Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37 results about "Lines per inch" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lines per inch (LPI) is a measurement of printing resolution. A line consists of halftones that is built up by physical ink dots made by the printer device to create different tones. Specifically LPI is a measure of how close together the lines in a halftone grid are. The quality of printer device or screen determines how high the LPI will be. High LPI indicates greater detail and sharpness.

Three-Dimensional Luminescent Display and Method for Using the Same

InactiveUS20070114907A1Increase brightnessFast response timeDischarge tube luminescnet screensCathode-ray/electron-beam tube vessels/containers3d imageLines per inch

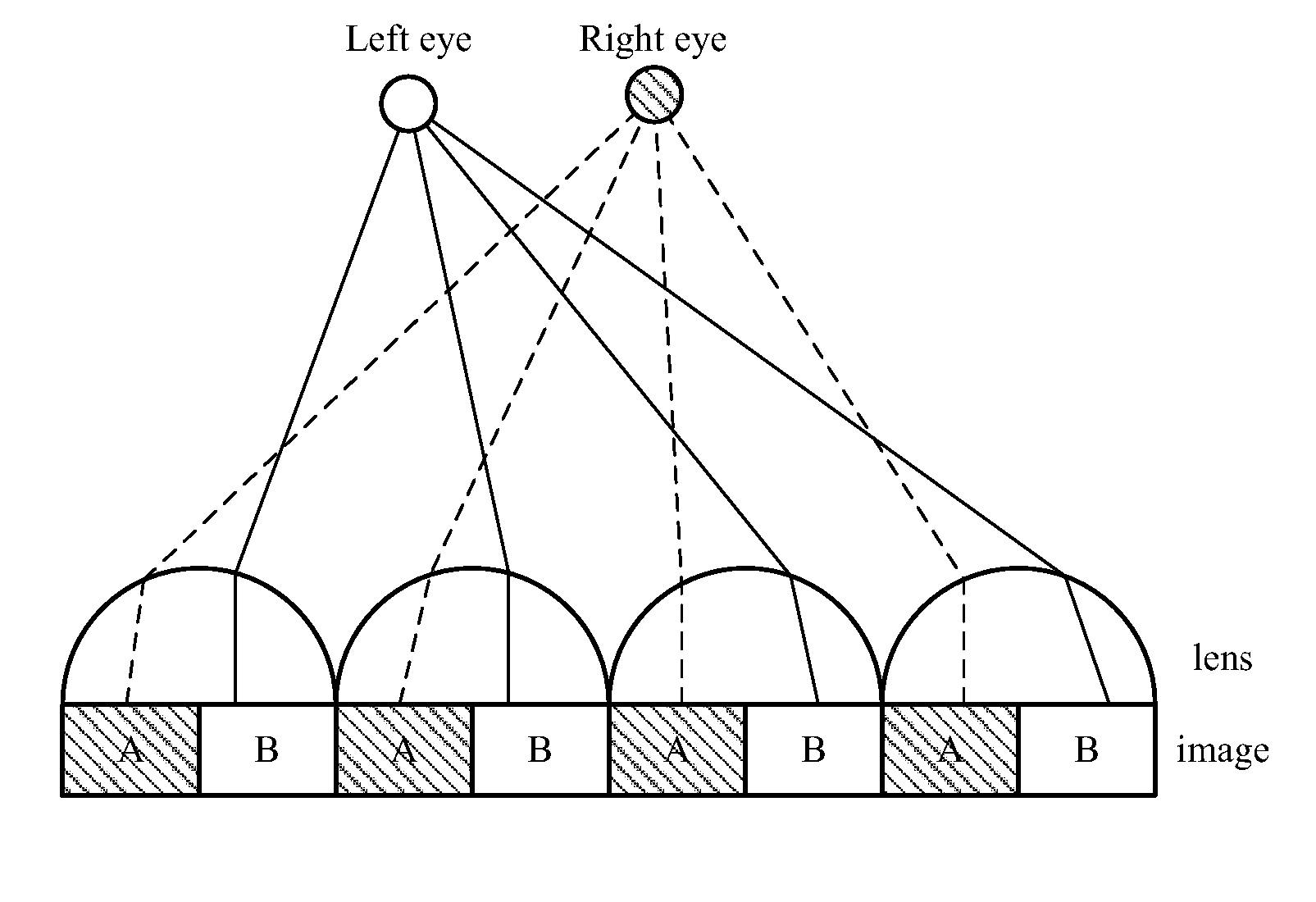

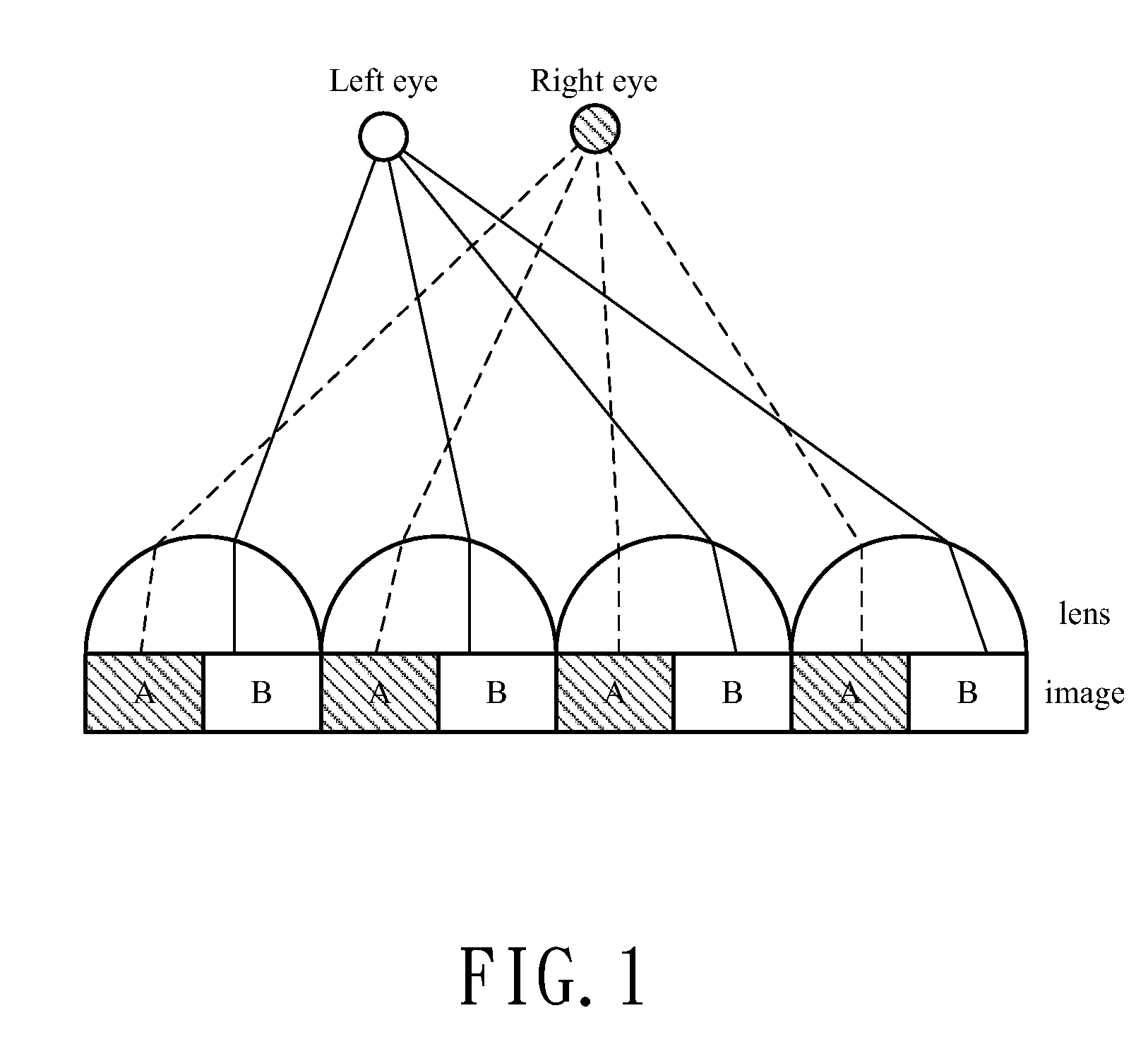

This invention provides a three-dimensional luminescent display, comprising: a first substrate, a second substrate, a plurality of light emitting devices provided between the first substrate and the second substrate, and a plurality of lenticular lenses to show 3D image. Each light emitting device comprises a pixel and has a square shape, and the pixels are provided to form an N by M matrix (N and M are integers) and have a pitch of Xp inch (distance between two neighboring pixels along either the N direction or the M direction). The lenticular lenses form a linear array and the pitch of the lenticular lenses is Plens per inch (lines per inch; LPI). The light emitting devices are provided at the focal plane of the lenticular lenses. Moreover, Xp and Plens satisfy the following equation: 3*k*Xp*Plens=1 in which k is an integer greater than or equal to 1.

Owner:LENTICS CORP

Soap retaining pouch

ActiveUS6998373B1Secure retentionEasy to disassembleCosmetic preparationsKitchenware cleanersPolyesterLines per inch

Soap retaining pouch that is approximately five inches tall by three and one half inches wide. The pouch is made of polyester screening having a thread count of approximately fourteen lines per inch or one hundred and ninety six squares per square inch. An elastic band is centrally attached to the outside of the pouch at the right and left edge of the pouch's width. The pouch is closable at one end by a water resistant zipper. The pouch includes an overflap that covers the zipper so that the zipper is not exposed to the user's skin during use.

Owner:FAINES JR JAMES LEE +1

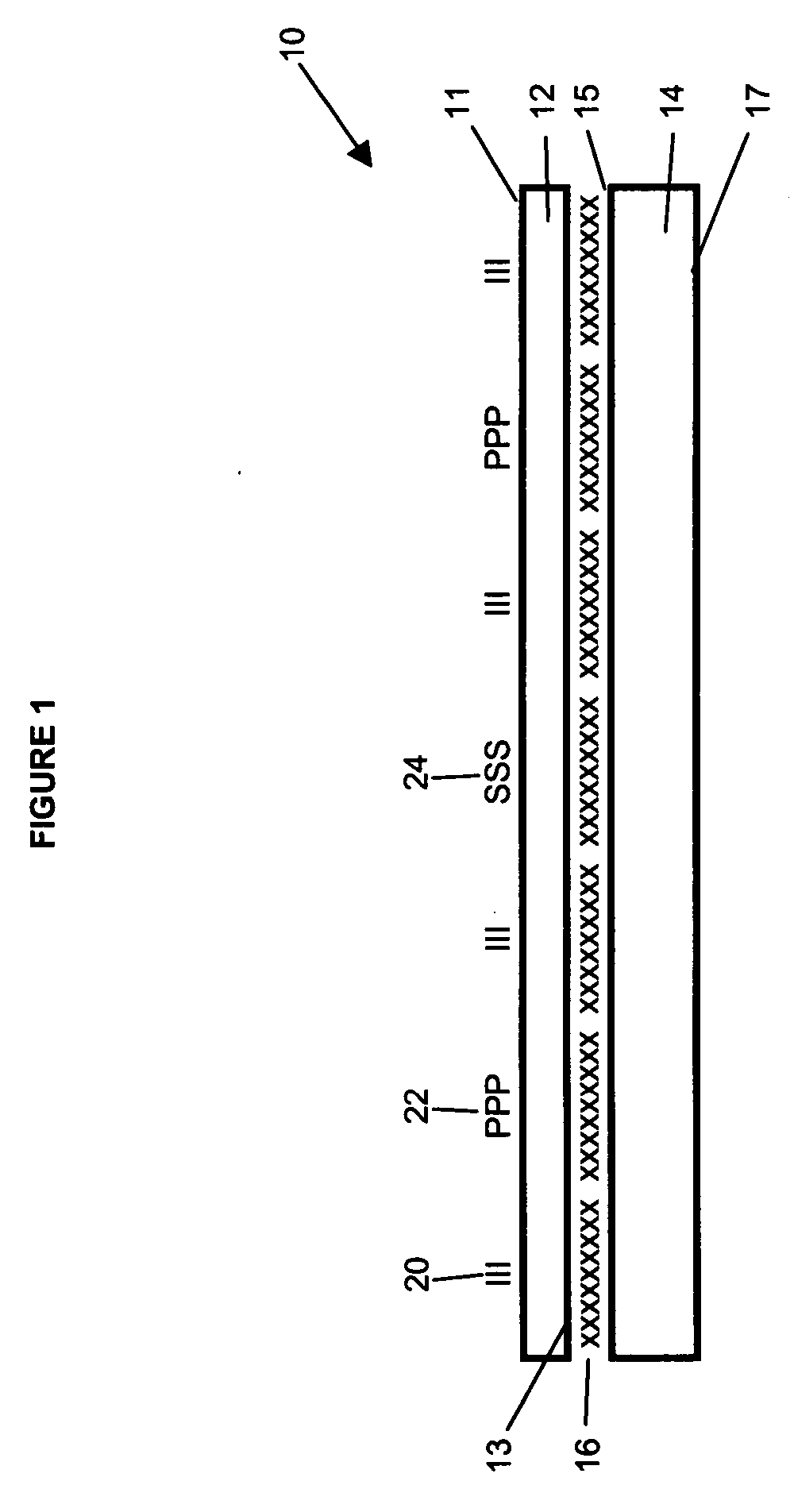

Method, system, program, and data structures for halftoning with line screens having different lines per inch (LPI)

InactiveUS6956670B1Quality improvementReduce moiré effectDigitally marking record carriersDigital computer detailsPattern recognitionArray data structure

