on the blow-brushing air supply branch pipe; the second driving device drives the aeration component and the blow-brushing unit to rotate. The system has the advantage of no blind area and dead center dynamic aeration oxygenation.

Owner:HUATIAN ENG & TECH CORP MCC

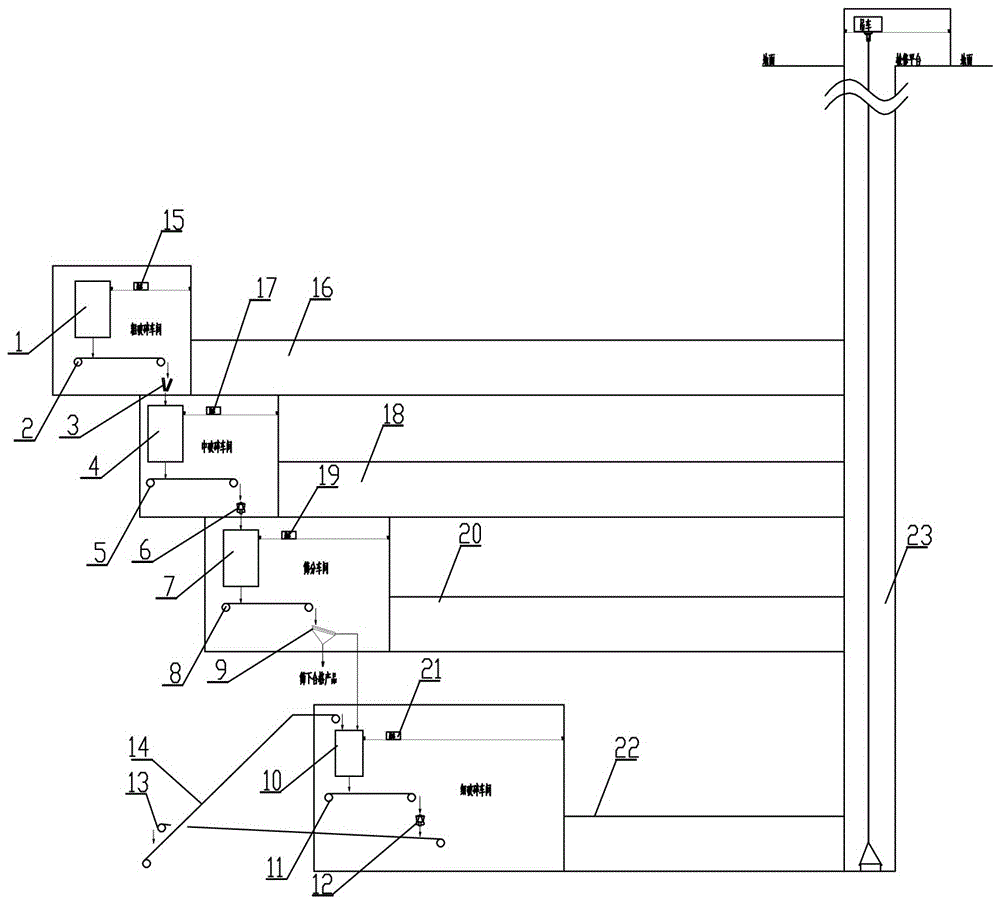

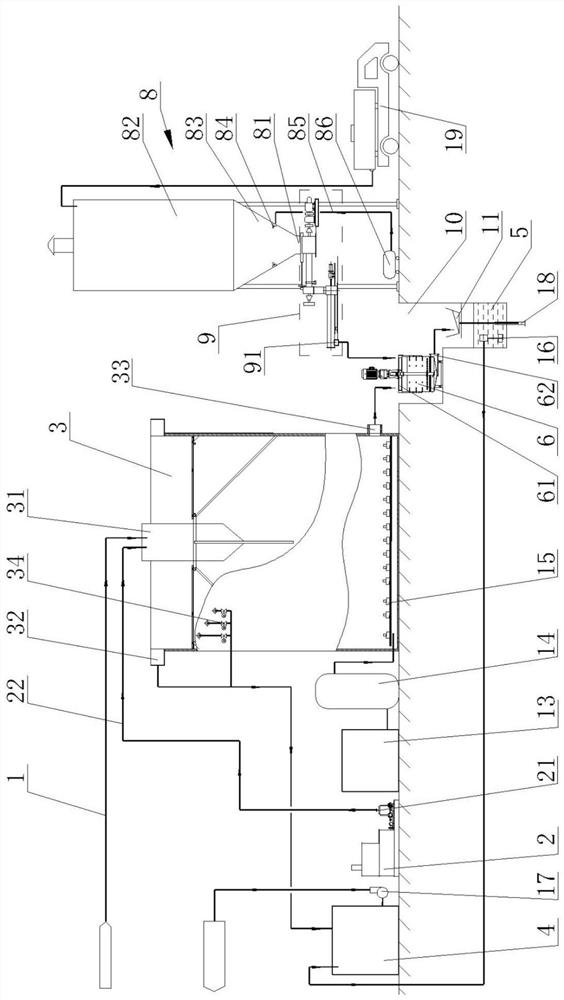

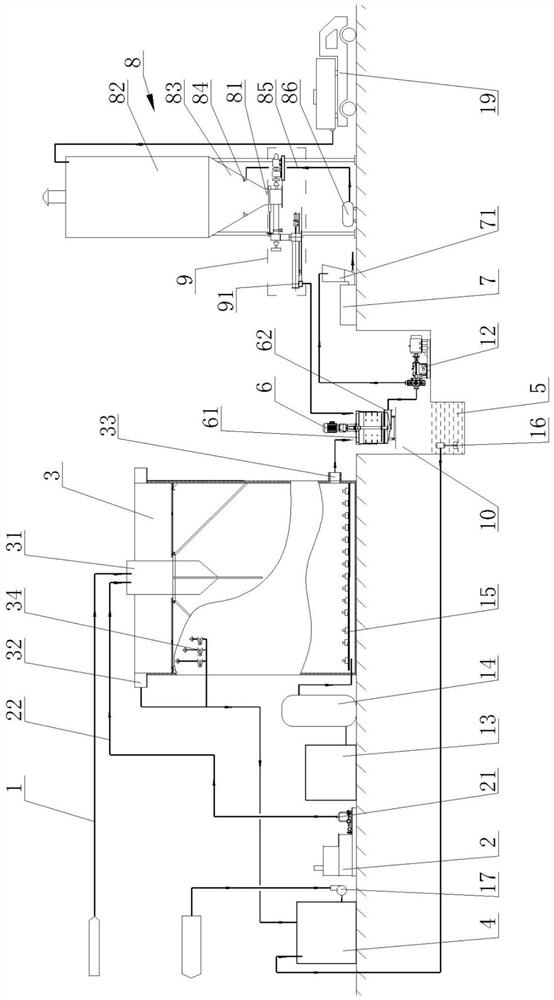

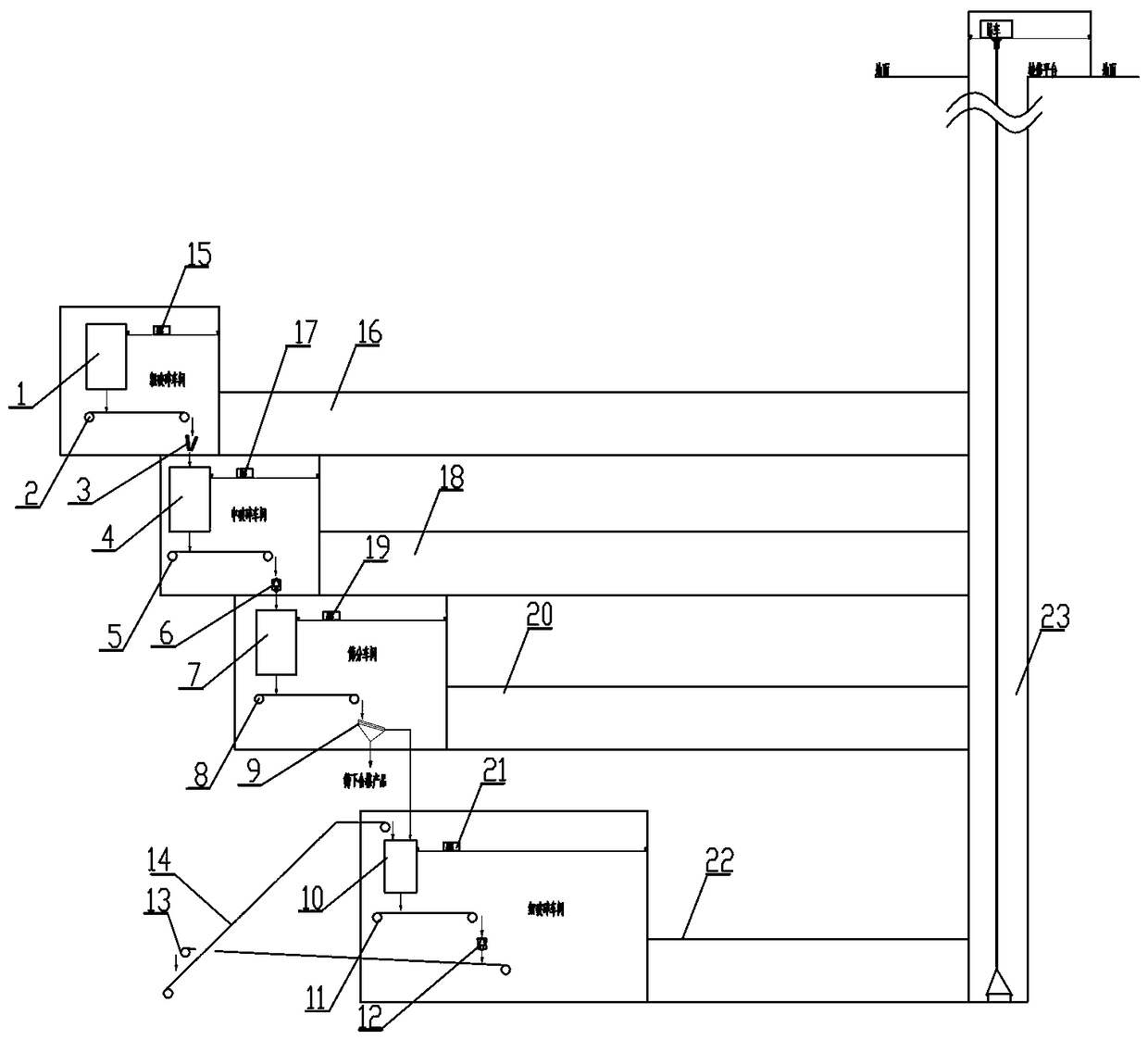

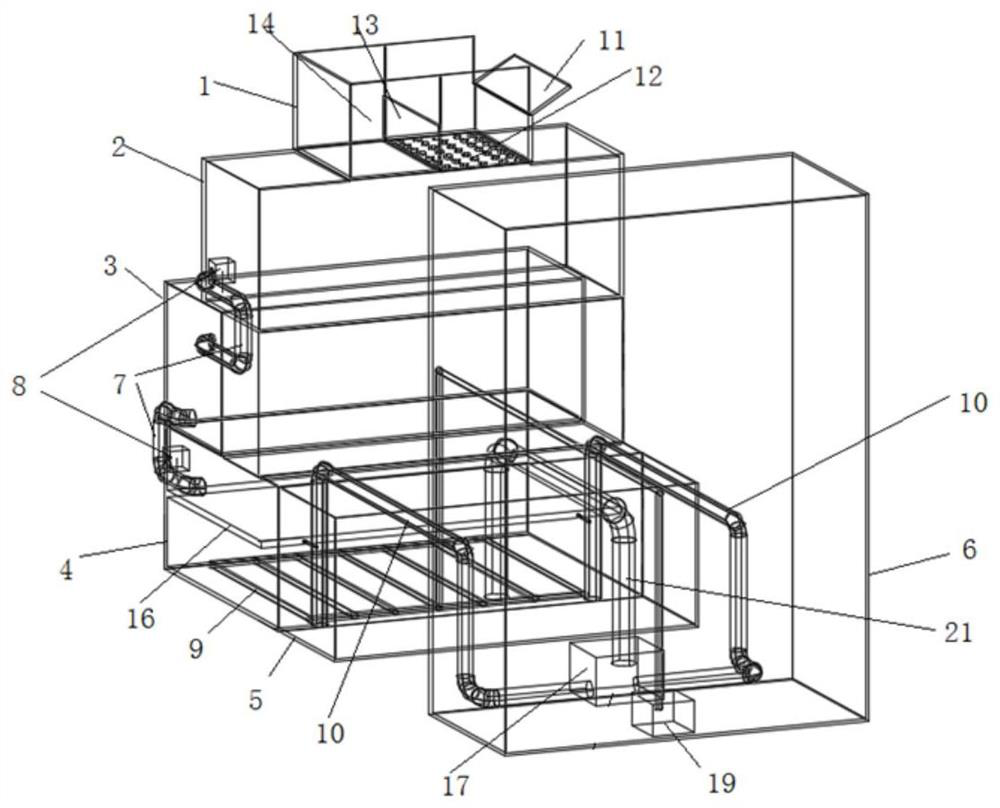

Filling slurry preparation system and preparation method thereof

PendingCN111852552ACompact layoutSmall footprintDifferential sedimentationMaterial fill-upProcess engineeringSlurry pump

The invention discloses a filling slurry preparation system and a preparation method thereof. The preparation system comprises a thickener, an accident pool, a stirring system, a filling pump and a cement conveying and metering device installed at a discharging port of a cement bin, wherein the thickener and the filling pump are both arranged on the ground, a stepped pit is dug under the ground, the stirring system is composed of a high-speed flexible stirring machine, the high-speed flexible stirring machine and the accident pool are arranged in the pit from top to bottom, a hopper and / or a thick slurry pump is further arranged in the part, between the high-speed flexible stirring machine and the accident pool, of the pit, a sand discharging port of the thickener and a delivery port of the cement conveying and metering device are connected with a feeding port of the high-speed flexible stirring machine, the hopper is connected between a discharging port of the high-speed flexible stirring machine and a filling drill hole of an underground filling pipe network, and the thick slurry pump is connected between the discharging port of the high-speed flexible stirring machine and a pumphopper of the filling pump. According to the filling slurry preparation system and the preparation method thereof, slurry preparation links are fewer, the plant construction investment is reduced, and the equipment arrangement is flexible.

