Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

165results about How to "Achieve cutting effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

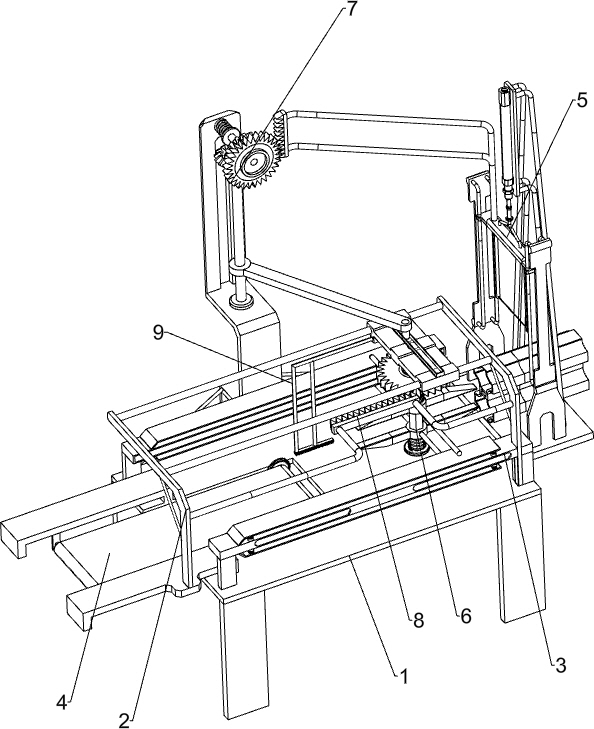

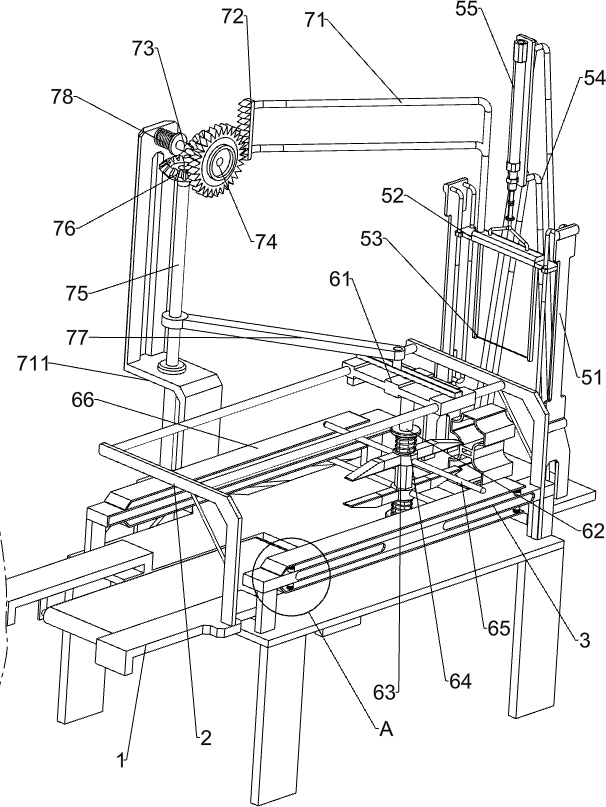

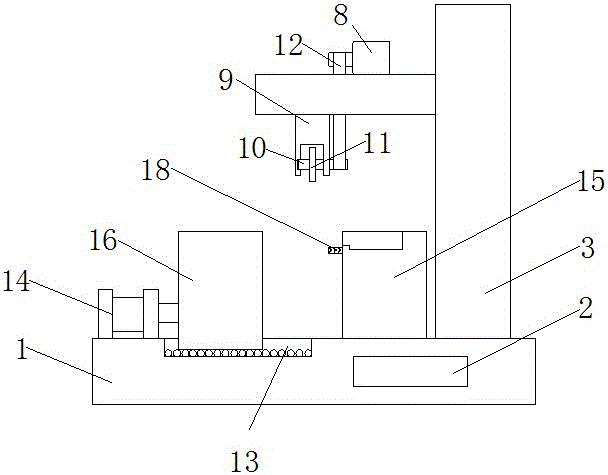

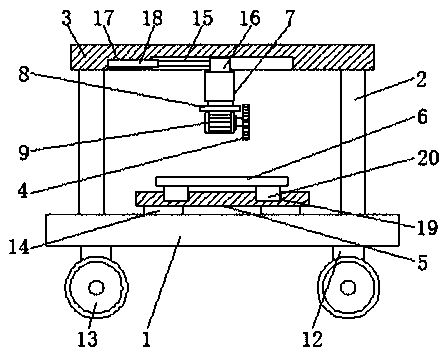

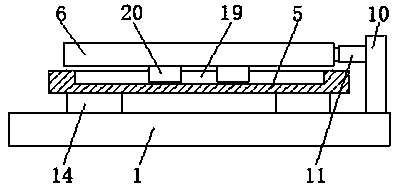

Adjustable board cutting device

ActiveCN111360324AAchieve cutting effectSave human effortMetal sawing devicesElectric machineryStructural engineering