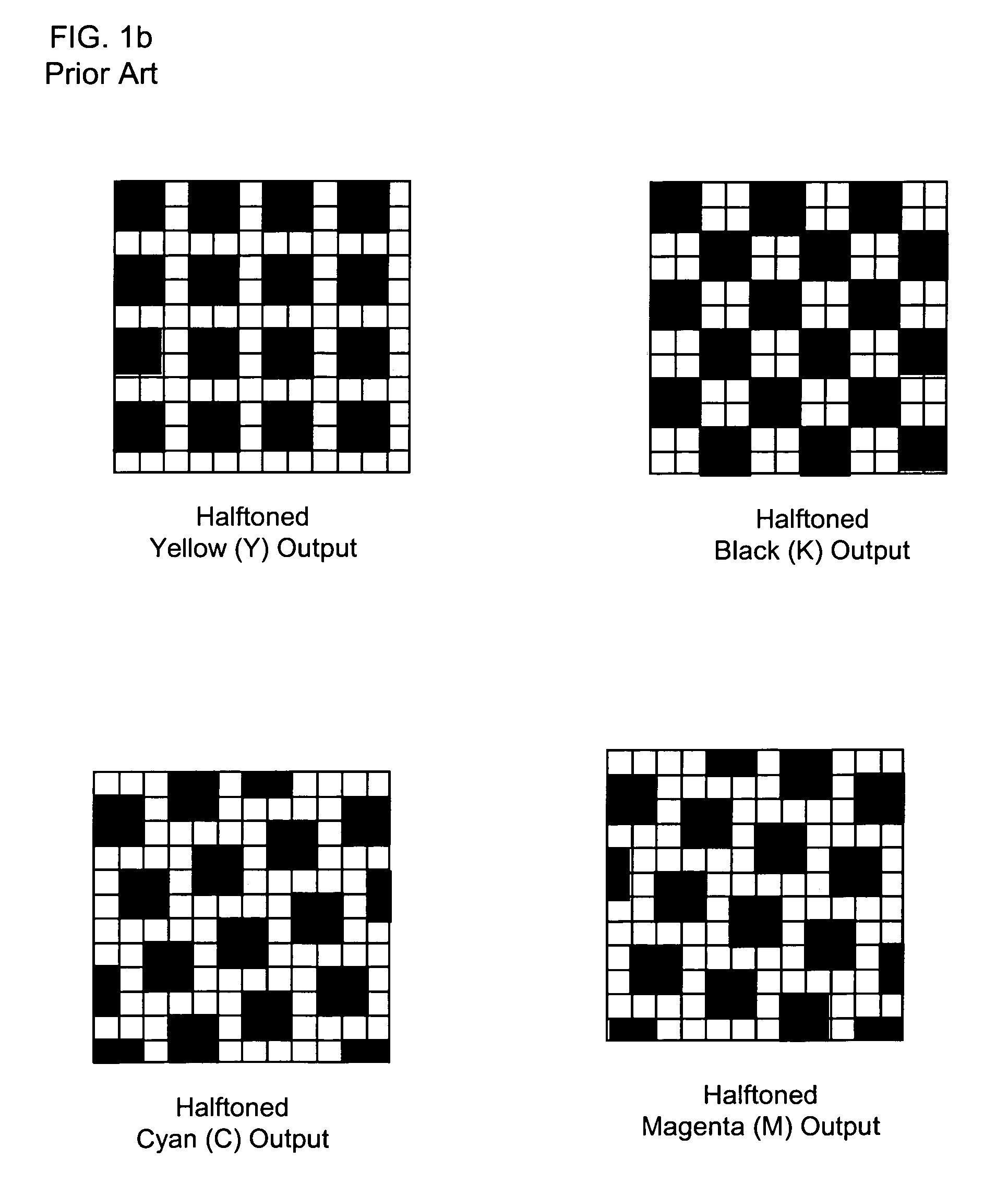

Provided is a method, system, program, and data structures for halftoning an input image comprised of at least two input color components. Each input color component provides input intensity values for the color component at pixel locations in the image. At least two halftoning screens are accessed. There is one screen for each color component and halftone output generated by at least one of the screens has a lines per inch (LPI) that is at least approximately twenty percent different than the LPI of halftone output generated by one other screen. The input image is separated into the separate color components. The accessed screen for each color component is applied to the input intensity values for the color component to produce output intensity values for the color component. The combined halftone outputs for all the color components form the output pixels.

Owner:RICOH KK

Continuous intermediate prime label pressure sensitive assembly

InactiveUS20060263558A1Easy to installReduce preparation timeStampsPaper/cardboard articlesImage resolutionLines per inch

The present invention is in the field of identifiers such as tags and labels, which may be used in advertising, marketing, communications or for designating a source of a particular product or service and relates to a method of manufacturing prime label intermediates in an unique continuous web format. The subject of this application specifically includes pressure sensitive laminates that are produced in a sheet to roll type of format and provided in one or more intermediate configurations to an end user. A series of sheets are pre-printed, then slit or cut to size to create individual ribbons or label segments, with each segment having prime label areas. The prime label segments are then applied to a continuously advancing web so as to create a web having a series of discontinuous label segments disposed thereon. More particularly, the pressure sensitive laminates of the instant application can be used to create individual, prime labels having a high or photo quality resolution level, of more than about 150 lines per inch and preferably about about 300 lines per inch.

Owner:WARDKRAFT

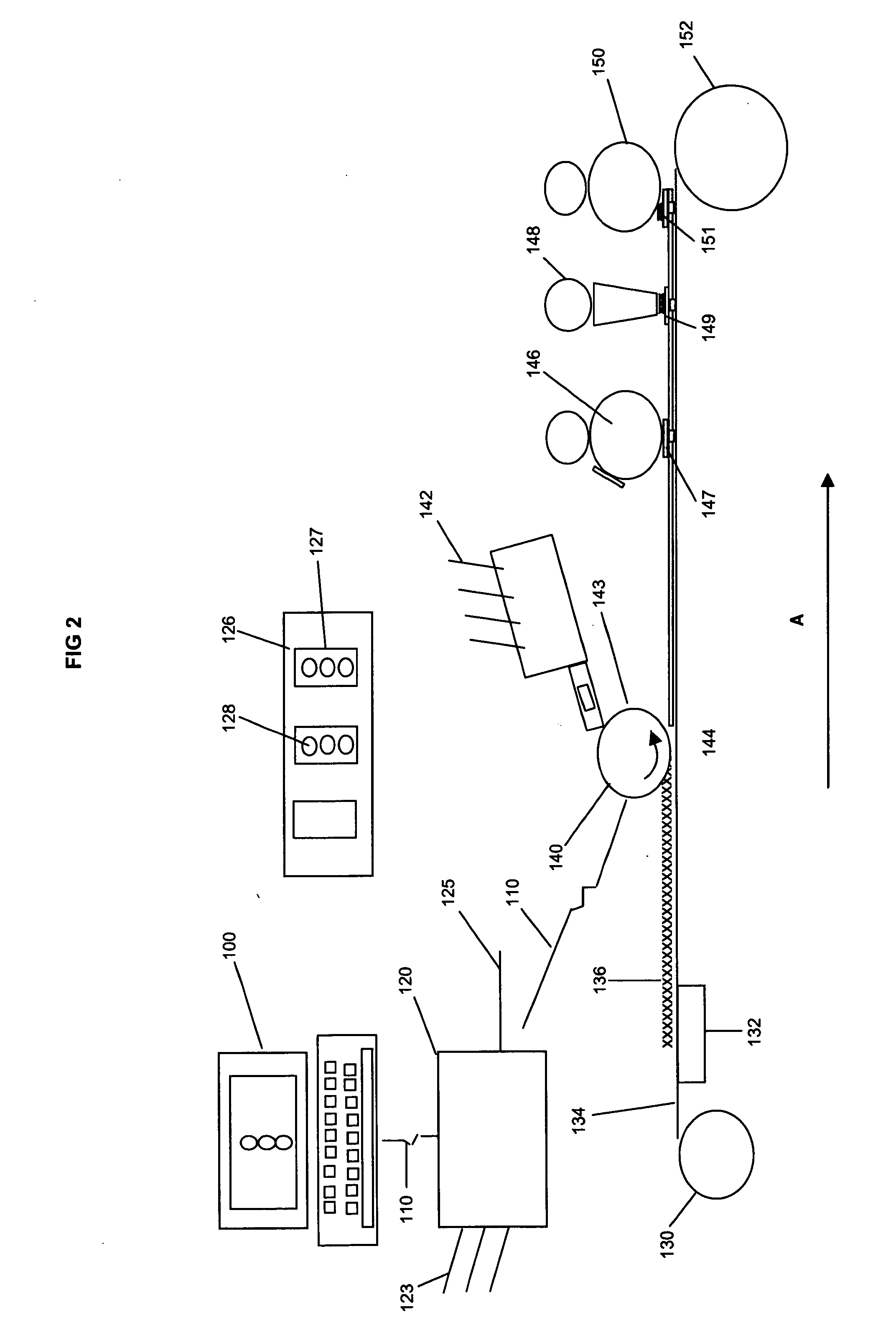

System for preparing prime label pressure sensitive intermediate laminates

InactiveUS20060260753A1Reduce preparation timeHigh image resolution productLamination ancillary operationsPaper/cardboard articlesGraphicsImage resolution

The present invention is in the field of composite manufacturing systems that are used in the preparation of articles, namely pressure sensitive laminates such as prime labels and tags. The system of the instant specification includes a computer for creating a file, an image generation means for rendering typically a graphical depiction on one or more surfaces of a substrate, an inserter for placing ribbon or label segments and a web processing apparatus. The labels of the present invention are produced in part, initially from a pre-imaged or printed sheet that are then converted or merged to a roll type of format. The sheets are printed with high quality graphics or images which are then slit or cut to size to form ribbons or label segments for the prime label application and then are converted to or merged with a continuously advancing web to create a continuous roll format. Then the label segments that have been affixed to the web are provided in one or more intermediate configurations to an end user typically for application to consumer packaged goods. More particularly, the pressure sensitive laminates of the instant application can be used to create individual, prime labels having a high or photo quality resolution level such as those about 300 lines per inch or approximately 2500 to 3500 dots per inch.

Owner:WARDKRAFT

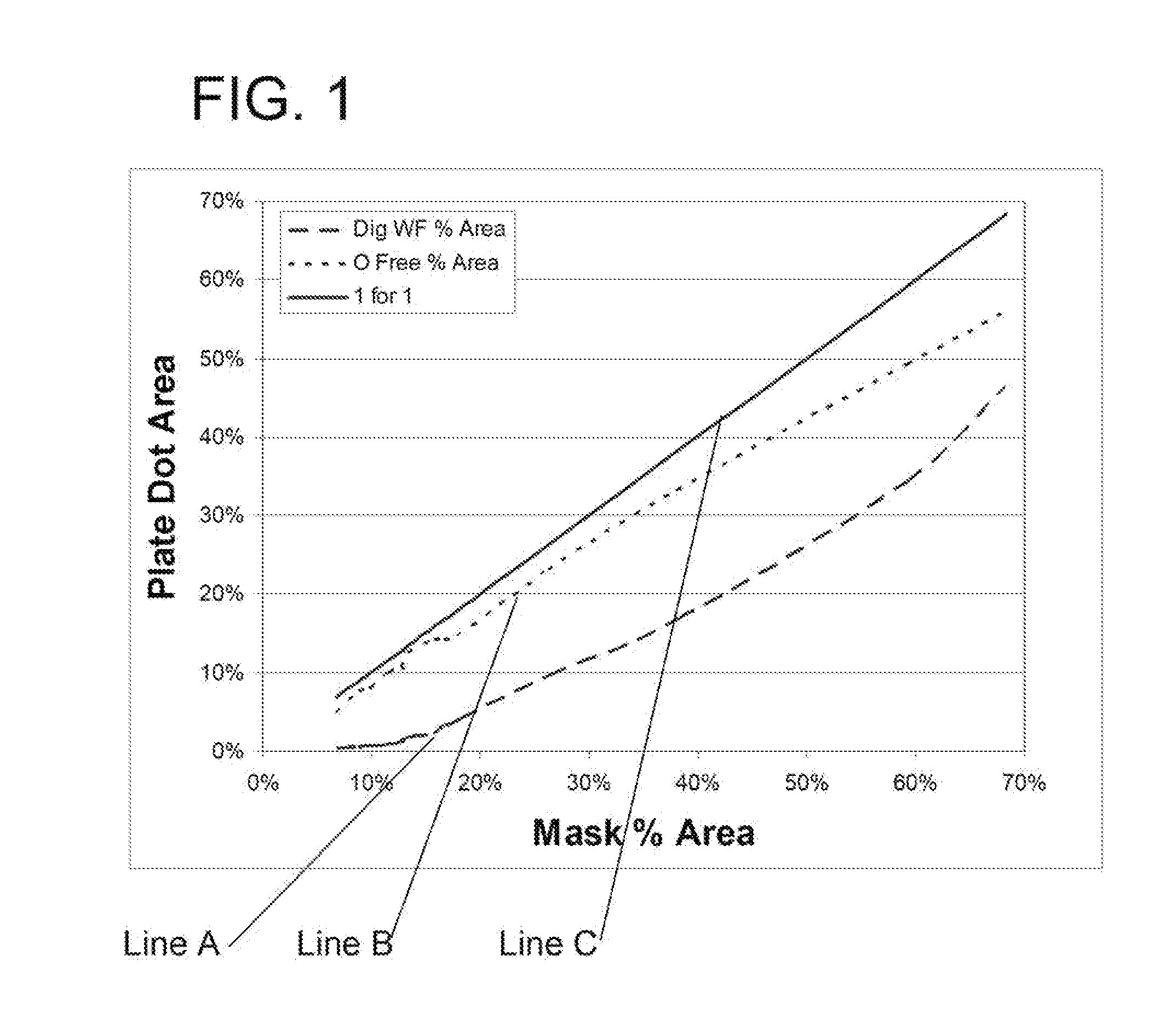

Method for printing a material onto a substrate

ActiveUS20120060711A1Platen pressesSemiconductor/solid-state device manufacturingImage resolutionLines per inch

The invention provides a method for printing a material onto a substrate with a relief printing form made from a photosensitive element. The method includes forming an in-situ mask having a line screen resolution equal to or greater than 250 lines per inch on the photosensitive element, exposing the element to actinic radiation through the in-situ mask in an environment having an inert gas and a concentration of oxygen between 190,000 and 100 ppm, and treating the exposed element to form a relief structure having a plurality of raised surfaces with a line screen resolution equal to or greater than 250 lines per inch. Printing is accomplished by applying an imaging material to the plurality of raised surfaces and contacting to transfer the imaging material to the substrate. The method is suitable for printing high resolution graphic images, as well as for forming a uniform layer of imaging material on the substrate.