Owner:CHINA MINMETALS CHANGSHA MINING RES INST

High-water-retention mine filling material

InactiveCN106892596ARealize comprehensive utilizationLow costCeramicwareFoaming agentFilling materials

The invention discloses a high-water-retention mine filling material which is a compound prepared from high-calcium pulverized fuel ash, gypsum, cement, sodium polyacrylate and a foaming agent. The high-water-retention mine filling material is low in cost, convenient to prepare, high in flow rate, easy to convey, has expansibility, facilitates top joint, can achieve self flowing and active pressure exertion for top joint and gob area filling and has a certain pressure-resistant strength. The high-water-retention mine filling material is suitable for usage after mining.

Owner:谢松甫

High-water-content micro-expansion filling material composition

InactiveCN102815963BRealize comprehensive utilizationSelf-flowingSolid waste managementMaterial fill-upFoaming agentHigh water content

Owner:ZIBO MINING GRP

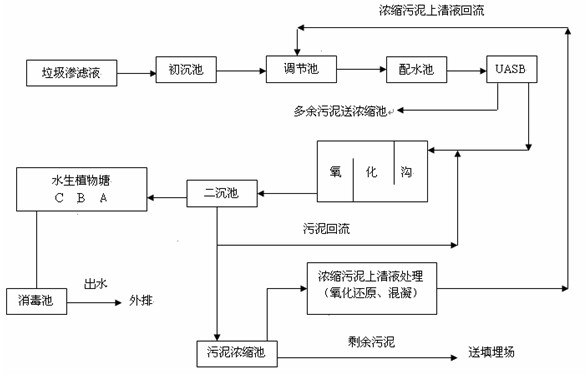

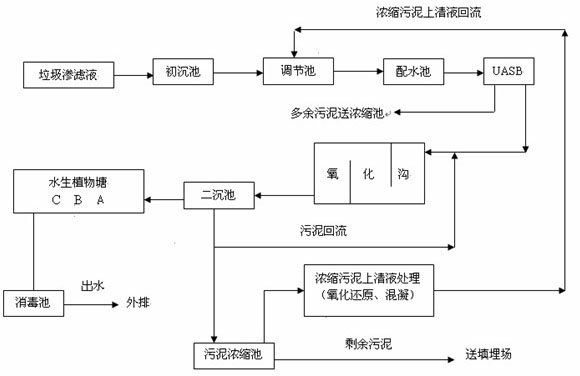

Landfill leachate treatment process

InactiveCN102515438AAccelerated settlementSelf-flowingMultistage water/sewage treatmentHigh concentrationMedicine

The present invention discloses a landfill leachate treatment process, which belongs to the high concentration organic wastewater treatment field, the treatment process comprises the following steps of pretreatment, anaerobic treatment, aerobic treatment, aquatic organisms pond treatment, sludge treatment and the like. The process of the present invention has the advantages of simple operation, obvious economic effect and significant treatment effect, and the effective removal of COD, total nitrogen, total phosphorus and heavy metal ions in the high concentration organic wastewater can be realized.

