Transparent heat insulation film and preparation method thereof

A technology of heat insulation film and transparent film, which is applied in the direction of coating, polyester coating, polyurea/polyurethane coating, etc., which can solve the problems of heat insulation effect, stability of transparent heat insulation film, UV aging resistance and wear resistance Deficiency and other problems, to achieve the effect of improving the anti-ultraviolet ability, improving the anti-ultraviolet aging and abrasion resistance, and improving the anti-ultraviolet effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

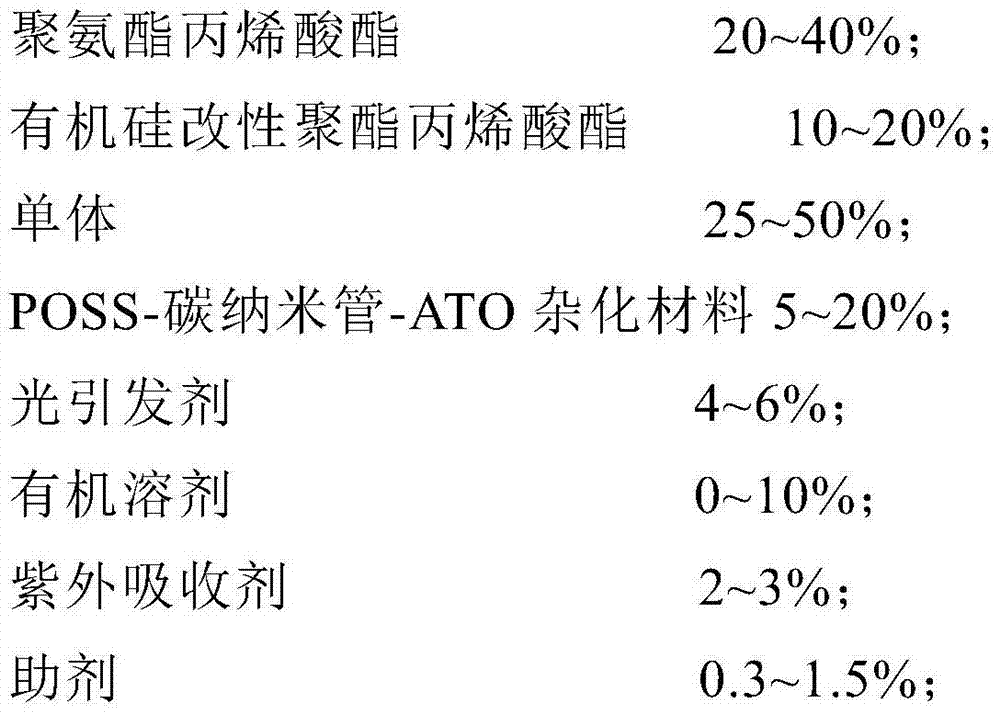

Method used

Image

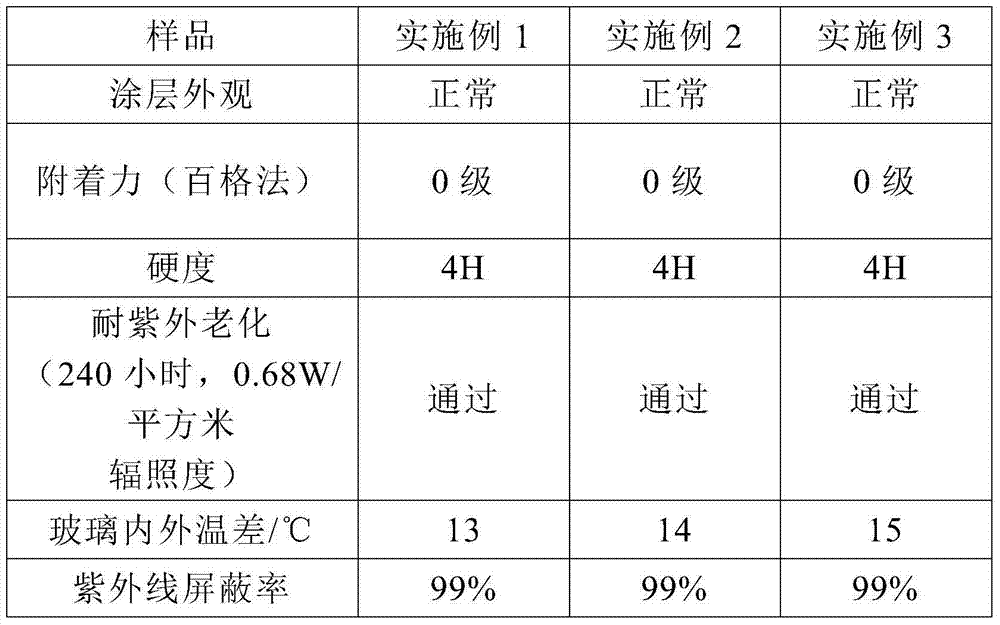

Examples

Embodiment 1

[0035] This embodiment provides a method for preparing a transparent heat-insulating film, the steps are:

[0036] 1) Preparation of POSS-carbon nanotube-ATO hybrid materials

[0037] a. Add 4g of dry carbon nanotubes and 100ml of mixed acid of 98% sulfuric acid and 60% nitric acid in a volume ratio of 3:1 in a beaker, ultrasonic treatment for 24 hours, suction filtration, washing, and vacuum drying at 100°C to obtain acidified carbon Nanotube 3g;

[0038] b. Put 3 g of acidified carbon nanotubes and 30 g of thionyl chloride prepared in step a into a flask, ultrasonically treat for 30 minutes, heat to 120° C., reflux for 30 hours under stirring, remove excess thionyl chloride by distillation, and heat at 80° C. Under vacuum drying obtains 2.6g of acylated carbon nanotubes;

[0039] c. Add 2.6g of acylated carbon nanotubes obtained in step b, 3.0g of nano antimony-doped tin dioxide and 2-(3,4-epoxycyclohexyl) ethyltrimethoxysilane 25g in the flask , sealed with a ground plug...

Embodiment 2

[0045] This embodiment provides a method for preparing a transparent heat-insulating film, the steps are:

[0046] 1) Preparation of POSS-carbon nanotube-ATO hybrid materials