Owner:DUPONT ELECTRONICS INC

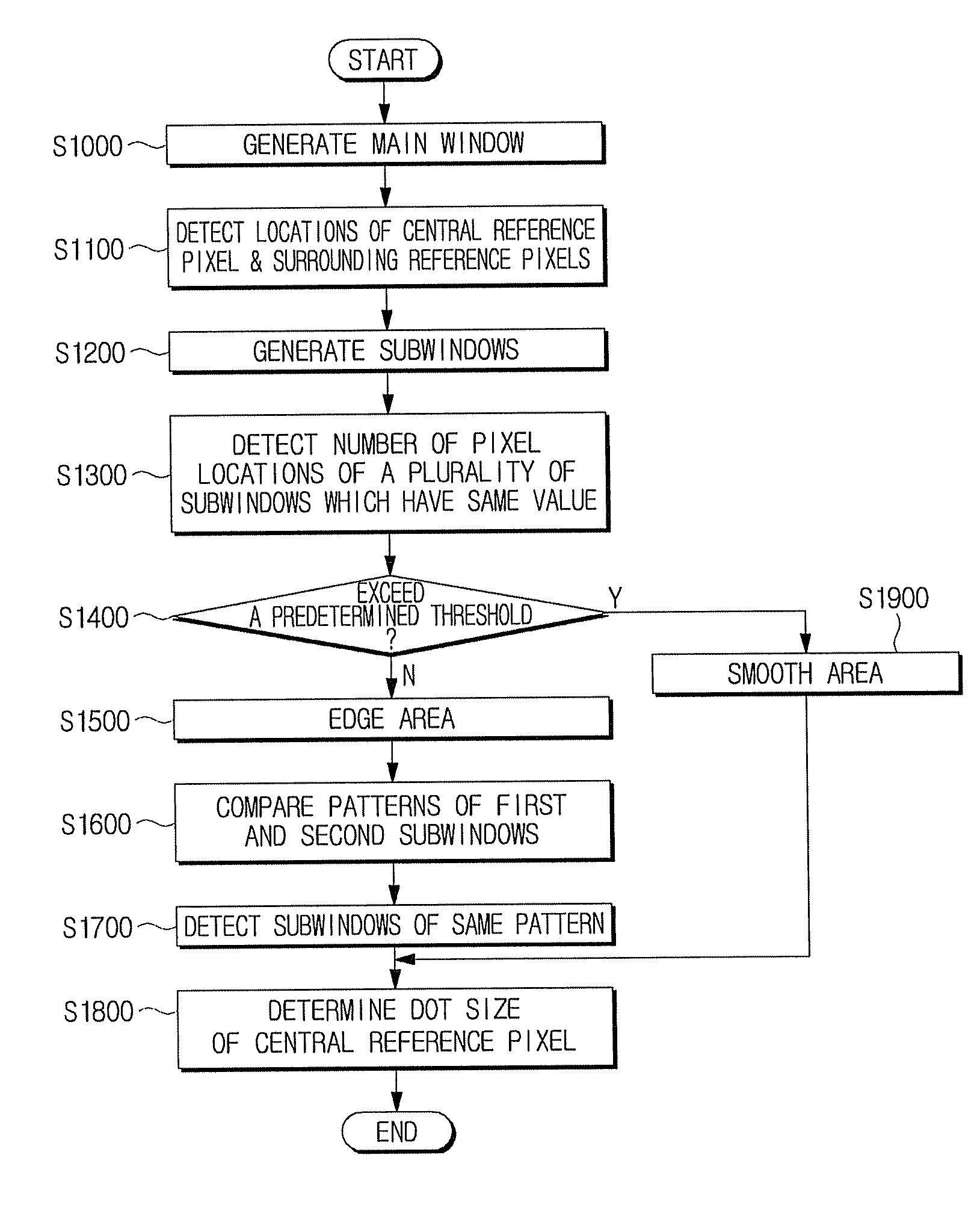

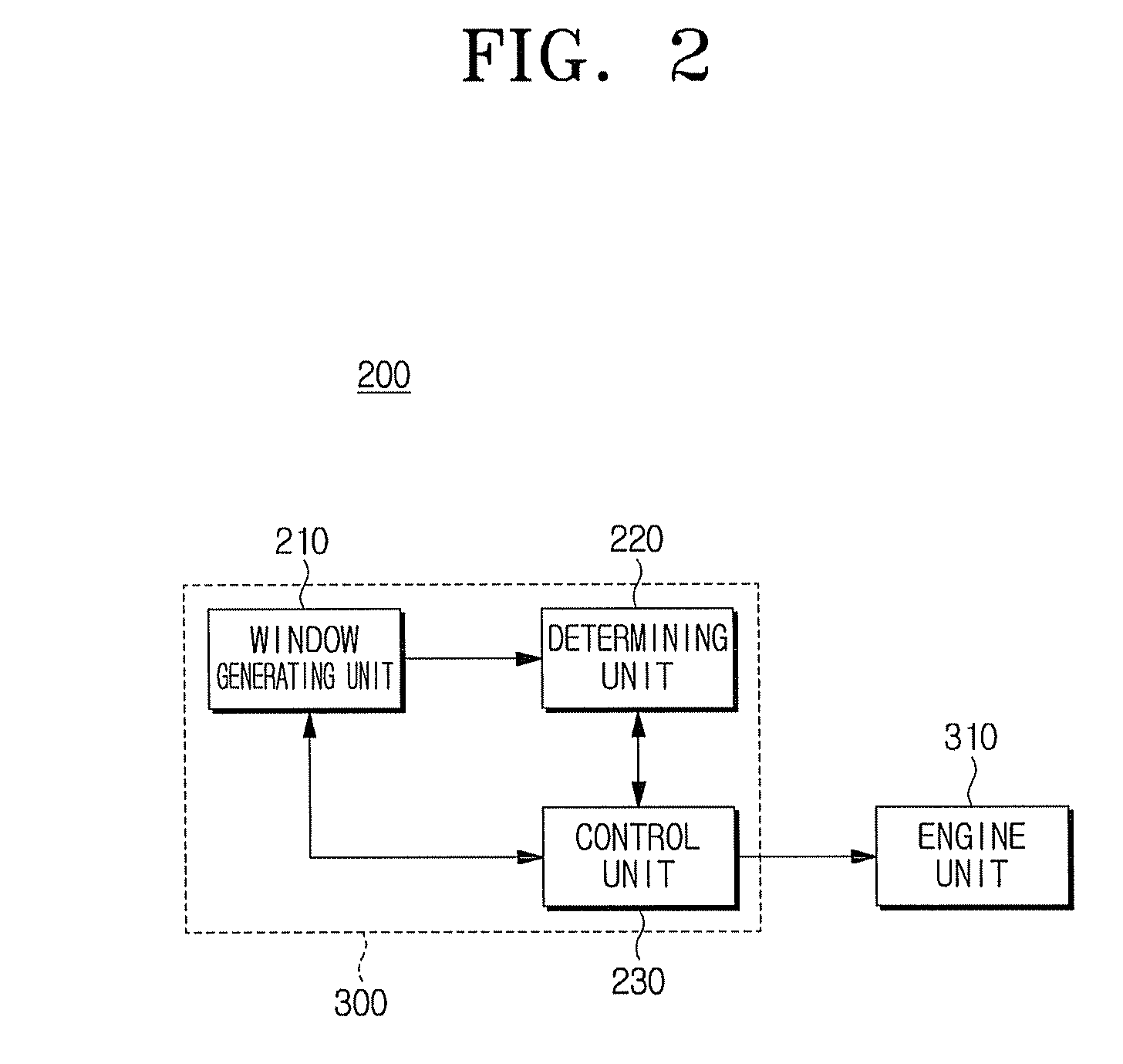

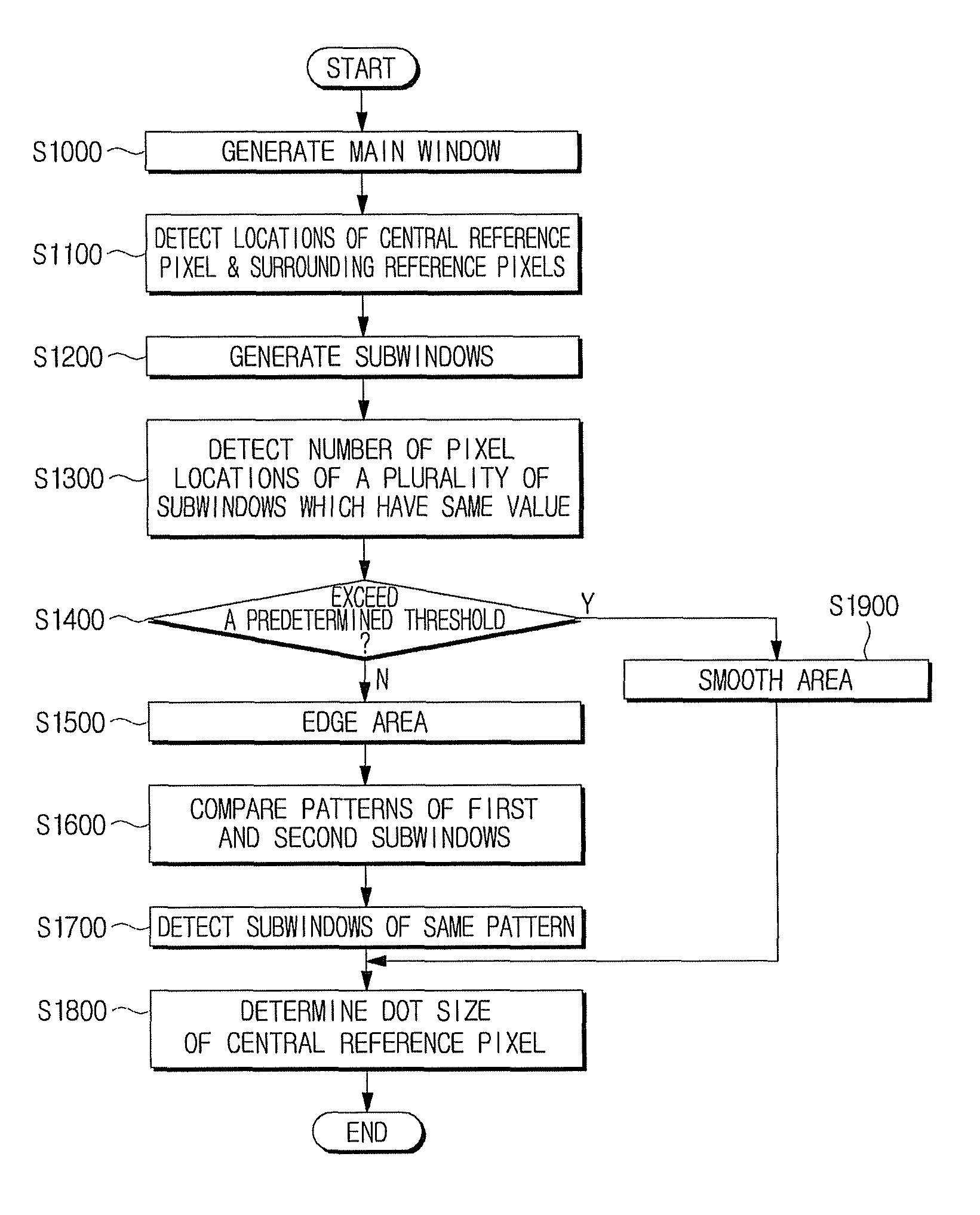

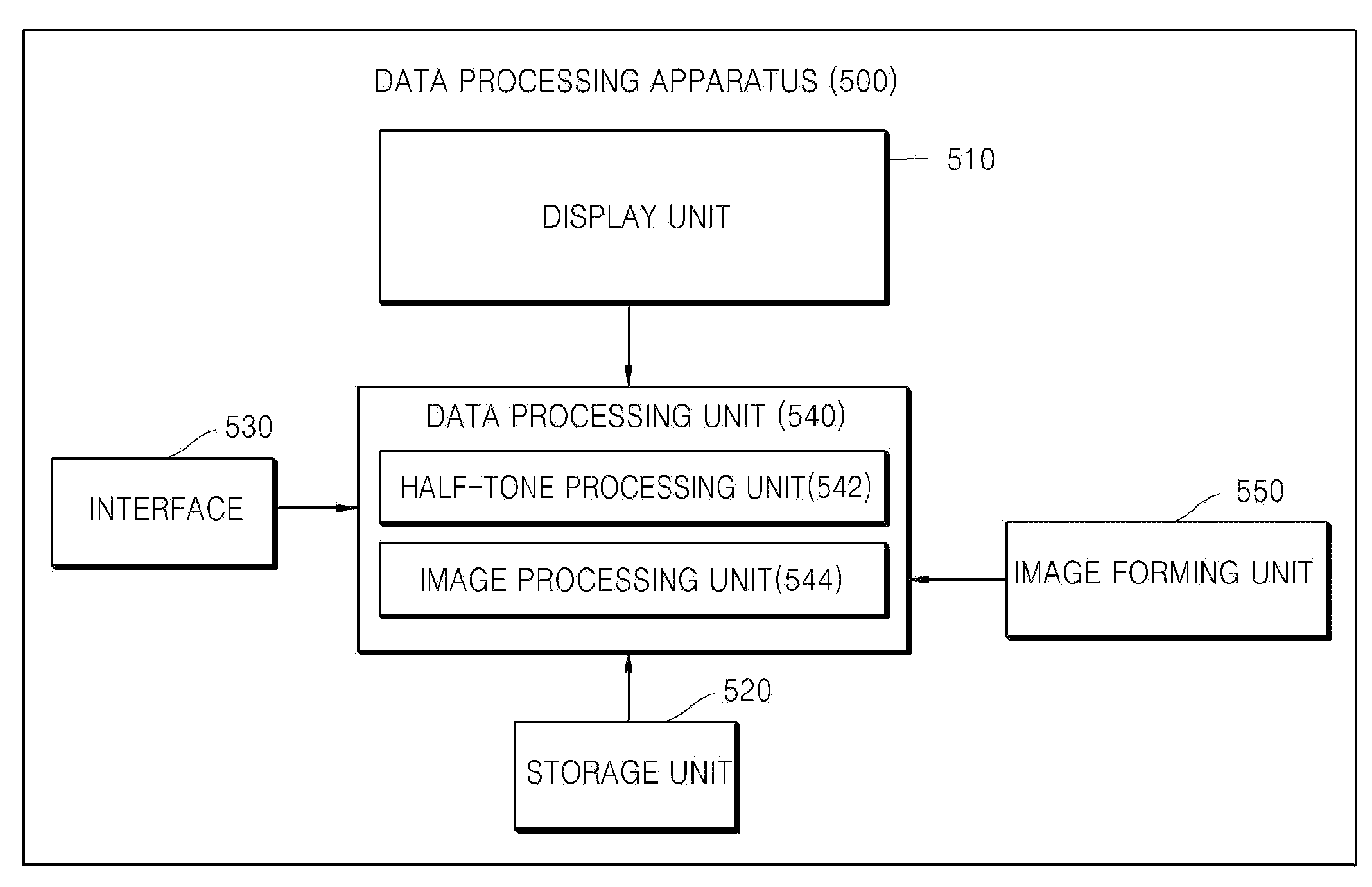

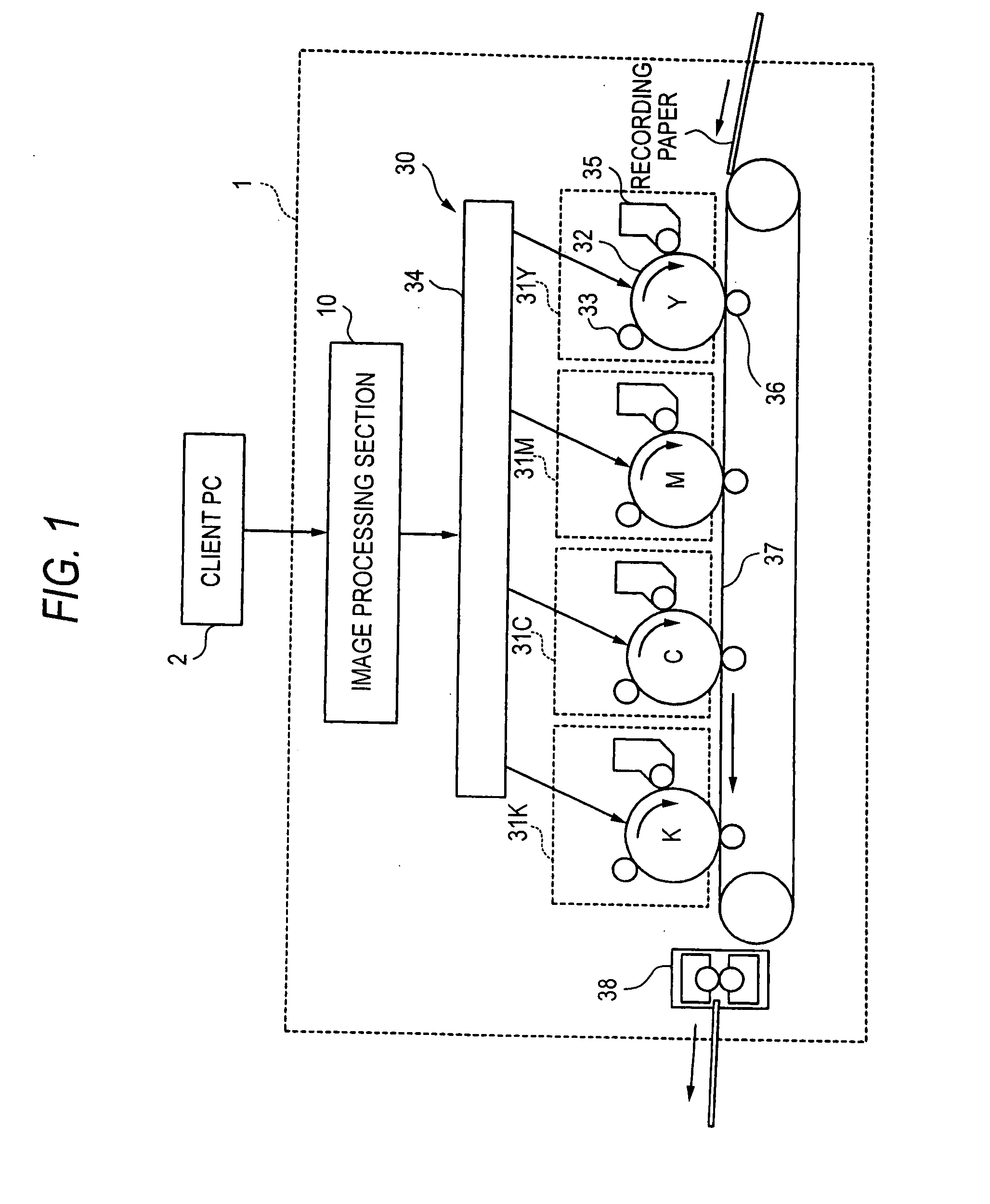

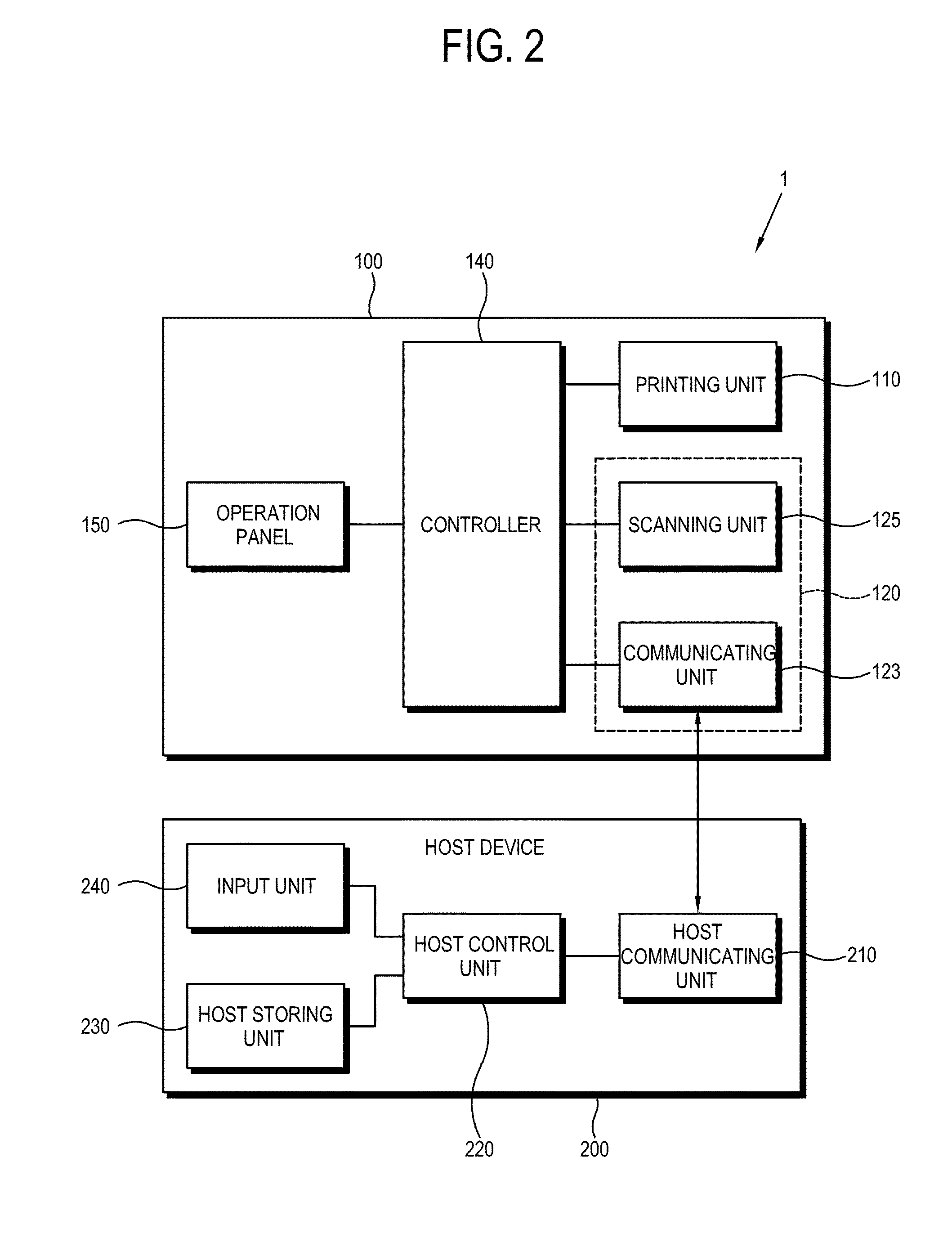

Image forming apparatus and image quality enhancement method thereof

ActiveUS20090021792A1Improve image qualityReduce usageImage enhancementVisual presentationImaging qualityImage formation

An image forming apparatus provides enhancement of image quality. The image forming apparatus includes a window generating unit to generate a main window of a predetermined size using a Lines Per Inch (LPI) and an angle of a dithering mask, and to generate a plurality of subwindows within the generated main window, a determining unit to determine the presence of an edge area by applying the plurality of generated subwindows to a binary image and according to pixel values of the binary image that correspond to the subwindows, and a control unit to determine a dot size of a central reference pixel at the center of the main window, according to the presence and absence of the edge area. Because image quality is enhanced adaptively according to edge and smooth areas, print quality improves.

Owner:HEWLETT PACKARD DEV CO LP

Image forming apparatus and method to improve image quality thereof

InactiveUS20080309955A1Improve image qualityImprove printing qualityDigitally marking record carriersDigital computer detailsGray levelImaging quality

An image forming apparatus to improve image quality. The image forming apparatus includes a window control unit to generate a window of a predetermined size using a lines per inch (LPI) value of a dithering mask and an angle, and to detect locations of a center reference pixel and neighboring reference pixels in the window, a weighting set unit to apply weighted values to the reference pixels based on locations of the detected center reference pixel and the neighboring reference pixels, and a control unit to determine a dot size of the center reference pixel corresponding to weighted values corresponding to locations of black pixels of the center reference pixel and neighboring reference pixels. Accordingly, image quality is improved by generating dots corresponding to a plurality of gray levels based on weighted values.

Owner:S PRINTING SOLUTION CO LTD

Image processing apparatus and image processing method

InactiveCN101197912APrevent degradationLarge capacityTelevision system detailsImaging processingLines per inch

The present invention discloses an image processing apparatus and an image processing method. An image processing apparatus includes a receiving section, an edge detection section and a screen processing section. The receiving section receives image information. The edge detection section detects an edge area from the image information received by the receiving section. The screen processing section performs a screen process, which is based on area coverage modulation, for the image information on a basis of the detection result by the edge detection section. The screen processing section performs a screen process for the edge area detected by the edge detection section with (i) a screen angle, which is equal to that of a screen process performed for a non-edge area other than the edge area, and (ii) a number of lines per inch, which is an integer multiple of that of the screen process performed for the non-edge area.

Owner:FUJIFILM BUSINESS INNOVATION CORP

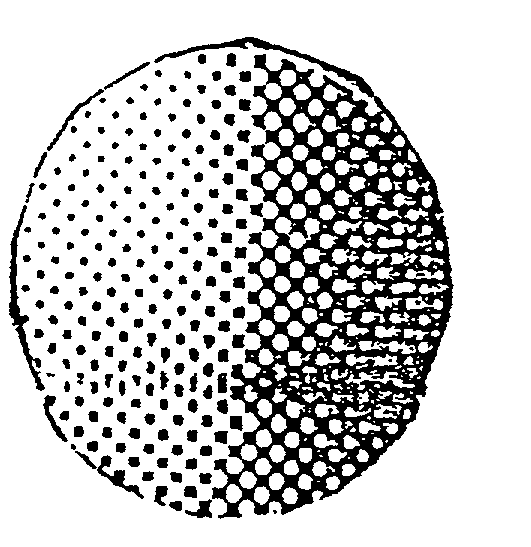

