Slag-coal ash compound solid exciter and preparation method thereof

A production method and a technology for fly ash, which are applied in the field of concrete building materials and cement, can solve the problems of low solubility, slow dissolution rate, inconvenient use, etc., and achieve the effects of increasing the pH value, reducing the amount of cement, and enhancing the excitation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1: modulus 2.5, Baume degree 40 degrees;

Embodiment 2

[0026] Embodiment 2: modulus 2.6, Baume degree 45 degrees;

Embodiment 3

[0027] Embodiment 3: modulus 2.7, Baume degree 48 degrees.

[0028] 2) After mixing the components of the examples in the table evenly, age under vacuum for 36 hours, dry at 150°C, and grind to a specific surface area of 305-310m 2 / kg to obtain a solid powder, which is used as a finished product activator.

[0029] Performance test of slag-fly ash composite solid activator:

[0030] 1. Detection of slurry form and composition of slag-fly ash cementitious material

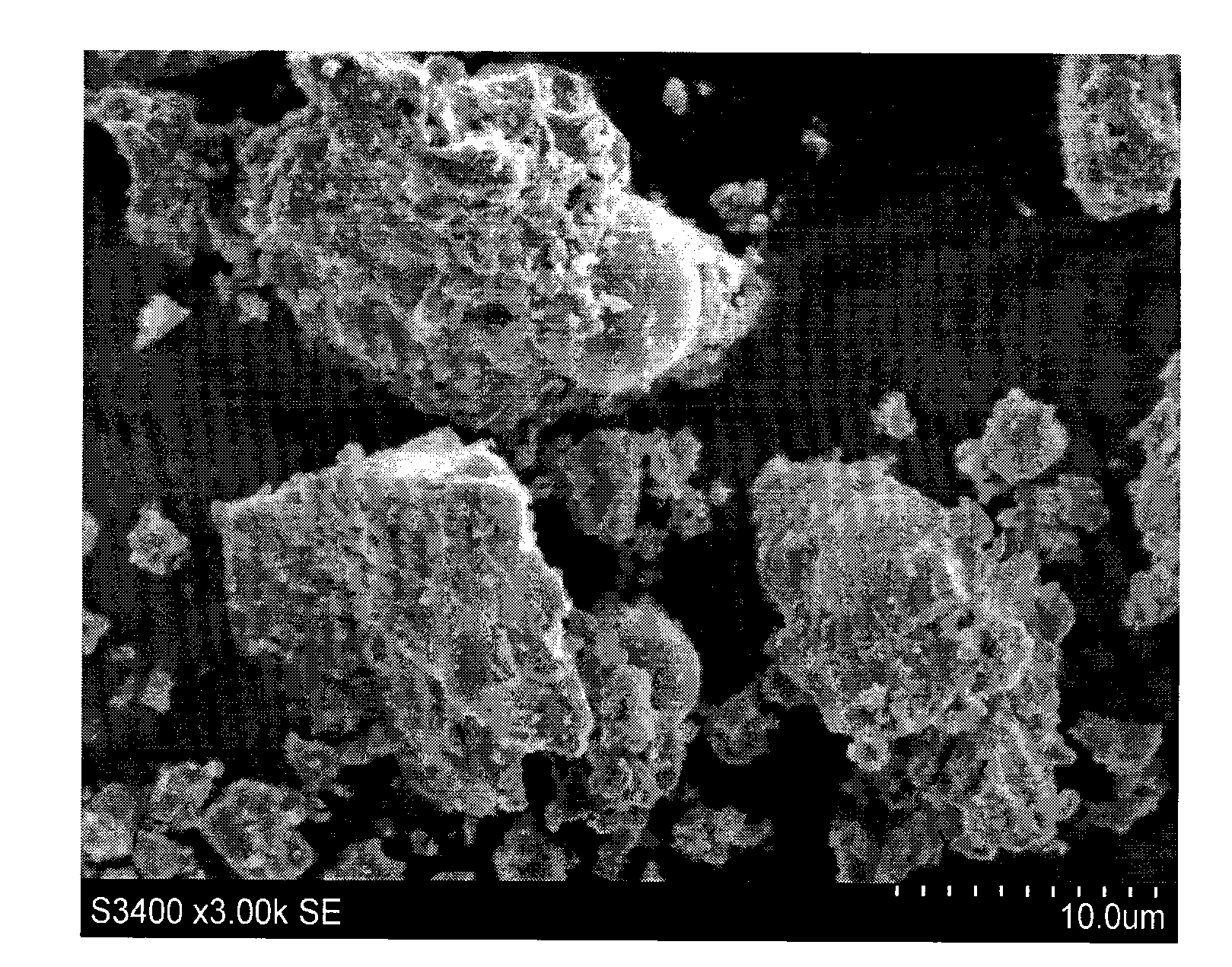

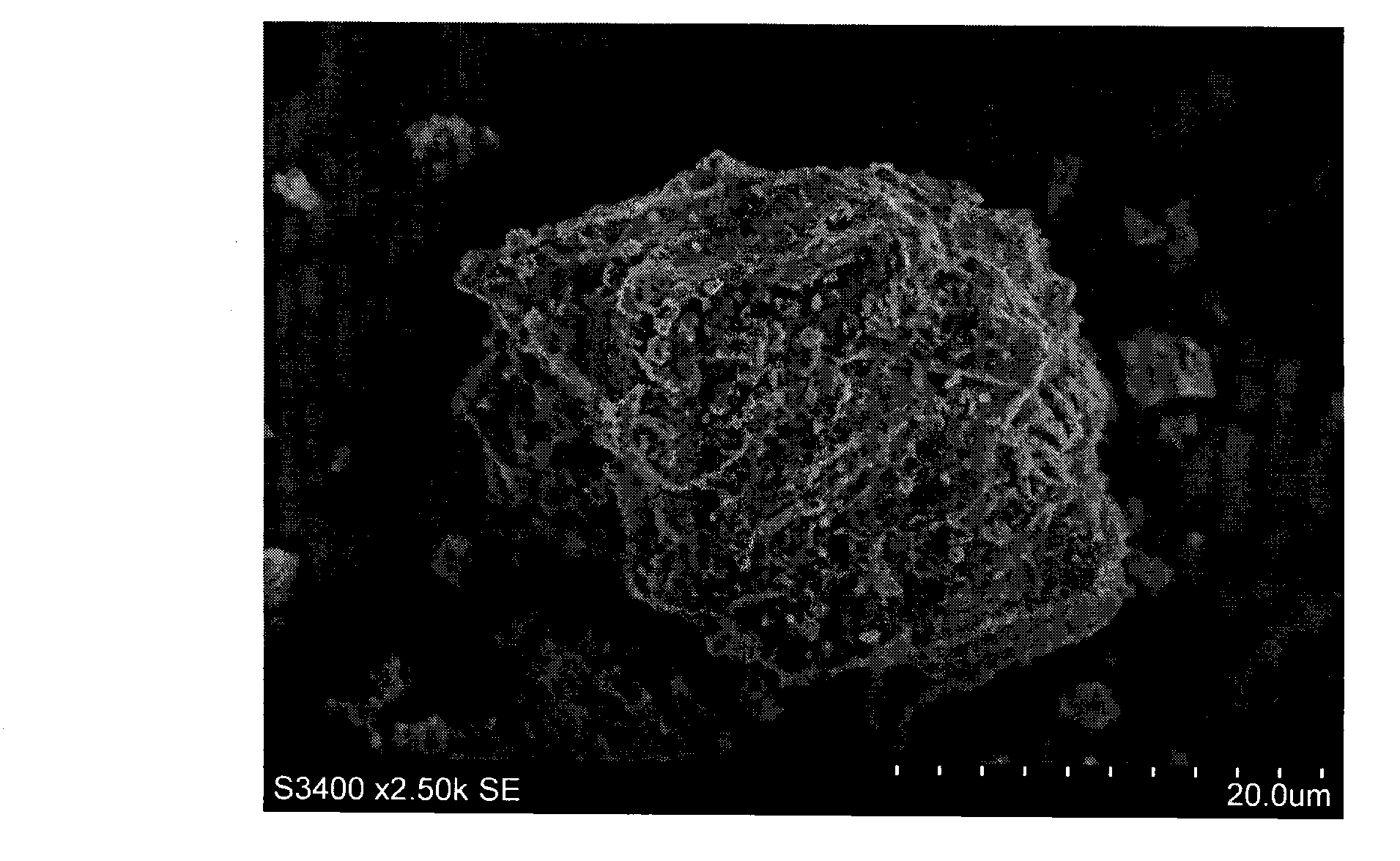

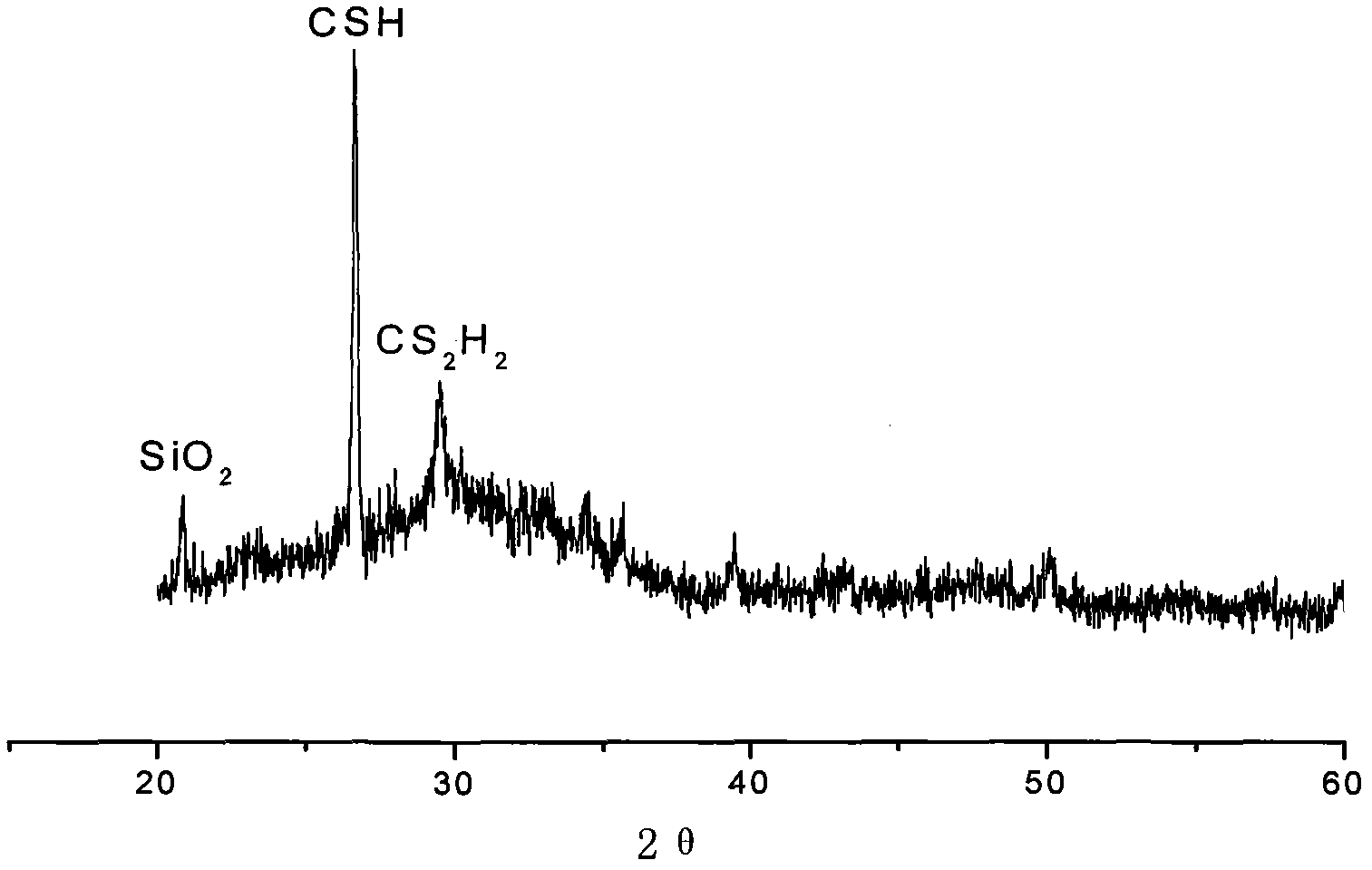

[0031] With 180g of slag powder, 120g of fly ash and 24g of the composite solid activator of the above embodiment 2, add 96g of water and mix evenly, put into the test mold, remove the mold after 1 day, transfer to the standard curing room, and make it after 3 days and 28 days. After processing, the microstructure inspection and X-ray diffraction inspection were carried out under the scanning electron microscope. See the test results figure 1 , figure 2 , image 3 and Figure 4 . figure 1 , figure 2 It...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com