Crushing system for iron mine underground mill and crushing process

A technology of crushing system and mineral processing plant, which is applied in the field of magnetite mineral processing, can solve the problems of high energy consumption and complicated process, and achieve the effect of reducing energy consumption and saving land

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

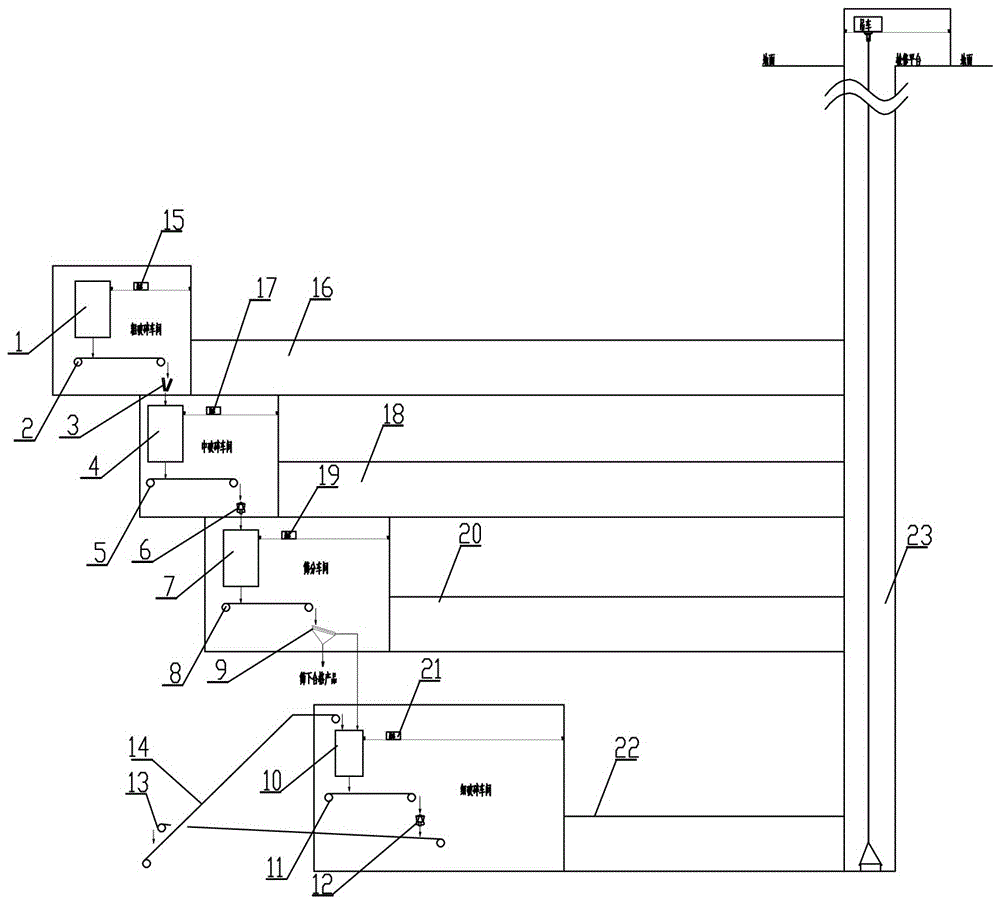

[0018] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

[0019] Such as figure 1 As shown, the crushing system of a kind of iron ore underground concentrator of the present invention is characterized in that it is mainly composed of coarse crushing workshop, medium crushing workshop, screening workshop, fine crushing workshop and maintenance system, coarse crushing workshop, medium crushing workshop, The screening workshop and the fine crushing workshop are arranged in steps from top to bottom along the vertical direction of the mining plant's transportation roadway according to the sequence of operations. The maintenance shaft 23 is set on the side of the crushing system of the iron ore underground concentrator, and the maintenance shaft is located above the ground surface The stepped arrangement is that the intermediate crushing workshop is arranged on the lower front side of the coars...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com