Halftone method and apparatus that provides simultaneous, multiple lines per inch screens

InactiveUS7170639B1Lift restrictionsVisual presentationPictoral communicationAlgorithmDividing attention

A halftone threshold matrix includes a plurality of submatrices, wherein a first group of the plurality of submatrices has a line screen frequency different from a second group of the plurality of submatrices. The halftone method and apparatus removes the restriction that at most one pel is turned on per basic cell for the next constant input level and allows the pels in some basic cells to be turned on much sooner that the corresponding positions in other basic cells. This creates a dominant low frequency line screen simultaneously with the higher frequency line screen of the other basic cells. The present invention also allows the basic cells inside the threshold matrix to have different shapes and sizes. Thus, the cells participating in the low frequency screen could be larger than the cells generating the higher frequency screen. For example, the low frequency screen's pleasing patterns can distract the eye from noticing less pleasing patterns in the high frequency grid and vice versa.

Owner:RICOH KK

Image forming apparatus and image quality enhancement method thereof

InactiveUS8054506B2Improve image qualityReduce usageImage enhancementVisual presentationImaging qualityImage formation

An image forming apparatus provides enhancement of image quality. The image forming apparatus includes a window generating unit to generate a main window of a predetermined size using a Lines Per Inch (LPI) and an angle of a dithering mask, and to generate a plurality of subwindows within the generated main window, a determining unit to determine the presence of an edge area by applying the plurality of generated subwindows to a binary image and according to pixel values of the binary image that correspond to the subwindows, and a control unit to determine a dot size of a central reference pixel at the center of the main window, according to the presence and absence of the edge area. Because image quality is enhanced adaptively according to edge and smooth areas, print quality improves.

Owner:HEWLETT PACKARD DEV CO LP

Dampening water control method and printing apparatus

InactiveUS20060162590A1Increased variation of densityHigh control sensitivityAddressographsPlaten pressesLines per inchVolumetric Mass Density

Line patches m and solid patches s are printed with a subject image, each line patches having at least 200 lines per inch and a duty ratio of at least 60%, to detect densities Dm and Ds. A water coefficient W (=Dm / Ds) is calculated from the detected densities Dm and Ds. Whether dampening water is fed at a proper rate or not is determined based on correlation data stored beforehand and showing a relationship between the feed rate of dampening water and the water coefficient W. The feed rate of dampening water is controlled to be a proper rate.

Owner:DAINIPPON SCREEN MTG CO LTD

Document processing method and apparatus

InactiveUS20100007897A1Avoid quality lossDigitally marking record carriersVisual presentation using printersLines per inchDocumentation

A document processing apparatus and method, the method including: selecting a document to be printed; displaying a user interface; setting at least one a number of vertical lines per inch value and a brush pattern expansion value, via the displayed user interface; and converting the document into printing data, according to the set value.

