Plate press machine with glue coating function

A technology of plate pressing machine and function, applied in the field of plate pressing machine with gluing function, can solve the problems of discontinuous process and low production efficiency, and achieve the effect of continuous process, high production efficiency and fast temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below by means of specific embodiments:

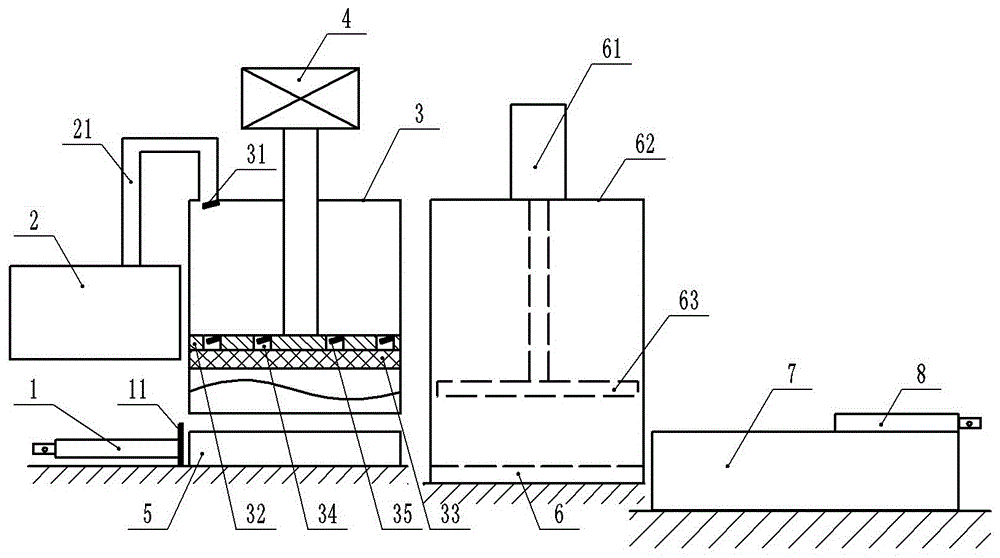

[0016] The reference signs in the drawings of the specification include: the first horizontal push cylinder 1, the fixed plate 11, the glue pool 2, the glue pumping pipe 21, the glue supply box 3, the first one-way valve 31, the piston 32, the sponge layer 33, the through hole 34, one-way valve 35, cylinder 4, plank 5, base 6, hydraulic cylinder 61, gantry frame 62, hot pressing plate 63, elevating platform 7, the second level promotes oil cylinder 8.

[0017] like figure 1 As shown, the platen press with gluing function is sequentially provided with a first horizontal push cylinder 1, a gluing device, a platen pressing device and a feeding device from left to right. The piston 32 rod of the first horizontal push oil cylinder 1 is connected with a fixed plate 11, the height of the fixed plate 11 is greater than the height of the plank 5, and the fixed plate 11 is used to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com