Owner:KUNMING UNIV OF SCI & TECH

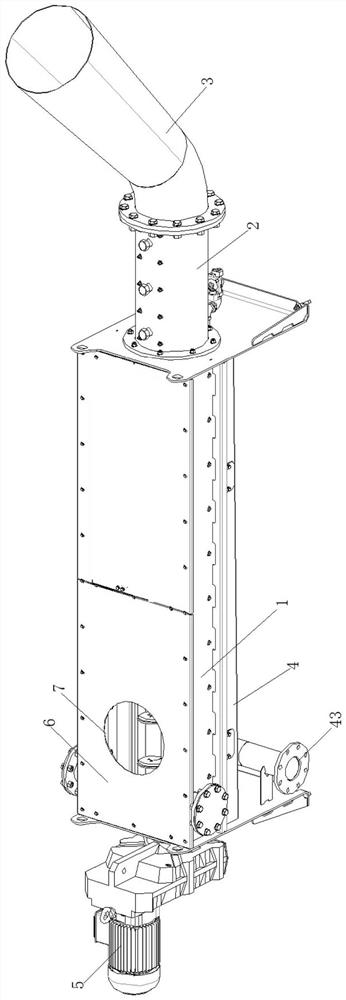

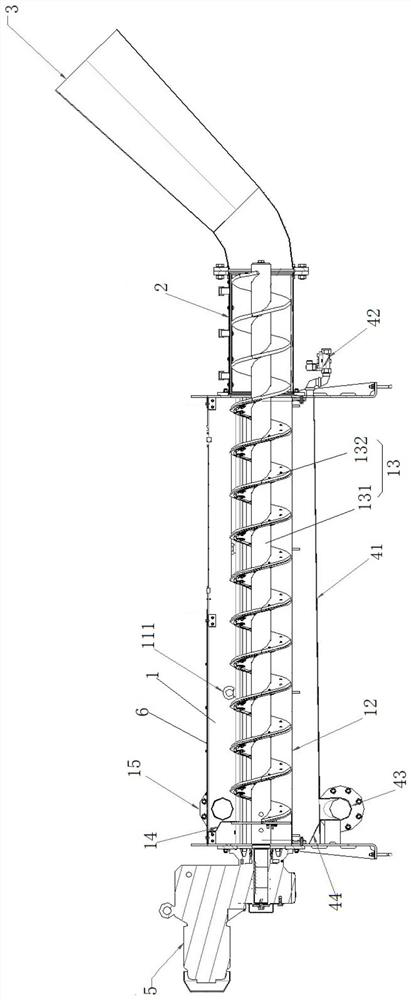

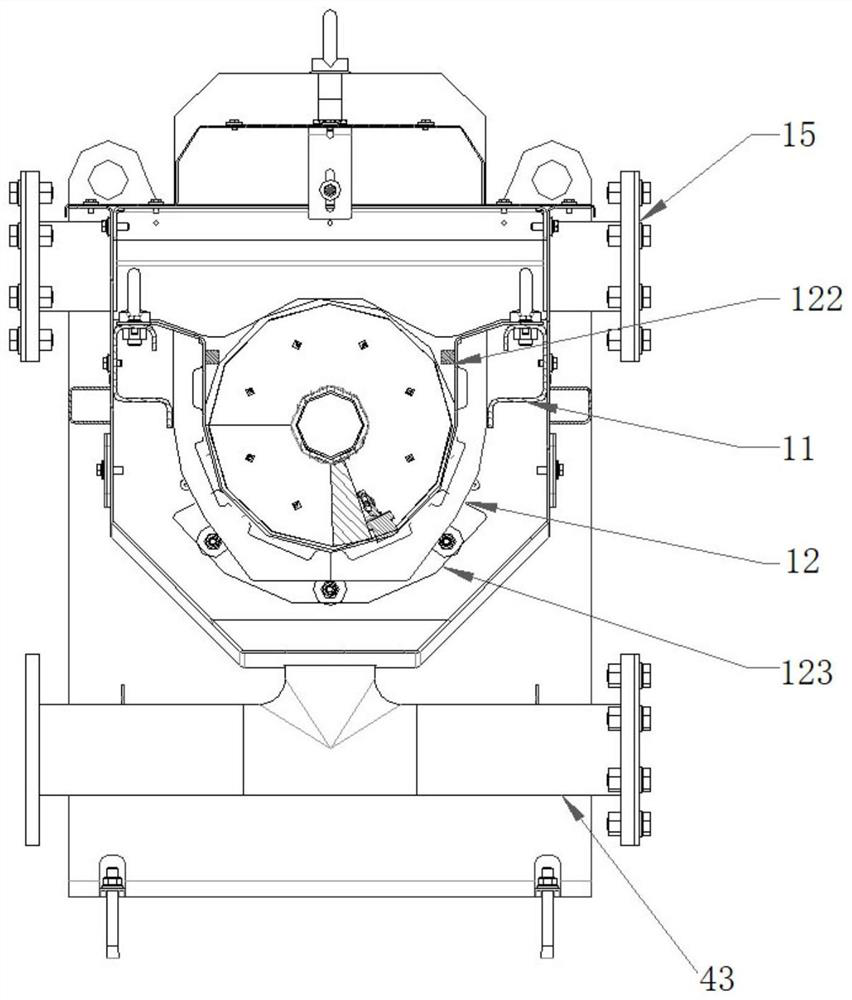

Modularized presser convenient to flexibly mount and working method thereof

ActiveCN114559696AEasy to installEasy maintenanceCleaning using liquidsPressesStructural engineeringEquipment use

The invention discloses a modular squeezer convenient for flexible installation, which comprises an equipment main body section, a squeezing section, a residue discharge pipe, a drainage section and a squeezing driving mechanism, an upper cover is arranged above the equipment main body section, a grid residue inlet is formed in the upper cover, the squeezing section is arranged at the output end of the equipment main body section, the residue discharge pipe is arranged at one end, far away from the equipment main body section, of the squeezing section, and the drainage section is arranged at the other end of the squeezing section. The two ends of the squeezing section are detachably connected with the equipment body section and the residue discharging pipe, the drainage section is arranged below the equipment body section, and the squeezing driving mechanism is arranged at the end, away from the squeezing section, of the equipment body section and connected with the equipment body section. The structure of the presser is optimized, the presser is designed in a sectional mode, all the parts are detachably connected, once a certain part breaks down or is damaged, the local part can be maintained or replaced, installation and maintenance are convenient, and the use cost of equipment is effectively reduced.

Owner:琥珀环保技术(中国)有限公司

Mine filling material and preparation method thereof

The invention provides a mine filling material and a preparation method thereof. The mine filling material is prepared from, by weight, 90-95 parts of a curing agent, 10-25 parts of sludge, 1-5 partsof construction waste particles, 0.5-2 parts of municipal waste particles, 0.1-0.5 part of a rheology modifier, 0.1-0.5 part of a thickening time control agent and 0.1-0.5 part of a defoaming agent; and the curing agent comprises 25-35 parts of ettringite, 25-35 parts of calcium silicate clinker, 15-25 parts of calcium sulfate, 15-20 parts of quick lime and 0.5-1 part of aluminum powder. The minefilling material can be stably conveyed into a filling mine for a long distance, the safety of a filling system can be guaranteed in the conveying process, condensation and segregation are avoided inthe conveying process, meanwhile, after a filling slurry is conveyed into a target mine, rapid condensation can be achieved, the strength is guaranteed, ecological environment treatment is achieved, and meanwhile waste materials are comprehensively recycled.

Owner:GUYAN TECH DEV CO LTD

A crushing system and crushing process of an iron ore underground concentrator

The invention relates to a crushing system for an iron mine underground mill and a crushing process. The crushing system for the iron mine underground mill is characterized in that the crushing system is mainly composed of a coarse crushing plant, a medium crushing plant, a screening plant, a fine crushing plant and an overhaul system; and the coarse crushing plant, the medium crushing plant, the screening plant and the fine crushing plant are arranged in a stair-step mode from top to bottom in the vertical direction of a mining factory travelling roadway according to the operation sequence. The crushing process includes the steps that after mined lump ore with the particle size being 600mm-1000mm is crushed by a coarse crushing machine, a medium crushing machine and a fine crushing machine, the ore grain size is turned to be 20mm-30mm; and then the undersize product of a vibrating screen is fed into roughing flotation operation of a grinding flotation system through a pump. The crushing system is low in energy consumption, no earth surface land is occupied, environmental protection is achieved, and qualified raw materials can be provided for the subsequent grinding flotation system.

Owner:MCC NORTH (DALIAN) ENG TECH CO LTD

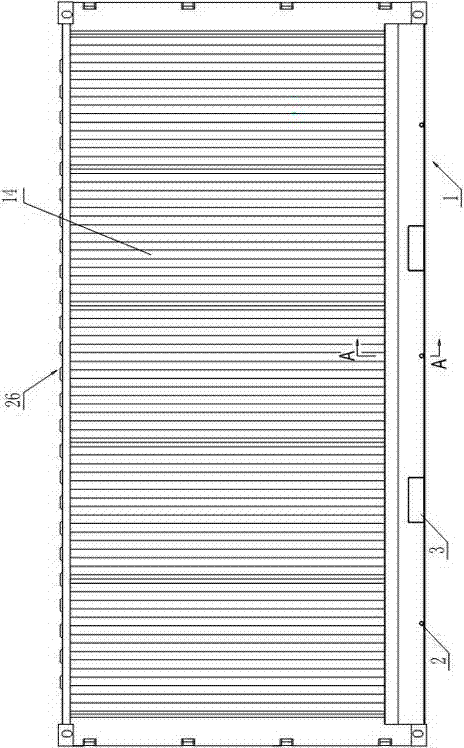

Container underframe for loading liquid vessel and container

ActiveCN103359428AWill not polluteImprove liquid permeabilityLarge containersLiquid storage tankChassis

The invention provides a container underframe for loading a liquid vessel, and a container. The container underframe and the container can solve the problem that liquid leaking from the liquid vessel in the existing container cannot be collected and leaks to the outside of the container easily. The container underframe comprises a lower bottom plate, bottom side beams on the two sides, end sills at the two ends, a plurality of bottom cross beams and a bearing floor, wherein the bearing floor consists of a plurality of grid floors. A cavity formed by the bottom side beam on the two sides, the end sills at the two ends and the lower bottom plate is a liquid storage tank, and the liquid storage tank is communicated with a cargo storage space of the container through gaps of the grid floors. According to the container underframe and the container, the liquid leaking from the container mounted in the cargo storage space of the container can flow down into the liquid storage tank formed by a structure of the container underframe, and can be discharged timely.

Owner:QINGDAO JINHUANGHAI CONTAINER

Environmental-friendly cofferdam on working site

PendingCN110513056ASelf-flowingConvenience for centralized recyclingDrilling rodsSealing/packingCofferdamReusability

The invention relates to an environmental-friendly cofferdam on a working site. According to the technical scheme, a sucker rod ship-type tank is formed in a sucker rod placing area, four sucker rod fixing brackets are welded into the sucker rod ship-type tank and arranged at equal intervals, sucker rods are placed on the sucker rod fixing brackets, a sucker rod sewage collection groove is formedin the end head in the sucker rod ship-type tank, four oil pipe ship-type tanks are formed in an oil pipe placing area, the adjacent oil pipe ship-type tanks are connected through a buckle plate, fouroil pipe adjustable fixing brackets are welded into the oil pipe ship-type tanks and arranged at equal intervals, and oil pipe sewage collection grooves are formed in the end heads in the oil pipe ship-type tanks. The environmental-friendly cofferdam has the beneficial effects that the advantages of the ship-type cofferdam that steel materials are used for welding, firmness, sealing and reusability are achieved, the use amount of an anti-seepage membrane is decreased from the source, the generation of secondary pollution are reduced from the source, and the self-flowing and centralized recovery of outlet liquid in a shaft are convenient.

