Preparation method of Cu-Nb multi-core composite wire with rectangular cross-section

A technology of rectangular cross-section and composite wire, which is applied in the usage of superconductor elements, the manufacture of extensible conductors/cables, and superconductive devices, etc. problem, to achieve the effect of increasing filling factor, improving processing efficiency and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

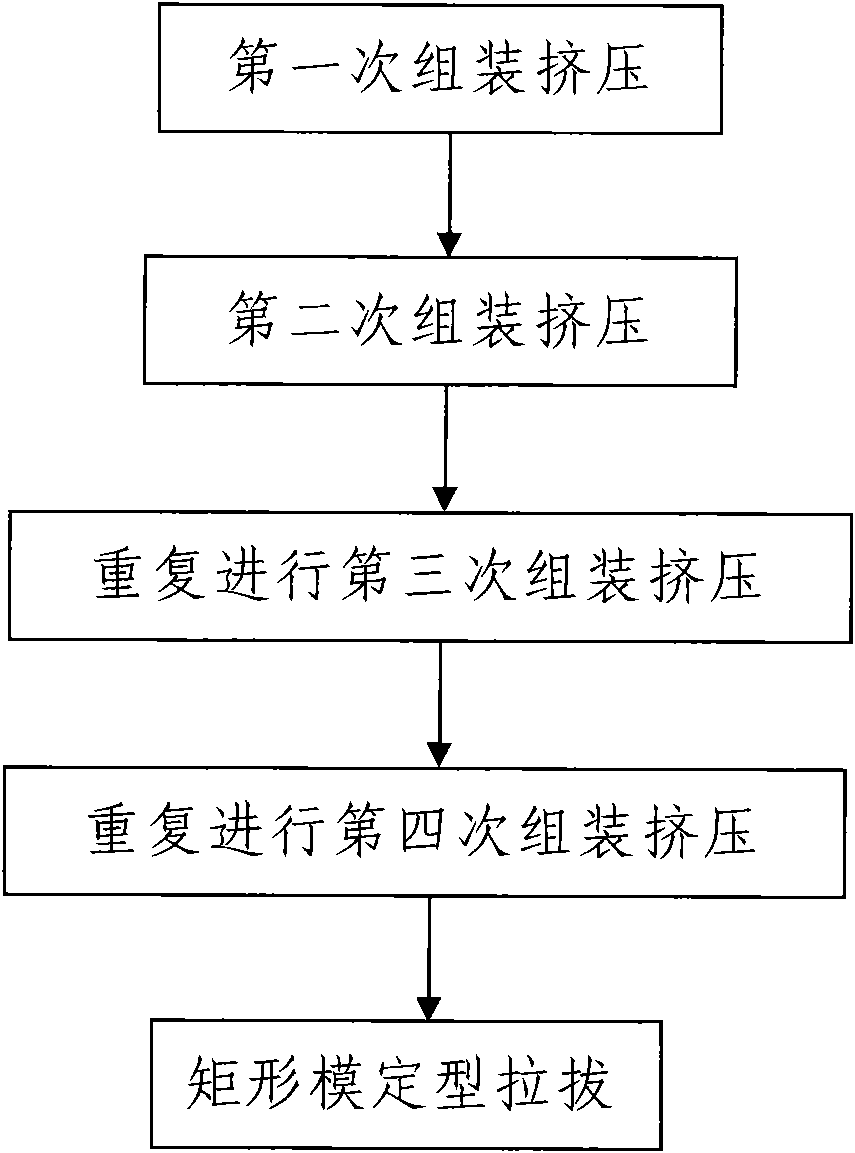

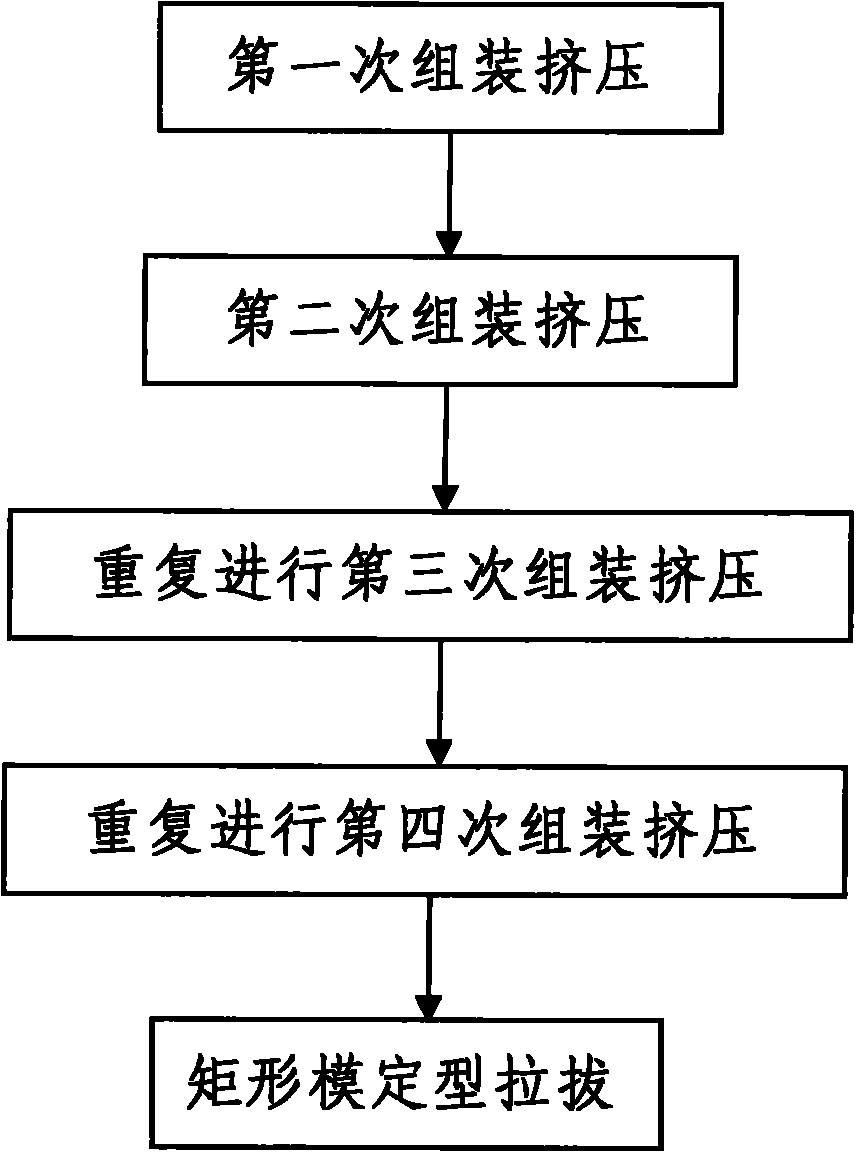

[0043] Such as figure 1 A preparation method of a Cu-Nb multi-core composite wire with a rectangular cross-section shown, comprising the following steps:

[0044] Step 1, the first extrusion assembly, the extrusion assembly process is as follows:

[0045] 101. The first assembly: assemble a single pure Nb rod and an oxygen-free copper outer sheath into a Cu-Nb composite sheath, and the Cu-Nb composite sheath is composed of a single pure Nb rod and a coaxial sleeve on a pure Nb The oxygen-free copper outer sheath on the rod consists of one; the oxygen-free copper outer sheath includes an oxygen-free copper outer sheath one and an upper end cap one and a lower end cap one arranged on the upper and lower ends of the oxygen-free copper outer sheath one;

[0046] 102. The first vacuum sealing welding: use vacuum welding to seal the upper end cap 1 and the lower end cap 1 described in step 101 on the upper and lower ends of the oxygen-free copper outer cladding tube 1;

[0047] 10...

Embodiment 1

[0065] In this embodiment, when the rectangular cross-section Cu-Nb multi-core composite wire is prepared, the preparation process is as follows:

