Braided bag and its production technology and device

A technology for woven bags and raw materials, applied in the field of plastic woven bags, can solve the problems of easy brittle cracking, aging, and low product cost, and achieve the effects of not easy brittle cracking and good weather resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

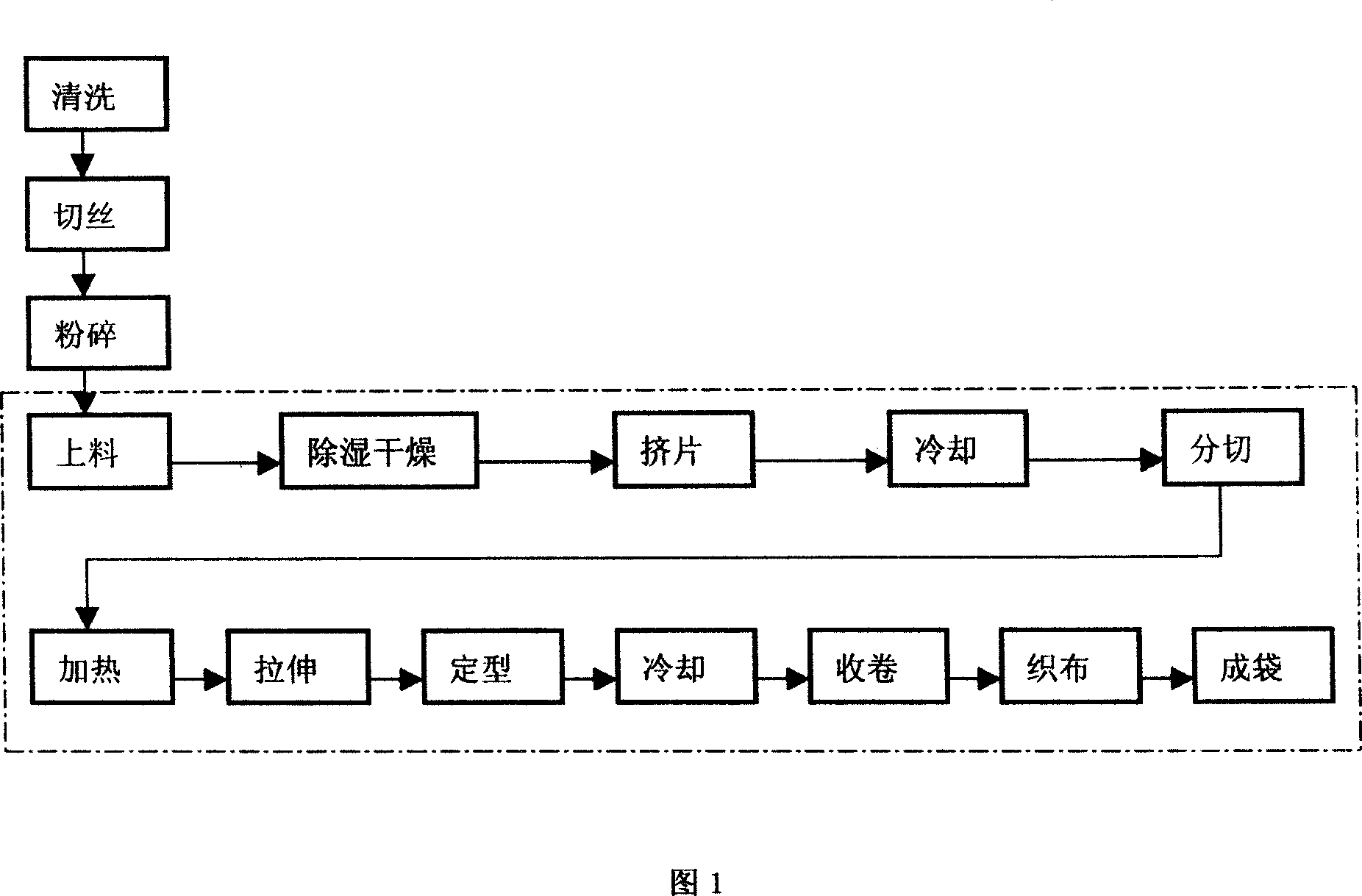

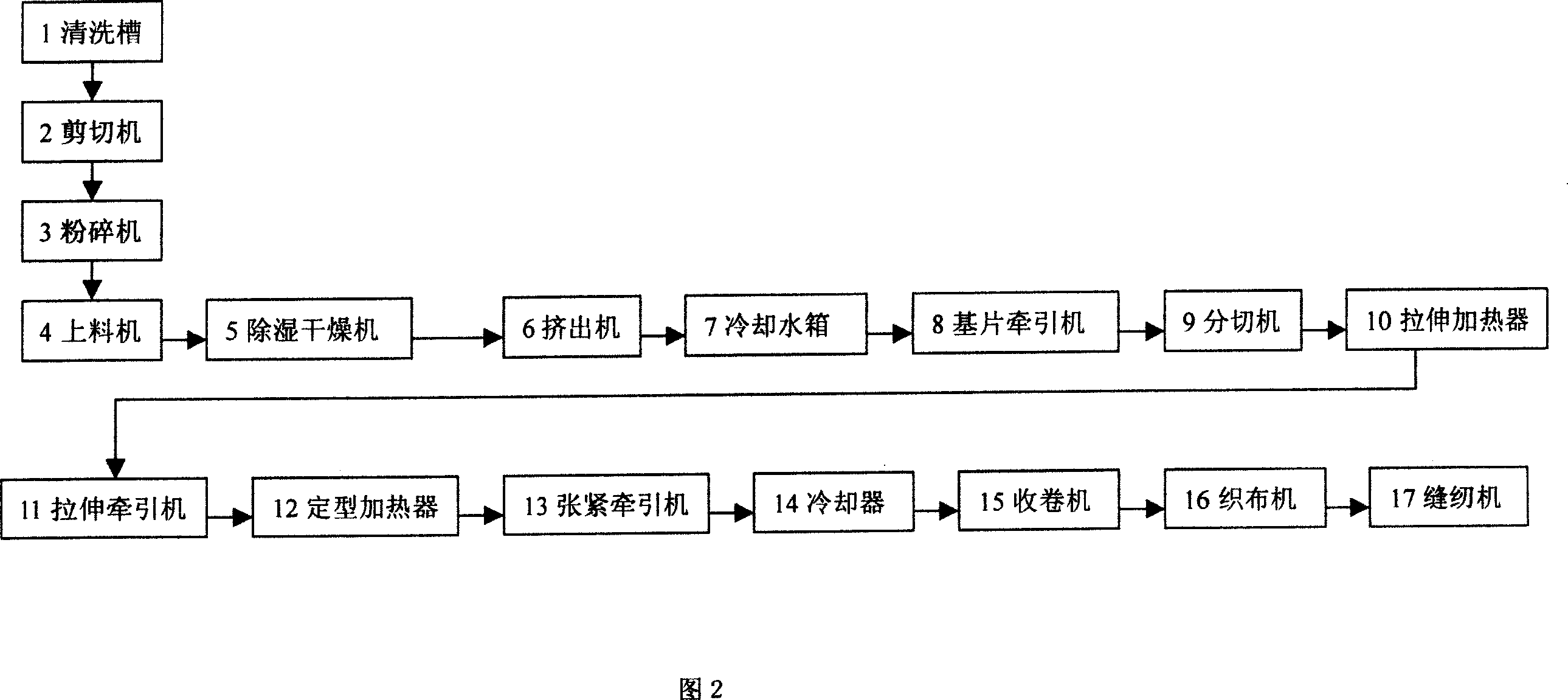

[0029] The present invention will be further described below in conjunction with the accompanying drawings.

[0030] Referring to Fig. 2: The processing device of the woven bag of the present invention comprises a cleaning tank 1, a shearing machine 2, a pulverizer 3, a feeding machine 4, a dehumidifying dryer 5, an extruder 6, a cooling water tank 7, and a substrate arranged in sequence Tractor 8, slitter 9, stretch heater 10, stretch tractor 11, sizing heater 12, tension tractor 13, cooler 14, winder 15, loom 16, sewing machine 17. Wherein, also can not set feeding machine 4, by manual feeding.

[0031] The above-mentioned processing device is improved on the basis of the existing PP woven bag production device, and a cleaning tank 1, a shearing machine 2, a pulverizer 3 and a dehumidifying dryer 5 are added upstream of the feeding machine 4. Wherein the dehumidifying dryer 5 can also be located between the feeder 4 and the extruder 6, the stretching heater 10 and the setti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Area | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Moisture content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com