Recess backfill material

A technology for empty grooves and stones, which is applied in the field of backfilling materials for empty grooves to achieve the effect of reducing the amount of cement, satisfying stability, and ensuring stability and safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

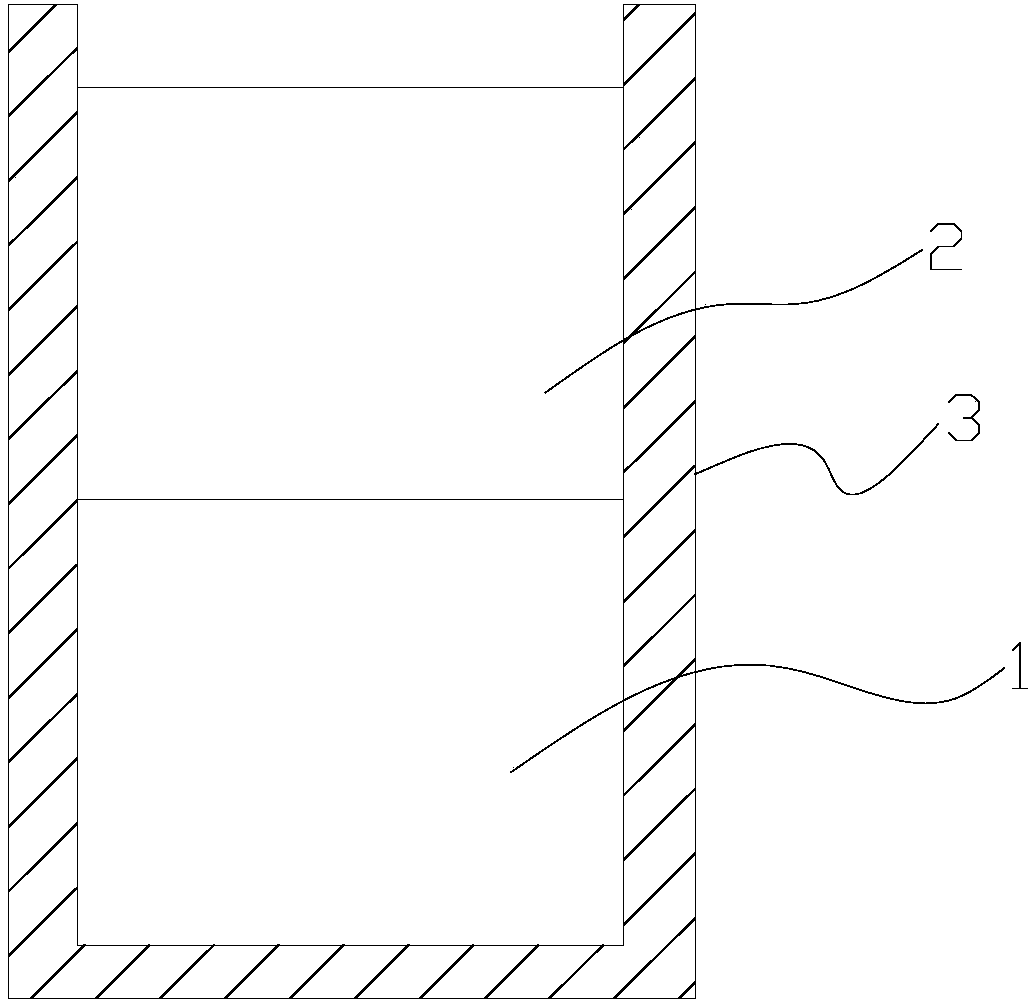

Image

Examples

Embodiment 1

[0018] A foundation pit partition wall void backfill material, which includes water 210kg / m3; fly ash 210kg / m3; sand 890kg / m3; gravel 992kg / m3; admixture 7kg / m3. Mix the raw materials with a mixer until smooth. The particle size of the sand is less than 5mm, and the particle size of the stone is 5mm to 40mm. The additive is a water reducer.

Embodiment 2

[0020] A foundation pit partition wall void backfill material, which includes water 200kg / m3; fly ash 255kg / m3; sand 900kg / m3; gravel 945kg / m3; admixture 9kg / m3. Mix the raw materials with a mixer until smooth. The particle size of the sand is less than 5mm, and the particle size of the stone is 5mm to 40mm. The admixture is a flocculant.

Embodiment 3

[0022] A foundation pit partition wall backfill material, which includes water 190kg / m3; fly ash 300kg / m3; sand 910kg / m3; stones 900kg / m3; admixture 9kg / m3. Mix the raw materials with a mixer until smooth. The particle size of the sand is less than 5mm, and the particle size of the stone is 5mm to 40mm. The additive is a water reducer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com