[0066] 101. The first assembly: Assemble a single Φ67mm pure Nb rod and a Φ100×15×280mm oxygen-free copper sheath into a Cu-Nb composite sheath. And before assembling, the pure Nb rod and the oxygen-free copper sheath must be pickled, dehydrated and dried. And when carrying out pickling, adopt the mixed acid that is made up of nitric acid and water to carry out pickling to oxygen-free copper outer sheath one, the volume ratio of nitric acid and water in described mixed acid one is 1: 2; Adopt nitric acid, water and hydrogen The mixed acid two composed of hydrofluoric acid is pickled with pure Nb rods, and then dehydrated with alcohol. The volume ratio of nitric acid, water and hydrofluoric acid in the mixed acid two is 1:2:3. The oxygen-free copper outer sheath includes an oxygen-free copper outer sheath one and an upper end cap I...

Embodiment 2

[0085] In this example, the difference from Example 1 is that when the first extrusion is performed in step 103, the extrusion temperature is 750°C, the holding time is 1.5h, and the extrusion ratio is 25; the second extrusion is performed in step 205 When extruding, the extrusion temperature is 750°C, the holding time is 1.5h, and the extrusion ratio is 25; when performing the third extrusion assembly in step 3 and the fourth extrusion assembly in step 4, the method steps and The relevant process parameters are the same as in step 2; and when two vacuum heat treatments are alternately performed during the fourth main drawing, the temperature of the two vacuum heat treatments is 200°C, and the holding time is 2h; the second time described in step 204 After vacuum sealing, the third vacuum sealing described in step 3 and the fourth vacuum sealing described in step 4, when hot isostatic pressing is performed, the heating temperature is 700°C and the applied pressure is 95Mpa , T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sectional area | aaaaa | aaaaa |

| Room temperature tensile strength | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com