Owner:S PRINTING SOLUTION CO LTD

Devices and methods for offset and similar printing systems

InactiveUS20020005961A1Digitally marking record carriersDigital computer detailsLines per inchContinuous tone

Owner:SHIRA COMP

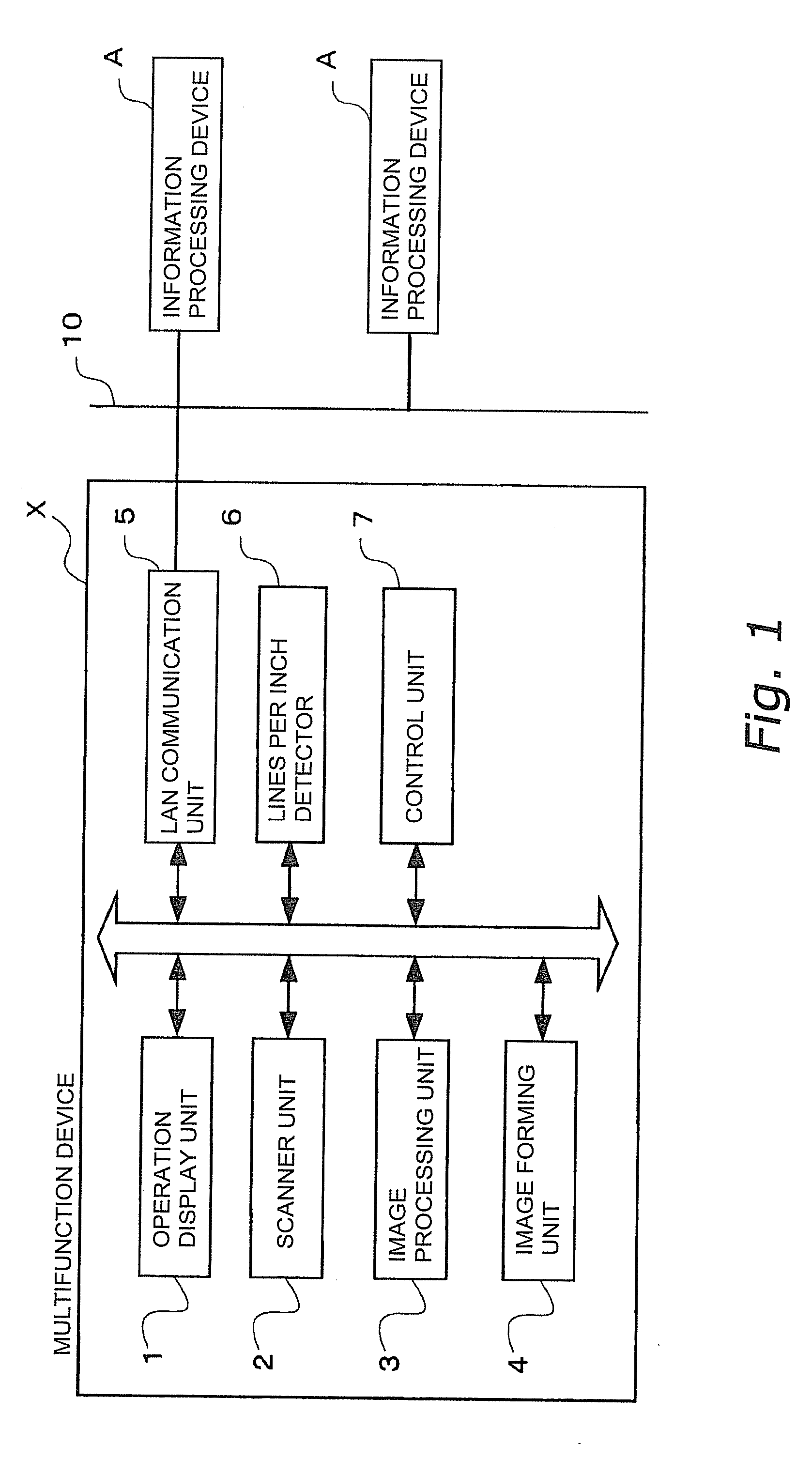

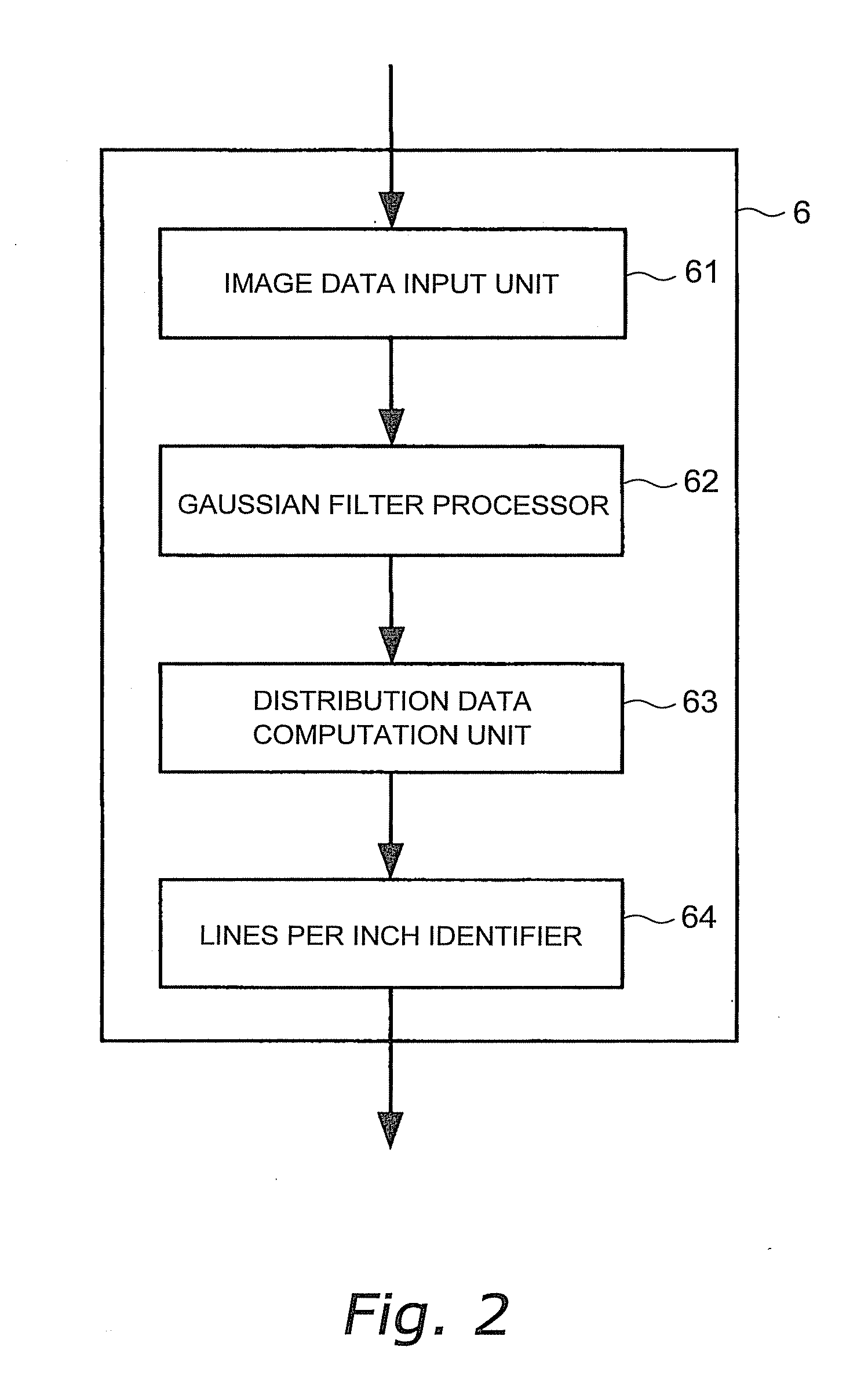

Image forming device

InactiveUS20070053732A1Shorten the timeReduce storage region for storingElectrography/magnetographyPictoral communicationPattern recognitionLines per inch

An image forming device is disclosed which can easily and promptly execute a copy restriction process that restricts the copying of an original document based on a background pattern included in the original document image that is obtained by scanning the original document. In the restriction process, when an original document is scanned, the number of lines (i.e., lines per inch) in the background pattern included in the original document image will be detected. Then, it will be determined whether the detected number of lines per inch is a predetermined number of lines per inch (e.g., less than 65 LPI). Based on the determination result, the copying of the original document will either be permitted or restricted.

Owner:KYOCERA DOCUMENT SOLUTIONS INC

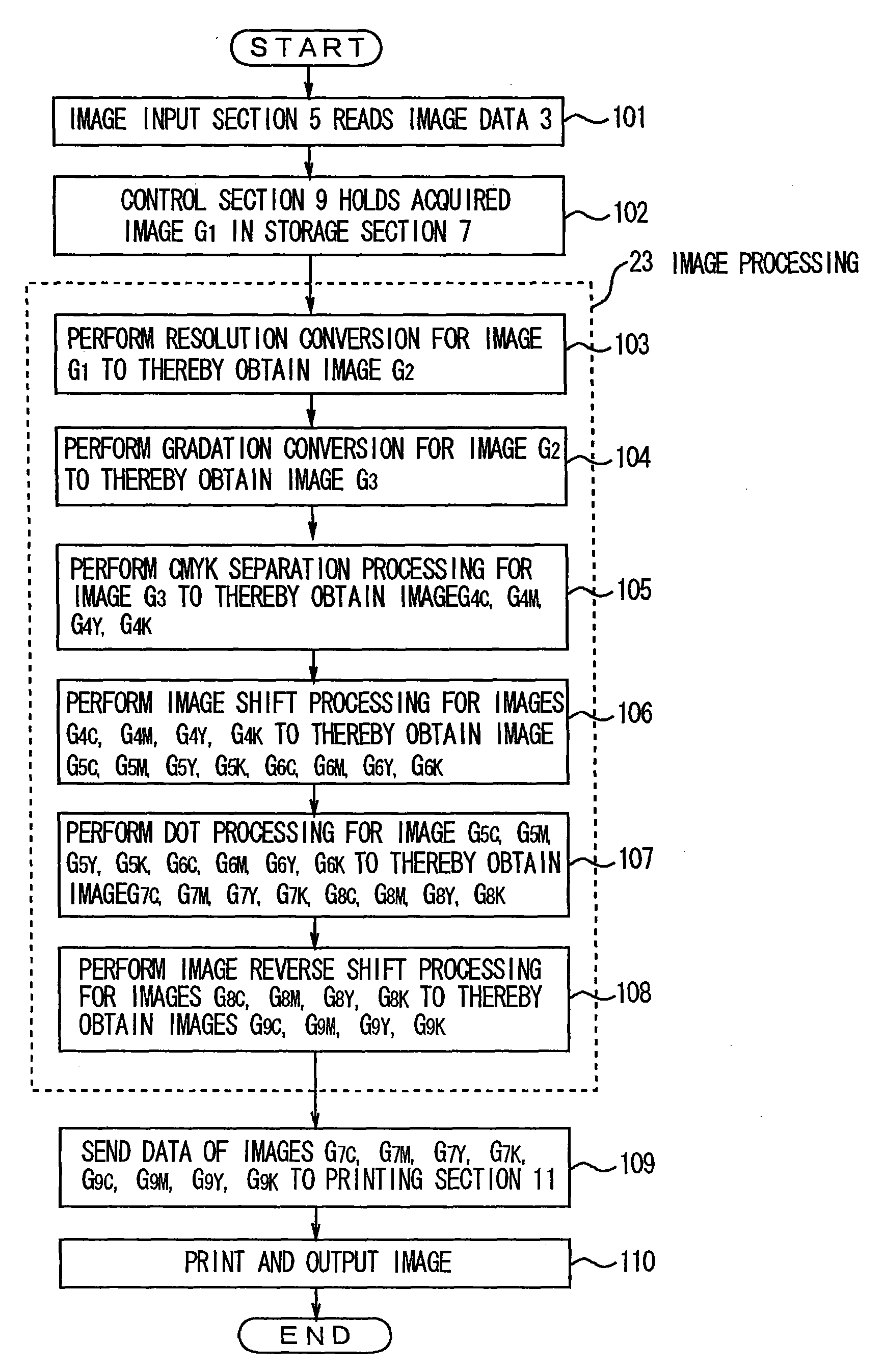

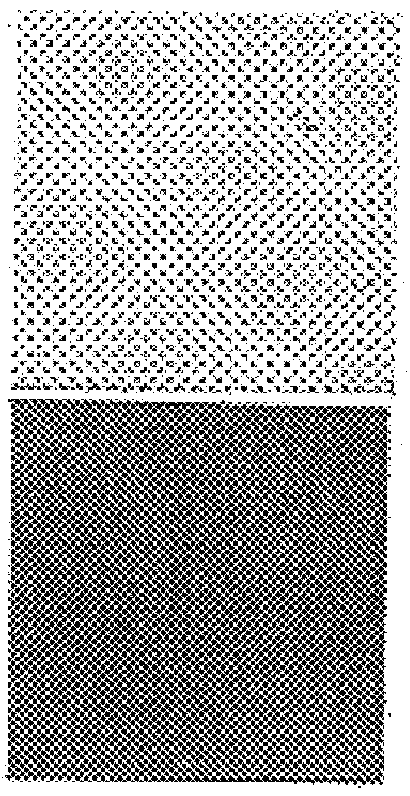

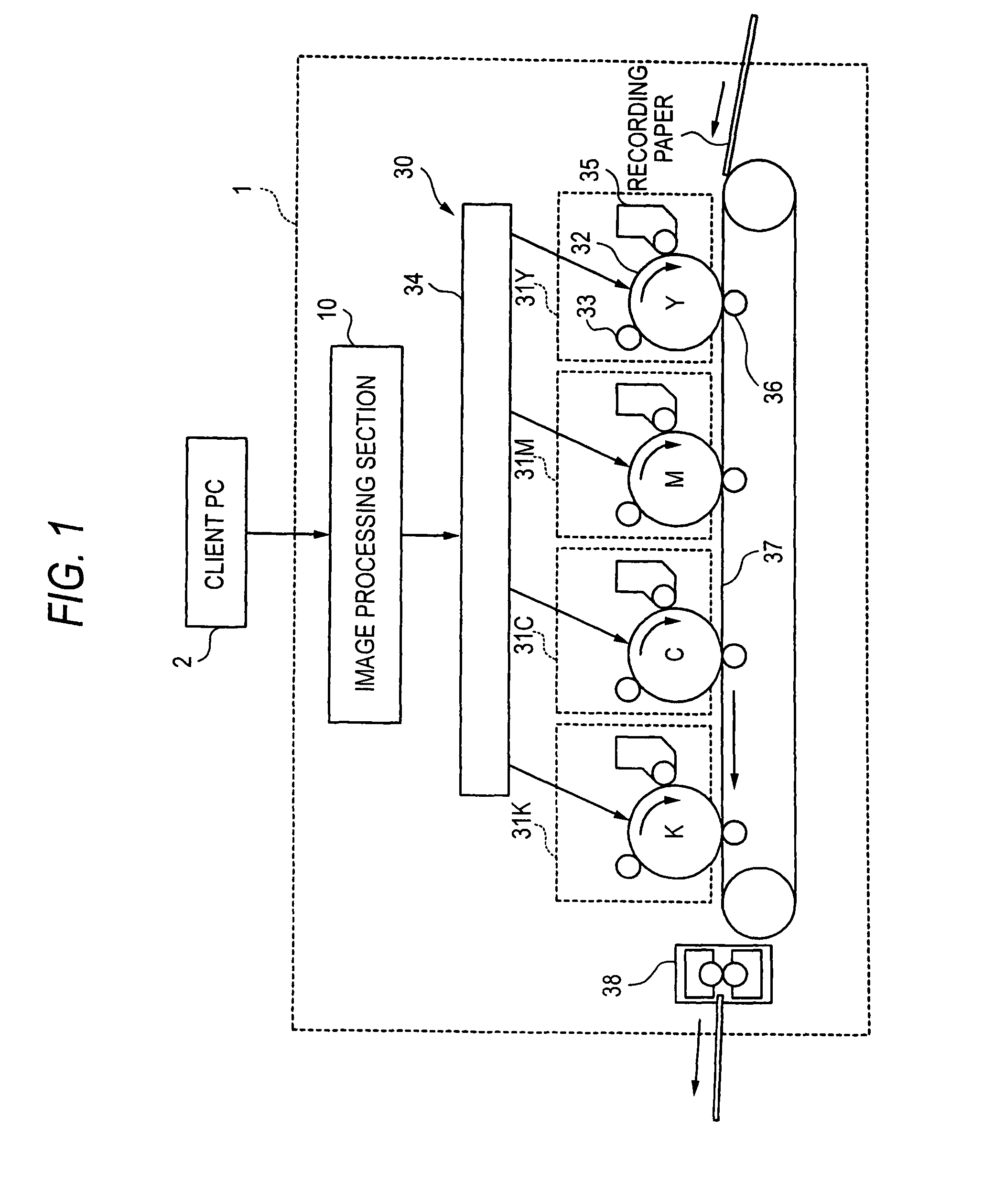

Thermal recording apparatus, image forming method, and printed object

InactiveUS20090066776A1Mission failureSmoothing imageRecording apparatusInking apparatusImage resolutionImage formation

