Tape measure for out-of-roundness detection and method of use thereof

A tape measure and roundness technology, which is applied in the field of tape measure for out-of-roundness detection, can solve the problems of affecting the accuracy of measurement, inaccurate measurement accuracy, inconvenience, etc., and achieve the effect of convenient measurement, high measurement accuracy and simple measurement method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

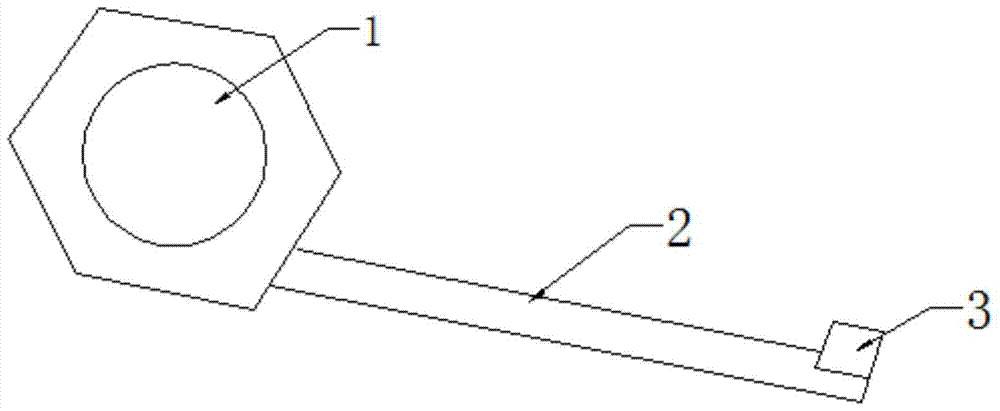

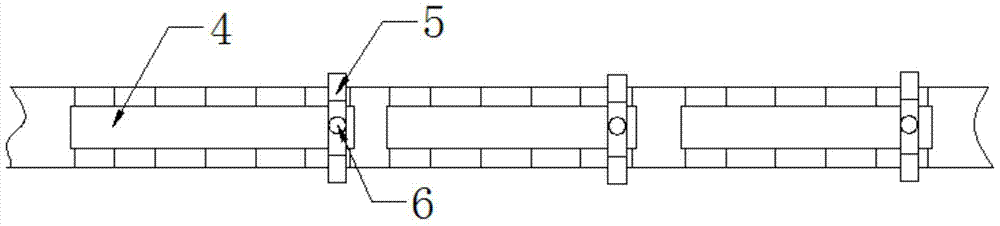

[0041] Such as figure 1 and 2 As shown, the measuring tape for out-of-roundness detection includes a tape measure housing 1 and a scale 2 stretched inside the tape measure housing 1, and the scale 2 is rigid or soft. The end of scale 2 is provided with grab 3, is provided with a plurality of draw-in slots 4 on scale 2, and a plurality of draw-in slots 4 are arranged in parallel, is all movable to be provided with a magnet at each draw-in slot 4, through grab 3 and The draw-in slot 4 cooperates, and then the tape measure is fixed on the outside of the pipeline by a movable magnet, so as to fix the tape measure. The length of the draw-in slot 4 is set along the length of the scale. In order to ensure the accuracy of measurement, if conditions permit, multiple measuring tapes are set, and the setting positions of the slots 4 on each measuring tape are different.

[0042] The width of the hook 3 is less than or equal to the width of the slot 4 .

[0043] A fluorescent layer is ...

Embodiment 2

[0058] The difference between this embodiment and embodiment 1 is:

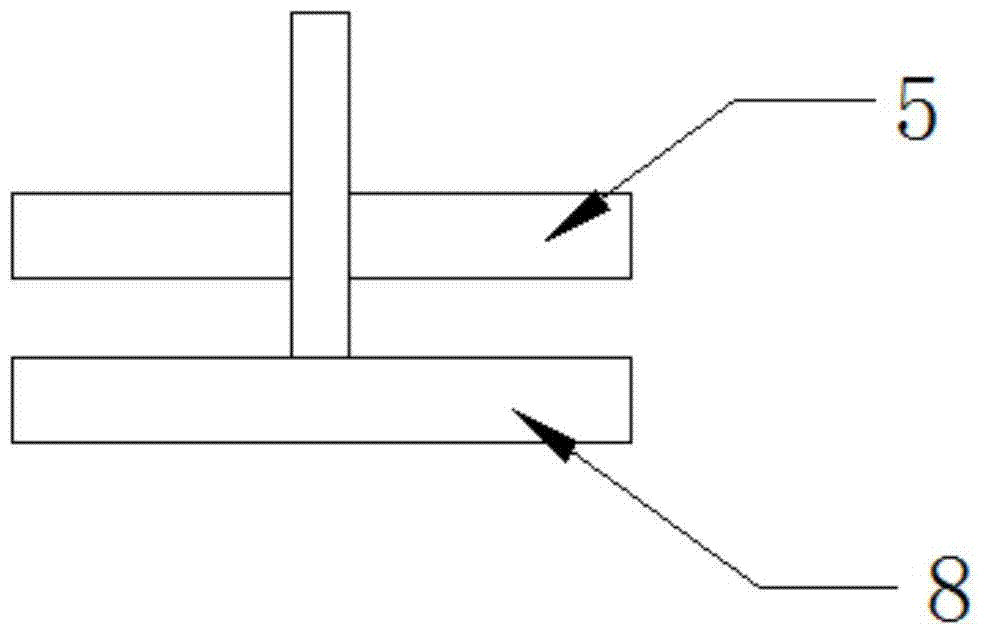

[0059] A housing is provided at the hook 3 through the rotating shaft 9, and one side of the middle part of the housing is fixed on the rotating shaft 9. The inside of the housing is provided with a magnet 7, and the magnet 7 is close to the bottom inside the housing. When the hook 3 is fixed in the slot 4, the rotating housing will attract the magnet 7 to the surface of the elbow after the pipe, and fix the tape measure. In the process of finding the end point of the long axis of the ellipse, the direction of the magnet on the side of the housing is far away from the pipe body or the elbow. , when the tape measure needs to be fixed, the housing rotates, and the side with the magnet is attracted to the surface of the pipe.

Embodiment 3

[0061] The difference between this embodiment and embodiment 1 is:

[0062] The magnet is arranged in a housing, and the housing is provided with a handle or a hole for facilitating the fixing and removal of the magnet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com