Owner:SHENGLI OILFIELD XIANHE IND & TRADE CO LTD

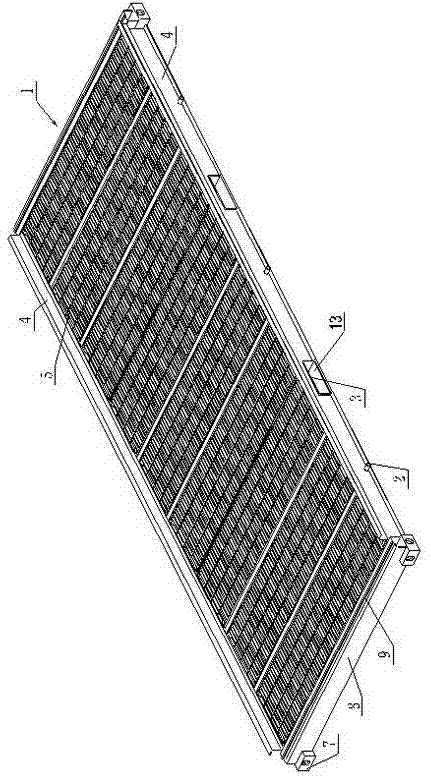

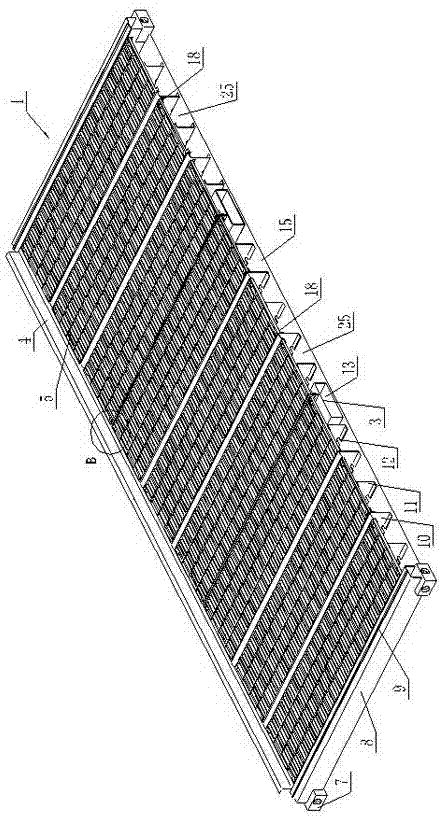

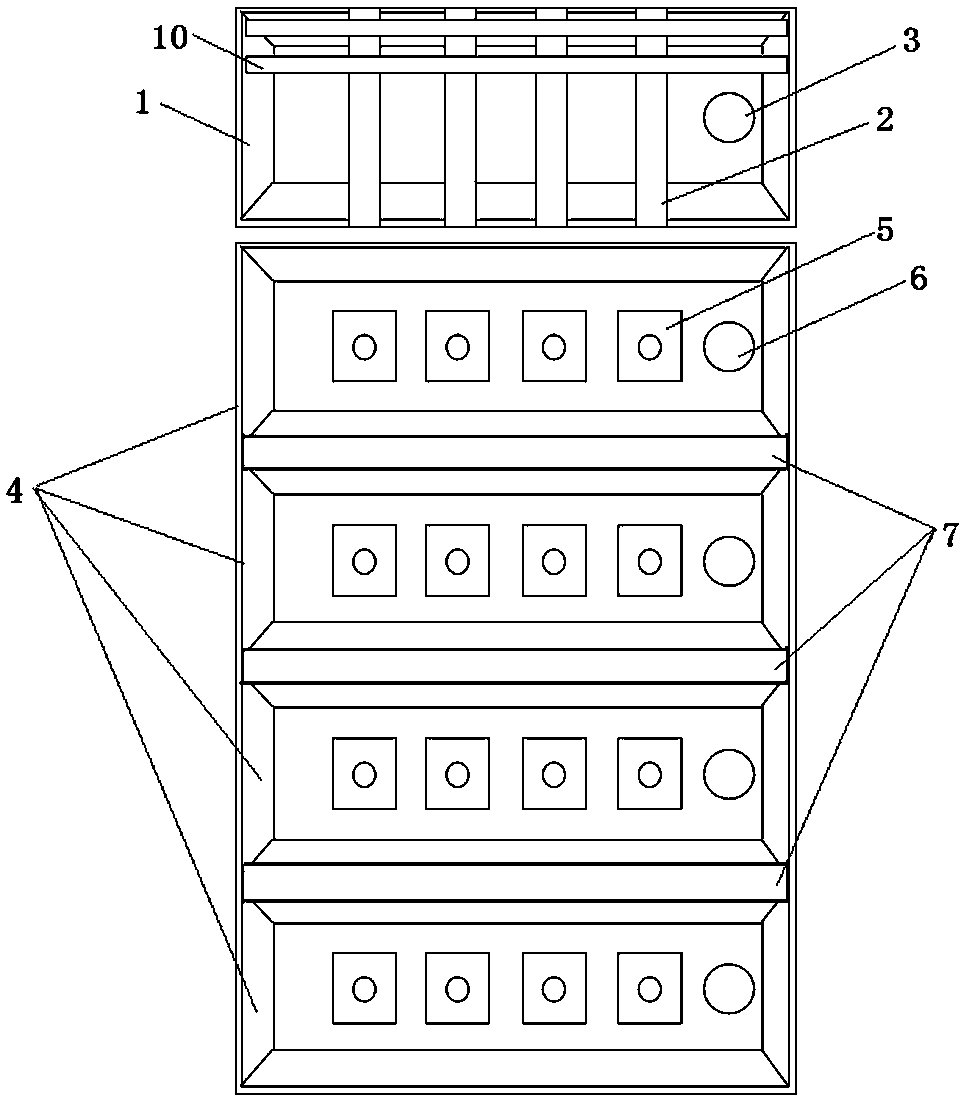

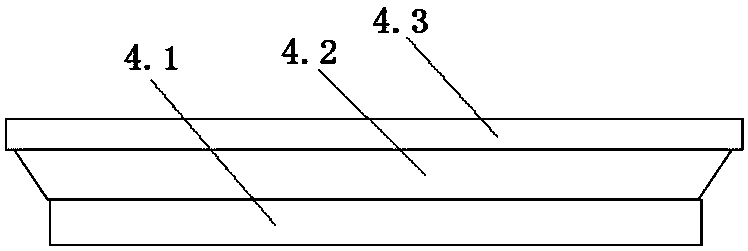

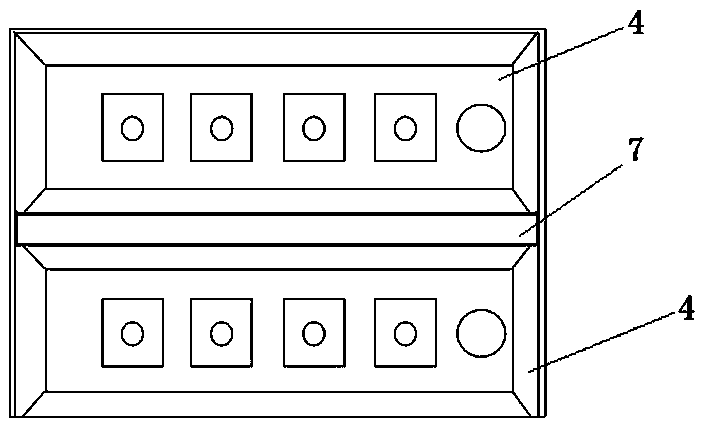

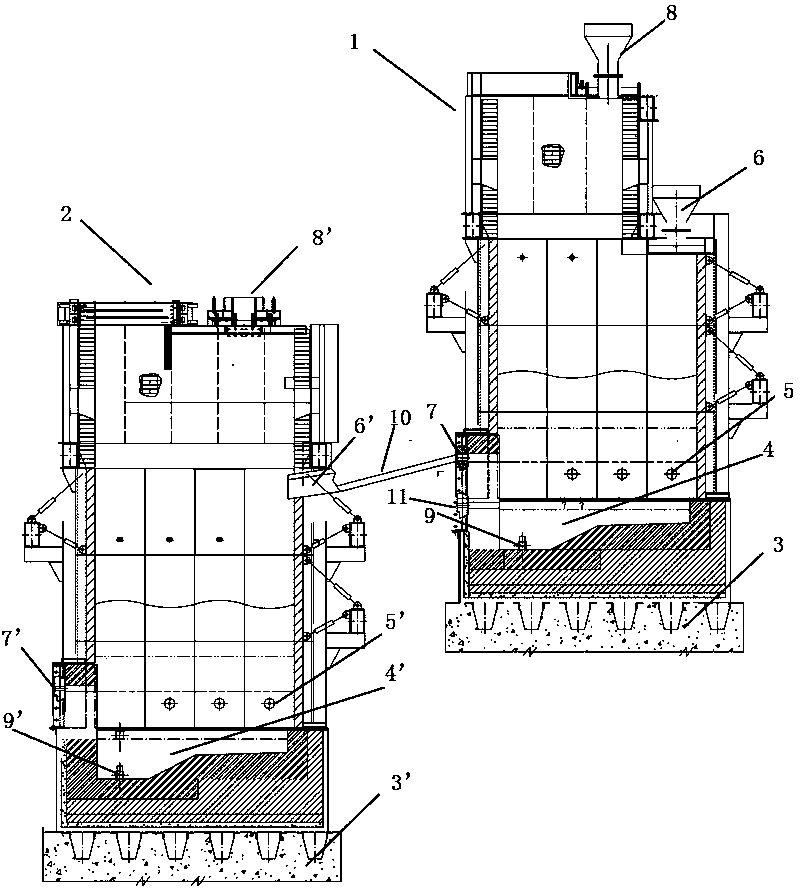

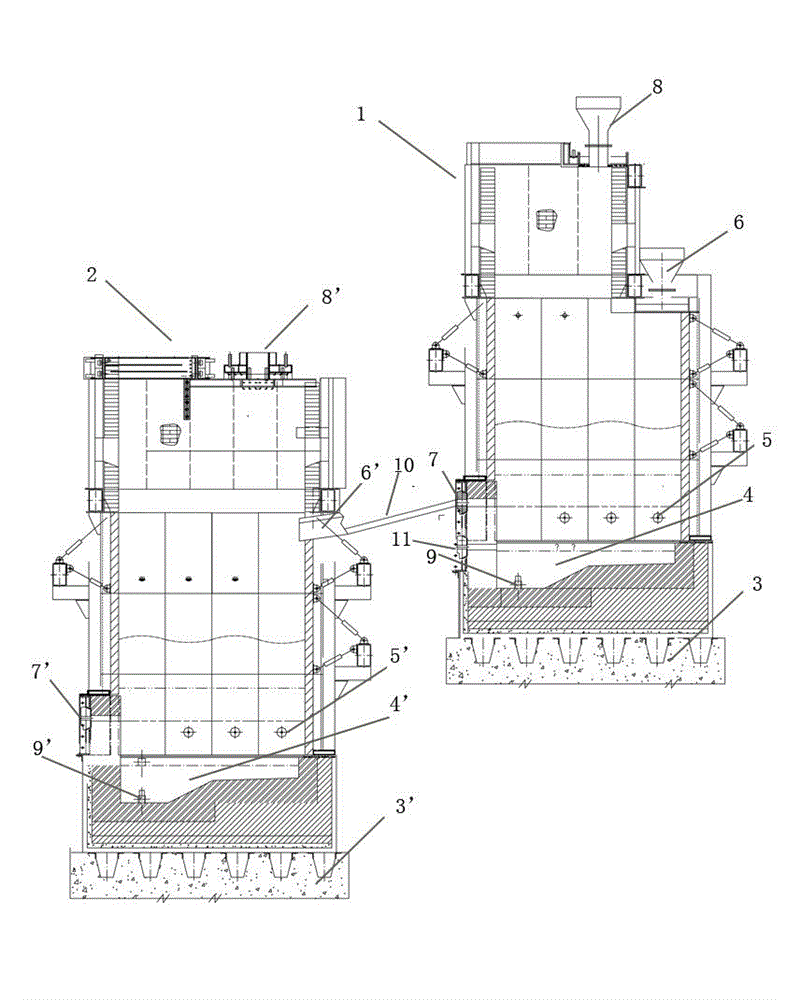

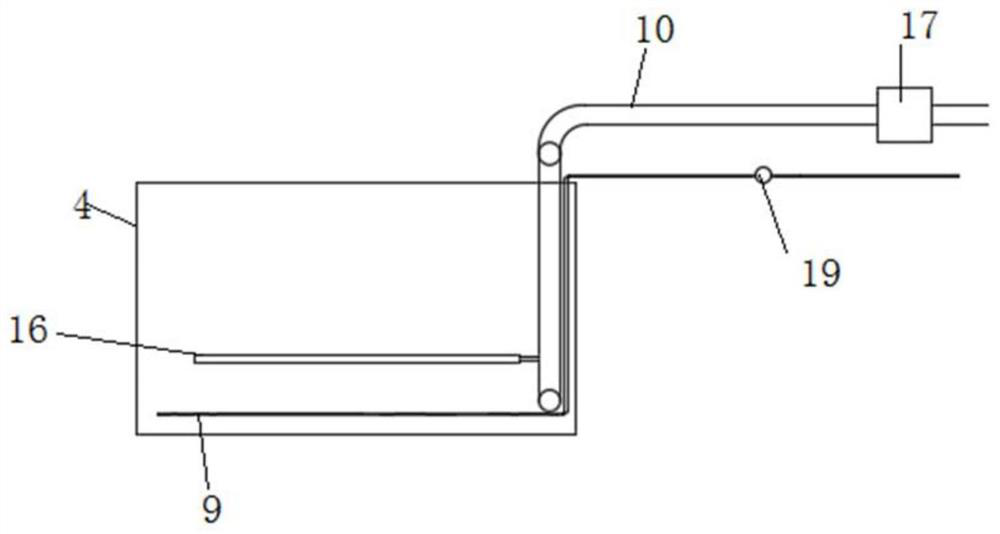

Oxygen-rich redox furnace

InactiveCN103146936BSelf-flowingAchieving acidProcess efficiency improvementHigh concentrationSiphon

