Magnetic core component, magnetic element, and production method for magnetic core component

A manufacturing method and magnetic technology, applied in the direction of magnetic core/yoke, inductor/transformer/magnet manufacturing, magnetic objects, etc., can solve the problem of large particle size distribution changes, poor plastic deformation of amorphous powder, and inability to press powder density to increase magnetic permeability Ratio amorphous powder magnetic core and other problems, to achieve the effect of increasing density and relative permeability, cheap and durable life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

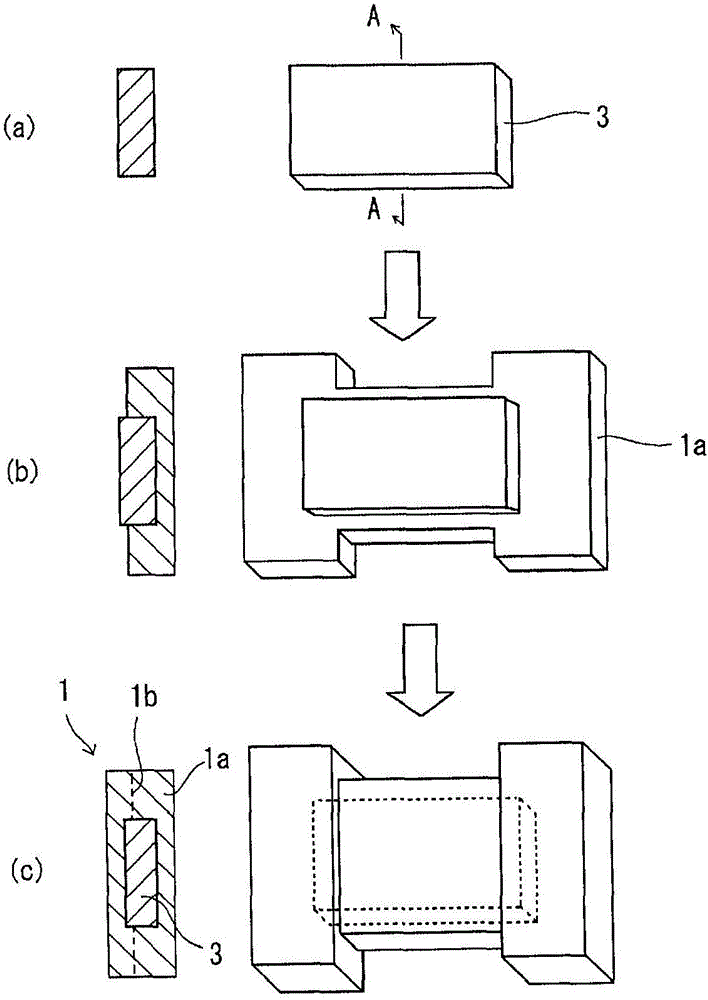

Image

Examples

Embodiment 1

[0090] The particle size is below 150μm and the median diameter D 50 1940 g of 50 μm amorphous metal magnetic powder (Fe—Si—B based amorphous metal) and 60 g of epoxy resin powder containing dicyandiamide as a curing agent were mixed at room temperature for 10 minutes with a blender. This mixture was put into a kneader and heated and kneaded at 110° C. for 12 minutes. The compounding ratio of the amorphous metal magnetic powder was 97% by mass. The cake agglomerated by the kneader was taken out and cooled, and then pulverized by a pulverizer to obtain a powder that passed through a 60-mesh sieve. Then use the mold at room temperature at 2t / cm 2 Compression molding is carried out under the molding pressure. The compression-molded product was taken out from the mold, and thermally cured at 180° C. in air for 1 hour to manufacture a flat cylindrical magnetic core member with an inner diameter of 20 mm, an outer diameter of 30 mm, and a height of 5 mm. The magnetic core member...

Embodiment 2

[0095] When the magnetic core member is made into a compression-molded product using the powder obtained from the amorphous metal magnetic powder and the epoxy resin powder obtained from the amorphous metal magnetic powder and the epoxy resin powder that passed through a 60-mesh sieve, except that the molding condition is set at a temperature of 110 ℃, time 5 minutes, in the same manner as in Example 1, under the condition of 180 ℃ of temperature in the air atmosphere for 1 hour, carry out thermosetting, thereby make the flat circle of inner diameter 20mm, outer diameter 30mm, height 5mm A cylindrical magnetic core member. The density of the magnetic core part is 5.17g / cm 3 .

[0096] The magnetic properties and mechanical properties of the obtained magnetic core member were measured in the same manner as in Example 1. show the result in Figure 4 ~ Figure 6 .

Embodiment 3

[0098] 1940 g of an amorphous metal magnetic powder having a particle size distribution having a particle size distribution of 300 μm or less added with fine powder as an amorphous metal magnetic powder, and 60 g of an epoxy resin powder containing dicyandiamide as a curing agent are used in a blender Mix for 10 minutes at room temperature. This mixture was put into a kneader and heated and kneaded at 110° C. for 12 minutes. The cake obtained by agglomeration in the kneader was taken out, cooled, and pulverized by a pulverizer to obtain a powder that passed through a 28-mesh sieve. Then use the mold at room temperature at 2t / cm 2 Compression molding is carried out under the molding pressure. The compression molded product was taken out from the mold, and thermally cured at 180° C. for 1 hour in an air atmosphere to manufacture a flat cylindrical magnetic core member with an inner diameter of 20 mm, an outer diameter of 30 mm, and a height of 5 mm. The magnetic core member h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com