Construction method of reinforcing aerated concrete precast slab formwork with butt buckle

A technology of aerated concrete and docking buckles, which is applied in infrastructure engineering, construction, etc., can solve problems such as excessive labor, irregular construction, and slow progress, and achieve enhanced stability and reliability, improved installation efficiency, and construction operations. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The content of the present invention is further described below with reference to the accompanying drawings.

[0030] The construction method of using the butt buckle to reinforce the aerated concrete precast panel formwork is to first make the butt buckle of the aerated concrete precast panel formwork, and then apply the butt buckle to the construction of the aerated concrete precast panel formwork.

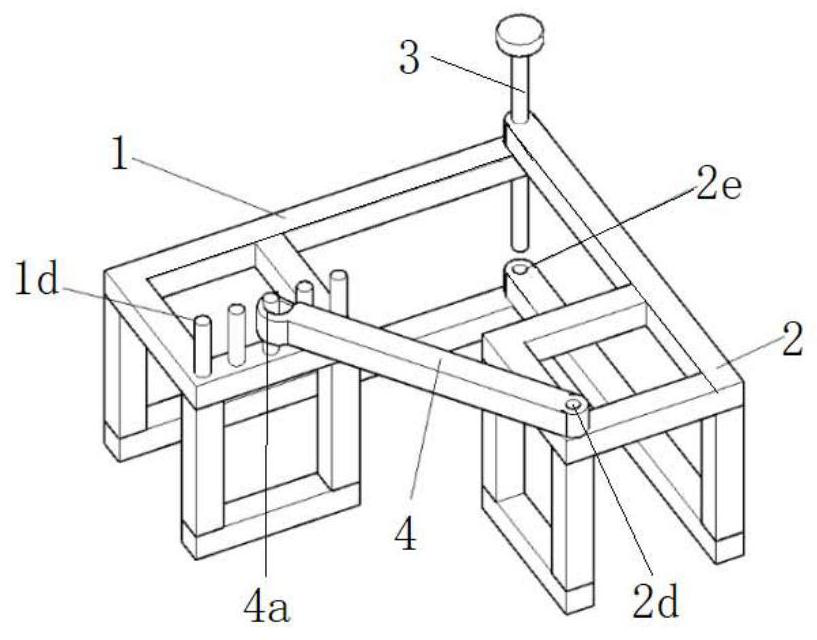

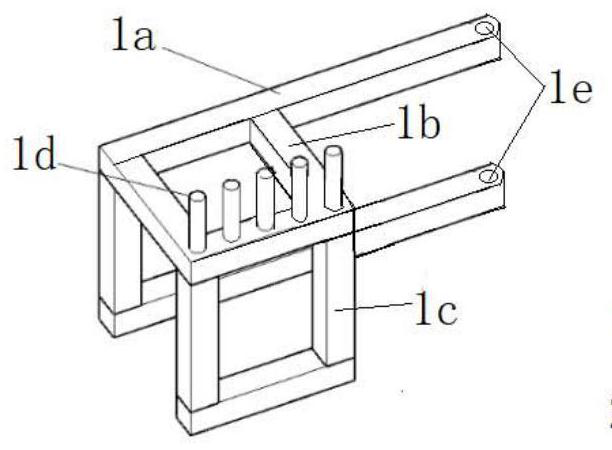

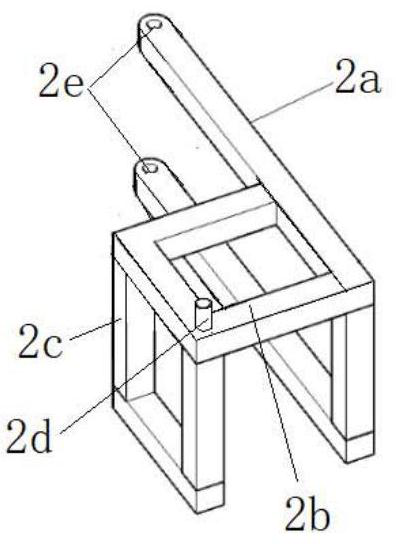

[0031] like Figure 1-Figure 4 As shown in the figure, the aerated concrete prefabricated plate formwork docking buckle includes a first steel member 1 formed by welding a square steel pipe, a second steel member 2 formed by welding a square steel pipe, and connecting the first steel member and the second steel member. The vertical screw 3 and the transverse tie rod 4.

[0032] The first steel member 1 includes a first trough-shaped vertical frame 1a with one side open, a first horizontal suspension 1b welded on the top surface of the closed side of the first trough-shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com