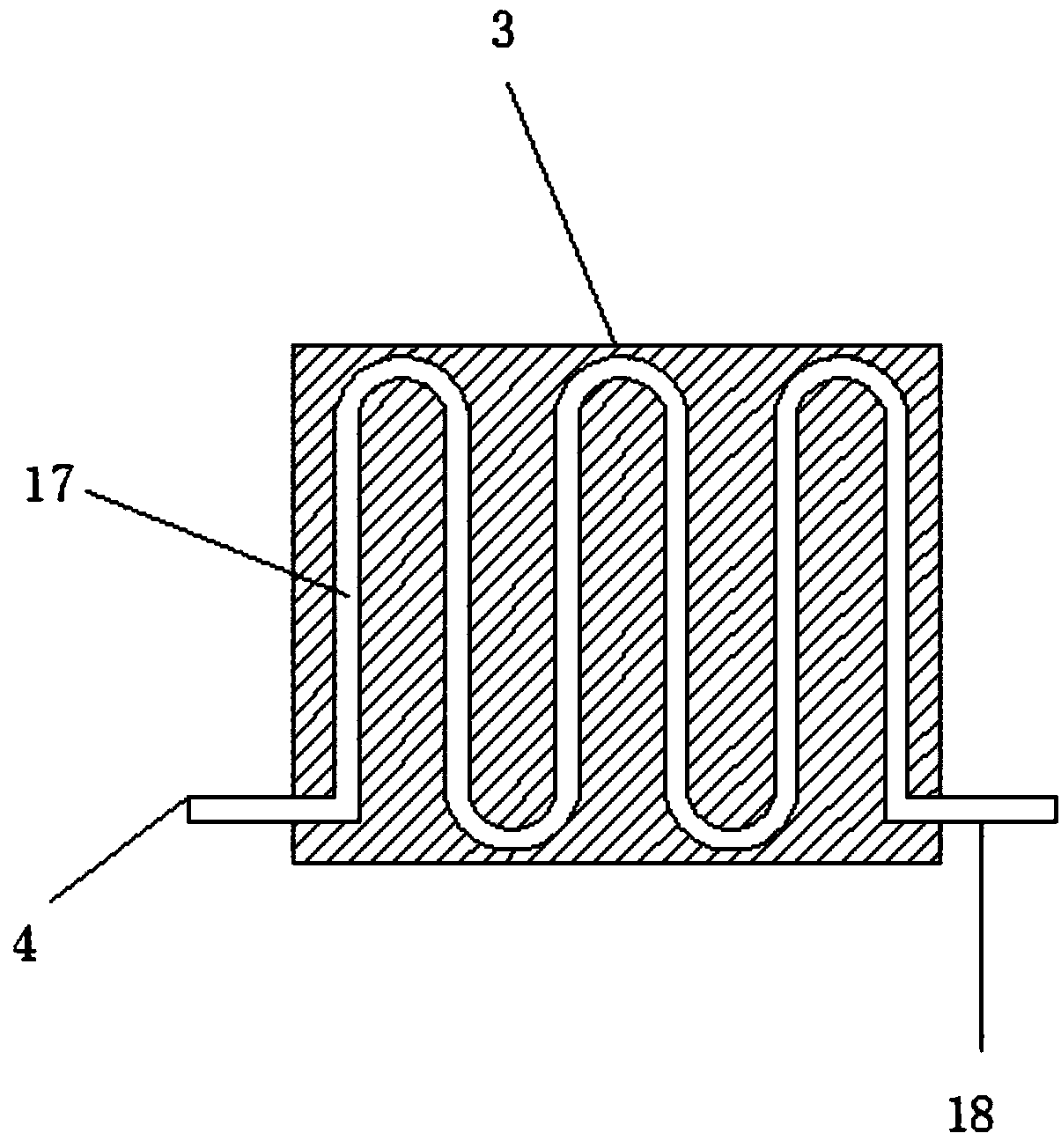

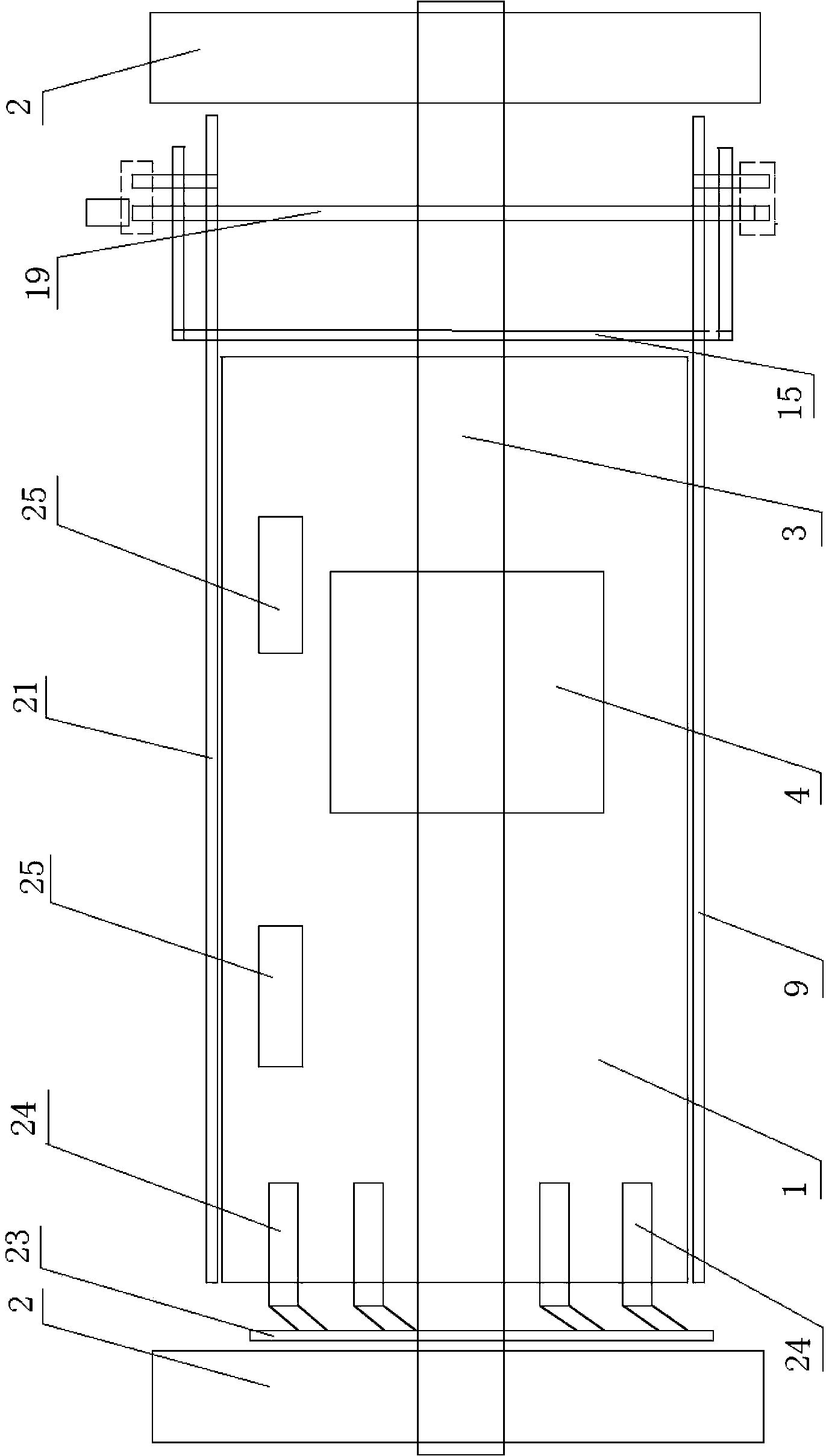

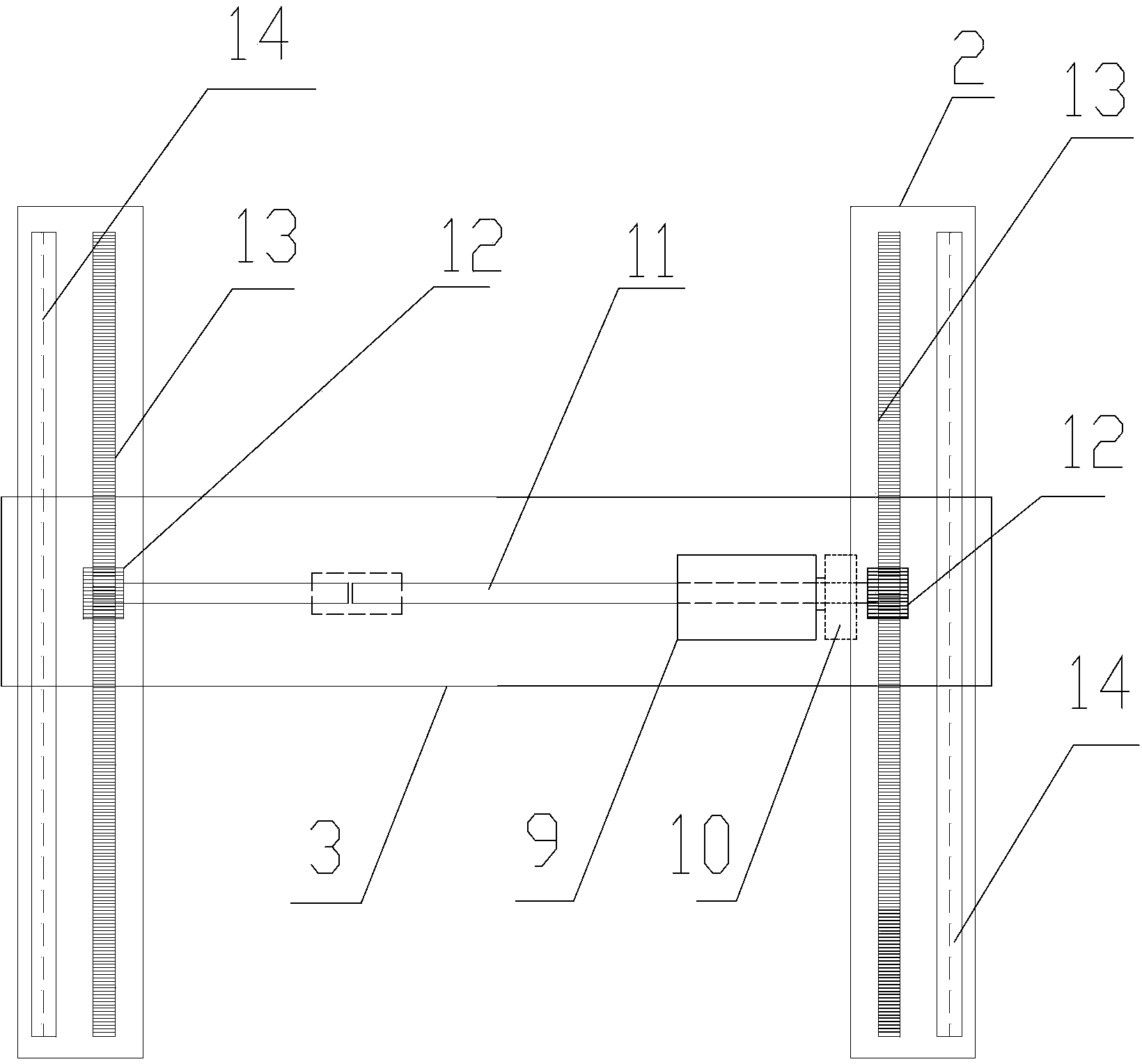

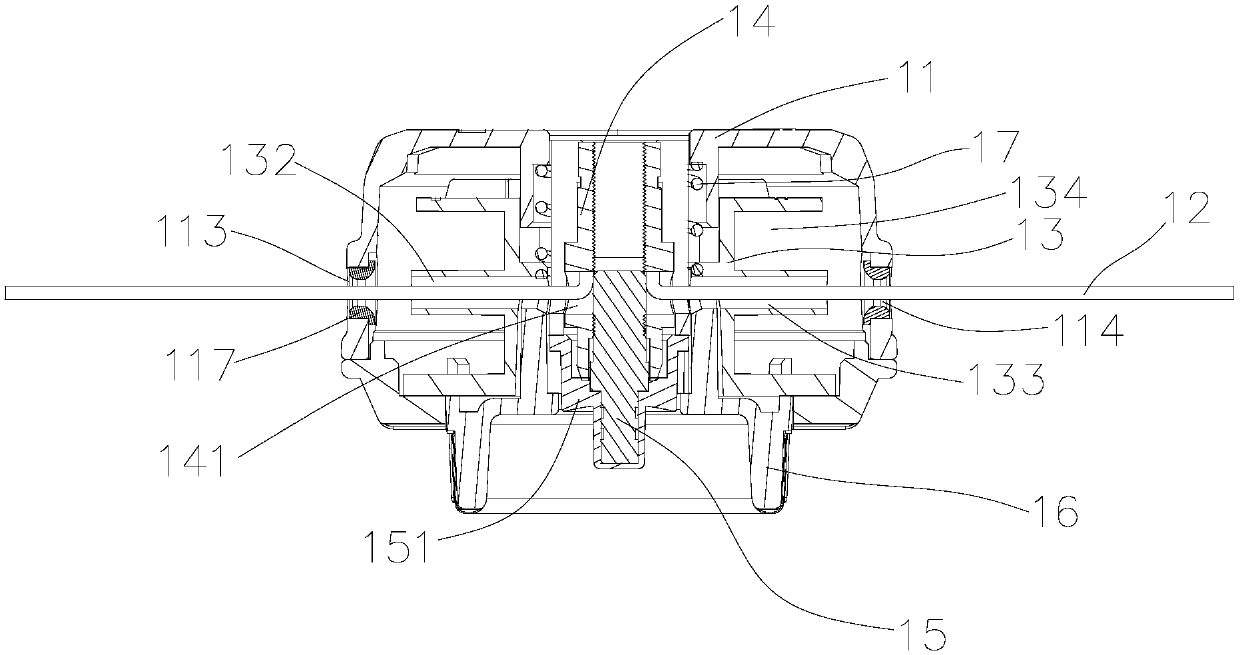

The invention relates to a cutting device, in particular to an adjustable board cutting device. The invention aims to design the adjustable board cutting device which is capable of performing board cutting without the need for manual operation and capable of saving manpower. The adjustable board cutting device comprises a base plate, a two-shaft motor and a driving device, wherein the bottom of the base plate is fixedly connected with a support leg; the two-shaft motor is mounted at the bottom of the base plate; one output shaft of the two-shaft motor is connected with a saw blade; the saw blade is used for cutting boards; the saw blade penetrates through the base plate; and the driving device is arranged on the base plate. According to the adjustable board cutting device, the two-shaft motor drives the driving device and the saw blade to operate so as to cut the boards, so that the effect of board cutting can be achieved.