The invention discloses an oxygen-rich redox furnace which is divided into an oxidation furnace body (1) and a reducing furnace body (2), wherein independent furnace bases (3, 3'), furnace hearths (4, 4'), a water jacket, air nozzles (5, 5'), a siphon port, feed ports (6, 6'), discharge ports (7, 7') and flue ports (8, 8') are arranged on the two furnace bodies; safety ports (9, 9') are arranged at the lowest positions of the furnace hearths (4, 4') in the two furnace bodies; the foundation surfaces of the furnace foundations (3, 3') higher than the part of the reducing furnace body (2) are arranged on the foundation surfaces of the furnace foundations (3, 3') of the part of the oxidation furnace body (1); the discharge port (7) of the oxidation furnace body part is connected with the feed port (6') of the reducing furnace body part through a chute (10); and a viscous slag port (11) is formed on the outer side surface of the furnace hearth (4) of the part of the oxidation furnace body (1). The oxygen-rich redox furnace disclosed by the invention can solve the problems or defects of inconvenience in terms of equipment manufacturing, transportation, mounting and operation, and also can make use of the heat energy generated by an oxidation reaction to reduce the consumption of energy and accessories; and meanwhile, the oxygen-rich redox furnace also has the advantages that high-concentration smoke is used for preparing acid, the furnace accretion is convenient to dispose and the like.

Owner:HUNAN JINWANG BISMUTH

A filling method for a room-type goaf

Owner:TAIYUAN UNIV OF TECH

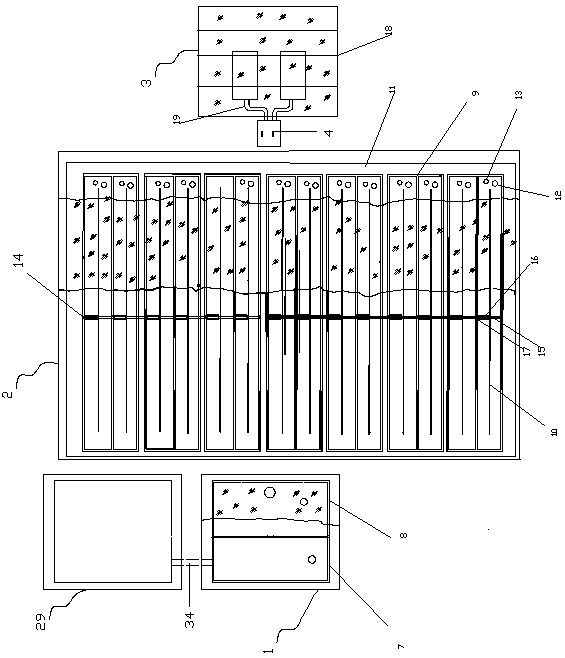

Sealed integrated system for producing spirulina

ActiveCN103238512ASelf-flowingReduce mechanical damagePhotobioreactorsCultivating equipmentsEngineeringIntegrated systems

The invention discloses a sealed integrated system for producing spirulina. By the aid of the system, the problems that existing spirulina cultivating devices are short in production cycle, short in service life and incapable of being produced in the large scale are solved. The system comprises a spirulina propagation tank, a spirulina cultivating tank and a spirulina solution recovery tank which are communicated, framework sealing bodies which enshroud tank surfaces and are set up on upright column foundations are arranged on the peripheries of tank edges of the spirulina propagation tank, the spirulina cultivating tank and the spirulina solution recovery tank respectively to form a spirulina propagation room, a spirulina cultivating room and a spirulina harvest room, a spirulina planting tank which is connected with the spirulina propagation tank is arranged inside the spirulina propagation room, and a spirulina collecting tank is arranged between the spirulina cultivating room and the spirulina harvest room. In general, by the aid of the system, the production cycle of the spirulina can be prolonged, the service life is long, economical and efficient effects are achieved, and the large-scale production can be achieved.

Owner:甘肃凯源生物技术开发中心有限责任公司

Oxygen-rich redox furnace

The invention discloses an oxygen-rich redox furnace which is divided into an oxidation furnace body (1) and a reducing furnace body (2), wherein independent furnace bases (3, 3'), furnace hearths (4, 4'), a water jacket, air nozzles (5, 5'), a siphon port, feed ports (6, 6'), discharge ports (7, 7') and flue ports (8, 8') are arranged on the two furnace bodies; safety ports (9, 9') are arranged at the lowest positions of the furnace hearths (4, 4') in the two furnace bodies; the foundation surfaces of the furnace foundations (3, 3') higher than the part of the reducing furnace body (2) are arranged on the foundation surfaces of the furnace foundations (3, 3') of the part of the oxidation furnace body (1); the discharge port (7) of the oxidation furnace body part is connected with the feed port (6') of the reducing furnace body part through a chute (10); and a viscous slag port (11) is formed on the outer side surface of the furnace hearth (4) of the part of the oxidation furnace body (1). The oxygen-rich redox furnace disclosed by the invention can solve the problems or defects of inconvenience in terms of equipment manufacturing, transportation, mounting and operation, and also can make use of the heat energy generated by an oxidation reaction to reduce the consumption of energy and accessories; and meanwhile, the oxygen-rich redox furnace also has the advantages that high-concentration smoke is used for preparing acid, the furnace accretion is convenient to dispose and the like.

Owner:HUNAN JINWANG BISMUTH

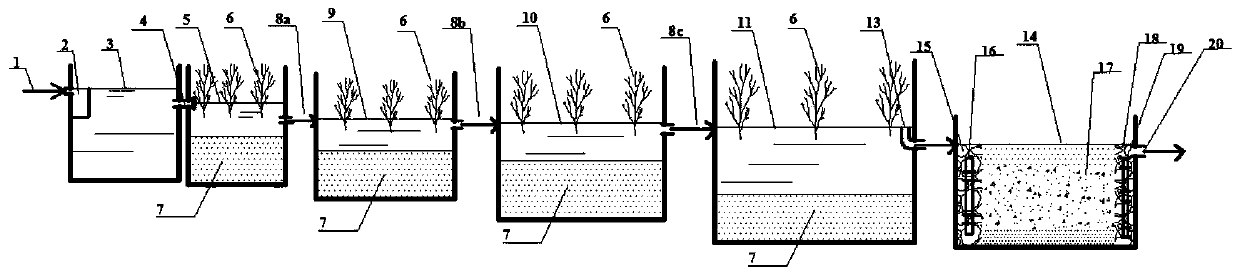

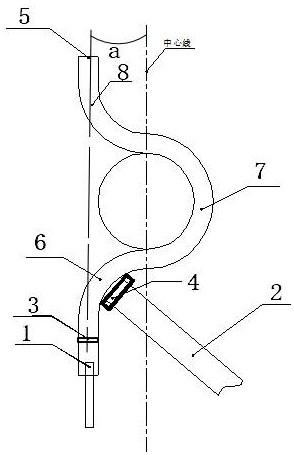

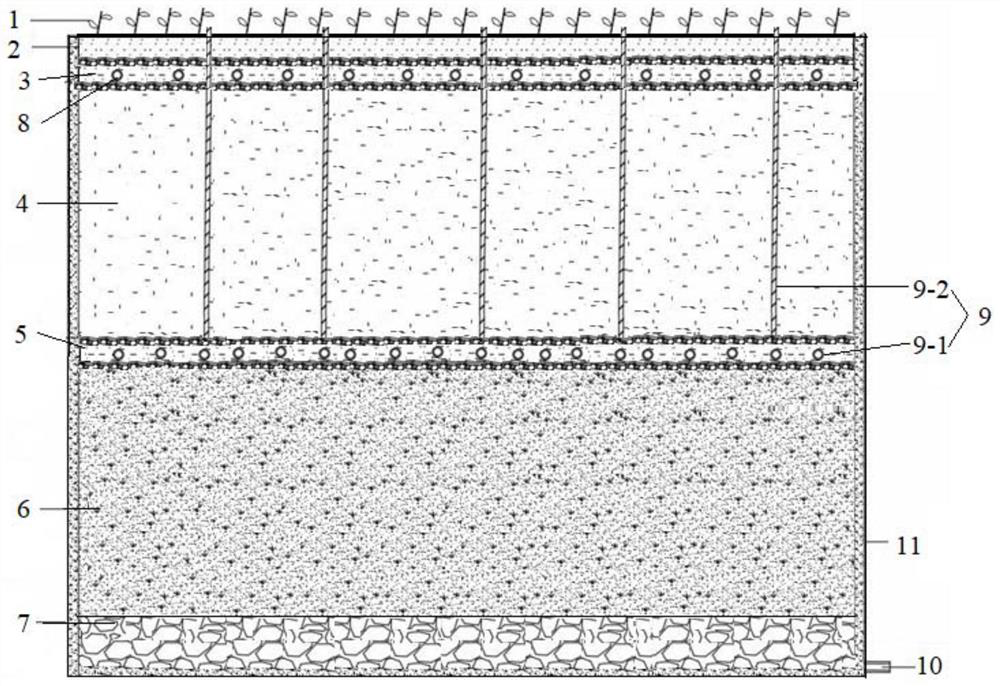

A method and device for advanced treatment of rural sewage combined with artificial wetland and infiltration system

ActiveCN105293841BGood serviceImprove the ecological environmentMultistage water/sewage treatmentConstructed wetlandEcological environment

The invention discloses a method for advanced treatment of rural sewage by combining an artificial wetland and a percolation system. At the same time, the device for rural sewage treatment is disclosed. The sewage is collected into the main water inlet pipe through the collection pipe network. The first, second, third and fourth surface flow artificial wetlands are connected in turn through the overflow weir, and then connected to the horizontal subsurface flow infiltration system through the "∟" type overflow drainage pipe. After the filter system perforates the "Ш" type water collection pipe, it discharges the treated water up to the standard through the "─" type direct current drainage pipe. This method is easy to operate and maintain, has landscape effects and economic benefits, simple structure, low investment, and realizes decentralized rural Efficient treatment of domestic and aquaculture sewage to achieve effective protection of the rural ecological environment.

