Water-based mold release and preparation method thereof and release paper prepared by utilizing water-based mold release

A water-based release type and release coating technology, which is applied to textiles, papermaking, papermaking, paper coatings, etc., can solve the problems of unsuitable for large-scale industrial production of release paper, slow thermal curing speed, and low production efficiency. Moderate hardness, short processing time and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041]Preparation of water-based release agent: 20g octamethylcyclotetrasiloxane, 10g vinyltriethoxysilane, 30g alkyd resin (HD-WA622), 4g sodium lauryl sulfate, 3g dodecane Add benzenesulfonic acid and 140g of distilled water into a four-necked flask, pre-emulsify at 25°C for 1 hour, then raise the temperature to a reaction temperature of 100°C, react at a constant temperature for 3 hours, cool to room temperature, adjust the pH value to 7 with ammonia water, and finally add 4g Hydrogen-containing silicone oil (XH-202) and 0.3g of chloroplatinic acid are mixed to prepare a water-based release agent.

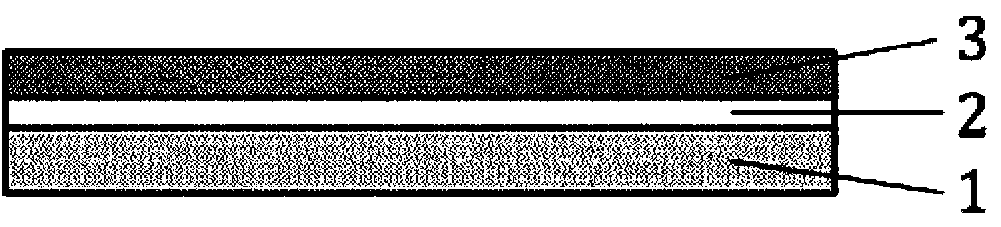

[0042] Preparation of release paper: On one side of the base paper 1, evenly coat a coating composed of styrene-acrylic latex and vinyl triethoxysilane emulsion (the mixing ratio is the same as in Example 1). Coating treatment, forming an undercoat 2 on one side of the base paper 1 (the formula of the undercoat 2 is: a mixture of styrene-acrylic emulsion and vinyl triethoxysilan...

Embodiment 2

[0044] Preparation of water-based release agent: 30g octamethylcyclotetrasiloxane, 10g vinyltrimethoxysilane, 30g alkyd resin (HD-WA622), 3g sodium dodecylbenzenesulfonate, 3g dodecylbenzene Alkylbenzenesulfonic acid and 140g of distilled water were added to a four-necked flask, pre-emulsified at 25°C for 0.5h, then heated to a reaction temperature of 95°C, reacted at a constant temperature for 3h, cooled to room temperature, adjusted to pH 7 with ammonia water, and finally Add 5g of hydrogen-containing silicone oil (XH-202) and 0.5g of chloroplatinic acid, and mix well to prepare a water-based release agent.

[0045] Preparation of release paper: On one side of the base paper 1, evenly coat a coating composed of styrene-acrylic latex and vinyltrimethoxysilane emulsion (the mixing ratio is the same as in Example 1), and after drying, complete the base coating of the base paper 1 treatment, forming an undercoat 2 on one side of the base paper 1 (the formula of the undercoat 2 i...

Embodiment 3

[0047] Preparation of water-based release agent: 20g hexamethylcyclotrisiloxane, 20g methylvinyldiethoxysilane, 40g alkyd resin (HD-DS006), 4g sodium lauryl sulfate, 3g ten Add dialkylbenzenesulfonic acid and 150g distilled water into a four-necked flask, pre-emulsify at 25°C for 1h, then raise the temperature to a reaction temperature of 100°C, react at a constant temperature for 3h, cool to room temperature and adjust the pH value to 7 with triethylamine , and finally add 3g of hydrogen-containing silicone oil (TSF-484) and 0.1g of chloroplatinic acid, and mix well to prepare a water-based release agent.

[0048] Preparation of release paper: On one side of the base paper 1, evenly coat a coating composed of styrene-acrylic latex and methacryloxypropyltrimethoxysilane emulsion (the mixing ratio is the same as that in Example 1), and after drying, complete For the primer treatment of base paper 1, base coat 2 is formed on one side of base paper 1 (the formula of base coat 2 i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| cure temperature | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com