Owner:江西家有儿女家具有限公司

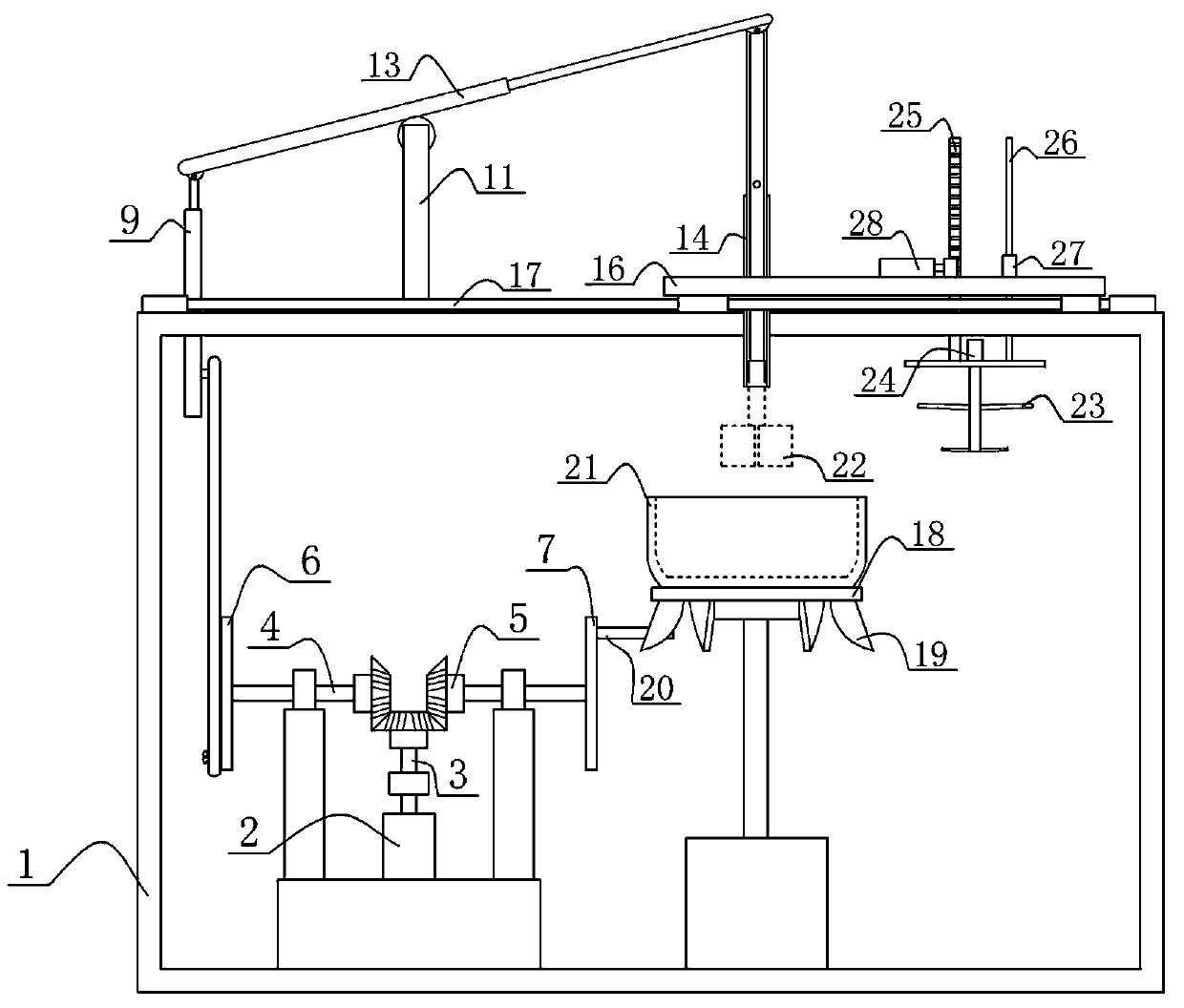

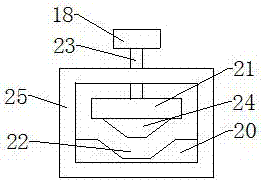

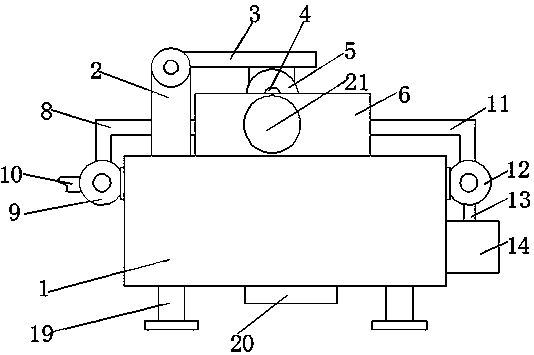

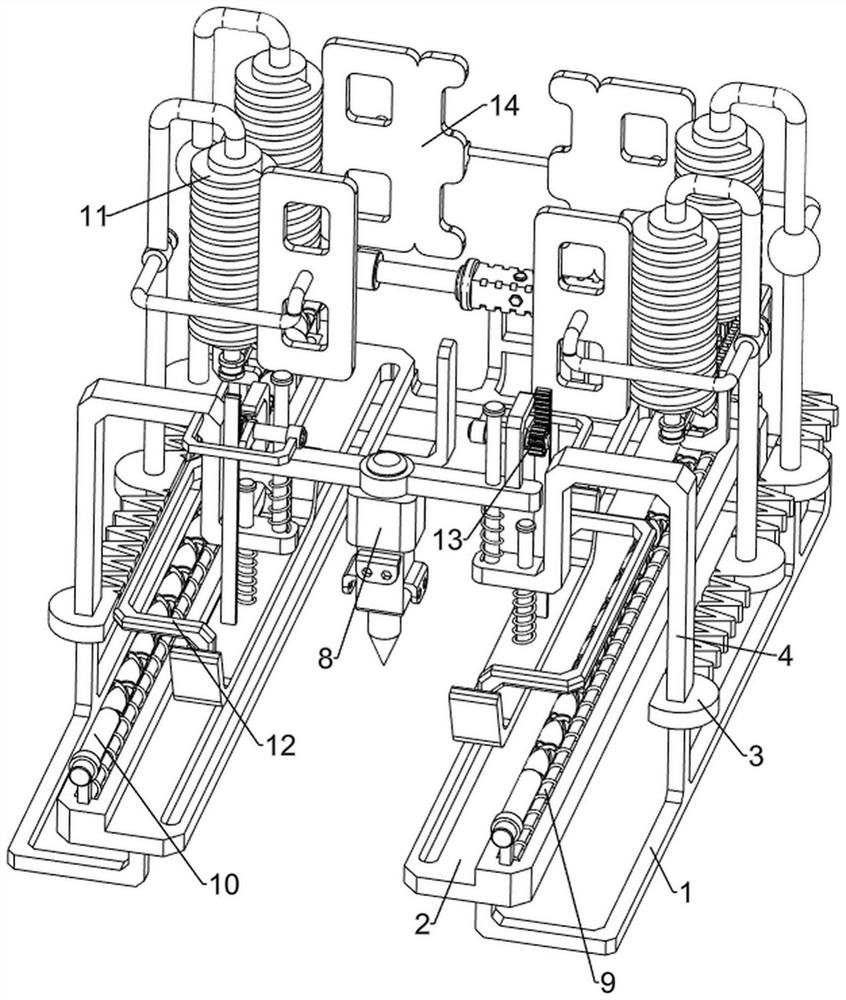

Equipment for crushing traditional Chinese medicines after cutting

PendingCN112476512AAchieve effectReduce stepsGrain treatmentsMetal working apparatusPharmaceutical drugStructural engineering

The invention relates to equipment for crushing after cutting and particularly relates to equipment for crushing traditional Chinese medicines after cutting. The invention provides equipment for crushing traditional Chinese medicines after cutting. The equipment is capable of automatically blanking and cutting traditional Chinese medicines and automatically grinding the traditional Chinese medicines into powder. The equipment for crushing the traditional Chinese medicines after cutting comprises a bottom frame, second support frames, a material cutting mechanism, a repeated cutting and pushingmechanism and a rotary grinding mechanism, wherein two first support frames are arranged on the bottom frame; two second support frames are arranged on the bottom frame; the material cutting mechanism is arranged between the tops of the first support frames and the second support frames; the repeated cutting and pushing mechanism is arranged on the material cutting mechanism; and the rotary grinding mechanism is arranged at the upper parts of the two first support frames. According to the equipment for crushing the traditional Chinese medicines after cutting, a material pushing plate moves forwards, so that the effect of pushing the cut medicines forwards into the rotary grinding mechanism.

