Uniform cutting equipment for wood board for furniture production

A technology for cutting equipment and wood boards, which is applied in the direction of sawing equipment, unloading equipment, sawing components, etc., and can solve problems such as slow speed and high risk factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

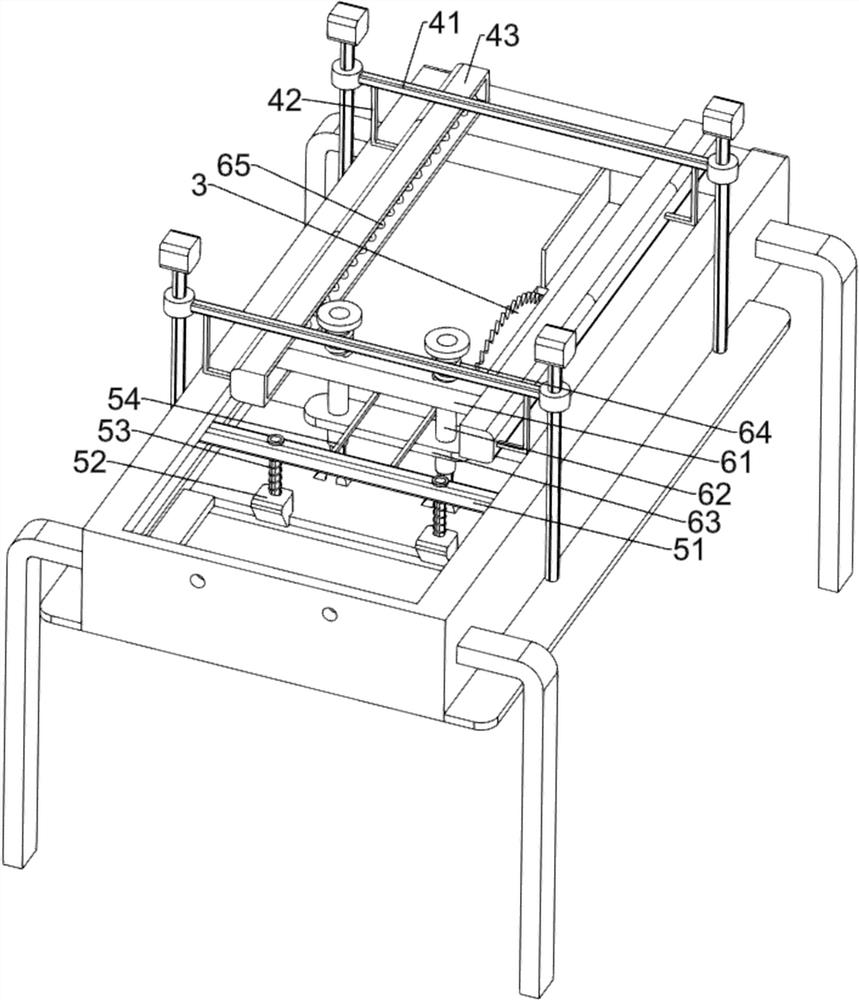

[0066] A kind of equipment for uniform cutting of wood boards for furniture production, such as figure 1 , figure 2 and image 3 As shown, it includes a base 1, a frame 2, a cutting machine 3, a guide mechanism 4, a manual pushing mechanism 5 and an automatic pressing mechanism 6, the base 1 is provided with a frame 2, and the lower side of the frame 2 is equipped with a cutting machine 3. The frame 2 is equipped with a guide mechanism 4, the frame 2 is equipped with a manual pushing mechanism 5, and the frame 2 is equipped with an automatic pressing mechanism 6.

[0067] Put the plank to be cut on the front side inside the frame 2, start the cutting machine 3, manually operate the manual pushing mechanism 5 to make the plank move into the automatic pressing mechanism 6, and the automatic pressing mechanism 6 drives the plank to move upward on the frame 2. After the movement, the cutting machine 3 moves so that the plank is cut in half from the middle. After cutting a plank...

