Sleeve grouting material for low-temperature steel bar connection and using method thereof

A sleeve grouting, low temperature technology, which is applied in the field of cement-based building materials and prefabricated building materials, can solve the problems that cannot meet construction requirements, cannot be used for ultra-low temperature steel bar connection sleeves, etc., so as to avoid the loss of grouting material strength. , to ensure the quality of construction, to ensure the effect of liquidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

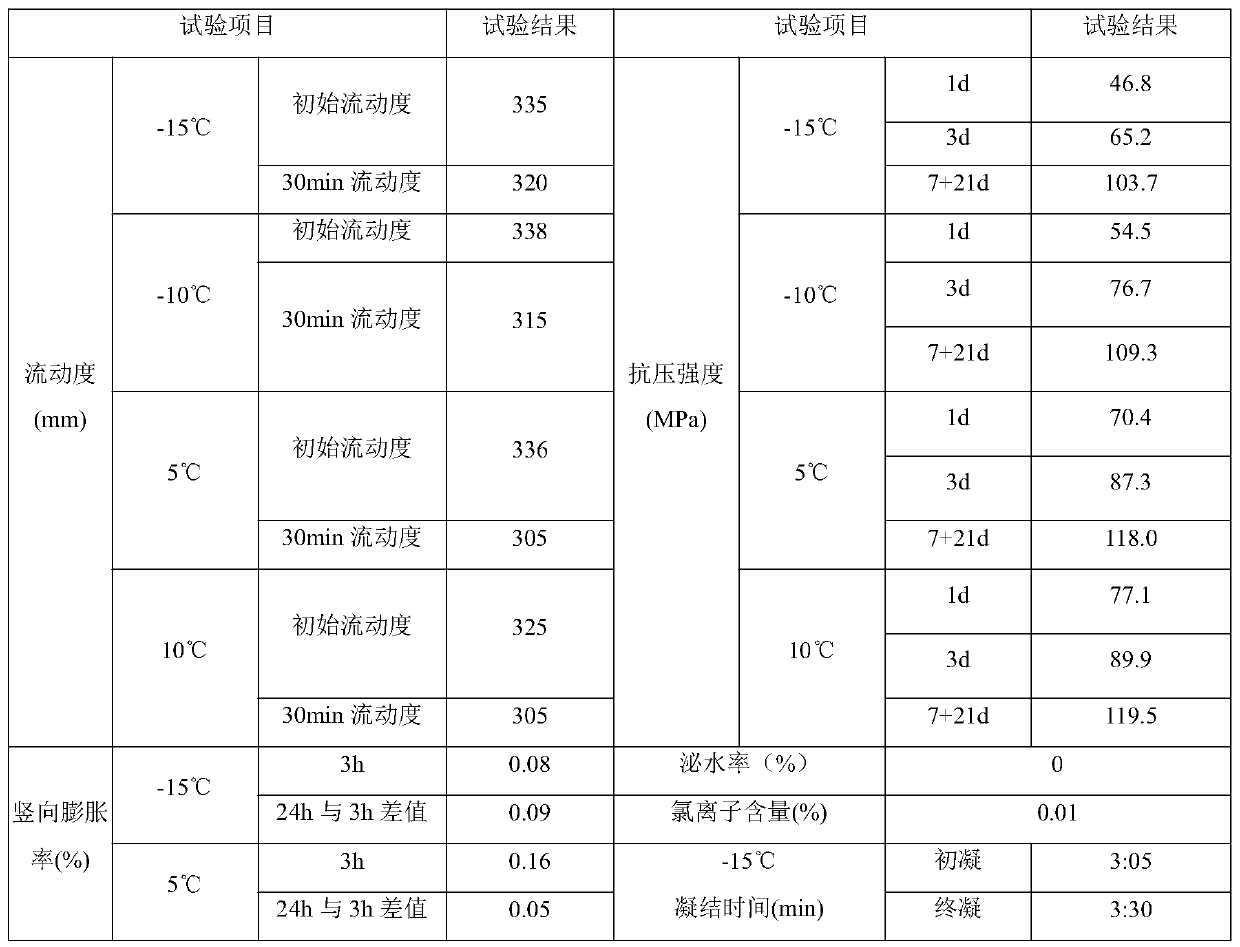

Embodiment 1

[0046] 25 parts of fast setting rapid hardening high belite sulfoaluminate cement;

[0047] Portland cement 23 parts;

[0048] 3 parts of ultra-high strength sulfoaluminate cement;

[0049] 0.7 parts of gypsum;

[0050] 2 parts of superfine fly ash;

[0051] 45 parts of aggregate;

[0052] 0.3 parts of nanocrystalline core;

[0053] 0.5 parts of sodium nitrite;

[0054] 0.2 parts of powder polycarboxylate high-performance water reducer;

[0055] 0.08 part of polyether defoamer;

[0056] 0.11 parts of expansion agent, including 0.1 part of HCSA expansion agent and 0.01 part of plastic expansion agent;

[0057] 0.001 parts of cellulose ether, the viscosity is 400mPa·s;

[0058] Viscosity reducer 0.15 parts;

[0059] Mix the above-mentioned raw materials in proportion to prepare the sleeve grouting material for low-temperature steel bar connection, mix it with a mixer with 12% water consumption, and put it aside for 2 minutes to defoam before construction and application...

