Deep groove processing method

A processing method and deep groove technology, which are used in metal processing equipment, manufacturing tools, attachment devices of sawing machines, etc., can solve the problems of difficult clamping processing, inability to carry out, and inability to accurately control the processing depth, and achieve high production efficiency. The structure is simple and compact, and has the effect of industrial utilization value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

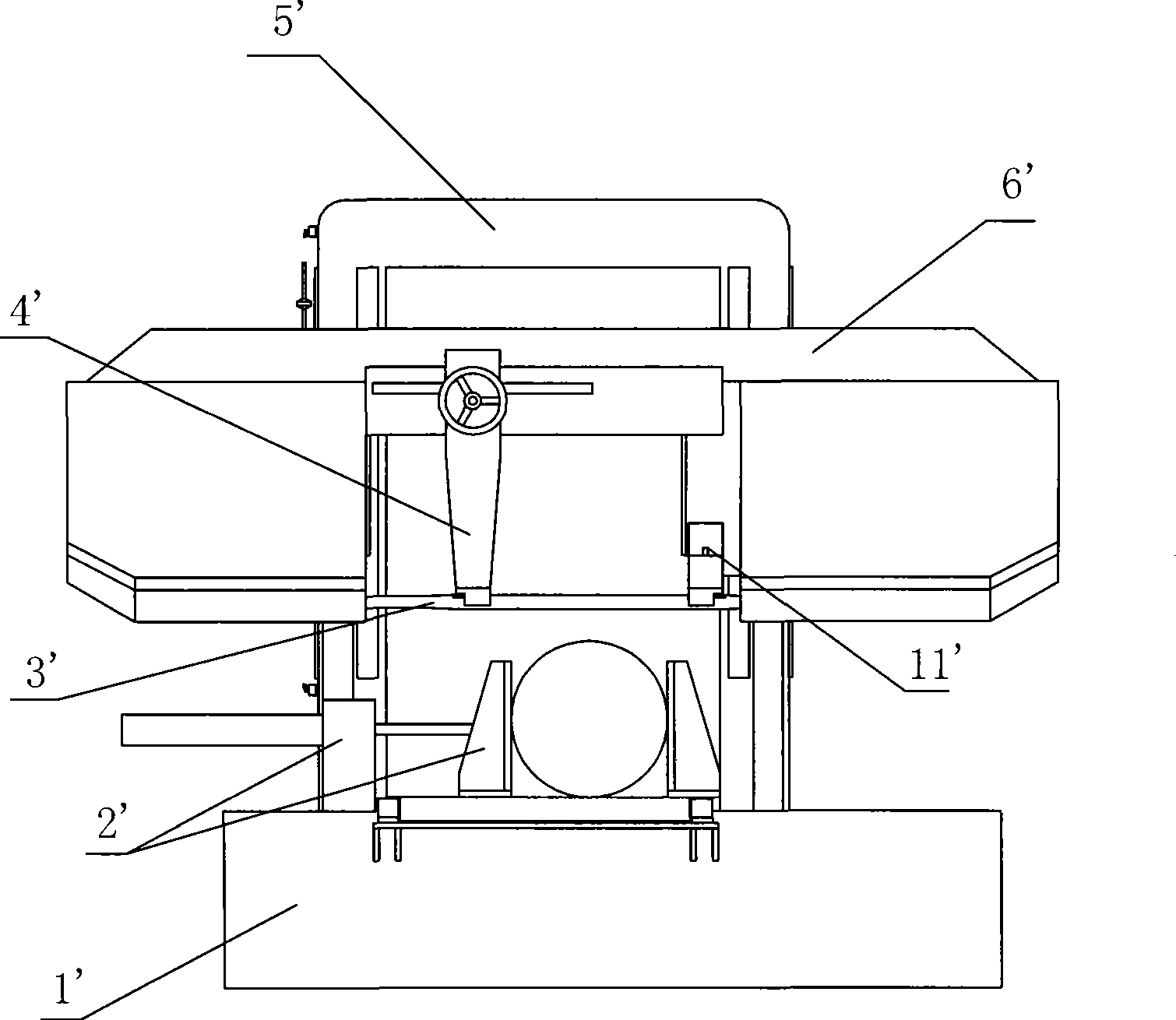

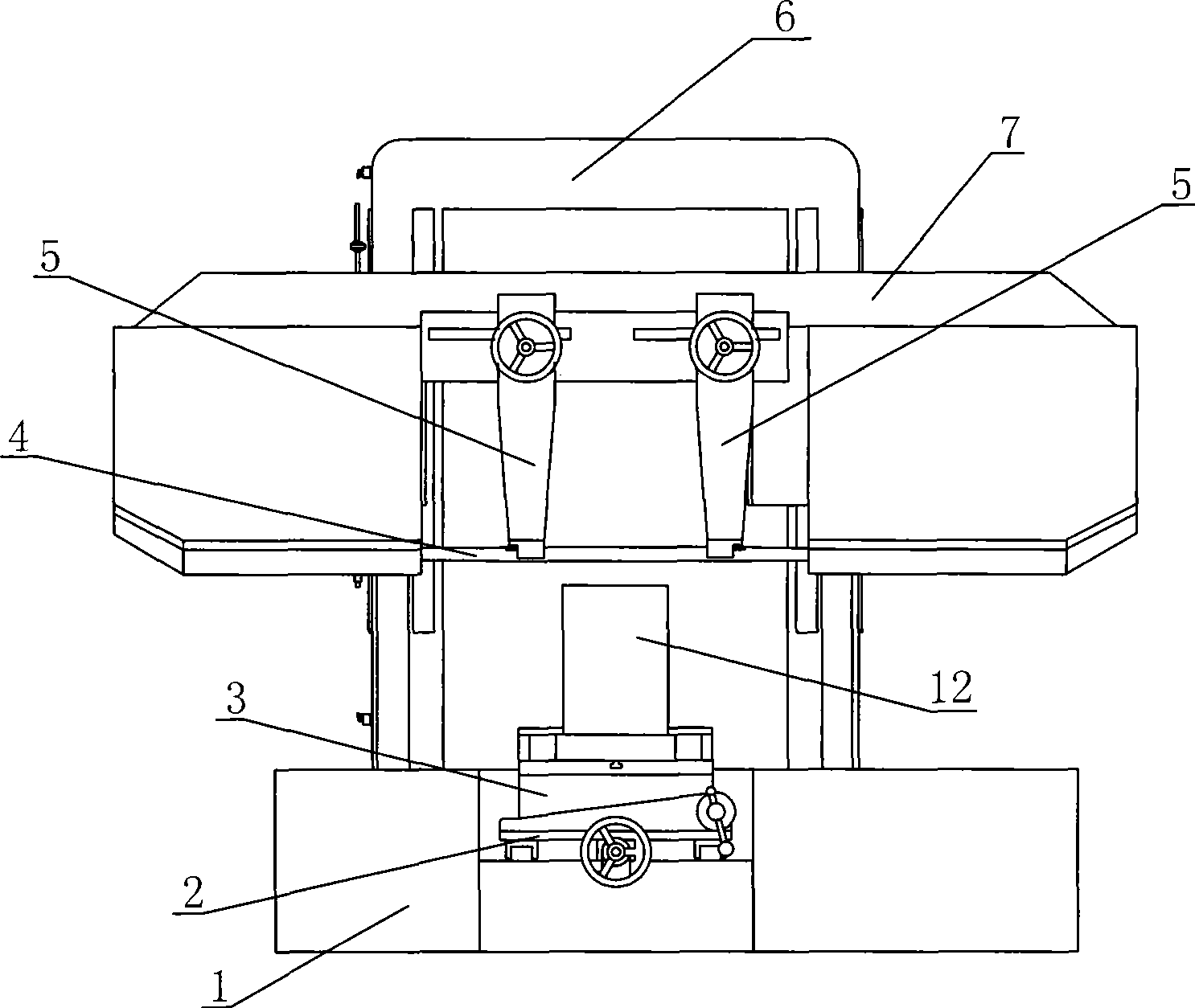

[0034] Such as Figure 3-5As shown, the deep groove processing device used in the deep groove processing method includes a base 1, a worktable 2, a rotary table 3, an annular band saw blade 4, a guide support part 5, a gantry frame 6, a power part 7, and a lifting feed cylinder 8. Depth fine-tuning component 9 and saw blade tensioning component 10 . Wherein, the workbench 2 is movably arranged on the base 1 horizontally and perpendicular to the cutting movement direction, and it can be locked on the base at any position within the movable range. The turntable 3 is installed on the worktable 2, and the workpiece 12 to be processed is clamped on the turntable during the processing, and the turntable 3 can be rotated horizontally 360° on the worktable 2 and can be locked on the Any position; in addition, scale markings including initial zero values are set on the operating parts of the workbench and the rotary table to facilitate production measurement operations. The depth f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com