Embodiment 2

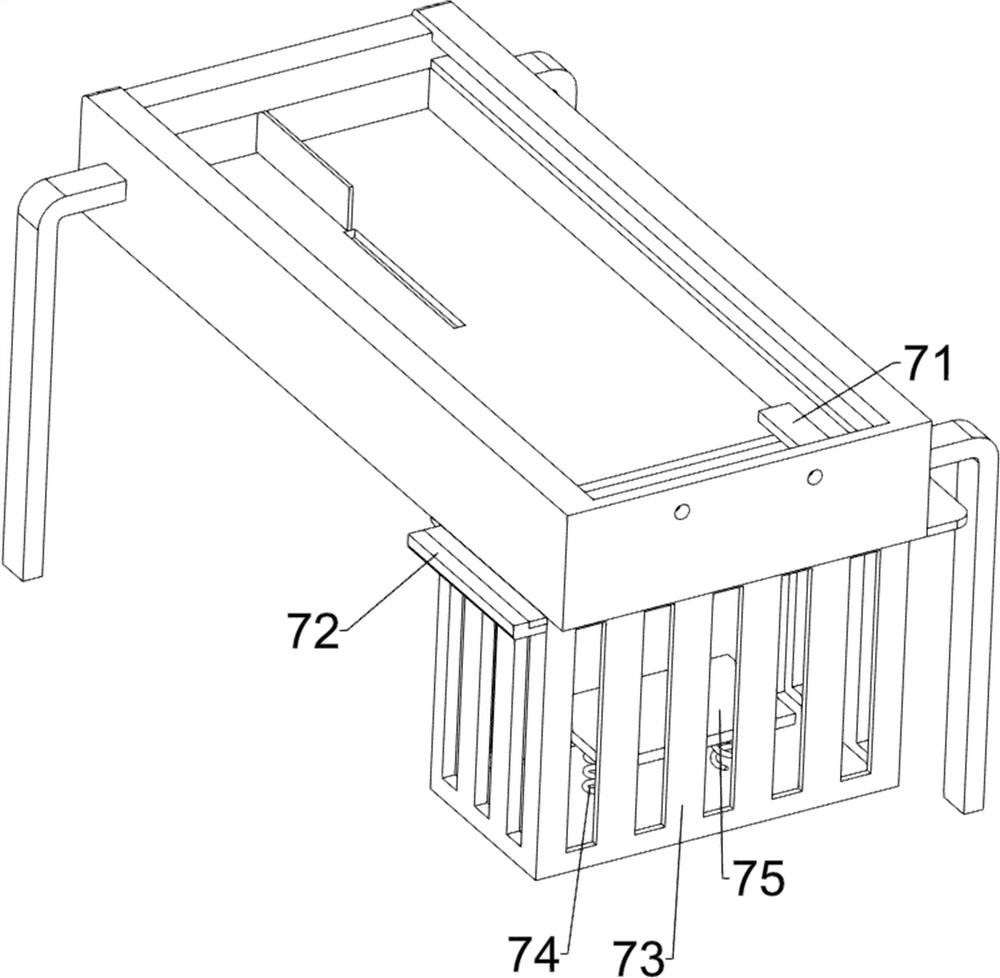

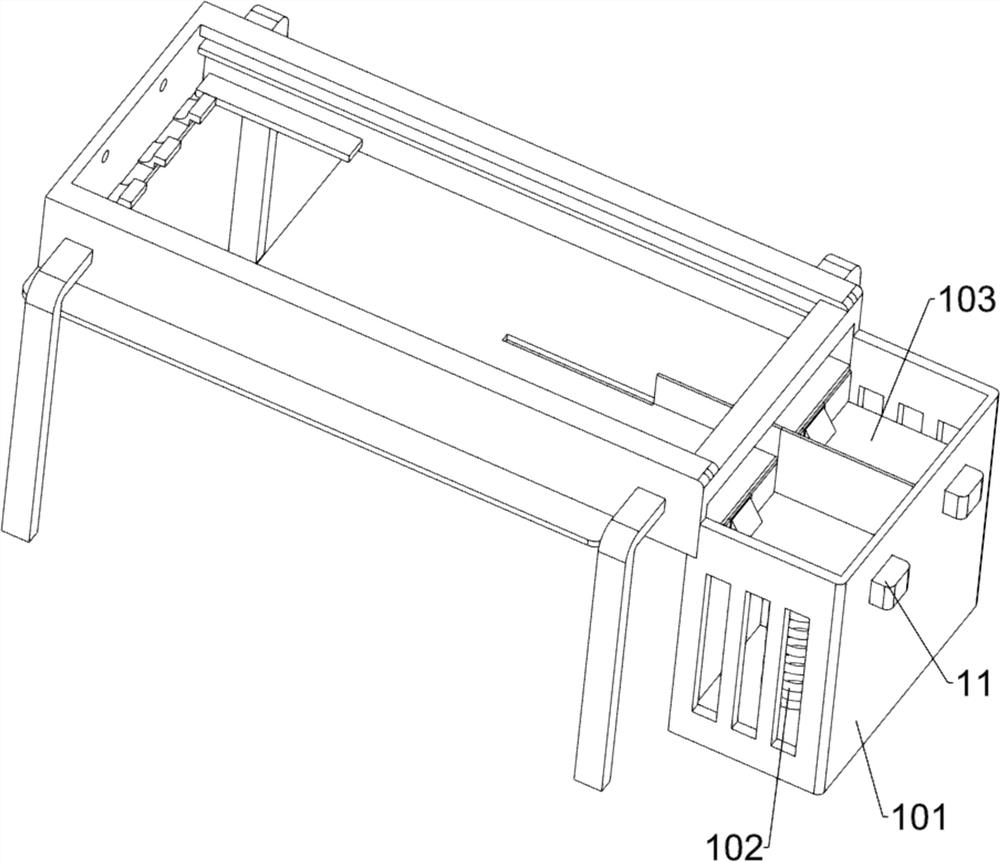

[0075] On the basis of Example 1, such as Figure 4 , Figure 5 , Figure 6 , Figure 7 and Figure 8 As shown, an automatic feeding mechanism 7 is also included, and the automatic feeding mechanism 7 includes a limiting plate 71, a block 72, a discharge frame outer frame 73, a third spring 74 and a first shelf plate 75, and the left and right sides of the frame 2 A restricting plate 71 is symmetrically arranged, and the left and right sides of the front part of the frame 2 are slidingly provided with clamping blocks 72, and an outer frame 73 of the discharge frame is arranged between the two clamping blocks 72, and the inner bottom of the outer frame 73 of the discharge frame is symmetrical A third spring 74 is provided, and a first shelf plate 75 is provided on the top of the third spring 74 .

[0076] The wooden block to be cut is placed in the discharge frame outer frame 73, when the wooden block is positioned above the first shelf plate 75, the third spring 74 is sque...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com