Selective laser melting manufacturing process for annular array blade guide

A laser selective melting, annular array technology, applied in the direction of additive manufacturing, process efficiency improvement, additive processing, etc., to achieve good dimensional accuracy, short manufacturing cycle, and excellent mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

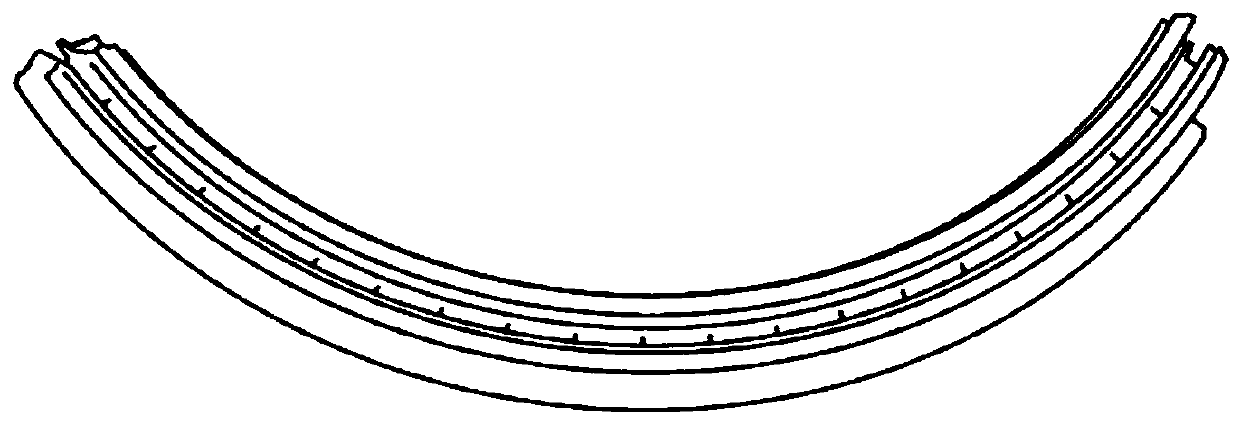

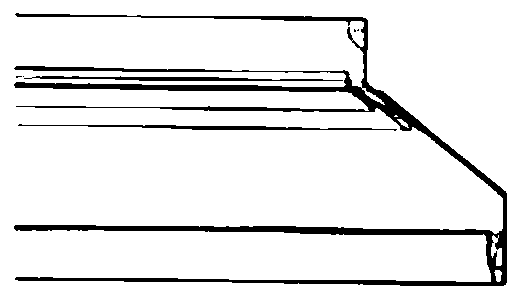

[0028] see Figure 1 to Figure 8 , a laser selective melting manufacturing process of an annular array vane guide, comprising the following steps:

[0029] S1. Model segmentation processing: Divide the three-dimensional model of the annular array vane guide into three segments or other number of segments according to the maximum forming size of the laser selective melting equipment. The smaller the forming size of the equipment, the more segments. Segmentation of the model enables laser selective melting equipment of different sizes and specifications to manufacture segments of the annular array vane guide, which are finally welded into a whole annular array vane guide. The shape of the section joints can be oblique or broken, which is convenient for combined splicing during welding.

[0030] S2. Select materials and set process parameters:

[0031] Material: GH4169 nickel-based superalloy powder with a particle size range of 15-45um or 15-53um.

[0032] Process parameters:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com