A control section 9 of a thermal printer 1 performs resolution conversion, gradation conversion, and CMYK color separation for input image data 3. After that, for image data of each color, the control section 9 performs shift processing for double-tone printing, to thereby obtain two types of image data. The control section 9 performs dot conversion and reverse shift processing for these image data, and prints the two types of image data in a superposed state. In the shift processing, the control section 9 shifts the image data of each color by the number of pixels corresponding to the resolution of the thermal printer 1 and the number of lines per inch. At that time, the image data of each color may be shifted by the corresponding number of pixels which differs among the colors. Further, for some colors, single-tone printing is performed, rather than double-tone printing, to thereby reduce the number of times of overprinting. Further, dot-on-dot processing, which is special shift processing, is performed for image data of a color to be printed second or later. Image data combining is performed such that the image data having undergone the dot-on-dot processing is used in a highlight region, and the image data having undergone the ordinary shift processing is used in the remaining region.

Owner:DAI NIPPON PRINTING CO LTD

Devices and methods for offset and similar printing systems

InactiveUS6163382ADigitally marking record carriersDigital computer detailsContinuous toneLines per inch

A method for producing a half-tone image faithfully representing a continuous-tone original includes a step of forming in the image a pattern of substantially continuous, substantially parallel lines at a frequency of between about 100 and 400 lines per inch, such that the width of the lines at a given point in the image varies in relation to the optical density of at least one color component at a corresponding point in the continous-tone original. The method may be used for color separations with each separation produced by scanning at a different angle. The method may be implemented using photomechanical or electronic scanning techniques.

Owner:SHIRA COMP

Image processing apparatus and method for generating an image signal for gradation

InactiveUS7796302B2Television system detailsDigitally marking record carriersImaging processingLines per inch

Owner:FUJIFILM BUSINESS INNOVATION CORP

Frangible card carrier with removable layer provided in a temporary laminated assembly

InactiveUS20070085338A1Effective and economical processOther printing matterLines per inchEngineering

The present invention relates to a temporary card carrier laminate that is produced by using a substantially rigid card base that is coated with a curable material. The coating is used to create a bond between the card base and an over laminate that is readily broken upon application of sufficient tearing pressure. The over laminate is then left substantially free of any adhesive residue after it is removed from the laminate assembly. The temporary laminate is produced through a unique process that includes preparing an over laminate web by printing, then cutting the web into individual segments and placing each of the segments on individual card blanks and then curing the card carrier assemblies. The web and / or card base are printed with indicia at a resolution of greater than about 150 lines per inch.

Owner:WARDKRAFT

Printing process for UV (ultraviolet) snowflake pattern by offset printing

InactiveCN103625138AImprove printing process efficiencyStrong flash effectOther printing apparatusPrinting after-treatmentComputer to plateLines per inch

The invention belongs to the technical field of printing, and in particular relates to a printing process for finishing a UV (ultraviolet) snowflake pattern by offset printing. The technical scheme of the printing process is characterized by comprising the following steps: (1) designing and typesetting according to the printed characters, patterns and signs to generate to a CTP (computer-to-plate) with 150 to 200 lines per inch; (2) arranging the CTP generated in the step (1) to the last group of printing units of a UV offset printing machine, and placing printing paper into a Fidek; (3) adjusting the viscosity of UV offset printing snowflake printing ink to be 20 to 30 S, and adjusting an inking position of the UV offset printing machine to be 20 to 70 percent; (4) adjusting the paper feeding speed of the UV offset printing machine to be 7,000 to 12,000 pieces / hour, starting a UV drying system of the UV offset printing machine, adjusting the drying power of the UV drying system to be 2 to 5 Kw, and starting the machine to print. According to the printing process, the UV snowflake pattern is printed by adopting the offset printing machine, so that the consumption of the printing ink is effectively reduced, the printing efficiency is improved, and the UV snowflake pattern with a strong flash effect and three-dimensional effect can be generated by printing once.

Owner:SHENZHEN NINE STARS PRINTING & PACKAGING GRP

Halftone method and apparatus that provides a line screen frequency of N/2 for a printer resolution of N dots per inch without negative print effects

InactiveUS7835034B1Negative print effectLower the thresholdVisual presentationPictoral communicationRotation functionImage resolution

A halftone method and apparatus provides a line screen frequency of N / 2 for a printer resolution of N without negative print effects. A 300 lines per inch halftone screen for a 600 dpi printer may thus be created by alternating white and saturated colored lines when half of a given color component's pels are on. Empirical rules are used to create the screens based on how that printer creates consistent and reliable levels for each color component. These rules allow intermediate intensity values between white and full-on at each pel. Since the halftoning is done in the hardware just before printing, the print direction relative to the threshold matrix is known. No rotation capability is needed in the hardware. If an image needs to be rotated, it can be done previously to being sent to the hardware. Furthermore, because a pair of pels are turned on for the lightest values (or possibly with a one level difference between the first and second dots in the pair), the electronics are stressed less. Moreover, the drive will be at a lower frequency than the first dot in the traditional halftone cell, which remains isolated for many levels.

Owner:RICOH KK

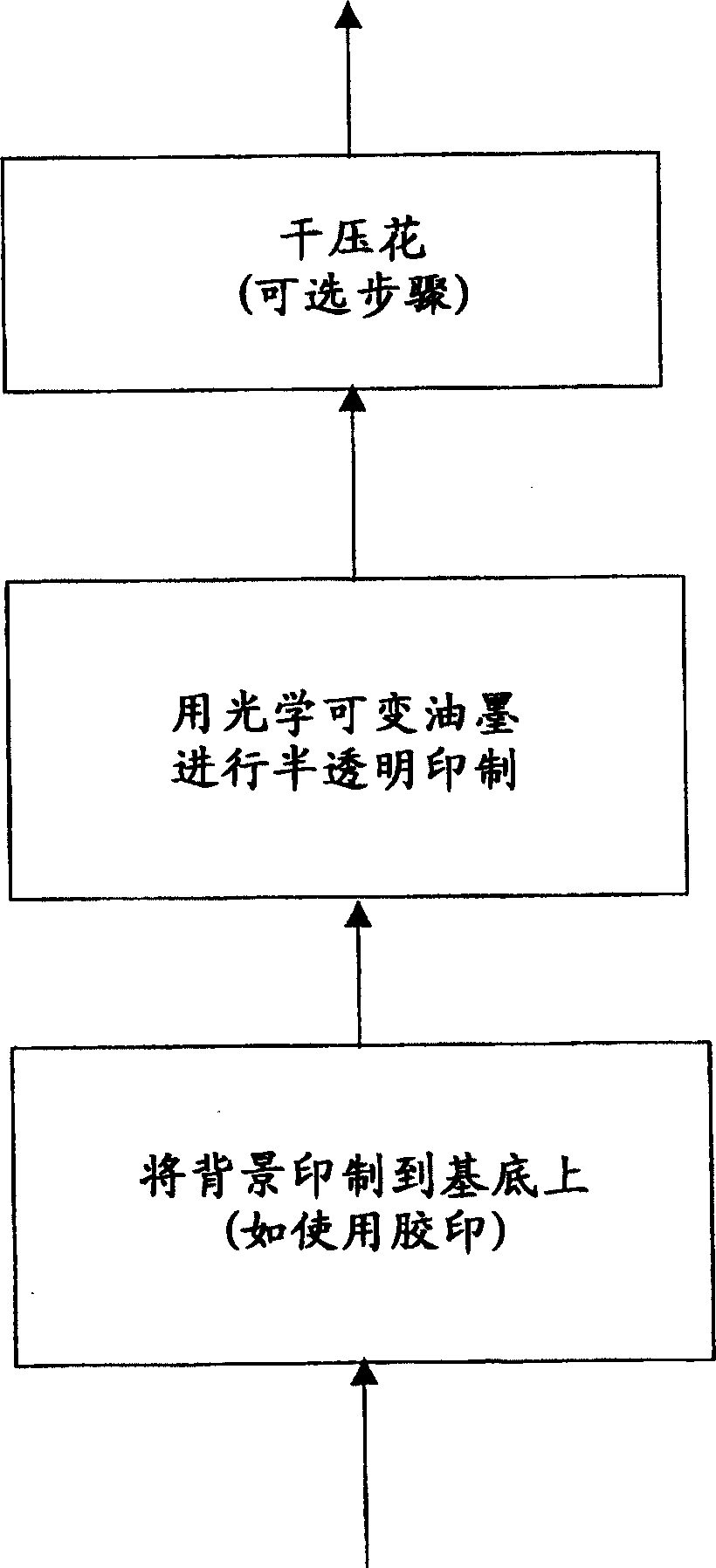

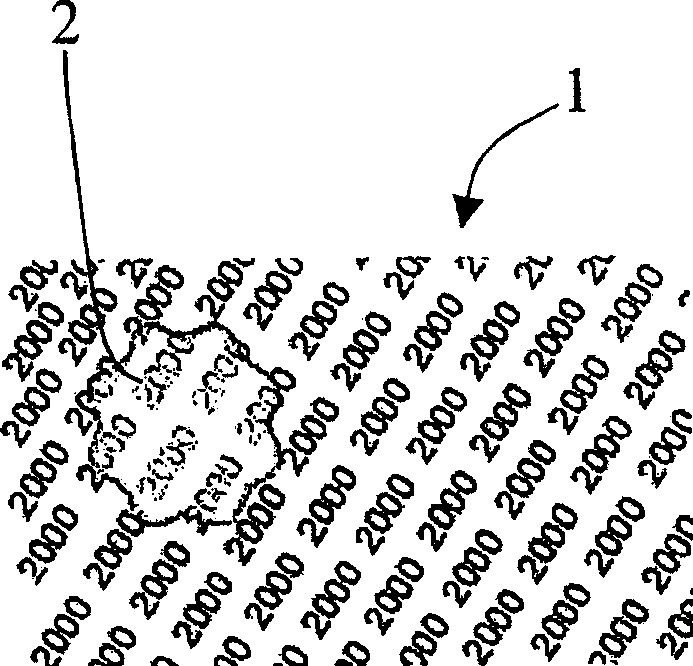

Method for printing a security element and security element

The process involves printing a semi-transparent security unit (2) with variable optical ink on a base (1) of a substrate. The security unit is printed to cover the base. The semi-transparent security unit is printed by a serigraphy process. A sifter utilized in the serigraphy process comprises 180 to 230 lines per inch according to X and Y directions of the sifter. An Independent claim is also included for a value-paper.

Owner:KBA NOTASYS SA

Image processing apparatus and image processing method

InactiveUS20080137962A1Television system detailsDigitally marking record carriersImaging processingLines per inch

An image processing apparatus includes a receiving section, an edge detection section and a screen processing section. The receiving section receives image information. The edge detection section detects an edge area from the image information received by the receiving section. The screen processing section performs a screen process, which is based on area coverage modulation, for the image information on a basis of the detection result by the edge detection section. The screen processing section performs a screen process for the edge area detected by the edge detection section with (i) a screen angle, which is equal to that of a screen process performed for a non-edge area other than the edge area, and (ii) a number of lines per inch, which is an integer multiple of that of the screen process performed for the non-edge area.

Owner:FUJIFILM BUSINESS INNOVATION CORP

Method of producing printed business communication laminates from dissimilar substrates having different thicknesses and products produced therefrom

InactiveUS20070077400A1Improve graphicsImprove image qualityDecorative surface effectsDuplicating/marking methodsGraphicsImage resolution

The present invention is directed toward a business communication laminate that is constructed from at least two layers having significantly distinct thicknesses. The first layer is provided with printing or imaging having a resolution of greater than about 150 lines per inch. Through preparation of the laminate in accordance with the present invention, high quality graphics and imaging can be applied to materials, such as thick corrugated substrates, to create effective business communication substrates and marketing collateral.

Owner:WARDKRAFT

Method for generating basic template utilized to form screening mask

InactiveUS20080246980A1Avoid influenceImage enhancementDigitally marking record carriersAlgorithmGray level

Disclosed is a method for generating a basic template utilized to form a screening mask. The method includes adjusting lines per inch or minimum pattern (such as cluster size or density) of a testing template, printing the adjusted testing template by an outputting device, determining if the gray level of the printing result matches a specific gray level, and continuously adjusting the setting of the lines per inch or the minimum pattern when it does not match the specific gray level, otherwise selecting the adjusted testing template as a basic template. The basic template is optimized according to the printing ability of the outputting device, so the printing performance of the outputting device when using the screening mask formed from the basic template can also be optimized, and the minimum color points can be printed faithfully thereby avoiding dropping of the carbon powder.

