A kind of sleeve grouting material for low-temperature steel bar connection and its application method

A sleeve grouting and low-temperature type technology, which is applied in the field of cement-based building materials and prefabricated building materials, can solve the problems that the ultra-low temperature type steel bar connection sleeve cannot be used and cannot meet the construction requirements, so as to ensure the construction quality and early The effect of high strength and later strength growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

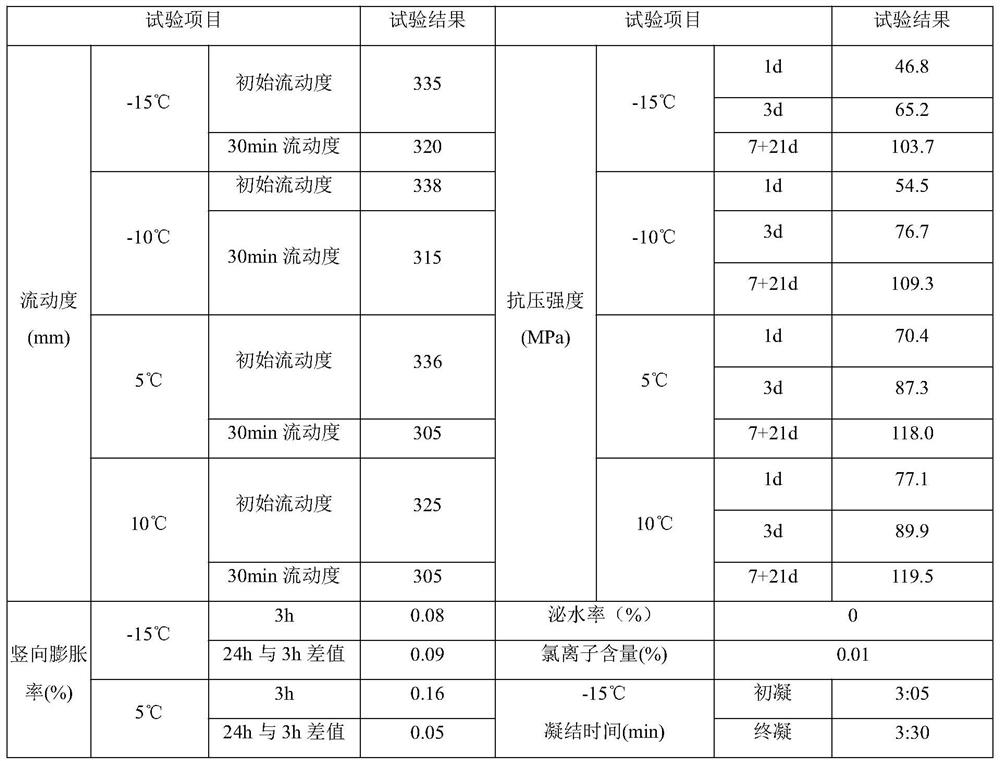

Embodiment 1

[0046] 25 parts of fast setting rapid hardening high belite sulfoaluminate cement;

[0047] Portland cement 23 parts;

[0048] 3 parts of ultra-high strength sulfoaluminate cement;

[0049] 0.7 parts of gypsum;

[0050] 2 parts of superfine fly ash;

[0051] 45 parts of aggregate;

[0052] 0.3 parts of nanocrystalline core;

[0053] 0.5 parts of sodium nitrite;

[0054] 0.2 parts of powder polycarboxylate high-performance water reducer;

[0055] 0.08 part of polyether defoamer;

[0056] 0.11 parts of expansion agent, including 0.1 part of HCSA expansion agent and 0.01 part of plastic expansion agent;

[0057] 0.001 parts of cellulose ether, the viscosity is 400mPa·s;

[0058] Viscosity reducer 0.15 parts;

[0059] Mix the above-mentioned raw materials in proportion to prepare the sleeve grouting material for low-temperature steel bar connection, mix it with a mixer with 12% water consumption, and put it aside for 2 minutes to defoam before construction and application...

