Filling body self-rotation stirring device and process thereof

A stirring device and rotary stirring technology, which can be used in fillings, safety devices, mining equipment, etc., can solve the problems of safety accidents, high pressure on the occupied area and high investment, and achieve the effects of high safety, small occupied area and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

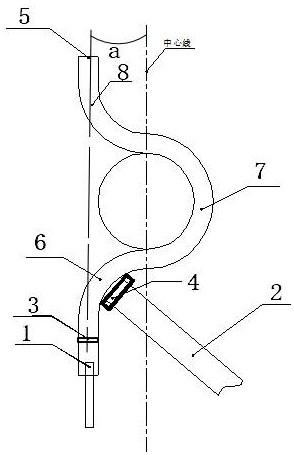

[0020] Such as figure 1 As shown, this specific embodiment provides a filling body self-rotating stirring device, including a cement slurry pipe 1, a rotating stirring pipe and a gangue conveying mechanism 2, and the rotating stirring pipe is provided with a cement slurry inlet 3, a gangue particle inlet and a mixing body outlet 5, the cement slurry pipe 1 is connected to the cement slurry inlet 3, and the feeding end 4 of the gangue conveying mechanism 2 is located at the gangue particle inlet; Vortex channel section 8, second stage reverse vortex channel section 7 and first stage forward vortex channel section 6, third stage forward vortex channel section 8, second stage reverse vortex channel section 7 and first stage forward The vortex channel sections 6 are all arc-shaped structures, and the curved orientation of the second-stage reverse vortex channel section 7 (that is, toward the left in the figure) is the same as that of the third-stage forward vortex channel section ...

specific Embodiment approach 2

[0023] This specific embodiment provides a filling body self-rotation stirring process, including the filling body self-rotation stirring device in the specific embodiment 1, and also includes the following steps:

[0024] A1: The mixture of cement and water flowing out of the cement slurry pipe 1 (referred to as cement slurry), enters the first-stage forward vortex channel section 6 through the cement slurry inlet 3, and connects with the feeding end 4 of the gangue conveying mechanism 2 The falling gangue particles are mixed, and the cement slurry and gangue particles are initially mixed through the rotation and tumbling of the clockwise cement slurry vortex in the second half of the first-stage vortex channel section 6;

[0025] A2: After preliminary mixing, pass through the second-stage reverse vortex channel section 7, and through the rotation and tumbling of the eddy current of the cement slurry in the counterclockwise direction, the cement slurry and gangue particles are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com