[0047] a. Add 4g of dry carbon nanotubes and 100ml of mixed acid of 98% sulfuric acid and 60% nitric acid in a volume ratio of 3:1 in a beaker, ultrasonic treatment for 24 hours, suction filtration, washing, and vacuum drying at 100°C to obtain acidified carbon Nanotube 3g;

[0048] b. Put 3 g of acidified carbon nanotubes and 30 g of thionyl chloride prepared in step a into a flask, ultrasonically treat for 30 minutes, heat to 120° C., reflux for 30 hours under stirring, remove excess thionyl chloride by distillation, and heat at 80° C. Under vacuum drying obtains 2.6g of acylated carbon nanotubes;

[0049] c. Add 2.6g of acylated carbon nanotubes obtained in step b, 3.0g of nano antimony-doped tin dioxide and 2-(3,4-epoxycyclohexyl) ethyltrimethoxysilane 25g in the flask , sealed with a ground plug...

Embodiment 3

[0055] This embodiment provides a method for preparing a transparent heat-insulating film, the steps are:

[0056] 1) Preparation of POSS-carbon nanotube-ATO hybrid materials

[0057] a. Add 4g of dry carbon nanotubes and 100ml of mixed acid of 98% sulfuric acid and 60% nitric acid in a volume ratio of 3:1 in a beaker, ultrasonic treatment for 24 hours, suction filtration, washing, and vacuum drying at 100°C to obtain acidified carbon Nanotube 3g;

[0058] b. Put 3 g of acidified carbon nanotubes and 30 g of thionyl chloride prepared in step a into a flask, ultrasonically treat for 30 minutes, heat to 120° C., reflux for 30 hours under stirring, remove excess thionyl chloride by distillation, and heat at 80° C. Under vacuum drying obtains 2.6g of acylated carbon nanotubes;

[0059] c. Add 2.6g of acylated carbon nanotubes obtained in step b, 3.0g of nano antimony-doped tin dioxide and 2-(3,4-epoxycyclohexyl) ethyltrimethoxysilane 25g in the flask , sealed with a ground plug...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com