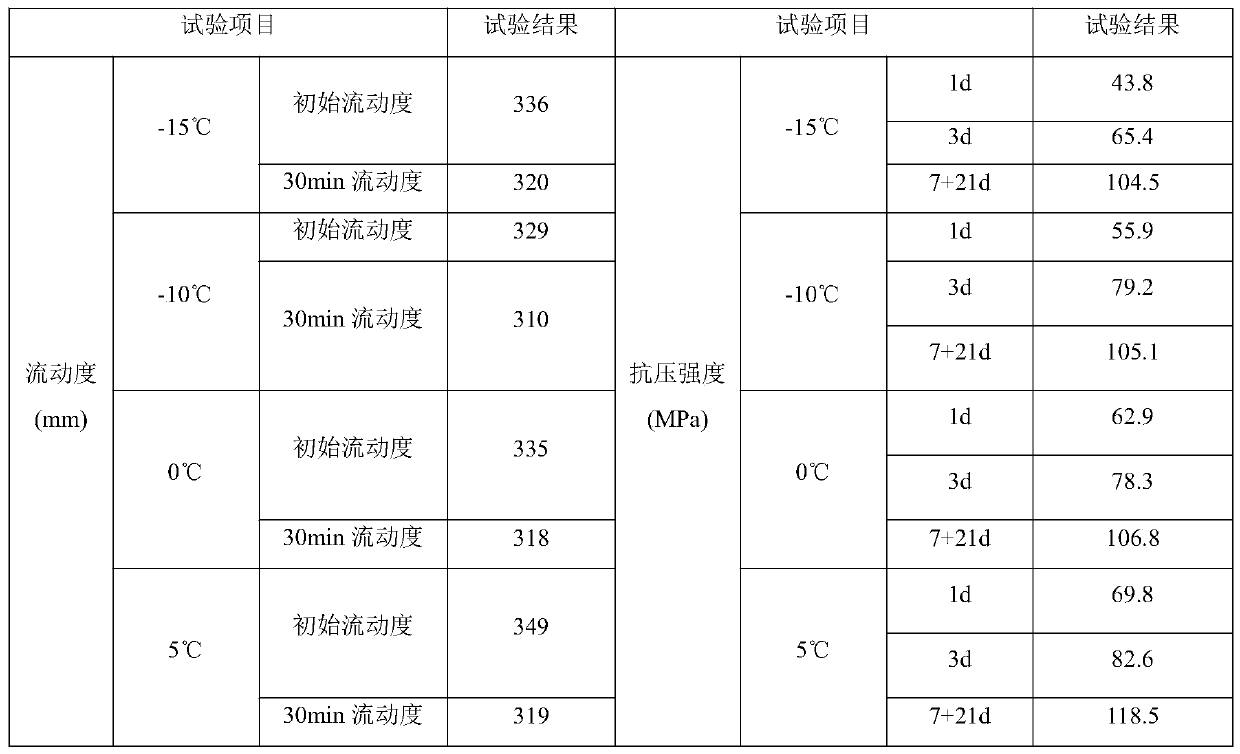

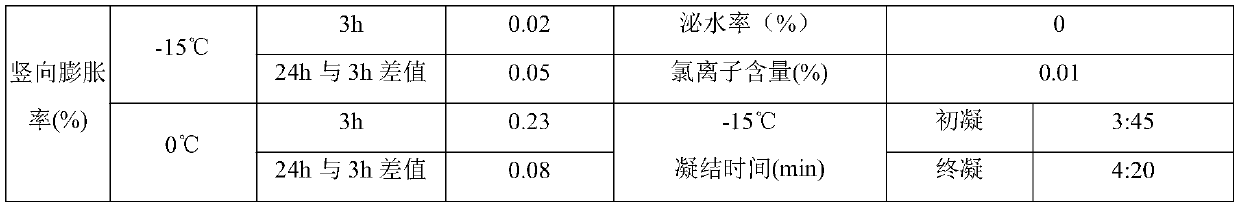

Embodiment 2

[0064] 30 parts of fast setting rapid hardening high belite sulfoaluminate cement;

[0065] Portland cement 15 parts;

[0066] 5 parts of ultra-high strength sulfoaluminate cement;

[0067] 1.4 parts of gypsum;

[0068] 5 parts of silica fume;

[0069] 40 parts of aggregate;

[0070] 1.0 parts of nanocrystalline core;

[0071] 1.5 parts of sodium nitrite;

[0072] 0.48 parts of powder polycarboxylate high-performance water reducer;

[0073] 0.09 part of polyether defoamer;

[0074] 0.13 parts of expansion agent, including 0.1 part of HCSA expansion agent and 0.03 part of plastic expansion agent;

[0075] 0.001 parts of cellulose ether, the viscosity is 400mPa·s;

[0076] 0.4 parts of viscosity reducer;

[0077] Mix the above-mentioned raw materials in proportion to prepare the sleeve grouting material for low-temperature steel bar connection, mix it with a mixer with 11% water consumption, and put it aside for 2 minutes to defoam before construction and application. ...

Embodiment 3

[0083] 20 parts of fast setting rapid hardening high belite sulfoaluminate cement;

[0084] Portland cement 30 parts;

[0085] 0.5 parts of ultra-high strength sulfoaluminate cement;

[0086] 0.1 parts of gypsum;

[0087] 3.6 parts of superfine fly ash;

[0088] 45 parts of aggregate;

[0089] 0.1 part of nanocrystalline core;

[0090] Calcium nitrite 0.2 parts;

[0091] 0.3 parts of powder polycarboxylate high-performance water reducer;

[0092] 0.03 part of polyether defoamer;

[0093] 0.11 parts of expansion agent, including 0.1 part of HCSA expansion agent and 0.01 part of plastic expansion agent;

[0094] 0.001 parts of cellulose ether, the viscosity is 400mPa·s;

[0095] Viscosity reducer 0.1 part;

[0096] Mix the above-mentioned raw materials in proportion to prepare the sleeve grouting material for low-temperature steel bar connection, mix it with a mixer with 11% water consumption, and put it aside for 2 minutes to defoam before construction and application....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com