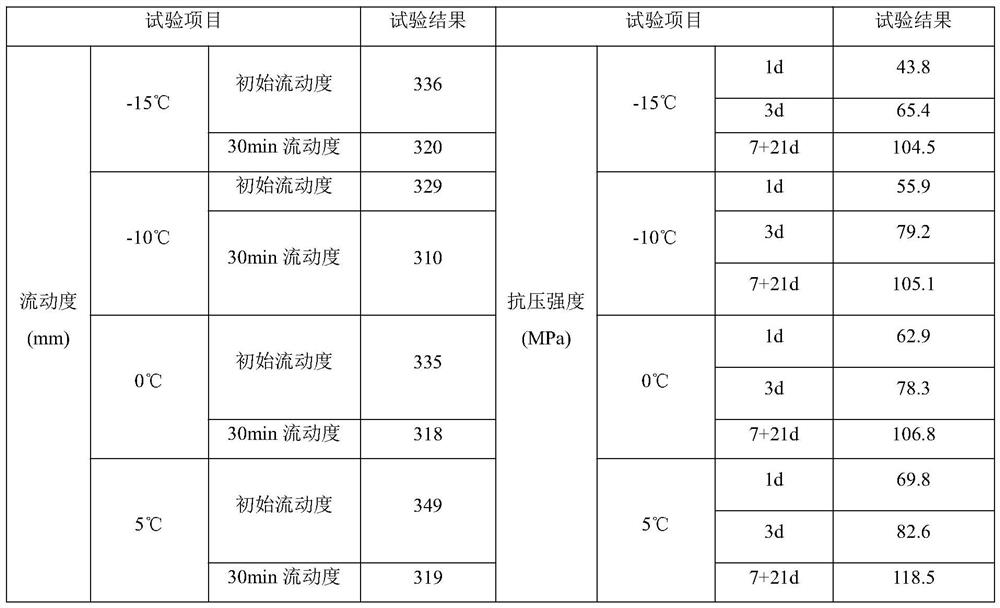

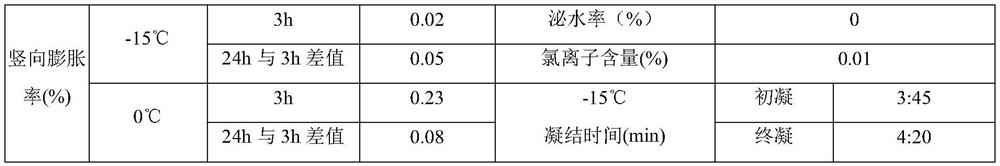

Embodiment 2

[0064] 30 parts of fast setting rapid hardening high belite sulfoaluminate cement;

[0065] Portland cement 15 parts;

[0066] 5 parts of ultra-high strength sulfoaluminate cement;

[0067] 1.4 parts of gypsum;

[0068] 5 parts of silica fume;

[0069] 40 parts of aggregate;

[0070] 1.0 parts of nanocrystalline core;

[0071] 1.5 parts of sodium nitrite;

[0072] 0.48 parts of powder polycarboxylate high-performance water reducer;

[0073] 0.09 part of polyether defoamer;

[0074] 0.13 parts of expansion agent, including 0.1 part of HCSA expansion agent and 0.03 part of plastic expansion agent;

[0075] 0.001 parts of cellulose ether, the viscosity is 400mPa·s;

[0076] 0.4 parts of viscosity reducer;

[0077] Mix the above-mentioned raw materials in proportion to prepare the sleeve grouting material for low-temperature steel bar connection, mix it with a mixer with 11% water consumption, and put it aside for 2 minutes to defoam before construction and application. ...

Embodiment 3

[0083] 20 parts of fast setting rapid hardening high belite sulfoaluminate cement;

[0084] Portland cement 30 parts;

[0085] 0.5 parts of ultra-high strength sulfoaluminate cement;

[0086] 0.1 parts of gypsum;

[0087] 3.6 parts of superfine fly ash;

[0088] 45 parts of aggregate;

[0089] 0.1 part of nanocrystalline core;

[0090] Calcium nitrite 0.2 parts;

[0091] 0.3 parts of powder polycarboxylate high-performance water reducer;

[0092] 0.03 part of polyether defoamer;

[0093] 0.11 parts of expansion agent, including 0.1 part of HCSA expansion agent and 0.01 part of plastic expansion agent;

[0094] 0.001 parts of cellulose ether, the viscosity is 400mPa·s;

[0095] Viscosity reducer 0.1 part;

[0096] Mix the above-mentioned raw materials in proportion to prepare the sleeve grouting material for low-temperature steel bar connection, mix it with a mixer with 11% water consumption, and put it aside for 2 minutes to defoam before construction and application....

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com