Owner:INST OF SUBTROPICAL AGRI CHINESE ACAD OF SCI

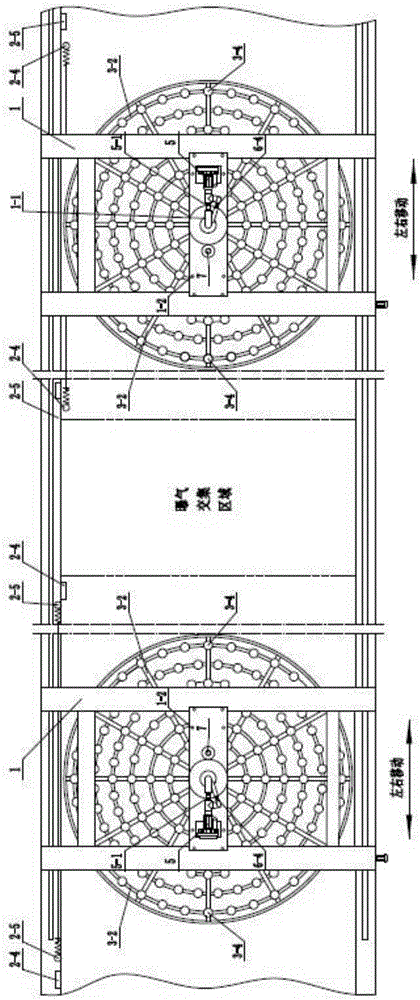

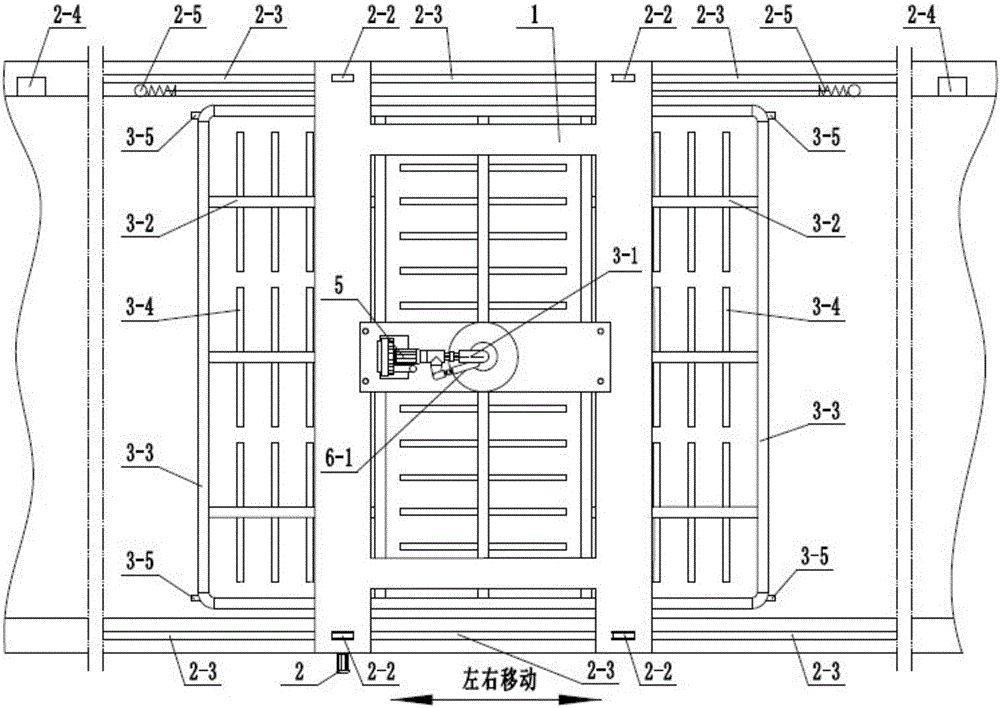

Reciprocation mobile bottom-layer aeration system and aeration method thereof

PendingCN106830299AExtend the mixing timeImprove oxygen transfer efficiencyWater treatment parameter controlSpecific water treatment objectivesAeration systemRadiation

The invention provides a reciprocation mobile bottom-layer aeration system and an aeration method thereof. The reciprocation mobile bottom-layer aeration system comprises a truss, a truss moving unit, aeration components, a scraper, a fan and a blowing unit, wherein the truss spans on an oxidation channel; the truss moving unit comprises a guide track, truss rollers, a driving device and a limiting device; the aeration components comprise an aeration air supply tube which is fixed on the truss, aeration air supply branch tubes which are connected with one end of the aeration air supply tube in a radiation manner, fixing brackets which are used for surrounding the aeration air supply branch tubes, and aerators which are arranged inside the fixing brackets and are communicated with the aeration air supply branch tubes; the scraper is arranged at the lower end of the fixing brackets; the air outlet of the fan is communicated with the aeration air supply tube; the blowing unit comprises a blowing air supply tube, blowing air supply branch tubes and air ejectors; one end of the blowing air supply tube is communicated with the air outlet of the fan; the other end of the blowing air supply tube is connected with the blowing air supply branch tubes; the blowing air supply branch tubes are mounted at the lower ends of the fixing brackets; the air ejectors are arranged on the blowing air supply branch tubes and are used for blowing the scraper. By adopting the reciprocation mobile bottom-layer aeration system, dynamic aeration and oxygenation without blind areas or dead zones can be achieved.