Owner:陈录坤

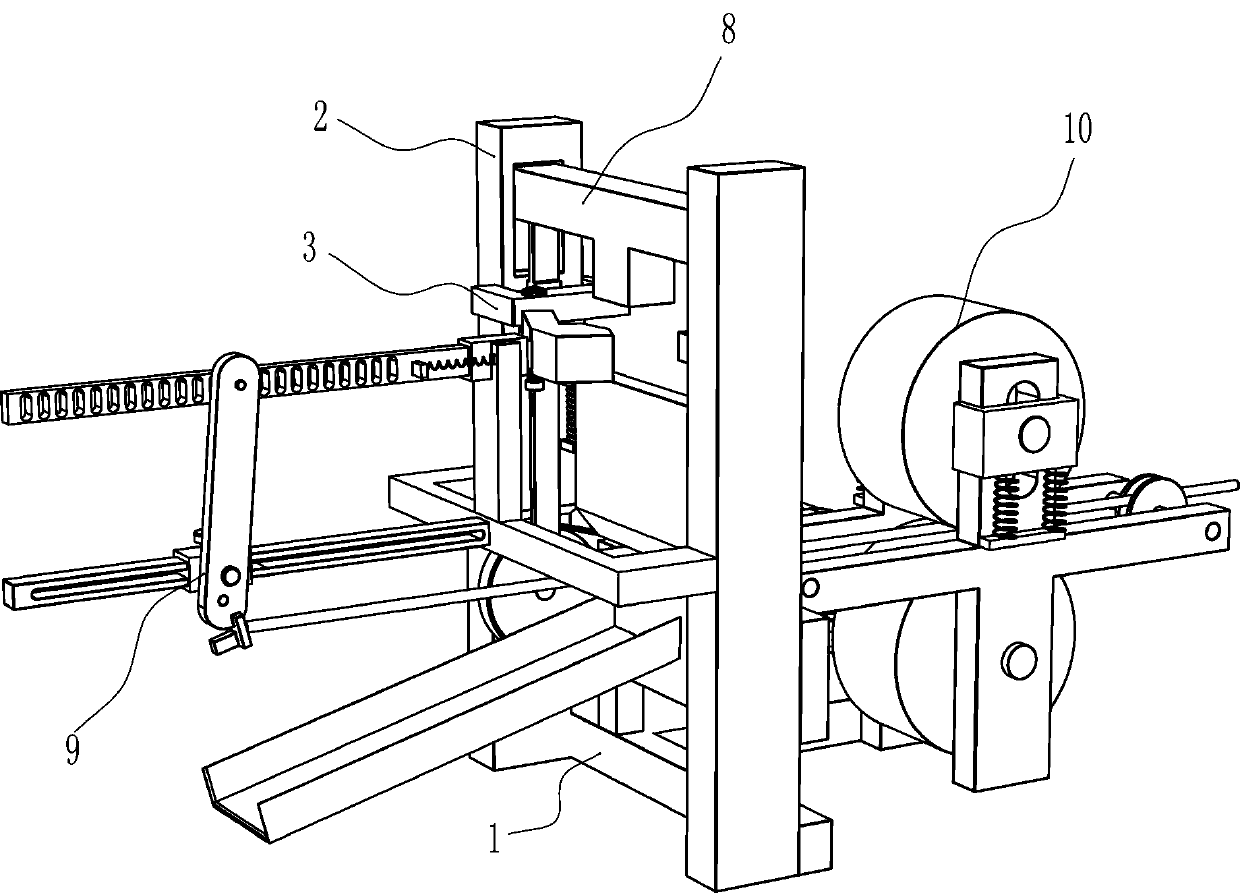

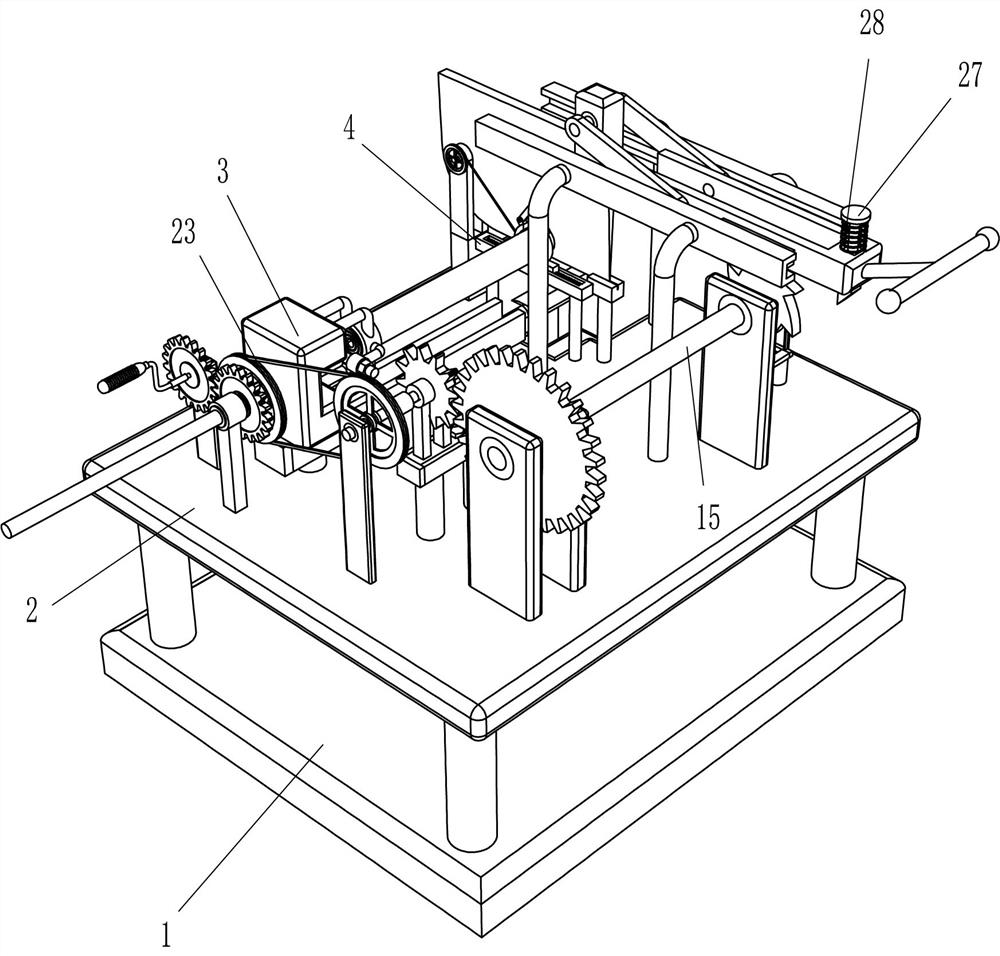

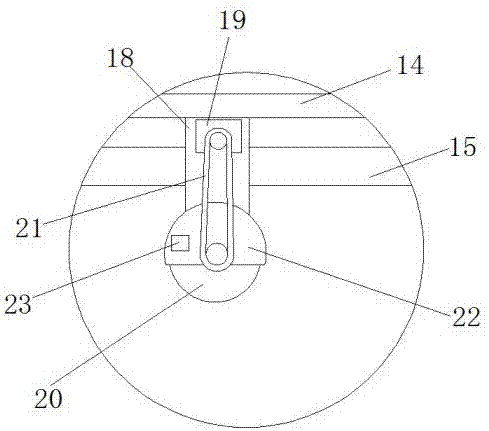

Vegetable cutting and filling stirring integrated machine

InactiveCN104172948AAchieve cutting effectRealize the stuffing actionKitchen equipmentReciprocating motionGear wheel

The invention discloses a vegetable cutting and filling stirring integrated machine which comprises a framework, a vegetable cutting motor, a rotary table, a vegetable knife, a filling stirring knife and a filling stirring motor. The vegetable cutting and filling stirring integrated machine is characterized in that a vegetable cutting driving mechanism comprises a left driven gear, a left rotary disc, a driving rod, a left slide rail, a right slide rail and a telescopic rod, the left driven gear is meshed with a driving gear, and the left rotary disc is coaxially fixed to the left driven gear; a left slide rod and a right slide rod which can slide along the length directions of the left slide rail and the right slide rail are respectively arranged in the left slide rail and the right slide rail, the lower end of the driving rod is hinged to the edge of the left rotary disc, and the upper end of the driving rod is connected with the bottom of the left slide rod. The vegetable cutting and filling stirring integrated machine has the advantages that the vegetable knife can reciprocate up and down, so that cutting effects can be realized for foods in a vegetable basin; the vegetable cutting and filling stirring integrated machine is provided with the filling stirring knife, the filling stirring motor, a guide rod, a lifting rack and a lifting motor, the filling stirring knife can extend to the bottom of the vegetable basin under the driving effect of the lifting motor, and filling stirring actions can be implemented under the driving effect of the filling stirring motor.

Owner:BINZHOU UNIV +1

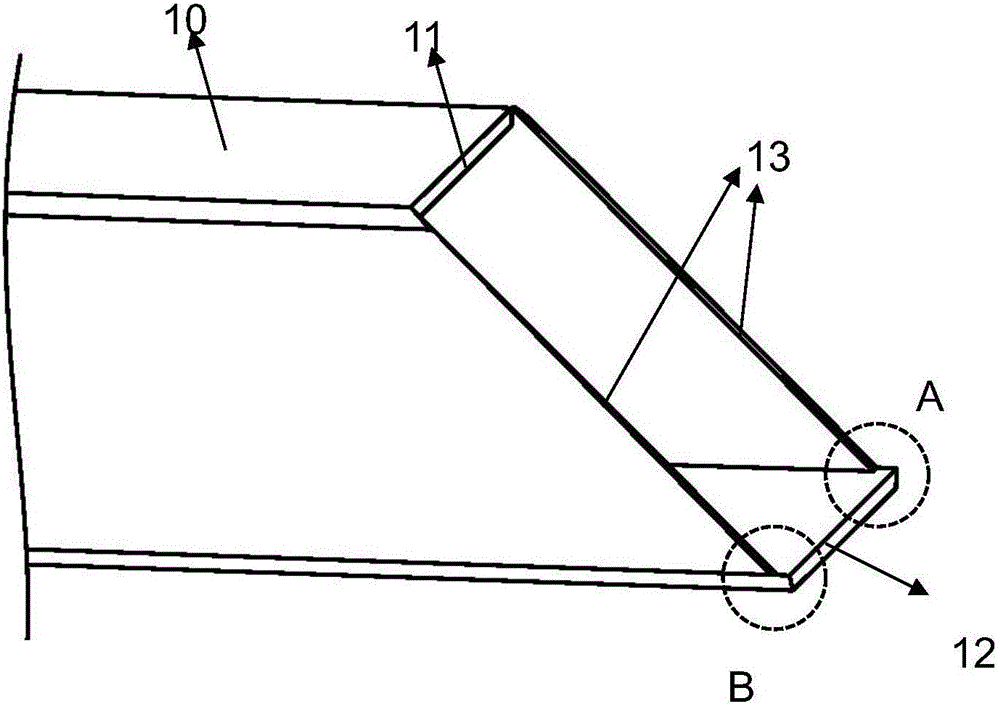

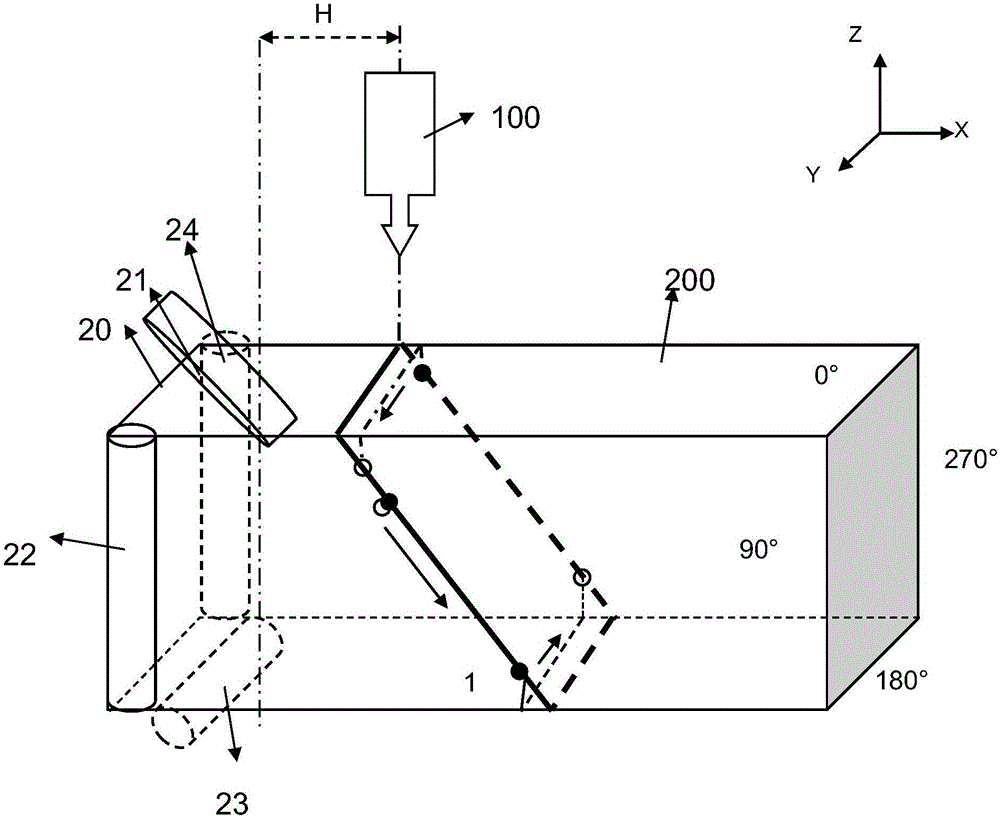

Cutting method for two-dimensional laser cutting tubular product

ActiveCN105772950AAddress the disadvantages of limitations of useIncrease profitMetal working apparatusLaser beam welding apparatusLaser cuttingBiomedical engineering

The invention provides a cutting method for a two-dimensional laser cutting tubular product. The cutting method comprises the following steps: step 1, setting a to-be-cut path of the tubular product and dividing the to-be-cut path into three sections: a first non-edge-shared contour and an edge-shared contour located at one end and a second non-edge-shared contour located at the other end, wherein the edge-shared contour is connected to the first non-edge-shared contour and the second non-edge-shared contour; step 2, cutting the first non-edge-shared contour by using a two-dimensional cutting head; step 3, cutting the second non-edge-shared contour by using the two-dimensional cutting head; and step 4, cutting the edge-shared contour by using the two-dimensional cutting head in a one-cut ring-cutting manner. The cutting method provided by the invention cuts the tubular product by using the two-dimensional cutting head, so that an effect of three-dimensional swing angle cutting can be realized, the function of the two-dimensional cutting head is enhanced and the machining range of the two-dimensional cutting head is expanded, the actual production demand is satisfied, and the shortcoming of using limitation of the two-dimensional cutting head is overcome.

Owner:HANS LASER TECH IND GRP CO LTD +1

Self-propelled road pavement lancing device for municipal engineering

InactiveCN107761532AReasonable structureInnovative designRoads maintainenceDrive shaftArchitectural engineering

The invention discloses a self-propelled road pavement lancing device for municipal engineering. The self-propelled road pavement lancing device comprises a support seat, wherein a U-shaped frame is arranged in the middle of the upper end of the support seat, an S-shaped bent pipe is mounted at the upper end in the U-shaped frame, a rotating shaft is mounted in the middle of the U-shaped frame, acam is mounted in the middle of the upper end of the rotating shaft, a limiting ball is mounted at the left end of the cam, a limiting rod is connected to the left end of the limiting ball, a limitingplate is mounted at the left end of the limiting rod, a telescopic rod is mounted in the middle of the left end of the limiting plate, a telescopic plate is connected to the left end of the telescopic rod, and a water guiding cylinder is mount outside the telescopic plate; and a cutting frame is mounted in the middle of the lower end of the support seat, a cutting wheel is mounted in the middle of the cutting frame, a driving shaft is mounted in the middle of the cutting wheel, a driving gear is connected to the other end of the driving shaft, a rotating gear is meshed to the upper end of thedriving gear, and a dust-removal cover is mounted outside the top end of the cutting frame. According to the self-propelled road pavement lancing device, a pavement can be cut, meanwhile, dust produced during the lancing can be removed, and the cutting wheel can be cooled.

