Coal gasification coarse slag non-fired material and preparation method thereof

A technology of coal gasification and coarse slag, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems of high energy consumption, low utilization rate of raw materials, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

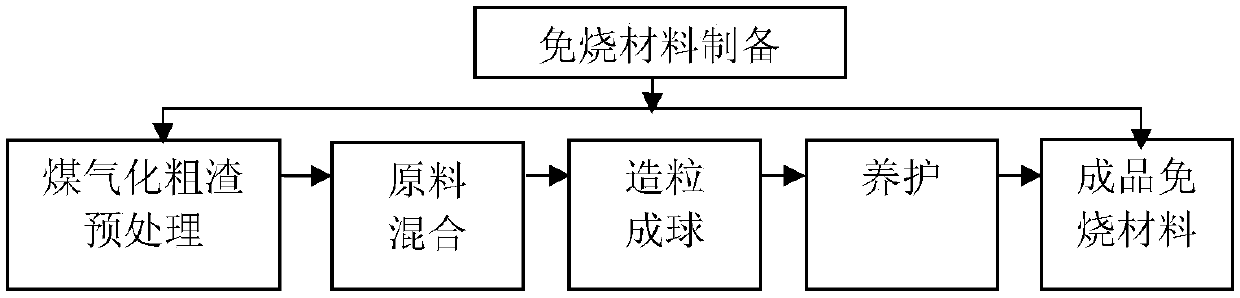

[0063]The present invention also provides a method for preparing the above-mentioned non-burning material, comprising: S) mixing 63-75 parts by weight of coal gasification coarse slag, 15-25 parts by weight of cement and 10-12 parts by weight of quartz sand with water , curing after molding to obtain non-burning materials; the mass ratio of the coal gasification coarse slag to cement is (4-5):1 or (2-2.52):1.

[0064] Wherein, the coal gasification coarse slag, cement and quartz sand are all the same as above, and will not be repeated here.

[0065] According to the present invention, the particle size of the coal gasification coarse slag is preferably 60 mesh or less; the raw material of the coal gasification coarse slag is preferably dried first, pulverized and then sieved to obtain the coal gasification coarse slag; the drying temperature is preferably 100°C to 120°C, more preferably 100°C to 110°C, and more preferably 105°C; the drying time is preferably 1 to 3 hours, more...

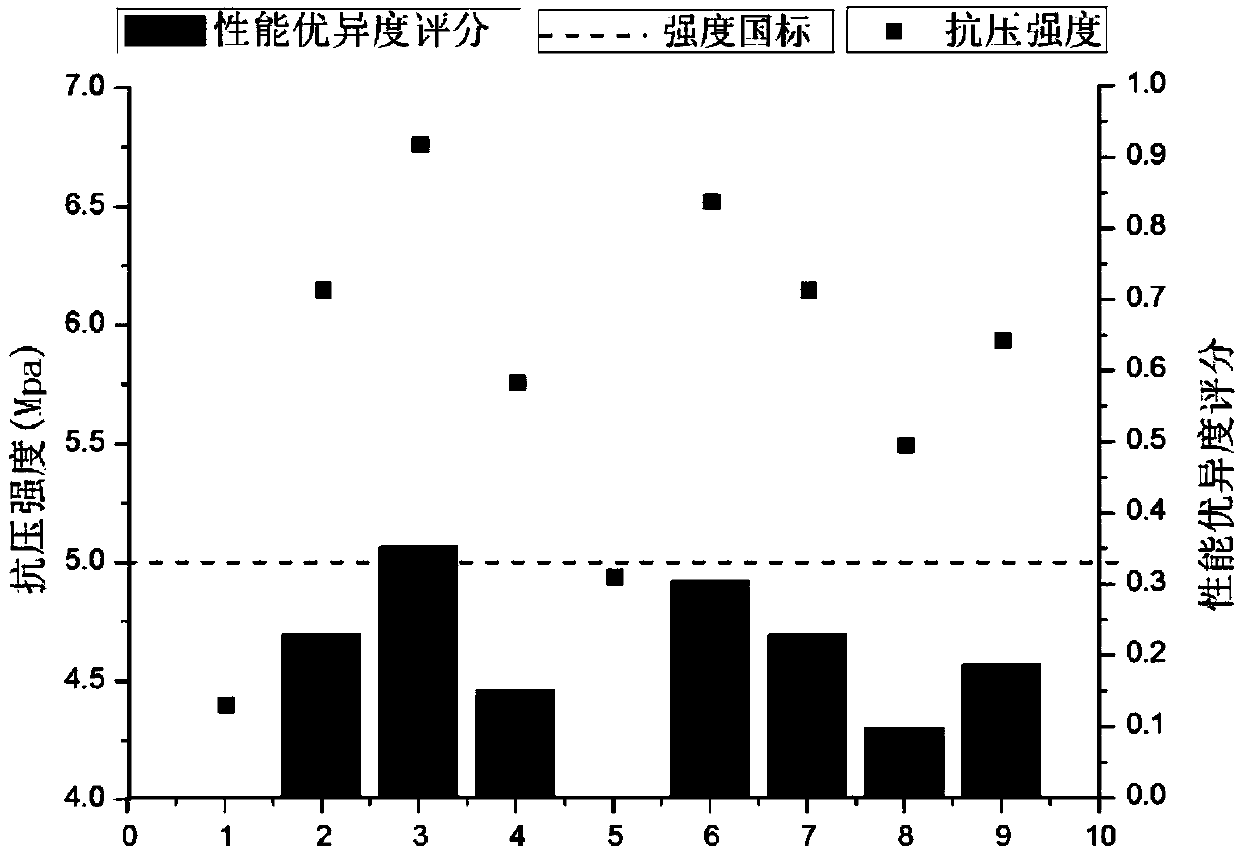

Embodiment 1~7 and comparative example 1~2

[0083] Raw material pretreatment: put the coal gasification coarse slag in an oven at 105°C for 2 hours to make it completely dry; then use a grinder to crush the dried coarse slag raw material for 2 minutes to grind the coarse slag finely; then use a 60-mesh sieve to sieve, The dry and finely ground coal cinder under the sieve was used as the test raw material, and then the coal gasification coarse slag raw material was dissolved in 32% (relative to the dry material) of 5% NaOH solution, stirred for 5 min and then filtered, and the filter residue on the filter paper was dried. as test material;

[0084] Cement can be directly used in the test without treatment;

[0085] Dry the quartz sand and crush it, then sieve the crushed quartz sand with a 60-mesh sieve, and take the dry and fine quartz sand powder as the test auxiliary material.

[0086] Mixing of raw materials: the pretreated raw materials, according to the proportioning in Table 3 (experimental group 1 is comparative...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com