Owner:HUATIAN ENG & TECH CORP MCC

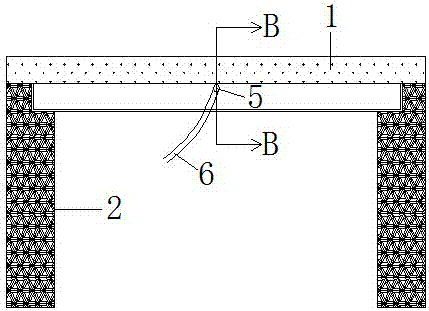

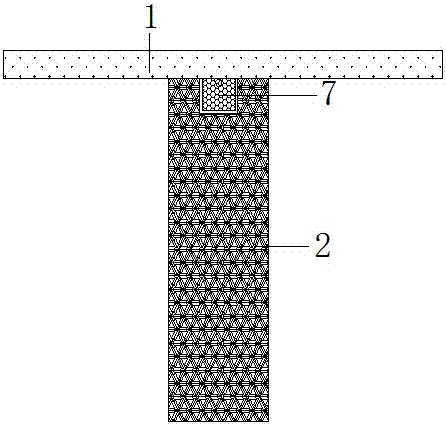

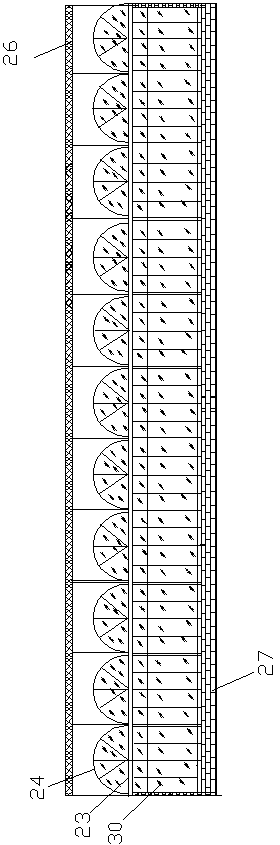

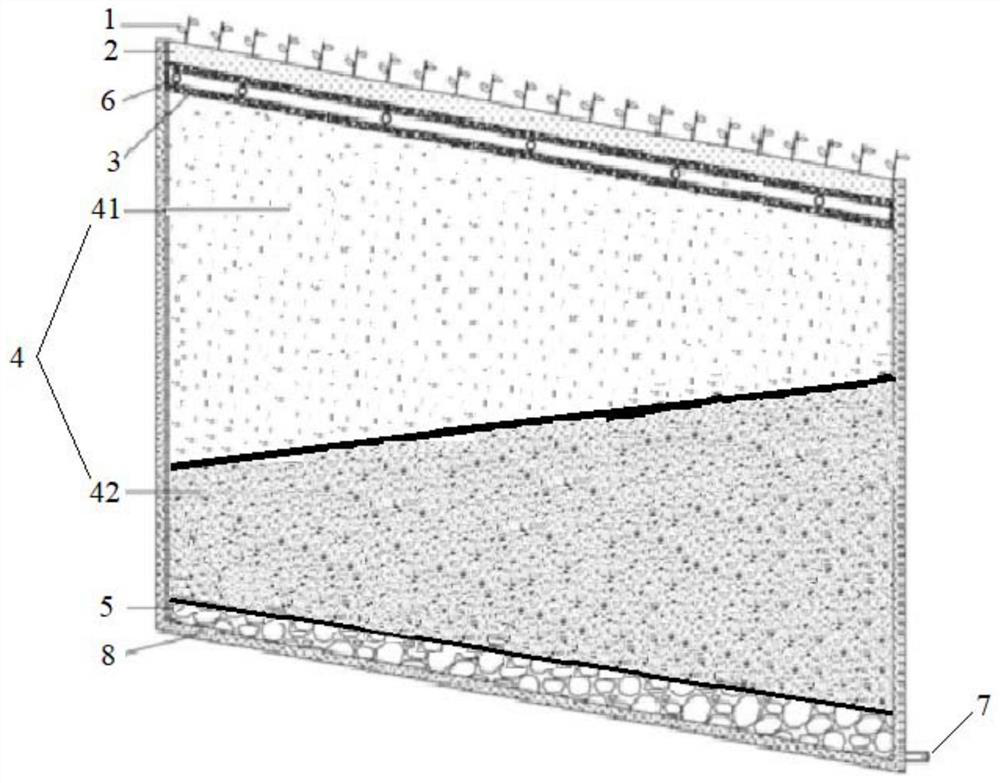

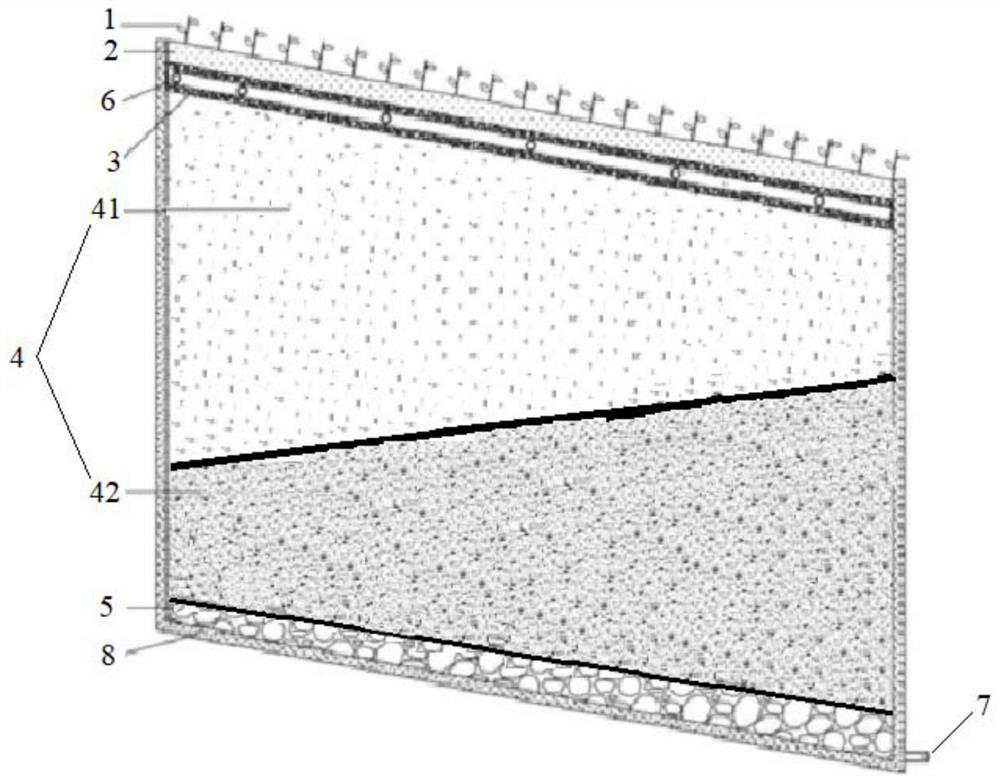

A self-flowing underground soil infiltration system without power

ActiveCN113087149BImprove the energy efficiency of treatment and purificationIncrease hydraulic retention timeTreatment with aerobic and anaerobic processesSoil scienceSmall footprint

The invention discloses an unpowered self-flowing underground soil infiltration system, which sequentially includes a planting soil layer, a water distribution layer, a soil infiltration layer and a supporting layer from top to bottom. The soil infiltration system is inclined as a whole, and the soil infiltration The filter layer includes a first soil infiltration layer and a second soil infiltration layer from top to bottom, and the first soil infiltration layer and the second soil infiltration layer are wedge-shaped structures that match each other, and the first soil infiltration The soil density of the layer is lower than that of the second soil infiltration layer; the water distribution layer is provided with a water distribution pipe, the highest part of the water distribution layer is provided with a water inlet, and the lowest part of the supporting layer is provided with a water outlet. The invention optimizes the division of redox environment and prolongs the hydraulic retention time of sewage in the system by constructing the soil infiltration layer with variable density and variable thickness, improves the system's treatment and purification energy efficiency of sewage, and reduces the occupation of the system at the same time. The floor area realizes the function of the system integrating high operating efficiency, small footprint, and no external driving force.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

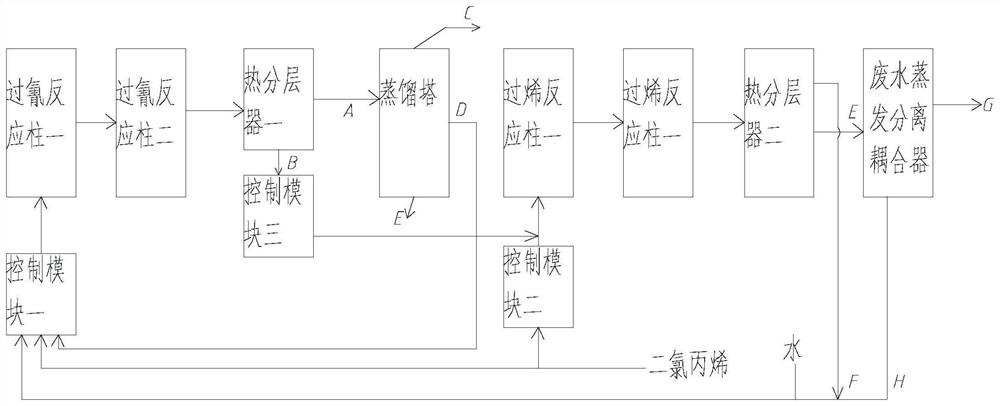

Isoester continuous production process and reactor

PendingCN114539114AImprove conversion rateIncrease profitProcess control/regulationOrganic chemistryCyanogenThiocyanic acid

The invention relates to the technical field of isoester synthesis, and provides an isoester continuous production process which comprises the following steps: S1, sequentially introducing a sodium thiocyanate aqueous solution and dichloropropene into a first cyanogen-passing reaction column, a second cyanogen-passing reaction column and a first thermal layering device for reaction to obtain a product A and a product B; s2, the product A is introduced into a distillation tower for a reaction, a product C and a product D are obtained, the product B and dichloropropene are sequentially introduced into an alkene-passing reaction column I, an alkene-passing reaction column II and a thermal layering device II for a reaction, and a product E and a product F are obtained; s3, introducing the product D and the product F into a cyanogen-passing reaction column I; s4, the product E is introduced into a wastewater evaporation separation coupler for a reaction, and a product G and a product H are obtained. Through the technical scheme, the problem of low conversion rate of sodium thiocyanate and dichloropropene in the prior art is solved.

Owner:河北野田农用化学有限公司

Filling body self-rotation stirring device and process thereof

The invention provides a self-rotating stirring device for a filling body and a process thereof, and relates to the technical field of mine equipment, and the adopted scheme is that the self-rotating stirring device comprises a cement paste pipe, a rotating stirring pipe and a gangue conveying mechanism, the rotary stirring pipe comprises a third-stage forward vortex flow channel section, a second-stage reverse vortex flow channel section and a first-stage forward vortex flow channel section which are sequentially and continuously arranged from top to bottom and are all of an arc-shaped structure, and the cement slurry inlet and the gangue particle inlet are located in the first-stage forward vortex flow channel section. The gangue particle inlet is closer to the second-stage reverse vortex flow channel section relative to the cement slurry inlet, the mixture outlet is located in the third-stage forward vortex flow channel section, and a connecting line between the center of the cement slurry inlet and the center of the mixture outlet is obliquely arranged and forms an inclination angle a with the vertical direction. The problems that an existing paste pumping filling mode is high in investment and large in occupied area, and safety accidents are easily caused due to the fact that the pressure is high during long-distance conveying of a conveying pump are solved.