Owner:钟晓梅

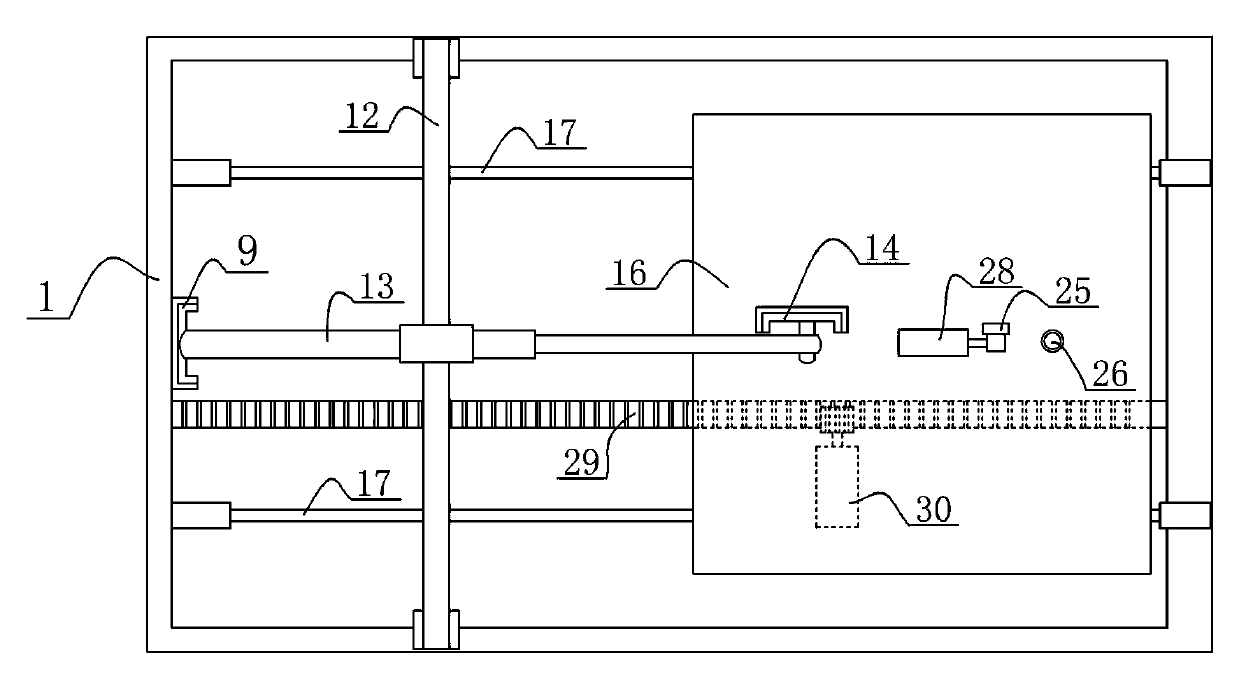

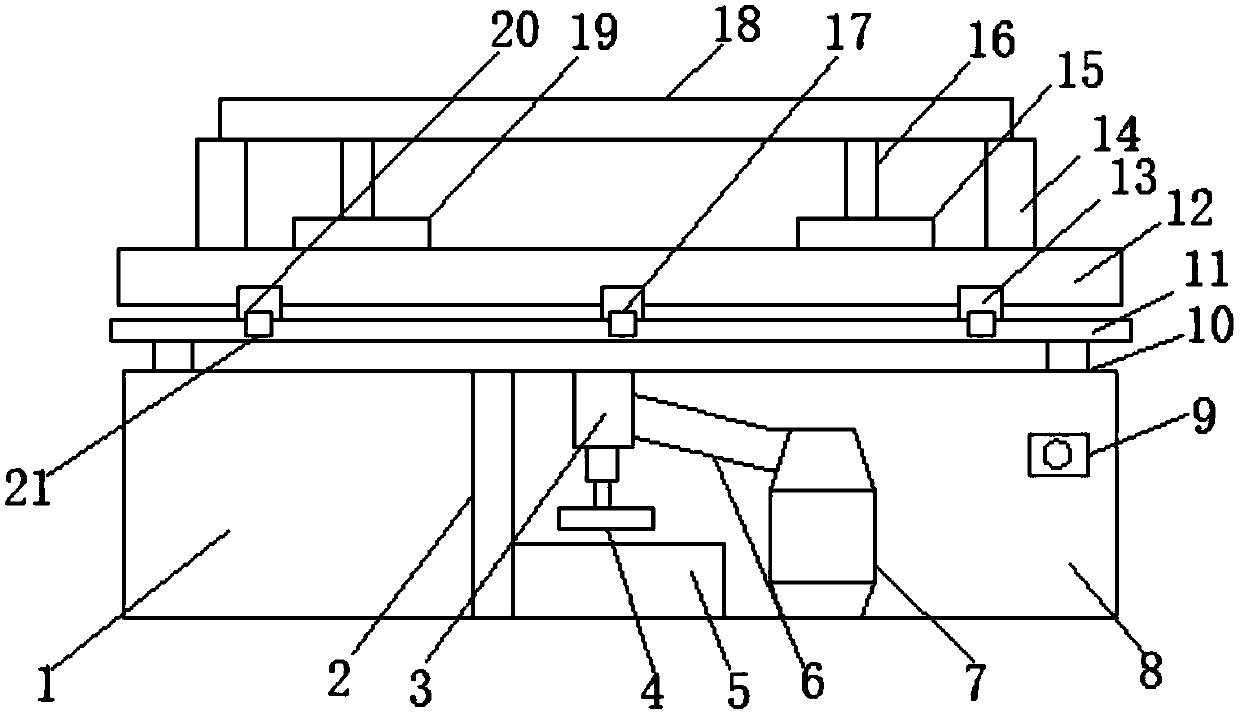

Plate cutting system

ActiveCN104057541AImplement the mobile cutting methodAchieve cutting effectWorking accessoriesStone-like material working toolsControl signalEngineering

The invention discloses a plate cutting system. The cutting system comprises first driving equipment, a cutting device and a central control unit, wherein the central control unit provides a longitudinal cutting position according to the plate cutting size, and the first driving equipment drives the cutting device to be transversely moved to the longitudinal cutting position and drives the cutting device to be longitudinally moved to finish longitudinal cutting of a plate according to control signals of the central control unit; the cutting system further comprises second driving equipment and longitudinal press beams, and the second driving equipment is used for driving the longitudinal press beams to be transversely moved to two sides of the longitudinal cutting position and pressed against the plate according to the control signals of the central control unit. The cutting system is applicable to plate fixation during repeated longitudinal cutting and repeated transverse cutting, and defects that the deviation occurs easily and size deviations are too large during longitudinal cutting due to the fact that no fixing device or clamping device exists or can be arranged longitudinally in the prior art are overcome.

Owner:北新建材(苏州)有限公司

Grass trimming head which is simple to operate and reliable to use and grass trimmer

PendingCN107646291ASimple and efficient operationReliable useMowersAgricultural engineeringStructural engineering

The invention provides a grass trimming head which is simple to operate and reliable to use and a grass trimmer. The grass trimming head comprises a shell body, a grass trimming rope, a wire ring which is arranged in the shell body and a locking device, wherein two wire outlet hole are formed in the shell body, and the grass trimming rope runs through the wire outlet holes; the wire outlet holes are evenly distributed along the circumference of the shell body, and the two outlet holes are a first wire outlet hole and a second wire outlet hole respectively; a central hole is formed in the wirering, the locking device is arranged at the central hole, and threading channels which transversely penetrate the wire ring and are communicated with the central hole are arranged on the side of the circumference of the wire ring; the threading channels are communicated with the first wire outlet hole and the second wire outlet hole, and the grass trimming rope sequentially runs through the firstwire outlet hole, the threading channels and the second wire outlet hole so as to penetrate the grass trimming head so that a user can conveniently load the grass trimming rope on the wire ring of thegrass trimming head without the need of disassembling the shell body; therefore, the operation of replacing the grass trimming rope can be simple and convenient, the position of the grass trimming rope can be locked through the locking device, and therefore it is ensured that the grass trimming rope can not be thrown out when in use, so that the grass trimming head can be used reliably.

Owner:ZHEJIANG YAT ELECTRICAL APPLIANCE CO LTD

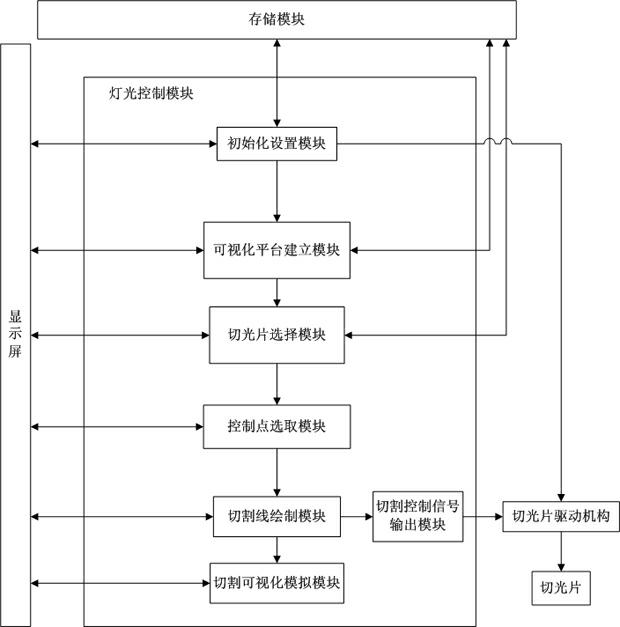

Control system and control method for visual adjustment of shutter sheets for stage lighting

The invention discloses a control system and a control method for visual adjustment of shutter sheets for stage lighting. The control system comprises a display screen, a light control module, a storage module and a shutter sheet driving mechanism, wherein the light control module is used for controlling luminaire shutter sheets and diaphragms, and the storage module is used for storing shutter sheet control threshold parameters and diaphragm parameters. The display screen, the storage module and the shutter sheet driving mechanism are all connected with the light control module. The shutter sheet driving mechanism is connected with a shutter sheet. By establishing a visual platform and using the single-control-point control way, the control system has the advantages of simplicity, convenience, quickness, visuality and the like in control. A precise algorithm is designed for conversion of a control point to a shutter sheet position, smooth and stable operation is guaranteed, and the shutter sheet can be controlled to precisely move to achieve the expected diaphragm sectional cutting effect so as to obtain an expected beam shape.

Owner:GUANGZHOU FINEART LIGHTING

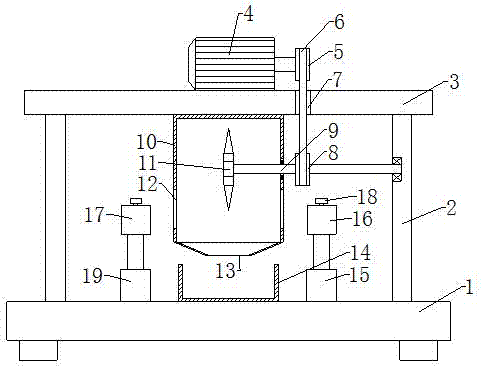

Rebar cutting device for building construction

The invention discloses a rebar cutting device for building construction. The rebar cutting device comprises a base, supporting vertical columns, a supporting cross beam, a driving motor, a rotating rod, a protective hood, a cutting knife, a collecting tank, a first clamping mechanism and a second clamping mechanism, wherein the protective hood is fixedly mounted on the lower surface of the middle of the supporting cross beam; the cutting knife is arranged inside the protective hood; feeding channels are symmetrically formed in two side plates of the protective hood; the collecting tank is arranged on the upper surface of the middle of the base; the first clamping mechanism is fixedly erected at the top end of a No.1 electric telescopic rod; and the second clamping mechanism is fixedly erected at the top end of a No.2 electric telescopic rod. The rebar cutting device disclosed by the invention is simple in structure, reasonable in design and convenient to use; the firm rebar clamping effect is achieved and the rebar cutting operation is facilitated; scraps are easy to collect in the cutting process; and the safety and the practicability are high.