Owner:PRIMAX ELECTRONICS LTD

Image processing device and image processing method

InactiveCN102984430BAlleviate the feeling of not fitting the converted imagePictoral communicationImaging processingLines per inch

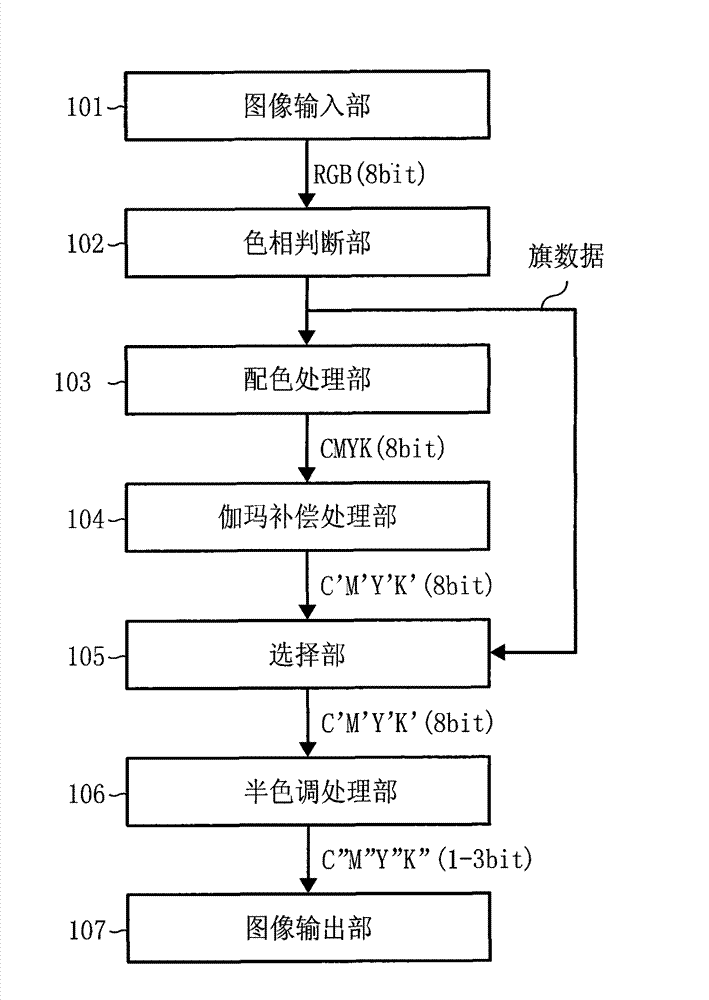

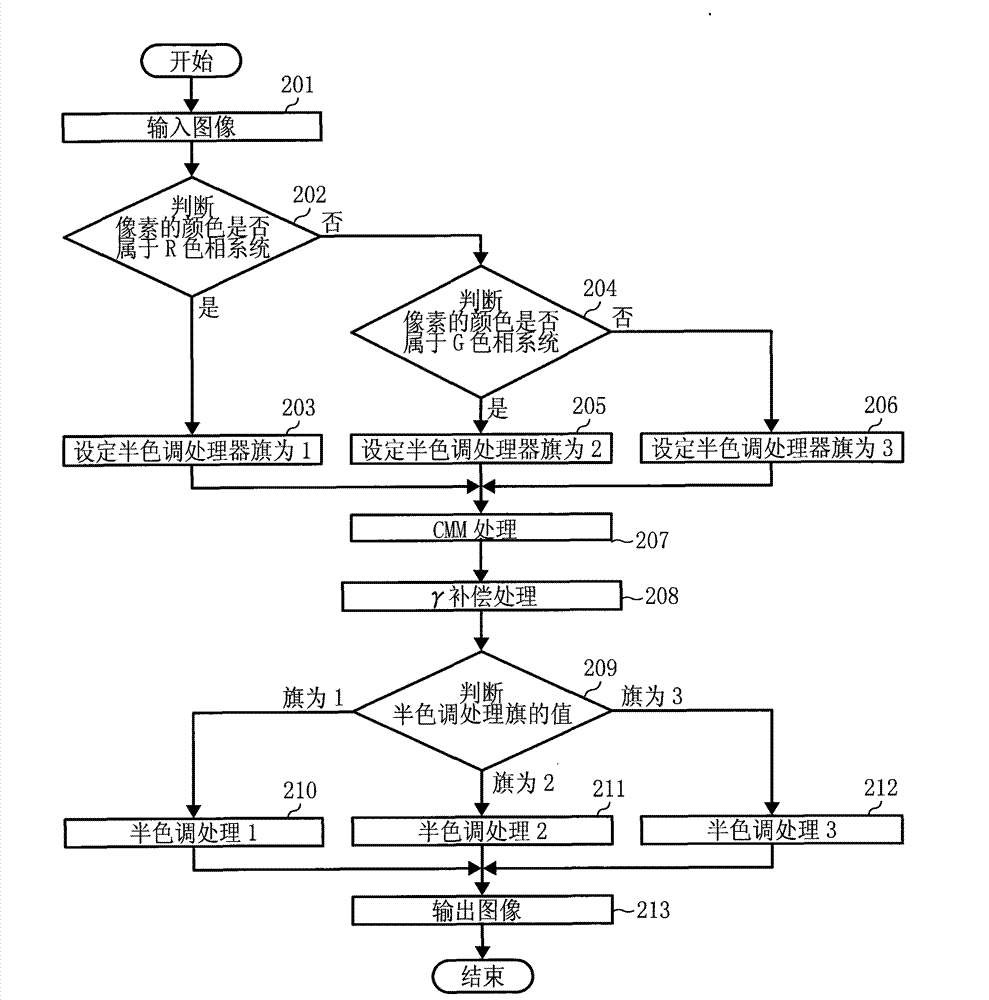

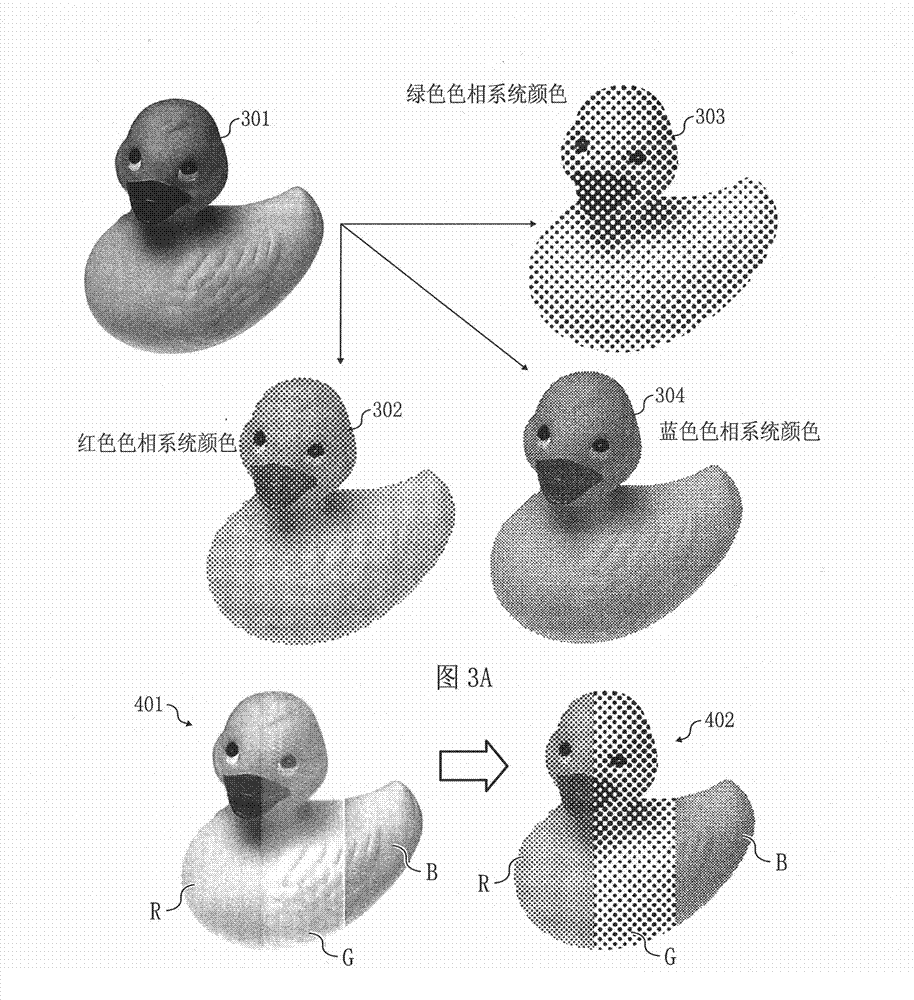

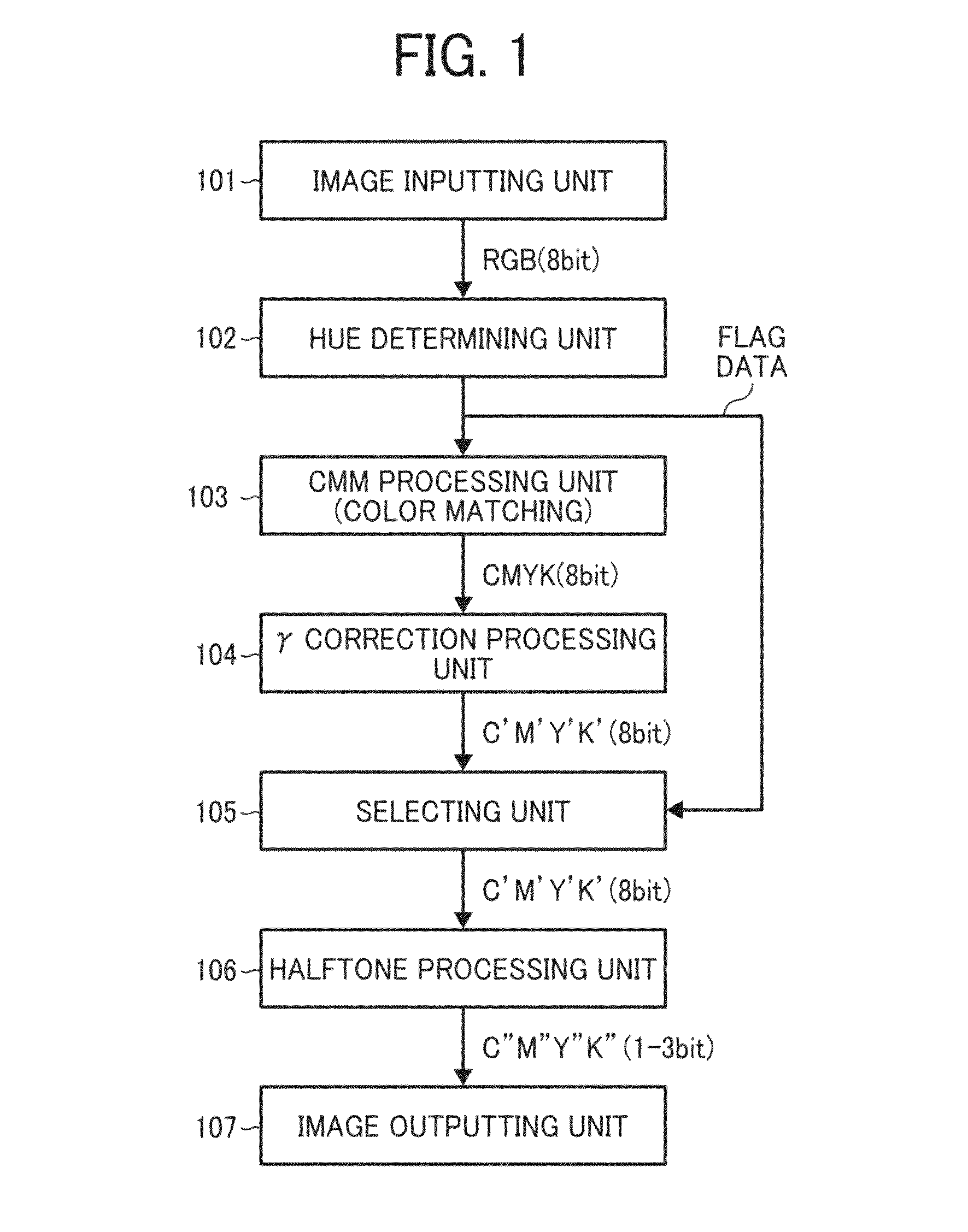

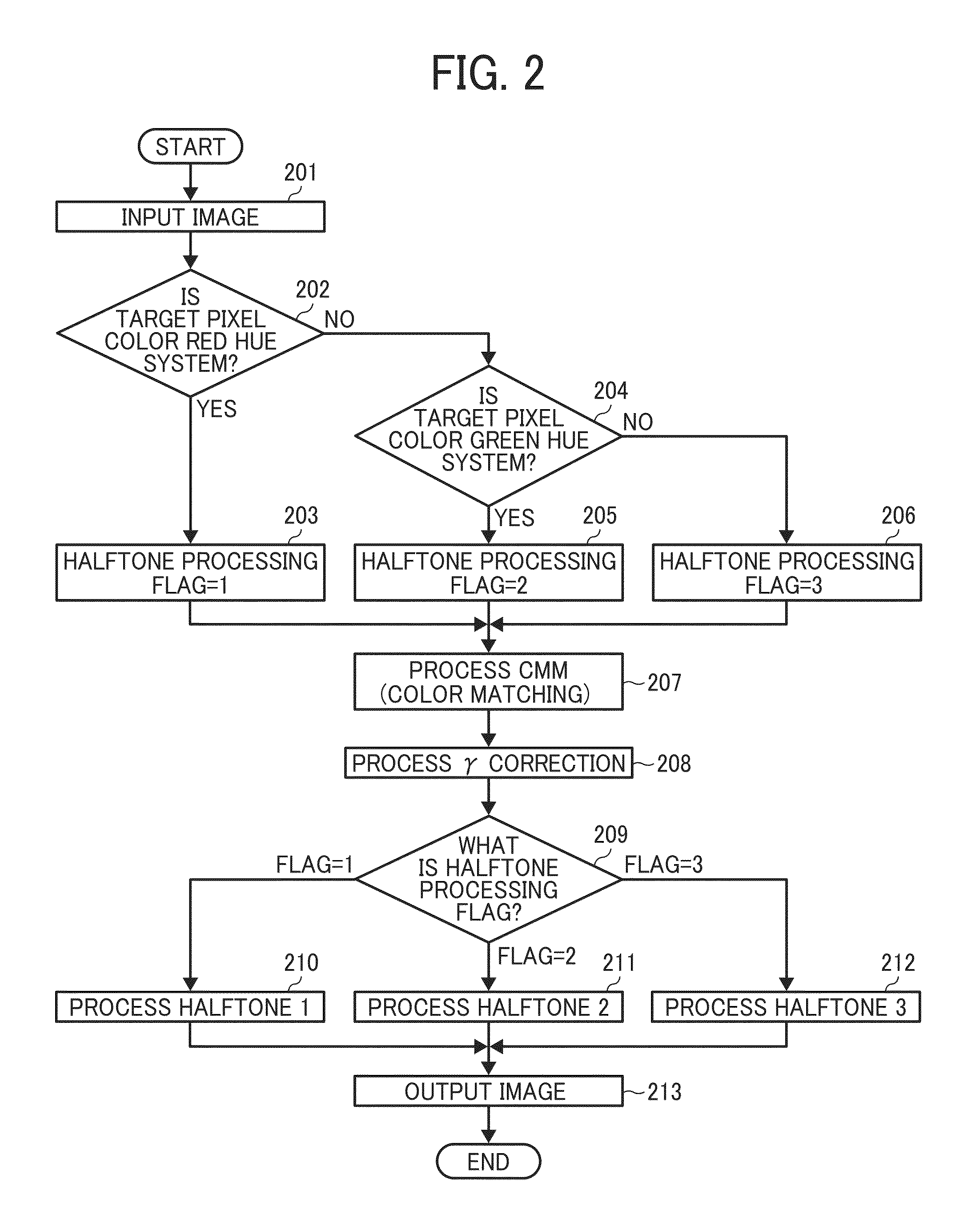

An image processing system that facilitates process of color universal design that enables people with color amblyopia to recognize color difference as image pattern without changing characteristic of coloration and gradation and people with no disabilities who look the same image to feel less discomfort. A hue determining unit 102 determines hue of image data, and a selecting unit 105 selects halftone processing in accordance with the determined hue. If the selected halftone processing is dithering process that uses AM dithering, a halftone processing unit 106 executes halftone processing with different line per inch depending on the determined hue.

