Filling slurry preparation system and preparation method thereof

A technology of filling slurry and preparation system, which is applied in the direction of filling, mining equipment, earth cube drilling and mining, etc., which can solve the problems of increasing the construction area of filling stations, limited selection of filling pump locations, and increased investment in equipment foundation, so as to reduce the cost of equipment The effect of layout height, improvement of stability and safety, and reduction of construction height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

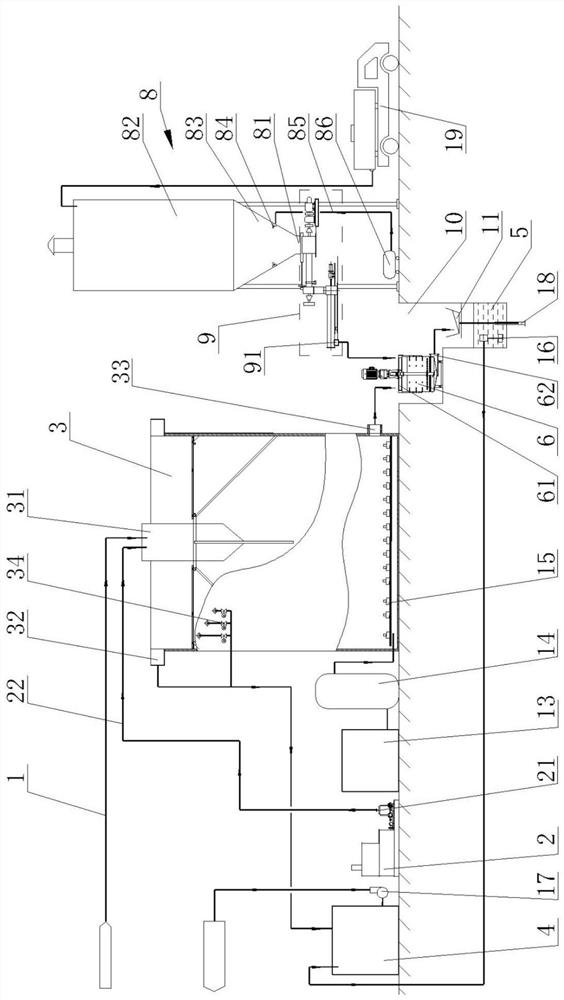

[0050] from figure 1 It can be seen that the filling slurry preparation system of the present invention includes a thickener 3 for storing and concentrating tailings mortar, a flocculant dosing machine 2 for adding flocculant to the thickener 3, and a thickener 2 for collecting and clarifying Overflow silo 4 for overflow water, accident pool 5 for collecting accident water, stirring system for preparing filling slurry, filling pump 7 for pumping filling slurry, cement silo for storing cement 8, The cement conveying and metering device 9 for quantitatively conveying cement, the hopper 11 for buffering and conveying the filling slurry, and the homogenizing slurry making device for the concentration of the slurry in the homogenizer 3, wherein the mixing system consists of a high-speed It is composed of a flexible mixer 6, and the homogenizing pulping device includes an air compressor 13, an air storage tank 14 and several nozzles 15,

[0051]Thickener 2, flocculant dosing machin...

Embodiment 2

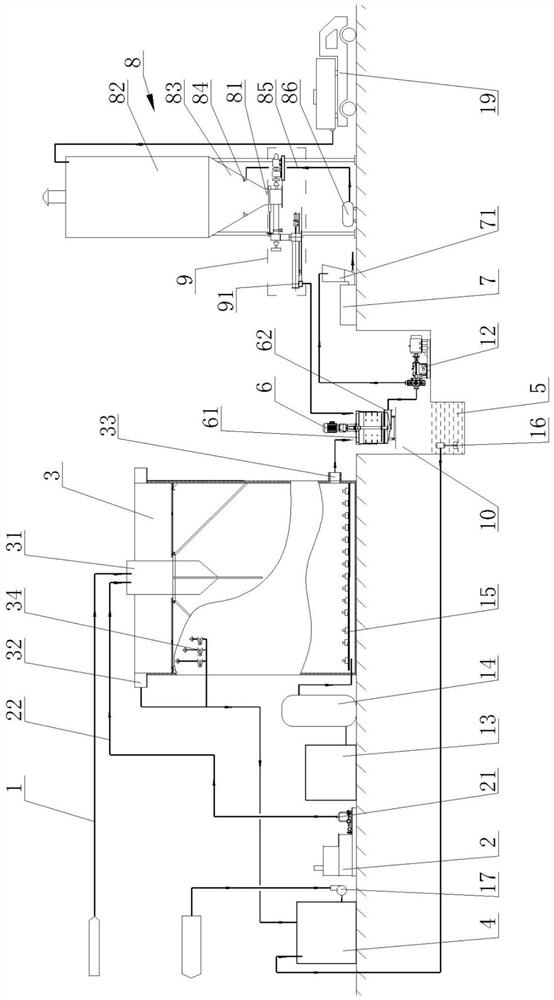

[0064] from figure 2 It can be seen that the difference between this embodiment and the first embodiment is that a thick slurry pump 12 is arranged in the pit 10 between the high-speed flexible mixer 6 and the accident pool 5, and the inlet of the thick slurry pump 12 passes through the slurry pipe and the high-speed slurry. The discharge port 62 of the flexible mixer 6 is connected, and the outlet of the thick slurry pump 12 is connected to the pump hopper 71 of the filling pump 7 through a slurry pipe.

[0065] The filling slurry preparation system in this embodiment is suitable for mines that require pump pressure transportation.

[0066] For mines conveyed by pump, the preparation method of this filling slurry of the present invention comprises the following steps:

[0067] S1. The low-concentration tailings slurry transported from the dressing plant is sent into the feed tank 31 of the thickener 3 through the tailings slurry transportation pipeline 1. At the same time, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com