Owner:朱发平

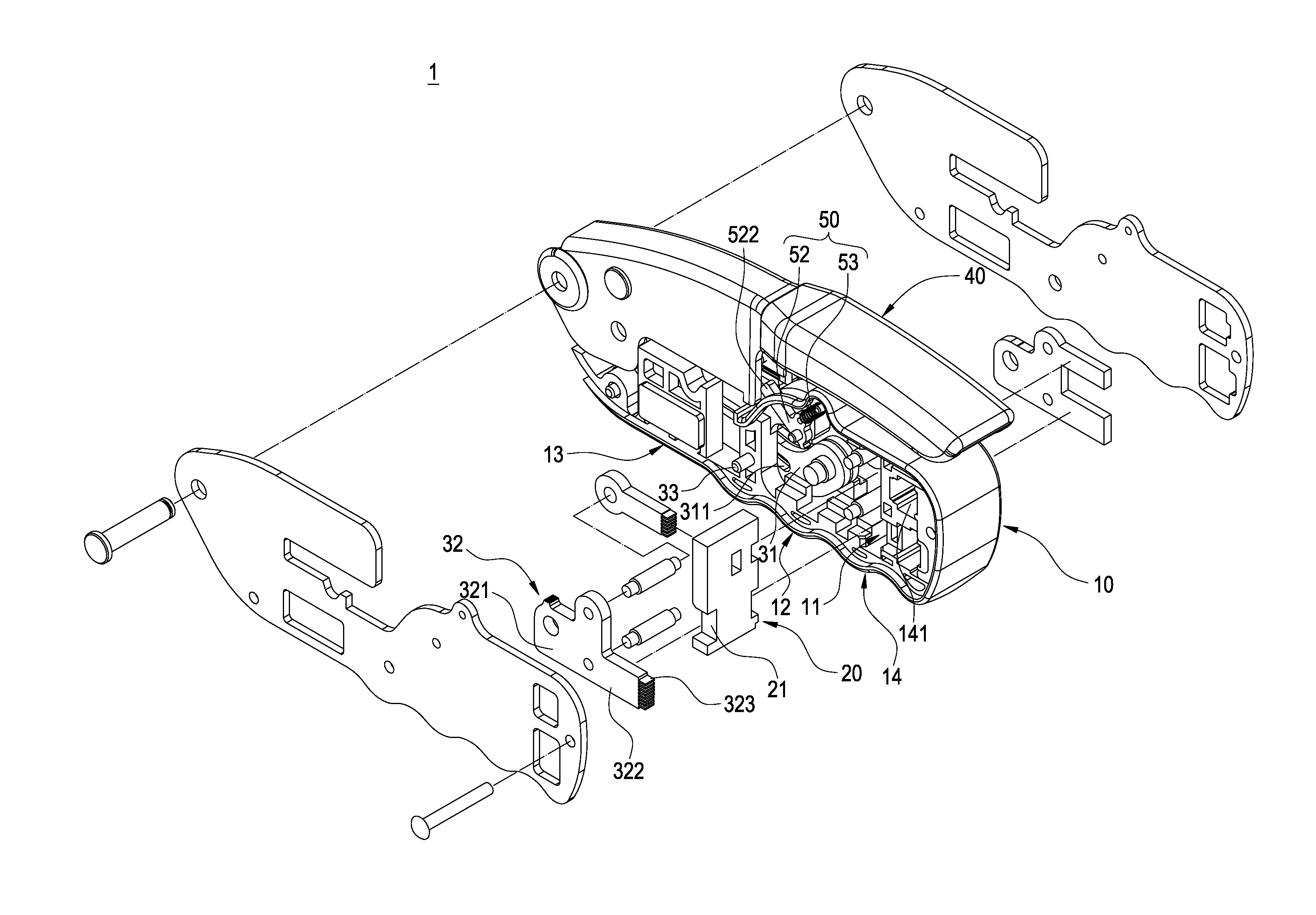

Crimping pliers

ActiveUS20150040638A1Smooth movementAchieve cutting effectLine/current collector detailsMulti-purpose toolsEngineeringMechanical engineering

A crimping pliers (1) includes a base (10), a guiding plate (20), a crimping member (30) and a compression handle (40). The base (10) includes a receiving space (11), a pivotal attachment portion (13) and an actuation section (14) having a crimping opening (141). The guiding plate (20) with a guiding hole (21) is installed in the receiving space (11) and corresponding to the crimping opening (141). The crimping member (30) is installed inside the receiving space (11) and comprises a connecting rod (31) attached to a sliding member (32) having a crimping portion (322) connected to the guiding hole (21) and corresponding to the crimping opening (141). The compression handle (40) is configured to drive the crimping portion (322) to move inside the crimping opening (141). Therefore, a uniform compression force is ensured to be applied to the connector and the conductive wire by the crimping portion.

Owner:YEN CHAO CHIN

Grey tile carved brick cutting device for constructional engineering

ActiveCN111941662ASave human effortEasy to operateWorking accessoriesStone-like material working toolsStructural engineeringMechanical engineering

The invention relates to a cutting device, in particular to a grey tile carved brick cutting device for constructional engineering. The technical problem to be solved by the invention is how to provide the grey tile carved brick cutting device for constructional engineering, which can save manpower during operation and ensure consistent cutting length each time. In order to solve the technical problem, the grey tile carved brick cutting device for constructional engineering comprises a support with a first guide connected to the top of the support, two fixing plates which are connected to thetwo sides of the top of the support, a conveying belt which are rotationally connected to one side of the support, a cutting assembly which is arranged on the support, and a clamping assembly which isarranged between the first guide rail and the fixing plates. According to the cutting device, the cutting assembly and the clamping assembly operate in cooperation to cut the grey tile carved brick,and therefore the effect of cutting the grey tile carved brick is achieved.

Owner:安徽雄风建设集团有限公司

Fixing cutter group with positioning device

The invention discloses a fixed cutter group with a positioning device. The fixed cutter group comprises an upper cutter part and a lower cutter part, wherein the upper cutter part comprises an upper cutter shaft, and a cutting disc I and a cutter pad I which are arranged on the middle part of the upper cutter shaft at a uniform interval; the lower cutter part comprises a lower cutter shaft, and a cutter pad II and cutting disc II which are arranged on the middle part of the lower cutter shaft at a uniform interval; a guide cutter pad I, a guide cutter I and a positioning cutter pad are arranged on the left part of the upper cutter shaft; the guide cutter pad I is positioned on the left side of the guide cutter I; the positioning cutter pad is positioned on the right side of the guide cutter I; the cutting disc I, the cutter pad I, the guide cutter pad I, the guide cutter I and the positioning cutter pad are fixedly connected into a whole; a guide cutter II, a guide cutter pad II and a positioning cutter are arranged on the left part of the lower cutter shaft; the guide cutter II is positioned on the left side of the guide cutter pad II; the positioning cutter is positioned on the right side of the guide cutter pad; and the cutter pad II, the cutting disc II, the guide cutter II, the guide cutter pad II and the positioning cutter are fixedly connected into a whole. The fixed cutter group has a reasonable design, high processing accuracy and high processing efficiency, and is convenient to detach and use.