Owner:RICOH KK

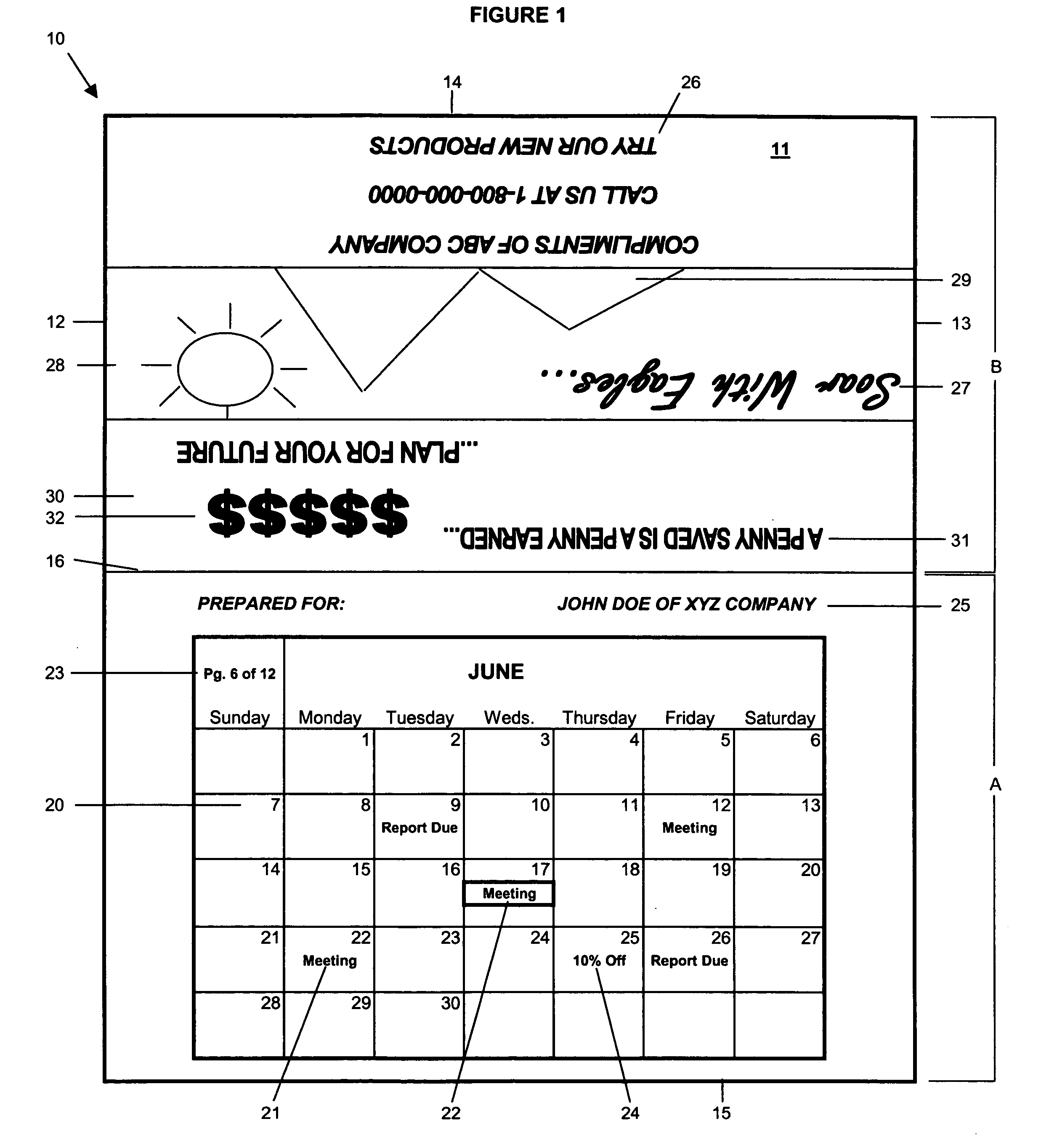

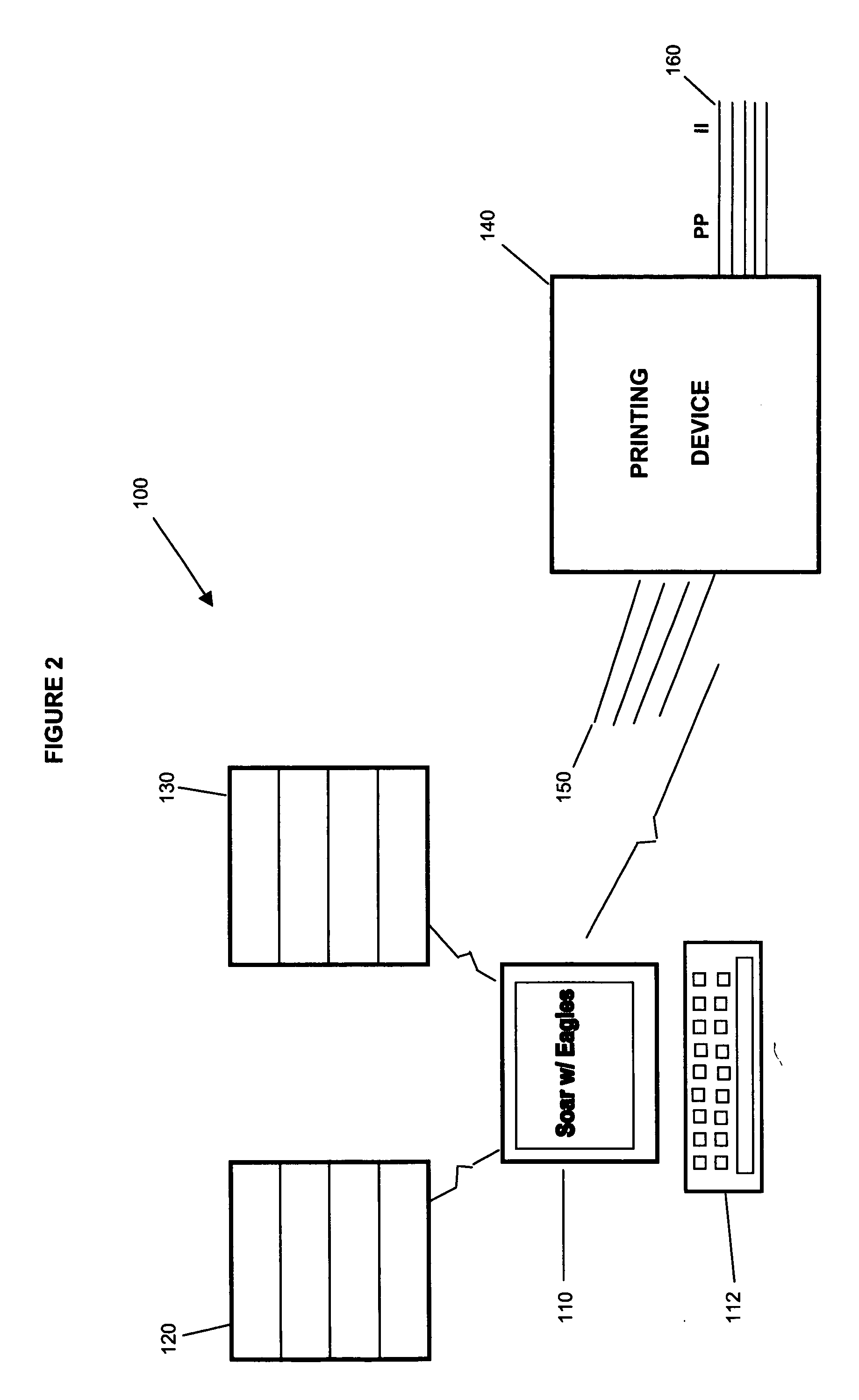

System for preparing personalized chronological sheets and product resulting therefrom

InactiveUS20070083555A1Office automationSpecial data processing applicationsPersonalizationImage resolution

The present invention is directed toward a system for rendering a personalized calendar for a series of pre-determined subscribers. The system enables users through a computer interface to select from a database of inspirational and motivational phrases and images and to obtain chronological information from a second database in order to create a highly personalized calendar sheet having a resolution of greater than about 150 lines per inch. The system may be provided at a single location or alternatively, the system may be provided at remote locations and the personalized products delivered by courier or other acceptable means.

Owner:WARDKRAFT

Image forming apparatus that emphasizes a boundary between two objects using a halftoning process

ActiveUS8498019B2Reduce impactReliable detectionDigitally marking record carriersOrganic chemistryImage formationLines per inch

Owner:HEWLETT PACKARD DEV CO LP

Image processing system, method, program, and storage medium to implement universal color design

InactiveUS8787640B2Designing can be facilitatedLess discomfortCharacter and pattern recognitionVisual presentationImaging processingLines per inch

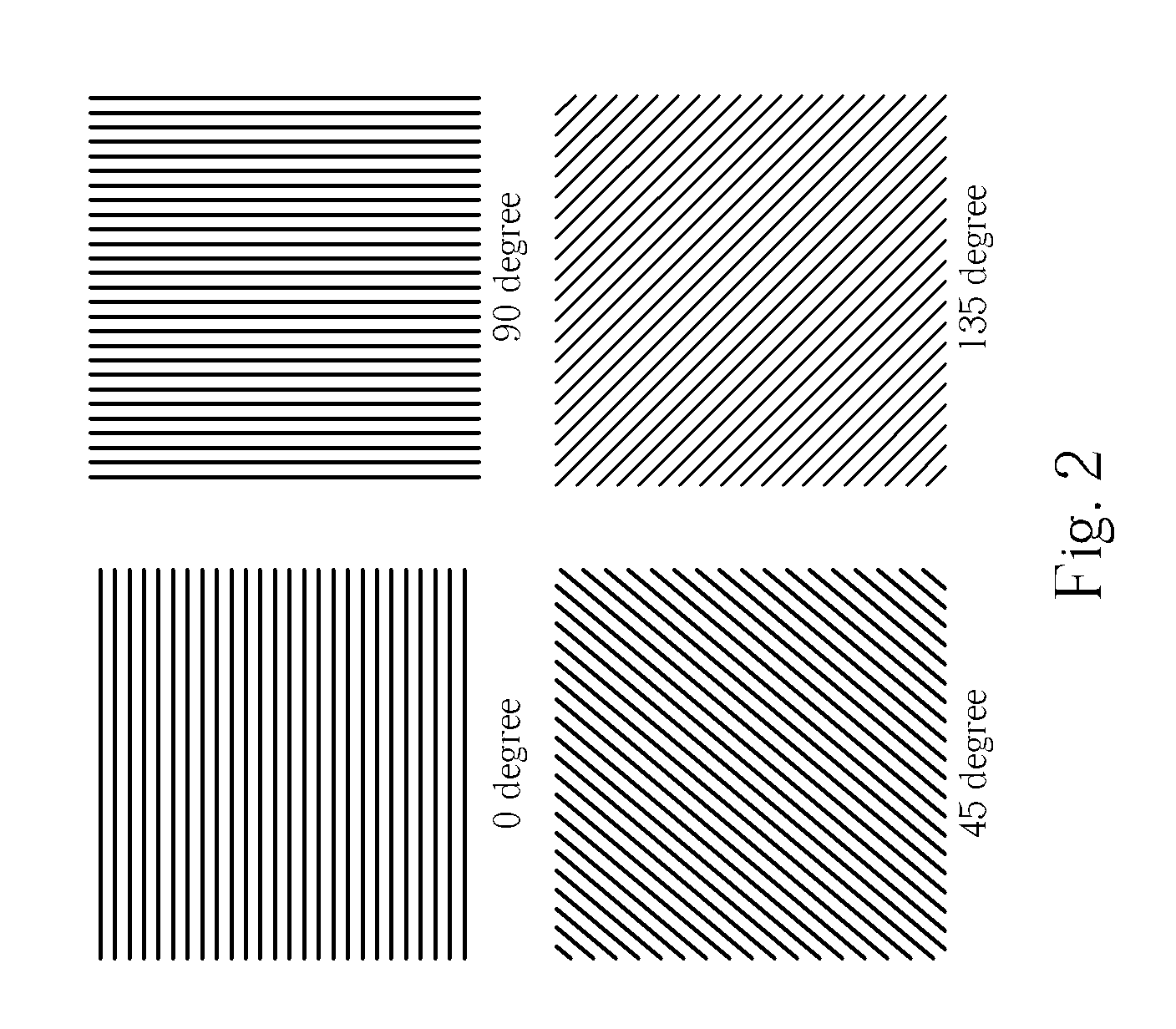

An image processing system that facilitates process of color universal design that enables people with color amblyopia to recognize color difference as image pattern without changing characteristic of coloration and gradation and people with no disabilities who look the same image to feel less discomfort. A hue determining unit 102 determines hue of image data, and a selecting unit 105 selects halftone processing in accordance with the determined hue. If the selected halftone processing is dithering process that uses AM dithering, a halftone processing unit 106 executes halftone processing with different line per inch depending on the determined hue.

Owner:RICOH KK

Dampening water regulating scale, and dampening water control method

InactiveUS20060180042A1Slow feed rateReduce rateAddressographsPlaten pressesLines per inchEngineering

A dampening water regulating scale P includes first detecting patches PY1, PM1, PC1 and PK1, and second detecting patches PY2, PM2, PC2 and PK2. The first detecting patches PY1, PM1, PC1 and PK1 are formed of line patches having the number of lines at 400 lines per inch and a duty ratio at 67%. The second detecting patches PY2, PM2, PC2 and PK2 are formed of dot patches having the number of lines at 150 and a dot percentage at 80%.

Owner:DAINIPPON SCREEN MTG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com