Geopolymer foamed light aggregate concrete and preparation method thereof

A lightweight aggregate concrete and geopolymer technology, which is applied in ceramic products, other household utensils, cement production, etc., can solve the problems of strength decrease, foamed cement solidification too fast, shape bubbles and bubbles difficult to grow, and achieve Fast setting and hardening speed, controllable construction process, and the effect of reducing CO2 emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

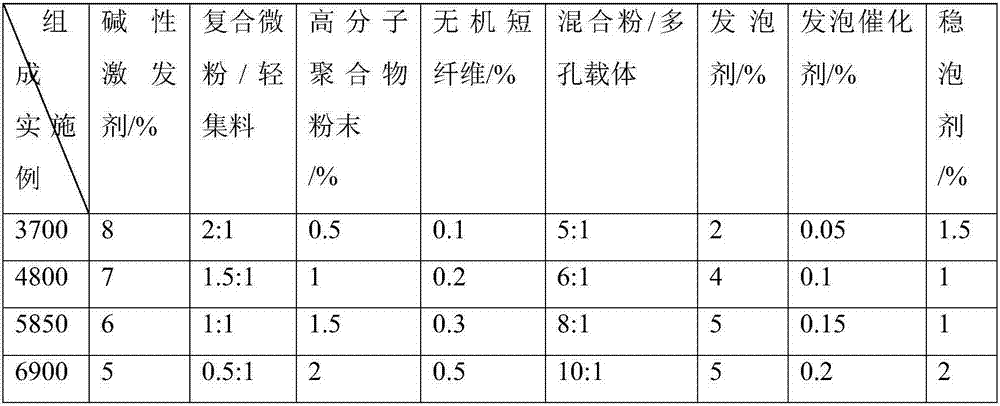

Embodiment 1

[0038] This embodiment provides a kind of geopolymer foamed lightweight aggregate concrete, which is composed of slag-fly ash composite micropowder, alkaline activator, inorganic ultra-light aggregate, high molecular polymer powder, inorganic short fiber, hydrogen peroxide chemical It consists of foaming agent, foaming catalyst, inorganic porous carrier and foam stabilizer.

[0039] In the composition of the above materials: the alkaline activator accounts for 6% of the mass of the slag powder-coal ash composite micropowder; the mass ratio of the slag-fly ash composite micropowder to the inorganic ultra-light aggregate is 1:1; - 0.1% of the mass of the fly ash composite micropowder; inorganic short fibers account for 0.1% of the mass of the slag-fly ash composite micropowder; hydrogen peroxide chemical foaming agent accounts for 2% of the mass of the slag-fly ash composite micropowder; chemical foaming The foaming catalyst of the agent accounts for 0.05% of the mass of the sla...

Embodiment 2

[0059] This embodiment provides a kind of geopolymer foamed lightweight aggregate concrete, which is composed of slag-fly ash composite micropowder, alkaline activator, inorganic ultra-light aggregate, high molecular polymer powder, inorganic short fiber, hydrogen peroxide chemical It consists of foaming agent, foaming catalyst, inorganic porous carrier and foam stabilizer.

[0060] In the composition of the above materials: the alkaline activator accounts for 8% of the mass of the slag-fly ash composite micropowder; the mass ratio of the slag micropowder to the inorganic ultra-light aggregate is 1:0.8; 0.1% of the mass of the micropowder; short inorganic fibers account for 0.1% of the mass of the slag-fly ash composite micropowder; the hydrogen peroxide chemical foaming agent accounts for 2% of the mass of the slag-fly ash composite micropowder; the foaming catalyst of the chemical blowing agent It accounts for 0.05% of the mass of slag-fly ash composite micropowder; the foam...

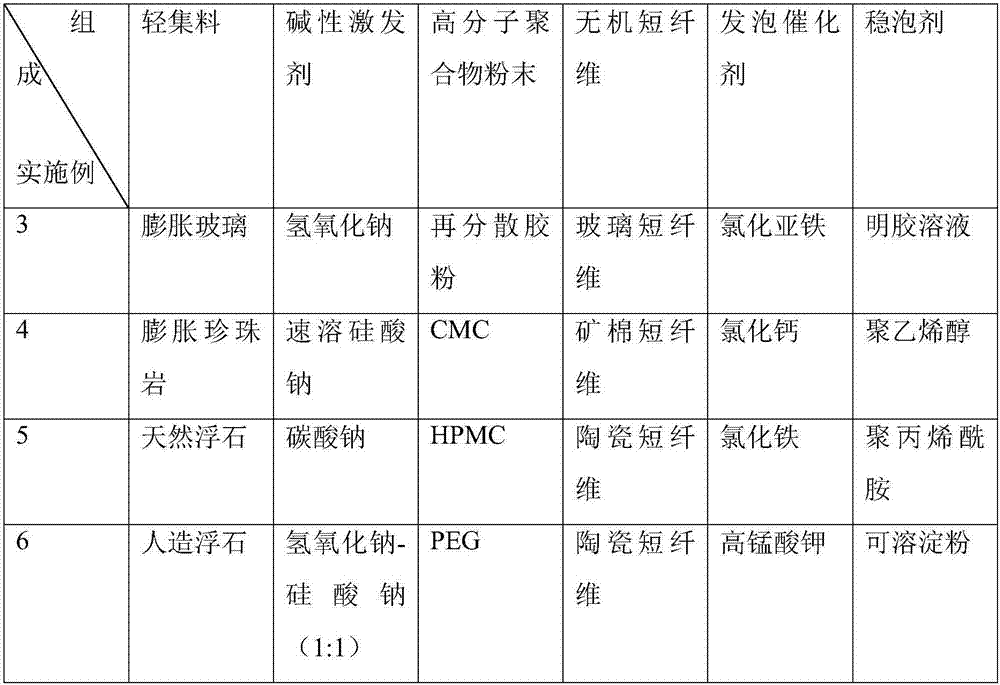

Embodiment 3

[0080] The foamed light aggregate geopolymer concrete smear material obtained in Example 3 can be directly applied on the outer side of the kiln wall and the outer side of the high-temperature gas delivery metal pipeline to be heat-insulated to form a heat-insulation coating with a thickness of 10-50mm, The cementitious material is scraped and smoothed before final setting, and finally hardened into a lightweight inorganic insulation shell with high temperature resistance, heat insulation, waterproof and corrosion resistance, with a dry weight of 350kg / m3, and its thermal conductivity at 700°C is less than 0.1W / (Km), the foamed lightweight aggregate concrete layer is not easy to crack, never falls off and has a consistent lifespan for the insulation structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com