Owner:THE NORTHWEST MACHINE

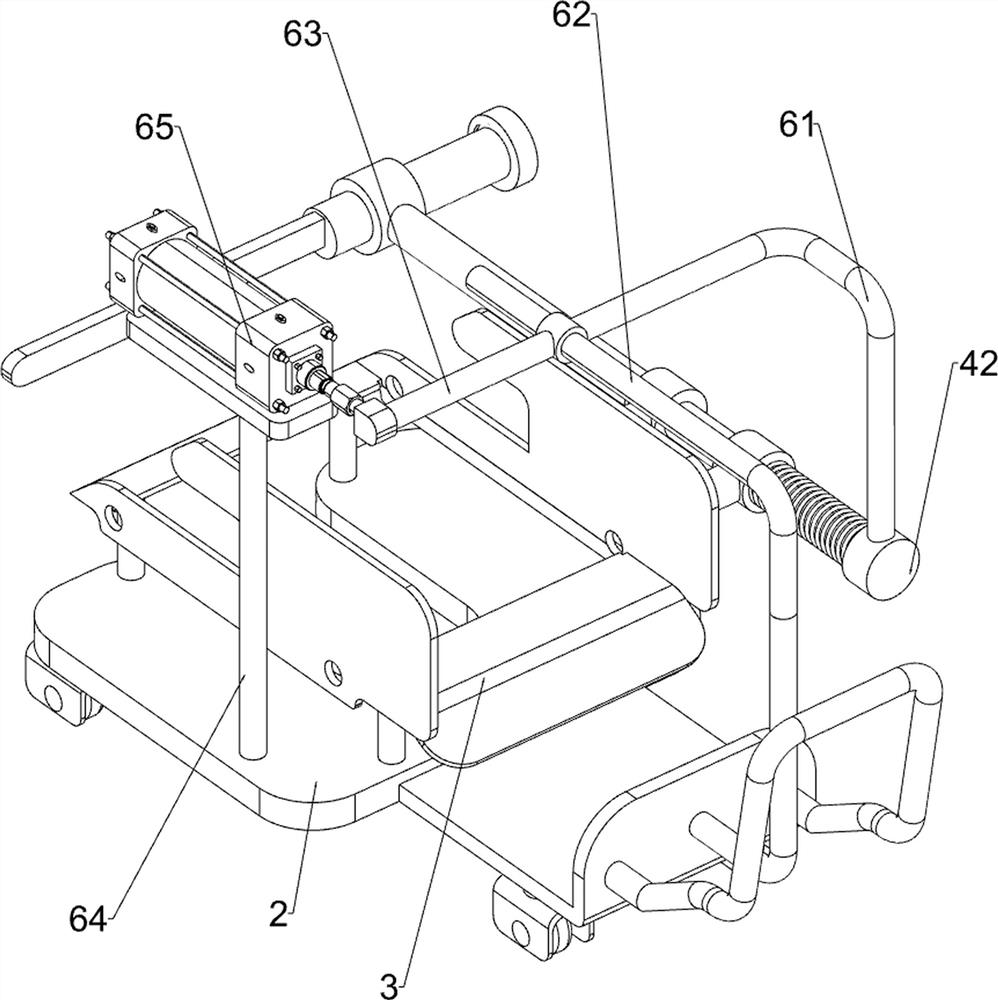

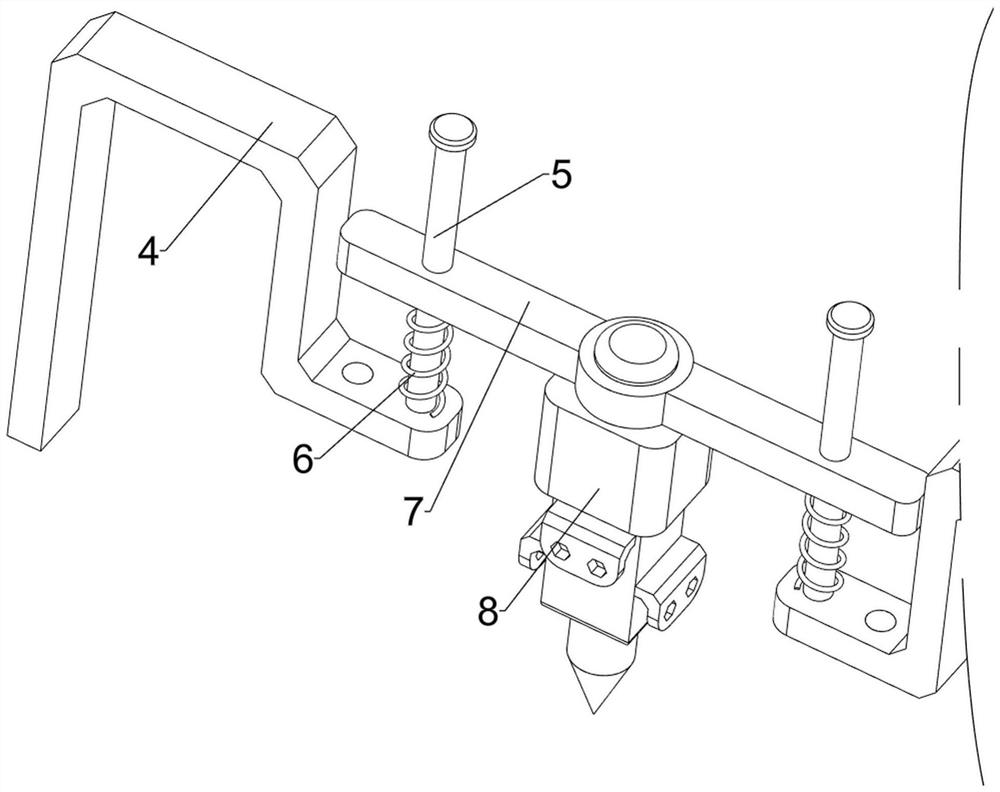

PPR pipefitting uniform cutting device

ActiveCN111531592AEasy to operateSave human effortMetal working apparatusEngineeringStructural engineering

The invention relates to cutting equipment, in particular to a PPR pipefitting uniform cutting device. The PPR pipefitting uniform cutting device is easy to operate, capable of effectively saving manpower, capable of saving consumed time during work, and capable of improving the work efficiency. The PPR pipefitting uniform cutting device comprises a base, a cutter and a cutter holder, a rack is connected to the base, fixed blocks are connected to the upper portions of the two sides of the rack, the bottoms of the fixed blocks are connected with guide rods, the cutter is in sliding connection to the position between the guide rods on the two sides, first reset springs are connected between the cutter and the guide rods, the cutter holder is connected to the lower portion in the rack, and the cutter holder is located below the cutter. Through a power mechanism, the cutter is driven to cut a PPR pipeline, and the effect of cutting the PPR pipeline is achieved.

Owner:马云艳

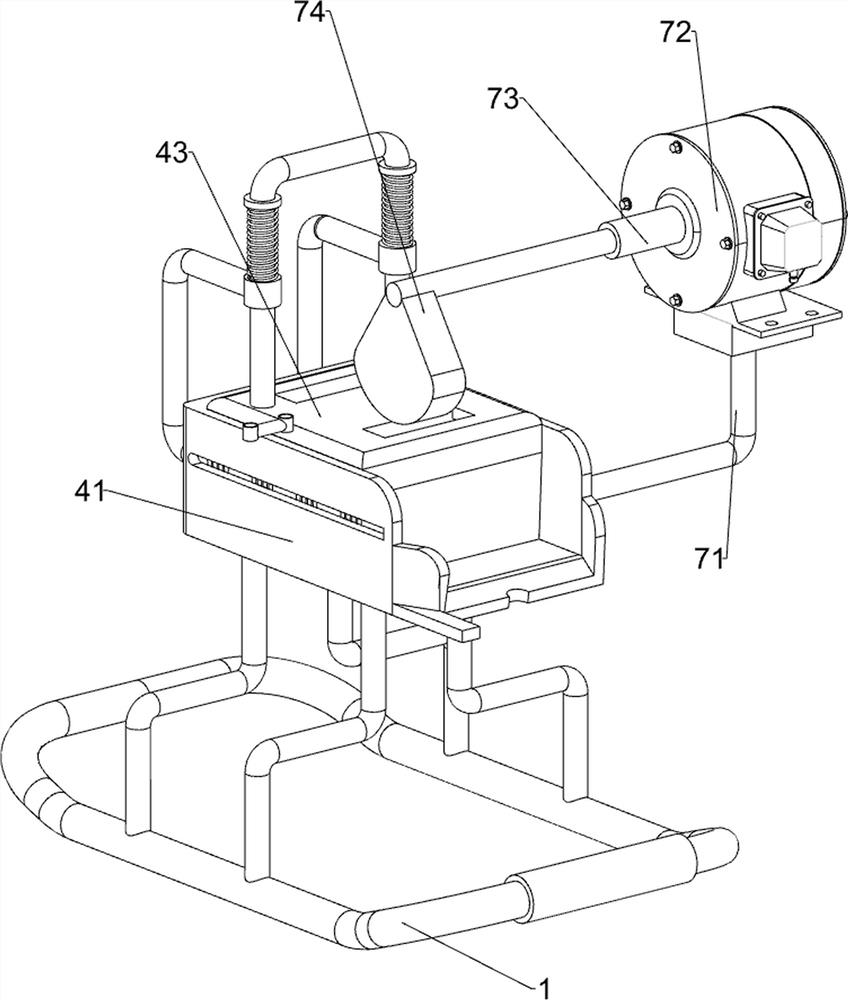

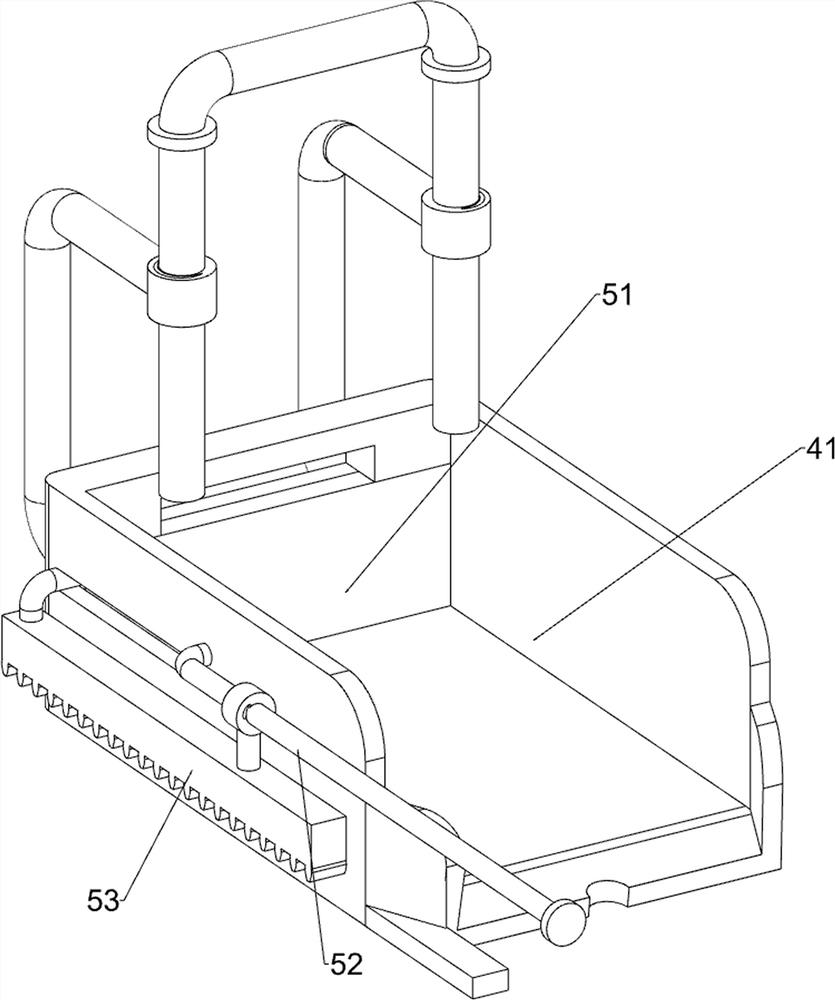

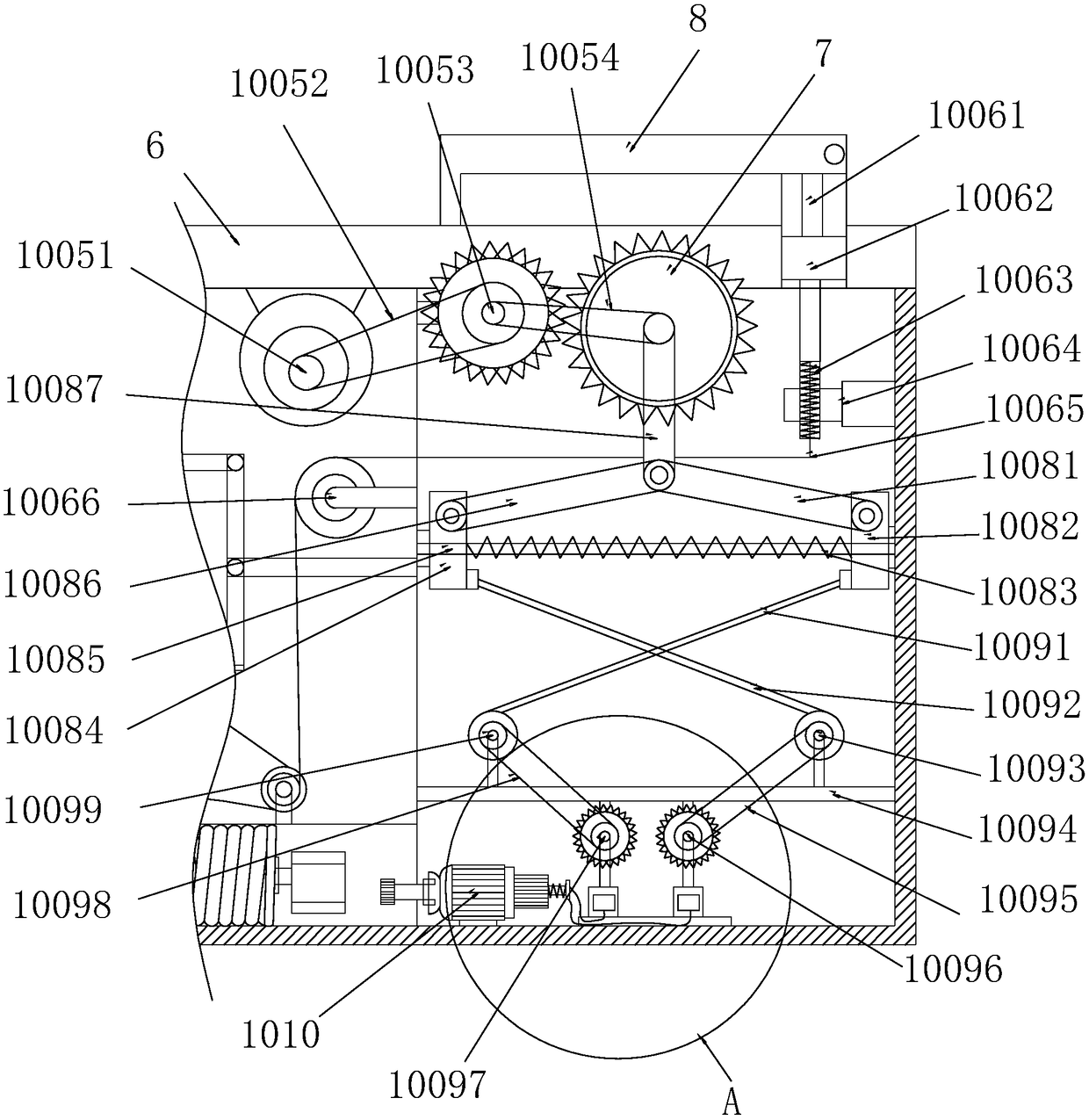

Garden deadwood breaking device

PendingCN112314223ARealize the slapping effectAchieve cutting effectCuttersCutting implementsEngineeringStructural engineering

The invention relates to a breaking device, in particular to a garden deadwood breaking device. The garden deadwood breaking device provided by the invention can achieve flexible conveying, improve the working efficiency and break branches of different structures. The garden deadwood breaking device comprises universal wheels, a working plate, a branch breaking mechanism and an intermittent cutting mechanism. Four universal wheels are evenly arranged at the bottom of a supporting plate; the working plate is arranged on the supporting plate; the branch breaking mechanism is arranged on the working plate; and the intermittent cutting mechanism is arranged on the branch breaking mechanism. Deadwood is placed behind a sliding flapping rod, a user pulls a connecting sliding rod backwards to drive the sliding flapping rod to move backwards to flap the deadwood, the flapped deadwood falls on the working plate, and therefore the flapping effect is achieved.