Owner:XINWEN MINING GROUP

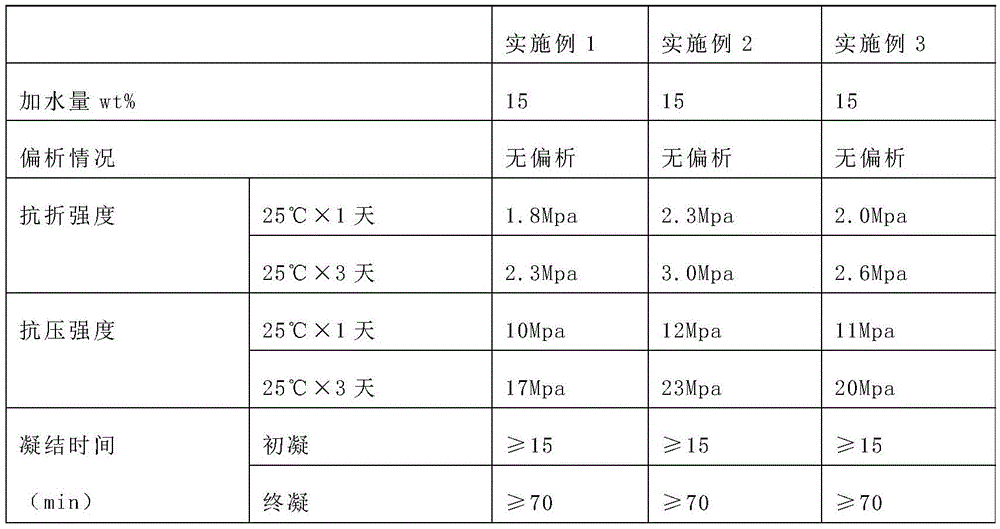

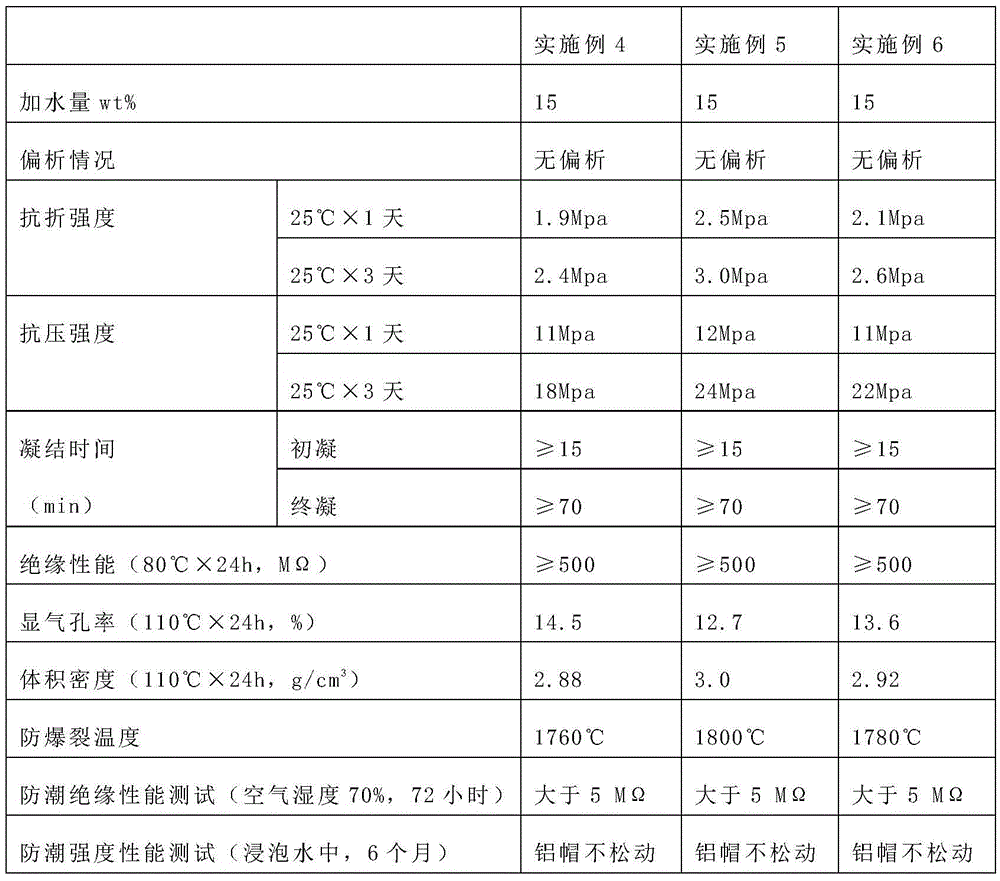

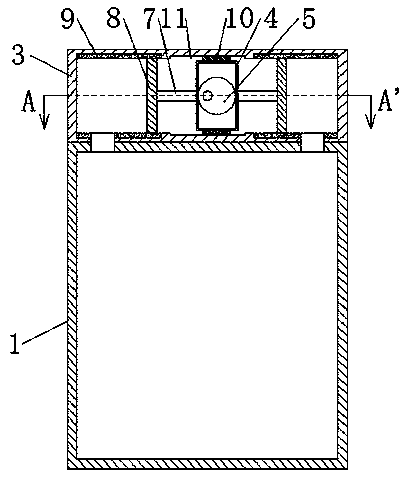

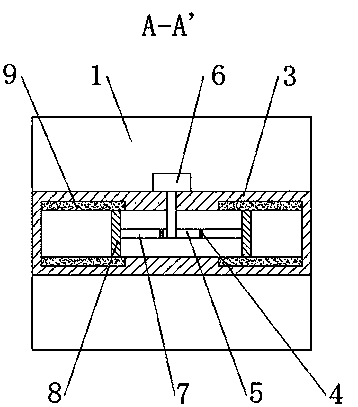

Self-leveling insulating castable for thermocouple wrapping

ActiveCN104402460BGood self-flowing filling performanceImprove insulation performanceGranularityPhosphoric acid

The invention discloses a self-levelling insulation castable for thermocouple packaging. The self-levelling insulation castable for thermocouple packaging is composed of the following components: brown corundum size sand, brown corundum fine powder, alumina powder, fused alumina cement and a water reducing agent. Through grain size distribution refinement and the like, the self-lleveling insulation castable for thermocouple packaging can realize automatic filling and filling space enriching without vibration under the circumstance of adding tap water, phosphoric acid or phosphate solution is not needed as a binding agent, and no external force is needed in the filling process to perform vibration. Tap water is directly added in the castable involved in the invention to realize even stirring, and then the evenly stirred castable is poured into the filling space needing casting. The castable can realize automatic filling and filling space enriching depending on self gravity, thereby realizing degassing levelling and densification.

Owner:北京东峰兴达耐火材料有限公司

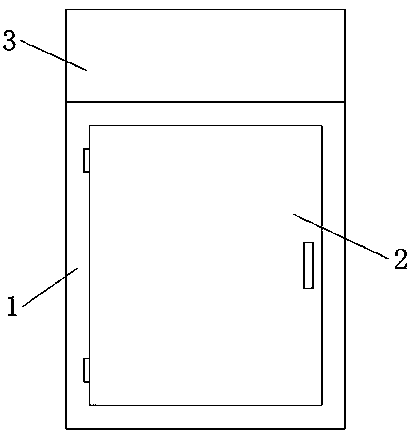

Novel switch cabinet

PendingCN110429497AReduce the temperatureSelf-flowingSubstation/switching arrangement cooling/ventilationEngineeringRefrigeration

The invention provides a novel switch cabinet. The switch cabinet comprises a switch cabinet body and a cooling component. The switch cabinet body comprises a cabinet body and a cabinet door. The cooling component is arranged in the middle of the top surface of the cabinet body; the switch cabinet comprises a box body, a transmission frame is arranged in the middle of the cavity of the box; a turntable is cooperatively mounted in the middle of the transmission frame; a mounting hole is formed in the edge of the turntable; a motor is arranged in the middle of the rear side of the box body, a motor shaft of the motor is fixedly connected with the mounting hole of the turntable, push rods are symmetrically arranged in the middles of the left and right sides of the transmission frame, pistonsare connected to the other ends of the push rods, annular refrigeration plates are symmetrically inlaid in the inner walls of the left and right ends of the box body, and the pistons are matched withinner cavities of the annular refrigeration plates. Compared with the prior art, the switch cabinet has the advantages that the cooling component is adopted, the temperature in the switch can be effectively reduced, air in the cabinet body can flow automatically, external dust entering the cabinet body is reduced, and safety is improved.

Owner:镇江市云鹏电器有限公司

Internet-based stepwise intelligent integrated rural sewage treatment system and method

ActiveCN110894128BRealize remote monitoringSelf-flowingWater treatment parameter controlTreatment involving filtrationActivated carbonWater treatment system

The invention discloses an Internet-based stepwise intelligent integrated rural sewage treatment system, which includes a filter tank, an upper water storage tank, an anaerobic tank and an MBR membrane tank connected in sequence from high to low, and the filter tank is equipped with Separation plate, the separation plate divides the filter pool into the fore pool and the back pool, and the activated carbon wrapped by the filter is filled in the fore pool, the bottom of the side wall of the upper water storage tank, the top and bottom of the side wall of the anaerobic pool, and the MBR membrane pool A hole is opened on the top of the side wall, an agitator is installed in the center of the anaerobic tank, fillers are set on the four sides of the anaerobic tank near the side walls, and an MBR membrane is installed horizontally in the center of the MBR membrane tank, and the MBR membrane is connected to the vacuum pump through a sealed pipeline. The present invention is an Internet-based stepwise intelligent integrated rural sewage treatment system. The system has significant advantages such as novel structure, integration, and intelligence. The water quality or different improvement needs have good application prospects and promotion value.

Owner:NANCHANG INST OF TECH

Series vertical aerobic and anaerobic combined underground soil infiltration system

ActiveCN113149209AGuaranteed mineralizationGood removal effectWater contaminantsTreatment with aerobic and anaerobic processesAmmoniacal nitrogenSoil science

The invention discloses a series vertical aerobic and anaerobic combined underground soil infiltration system which sequentially comprises a plant layer, a planting soil layer, a water distribution layer, a first soil infiltration layer, a first supporting layer, a second soil infiltration layer and a second supporting layer from top to bottom. A water distribution pipe is arranged in the water distribution layer, a water inlet is formed in the top of the water distribution layer, and a water outlet is formed in the bottom of the second supporting layer; a breather pipe is arranged in the first supporting layer and is communicated with external air; the water distribution layer, the first supporting layer and the second supporting layer all comprise gravel blocks or coarse sand, and the first soil infiltration layer and the second soil infiltration layer both comprise loess. During operation of the system, the characteristics of upper-layer stagnant water migration behaviors in hydrogeology are shown, sewage is subjected to distribution combination of an aerobic environment, an anaerobic environment, the aerobic environment and the anaerobic environment in the vertical seepage direction, the mineralization effect on organic nitrogen is guaranteed, the removal effect on the mineralized nitrogen is also achieved, and the ammonia nitrogen and total nitrogen removal capability is greatly improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Unpowered self-flowing type underground soil infiltration system

ActiveCN113087149AIncrease hydraulic retention timeImprove the energy efficiency of treatment and purificationTreatment with aerobic and anaerobic processesSoil scienceSewage

The invention discloses an unpowered self-flowing type underground soil infiltration system which sequentially comprises a planting soil layer, a water distribution layer, a soil infiltration layer and a supporting layer from top to bottom, the whole soil infiltration system is inclined, and the soil infiltration layer sequentially comprises a first soil infiltration layer and a second soil infiltration layer from top to bottom. The first soil percolation layer and the second soil percolation layer are of wedge-shaped structures matched with each other, and the soil density of the first soil percolation layer is lower than that of the second soil percolation layer. A water distribution pipe is arranged in the water distribution layer, a water inlet is formed in the highest position of the water distribution layer, and a water outlet is formed in the lowest position of the supporting layer. By constructing the variable-density and variable-thickness soil percolation layer, partitions of an oxidation-reduction environment are optimized, the hydraulic retention time of sewage in the system is prolonged, the sewage treatment and purification energy efficiency of the system is improved, meanwhile, the occupied area of the system is reduced, and the integrated functions of high operation efficiency, small occupied area and no external source driving force of the system are realized.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

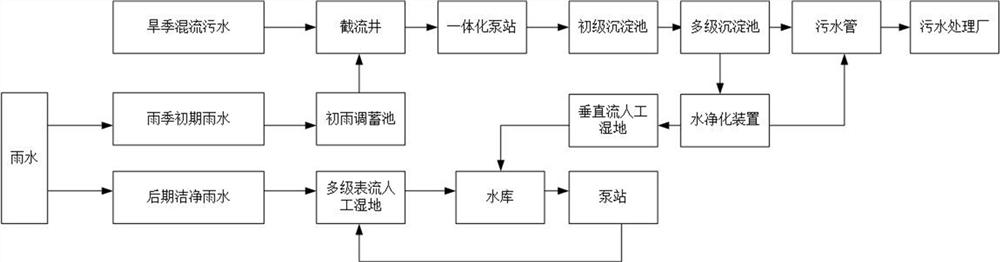

Rainwater and sewage intercepting construction process

InactiveCN112647578AThe process path is changeableSave waterFatty/oily/floating substances removal devicesSewerage structuresMixed flowSewage

The invention discloses a rainwater and sewage intercepting construction process. The rainwater and sewage intercepting construction process comprises the following steps that dry season mixed flow sewage is intercepted to an upstream sewage pipeline through an intercepting well, then is pumped into a primary sedimentation tank for sedimentation through an integrated pump, then is enabled to enter a multi-stage sedimentation tank for sedimentation, and finally, the sewage subjected to sedimentation is conveyed into a sewage treatment plant through a sewage pipe for treatment; and initial rainwater in rainy seasons is stored in an initial rainwater storage pond, then passes through the intercepting well to the upstream sewage pipeline, is pumped into the primary sedimentation tank through the integrated pump to be settled, then enters the multi-stage sedimentation tank to be settled, and finally, the settled sewage is fed into the sewage treatment plant through the sewage pipe to be treated. According to the rainwater and sewage intercepting construction process, the process path is variable, adjustment can be conducted at any time, the intercepting well can be cleaned, and the pipeline can be dredged.

Owner:中建生态环境集团有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com