Surface marked articles, related methods and systems

a surface marking and surface technology, applied in the field of articles, can solve the problems of insufficient aesthetic appeal of synthetic materials with ink-jet graphics alone, lack of textural feel inherent in many natural materials, and lack of attractive appearance and authenticity of natural materials, etc., and achieve the effect of high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

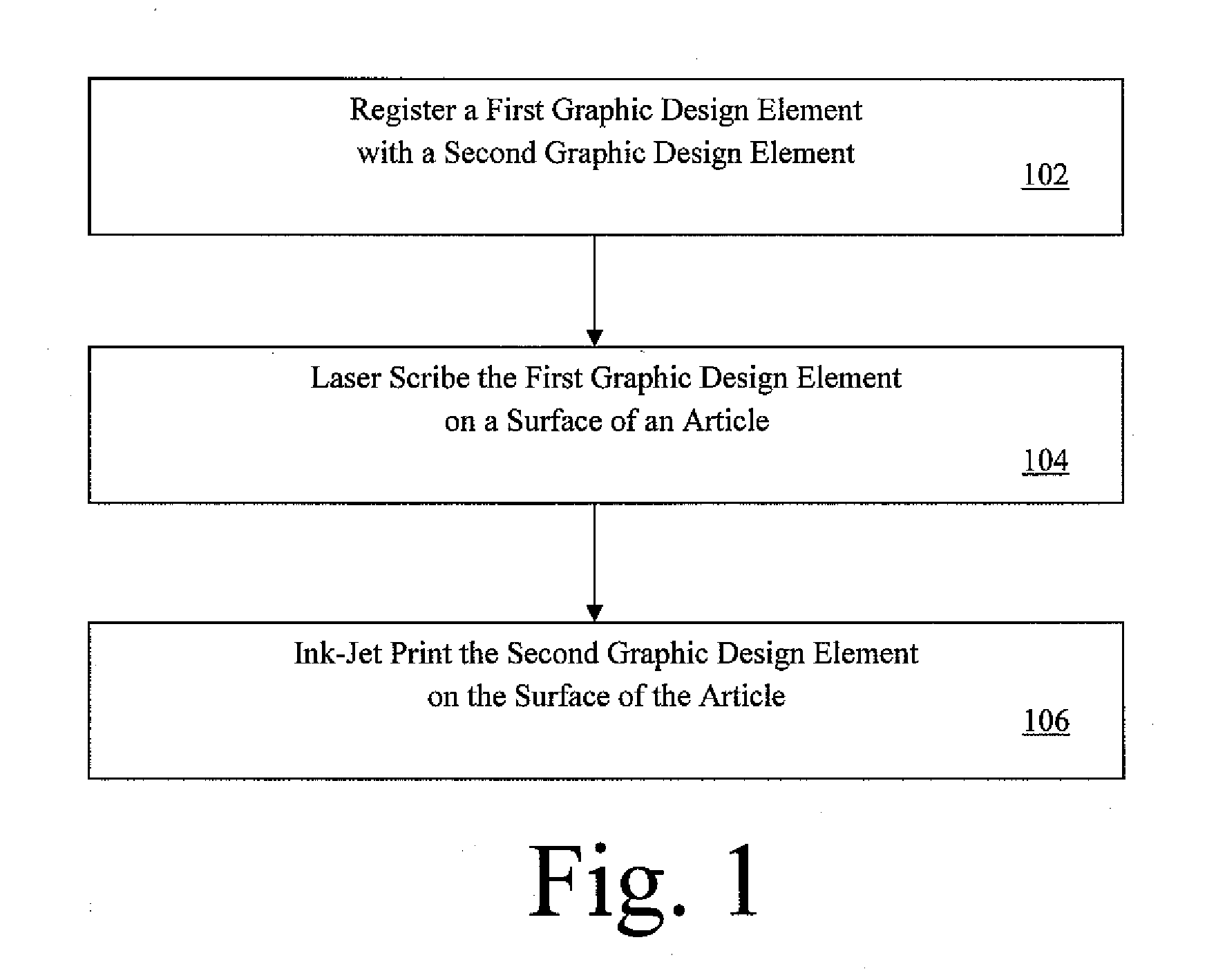

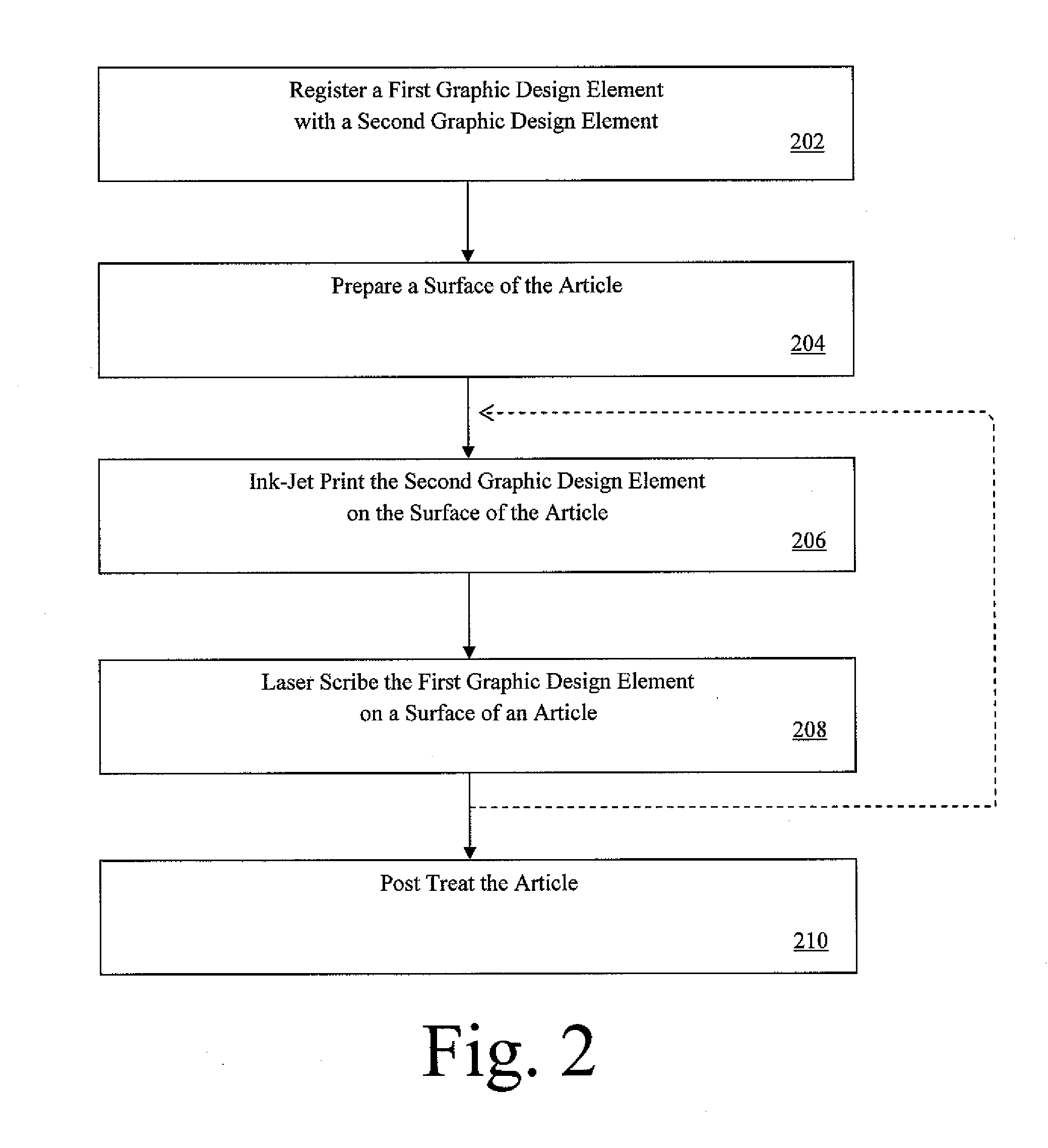

Method used

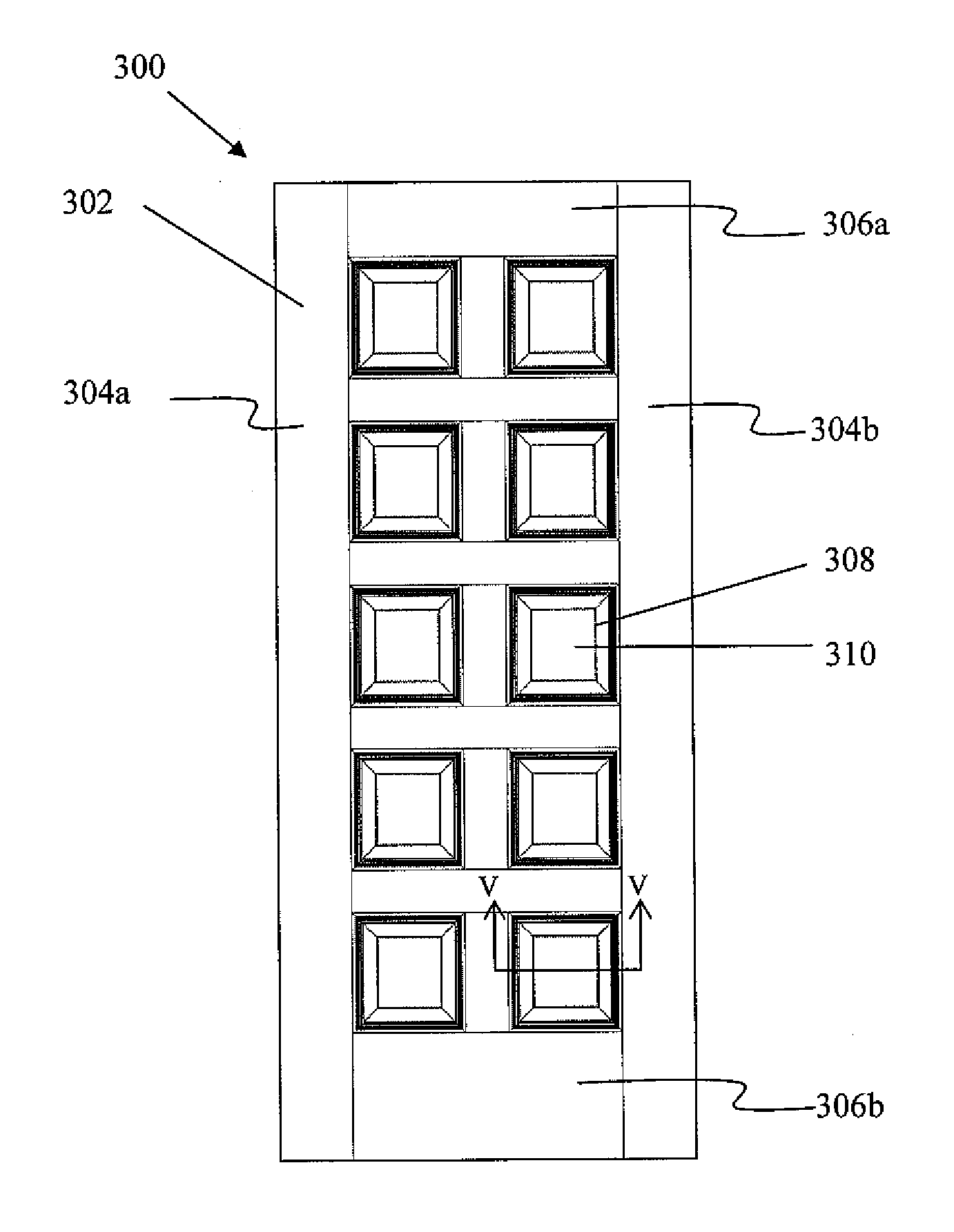

Image

Examples

examples

[0089]To demonstrate the influence of substrate material and graphic image pattern on laser power and scan speed, the experiments set forth in Table I below were carried out on various substrates.

TABLE ILaserLaser ScanGraphicPowerSpeedSubstrateImage(Watts)(m / s)PVC CompositeCedar175010Polyethylene wood compositeCedar250010Polyethylene wood compositeMaple200010Polyethylene wood compositeLeopard175010HardboardWalnut250015Painted MDF (2 paint layers)Simple Oak250040Medium Density FiberboardRose Pedals250015(MDF)Medium Density FiberboardSimple150022(MDF)WalnutMedium Density FiberboardOak Cross150022(MDF)GrainPainted Hardboard (2 paintMaple137515layers)Painted Hardboard (1 paintSimple Oak250028layer)Primed HardboardSimple Oak250032PVCCedar250010Reaction-Injected MoldedCedar225010Plastics

[0090]The effects of controller speed on laser power change width for two separate graphic images are demonstrated by Tables II and III below. Table II contains data for 32 laser lines per inch and Table I...

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight percent | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| scan speeds | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com