Preparation method of ecological plate

A technology of ecological board and melamine, applied in the jointing of wooden veneers, chemical instruments and methods, manufacturing tools, etc., can solve the problems of poor scratch resistance, wear resistance, deformation, and inability to achieve mass production, etc., to achieve cost saving, Good wear resistance and the effect of saving non-renewable resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

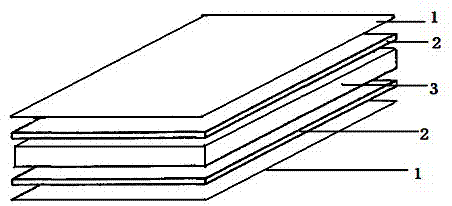

[0025] figure 1 It is a schematic structural diagram of an ecological board, which includes a melamine-impregnated film paper 1 , a special-shaped veneer 2 and an intermediate substrate 3 . The method for preparing an ecological board comprises the following steps:

[0026] Step 1: Prepare melamine-impregnated film paper. During the preparation process, the amount of gluing is increased by 15-20% compared with the traditional formula, that is: the content of melamine is adjusted to 70%, the proportion of gluing amount of triammonium reaches 145%, and the volatile matter content Tune to: 5.0.

[0027] Step 2, press and paste the melamine-impregnated film paper on the special-shaped veneer;

[0028] The thickness of the special-shaped veneer is required to be about 60S, and the size is four to eight feet. It is required that the entire veneer has no dead knots, no insect holes, no yin and yang sides, no color difference, no jamming, and no horizontal knife marks during rotary ...

Embodiment 2

[0035] Step 1: Prepare melamine-impregnated adhesive film paper. During the preparation process, the amount of gluing is increased by 15-20% compared with the traditional formula, that is, the content of melamine is adjusted to 100%, the ratio of gluing amount of triammonium reaches 160%, and the volatile matter content Adjust to 6.0.

[0036] Step 2, press and paste the melamine-impregnated film paper on the special-shaped veneer;

[0037] The thickness of the special-shaped veneer is required to be around 80S, and the size is four to eight feet. It is required that the entire veneer has no dead knots, no insect holes, no yin and yang sides, no color difference, no jamming, and no horizontal knife marks during rotary cutting. The type of veneer is Kauri.

[0038] Said pressing refers to placing the melamine-impregnated film paper horizontally on the special-shaped veneer, and then putting it into a press for pressing.

[0039] The pressing is specifically as follows: the te...

Embodiment 3

[0044] Step 1: Prepare melamine-impregnated adhesive film paper. During the preparation process, the amount of glue added is increased by 15-20% compared with the traditional formula; Content adjusted to: 6.5.

[0045] Step 2, press and paste the melamine-impregnated film paper on the special-shaped veneer;

[0046] The thickness of the special-shaped veneer is required to be about 70S, and the size is four to eight feet. It is required that the entire veneer has no dead knots, no insect holes, no yin and yang sides, no color difference, no jamming, and no horizontal knife marks during rotary cutting. The type of veneer is poplar.

[0047] Said pressing refers to placing the melamine-impregnated film paper horizontally on the special-shaped veneer, and then putting it into a press for pressing.

[0048] The pressing is specifically as follows: the temperature of the upper and lower templates of the press is 170° C., the pressure is 25 Pa, and the holding time is 2 minutes.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com