A current sensor fixing device

A technology of current sensor and fixing device, which is applied in the direction of measuring device, measuring device casing, and parts of electrical measuring instruments, etc. problems, to improve measurement accuracy, prevent excessive deformation, and avoid collisions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

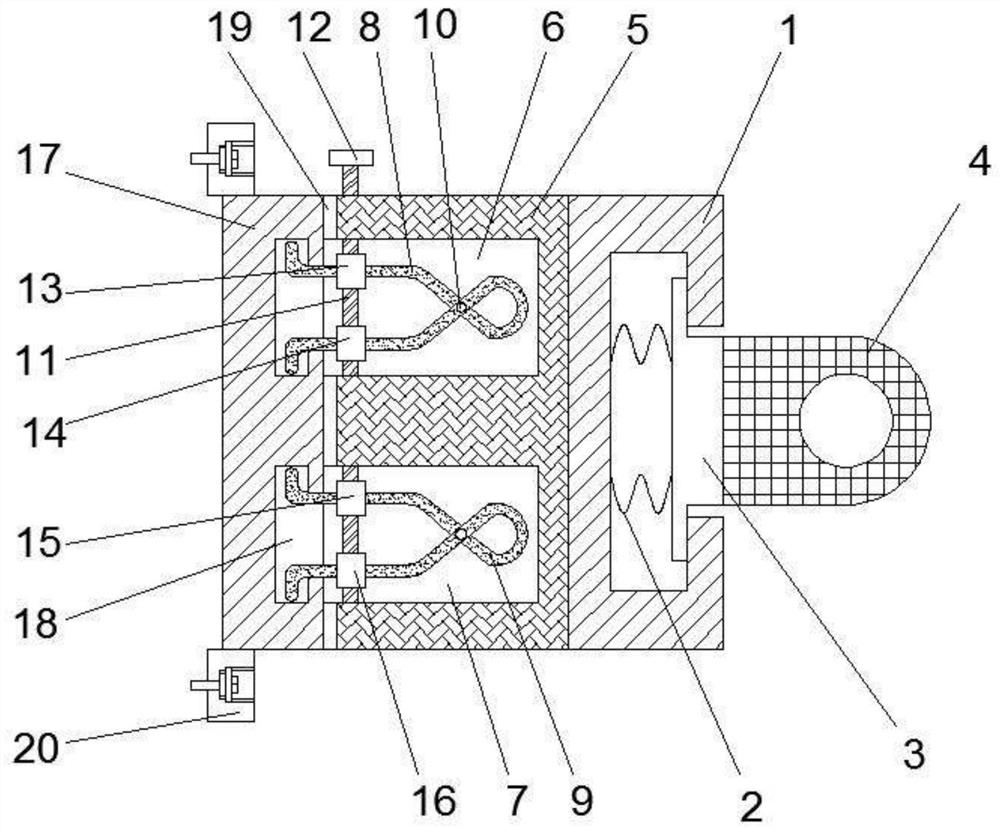

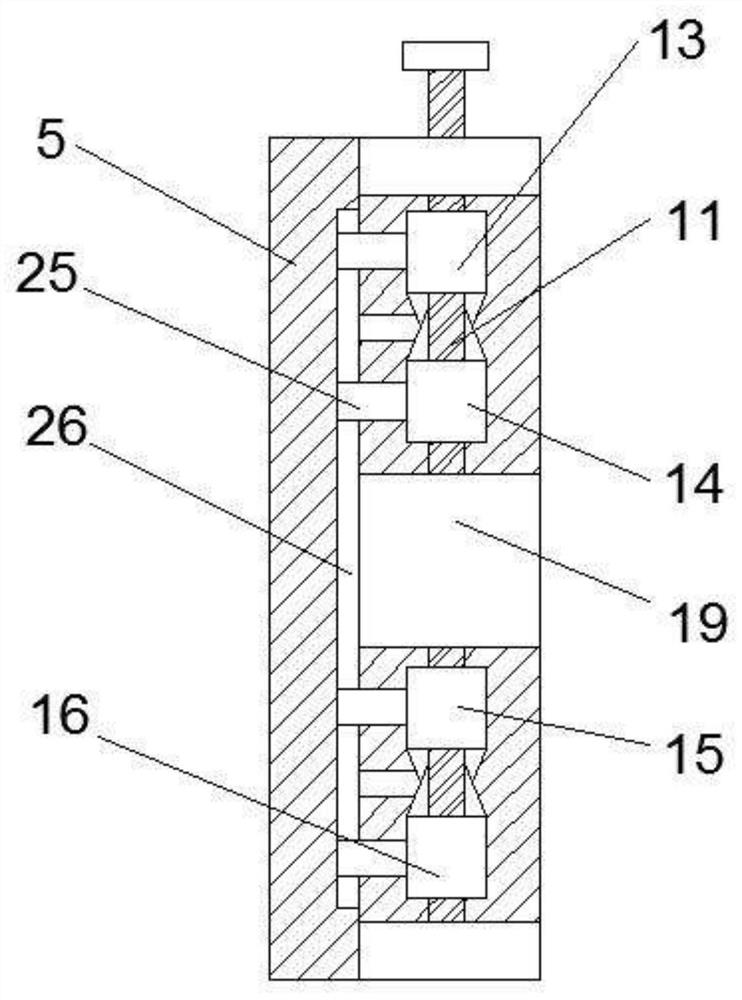

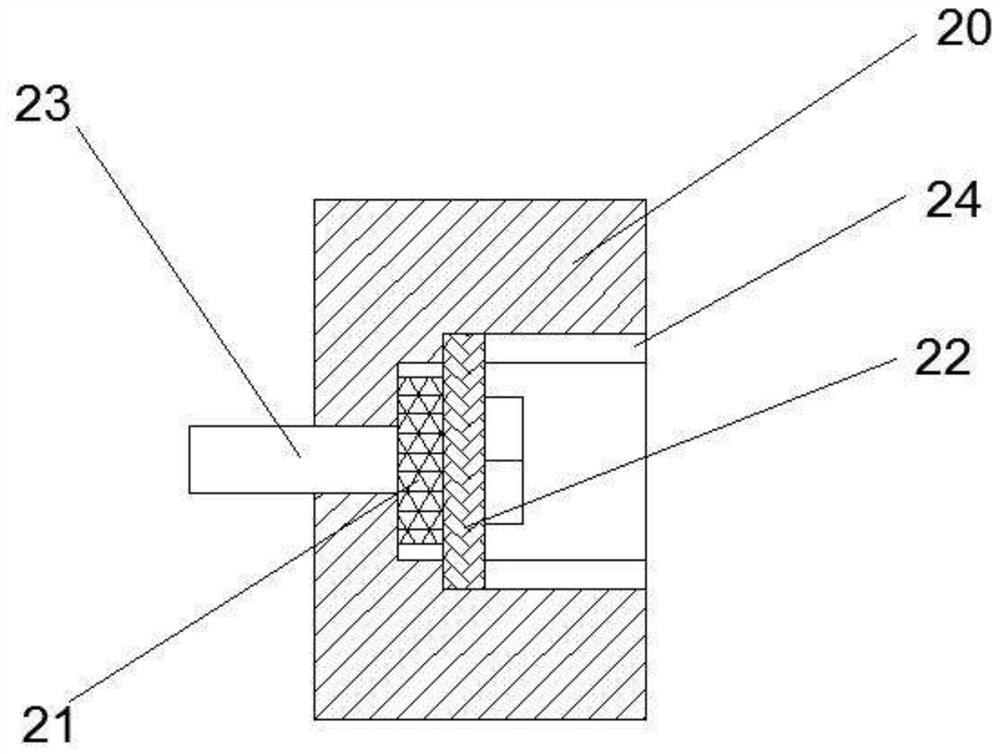

[0020] Such as Figure 1-Figure 3 As shown, a current sensor fixing device proposed by the present invention includes a sensor frame body 1, buffer springs 2 are arranged on the upper and lower sides of the left side wall of the sensor frame body 1, and the right ends of the two buffer springs 2 are fixedly connected with a base 3, The right end of the base 3 is provided with a current sensor 4, and the left end of the sensor frame body 1 is fixedly connected with a middle fixed seat 5, and the upper part of the middle fixed seat 5 is provided with an upper cavity 6, and the lower part of the middle fixed seat 5 is provided with a lower cavity 7, and an upper cavity 6 A first deformable joint 8 is arranged inside, and a second deformable joint 9 is arranged in the lower cavity 7. Both the first deformable joint 8 and the second deformable joint 9 are connected to the middle fixing seat 5 through joint bolts 10, and the first deformable joint 8 A first sleeve 13 is provided on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com