Owner:丁振英

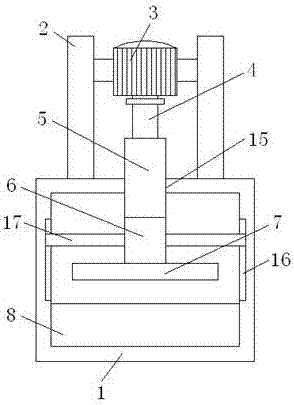

Cutting device for electronic components

InactiveCN105798206AAchieve cutting effectQuality assuranceMetal working apparatusEconomic benefitsEngineering

The invention discloses a cutting device for electronic components. The cutting device comprises a base, wherein a controller is arranged on the front surface of the base; a support plate is arranged on one side of the top of the base; a through groove is formed in one side of the top of the support plate; a chute is fixedly mounted on the other side of the inner wall of the support plate; a first cylinder is arranged at the bottom of the inner chamber of the support plate; a first telescopic rod is arranged at the top of the first cylinder; and a supporting plate penetrating the interior of the through hole is fixedly connected to the top of the first telescopic rod. The cutting device for the electronic components is simple in structure and convenient to operate, achieves a cutting effect of the electronic components, guarantees the quality of the cut electronic components, and avoids material waste; as an infrared sensor is arranged, the lengths of plug pins of the electronic components can be controlled during cutting, and accordingly, the cutting quality is improved; and under the action of a second cylinder and balls, the position of a positioning block can be adjusted, so that a convenient cutting effect is achieved, economic benefits are increased and the working efficiency is improved.

Owner:CHANGZHOU WUJIN HENGHUI COMM EQUIP CO LTD

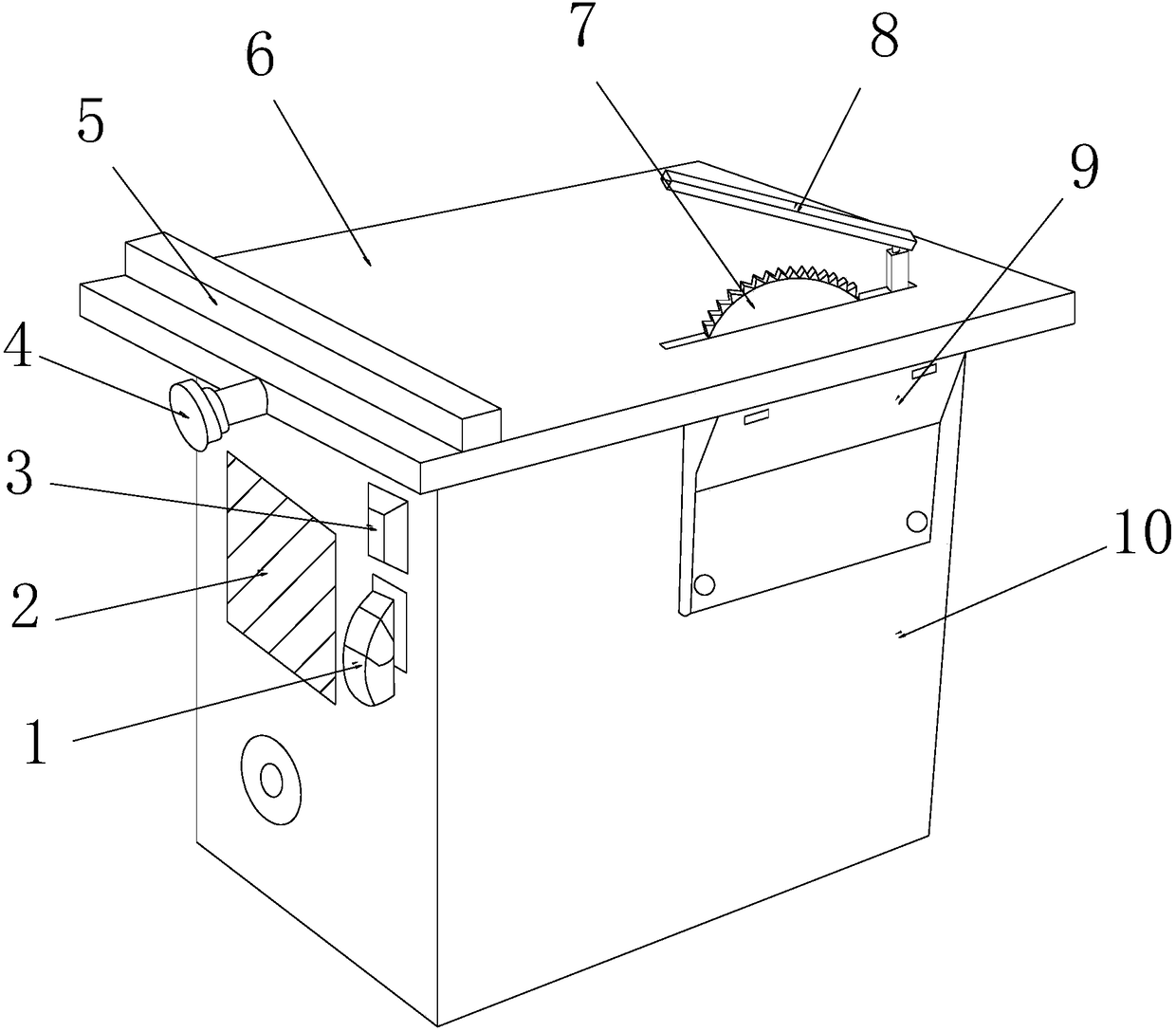

Novel multifunctional wood cutting device

InactiveCN108340442ARealize signal dockingAvoid safety hazardsCircular sawsEquipment useControl switch

The invention discloses a novel multifunctional wood cutting device. The device structurally comprises a safety switch, a cooling port, a control switch, a rotary knob, a baffle, a work table top, a saw blade, a safety protecting cover, an access door and a control main cabinet. According to the device, the saw blade is mounted in the safety protecting cover, when cutting work is not needed, the safety protecting cover can achieve a protecting effect and prevents the saw blade from being damaged by external factors, and the safety performance of the device is also improved; in addition, an ejecting unit arranged in the saw blade can stretch out and contract back freely according to the working state of the saw blade, and manual operation is not needed; and a saw blade pushing mechanism isdriven through a pushing transmission unit, when the saw blade does not need to work, a switch of the pushing transmission unit is turned off, the saw blade can be taken back into a main cabinet chamber by contracting back the saw blade pushing mechanism, unnecessary safety problems caused by exposure of the saw blade are solved, dual safety protection effects are achieved, the equipment using safety can be effectively improved, and the dangerousness is reduced.

Owner:孙秋梅

Slicer for processing

InactiveCN108687827AAchieve cutting effectImprove cutting efficiencyMetal working apparatusThreaded pipeArchitectural engineering

The invention discloses a slicer for processing, comprising a base. Support rods are fixedly connected to both sides of the top of the base, a fixing plate is fixedly connected to the top of the support rods, and a through hole is formed in the bottom of the fixing plate. A motor is fixedly connected to the left side of an inner cavity of the fixing plate, a threaded rod is fixedly connected to arotating shaft of the motor, and a threaded pipe is connected to the surface of the threaded rod in a threaded mode. The effect of placing traditional Chinese medicinal materials is achieved by arranging the base, the effect of driving the threaded rod to rotate is achieved by the motor, the effect of driving a first electric telescopic rod to move is achieved by the threaded rod and the threadedpipe, the effect of driving a connecting plate to move is achieved by the first electric telescopic rod, the effect of driving a second cutter body to move is achieved by a first sliding block and a first sliding groove, the effect of cutting the medicinal materials is achieved by a first cutter body and the second cutter body, and the slicer can cut repeatedly, so that cutting efficiency is improved.

Owner:山丹县润沐农林牧科技发展有限公司

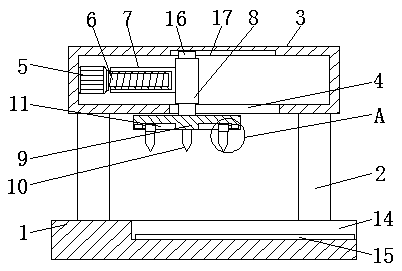

Auxiliary cutting equipment for cutting cortex magnoliae officinalis

The invention relates to cutting equipment, in particular to auxiliary cutting equipment for cutting cortex magnoliae officinalis. In order to solve the technical problems, the invention provides theauxiliary cutting equipment for cutting cortex magnoliae officinalis, which is simple in operation, can improve work efficiency, and can guarantee safety of an operator during operation. The auxiliarycutting equipment for cutting cortex magnoliae officinalis comprises a base, a feeding mechanism and a cutting mechanism, wherein the top of the base is connected to a workbench; the top of the workbench is connected to a supporting plate; the feeding mechanism is arranged on the top of the base; and the cutting mechanism is arranged on the top of the base. The feeding mechanism is matched with the cutting mechanism for operation so as to cut cortex magnoliae officinalis, so that cortex magnoliae officinalis cutting effect is achieved; and a stirring rod is matched with a six-tooth ratchet wheel to operate for driving the feeding mechanism to operate, so that the feeding mechanism does not need to manually drive to operate, and therefore, labor power is effectively saved.

Owner:王江明

Plate shearing machine with cutting size convenient to adjust

InactiveCN107350537AEasy to adjust cutting sizeControl cut sizeShearing machinesShearing machine accessoriesMeasurement deviceCoupling

The invention discloses a plate shearing machine which is convenient for adjusting the cutting size, comprising a box body, the surface of the box body is fixedly connected with a support rod, the surface of the support rod is fixedly connected with a motor, and the output shaft of the motor is fixedly connected through a coupling There is a threaded rod, the surface of the threaded rod is threadedly connected with a threaded pipe, one end of the threaded pipe penetrates and extends to the inside of the box, one end of the threaded pipe is fixedly connected with a pressure rod, and the surface of the pressure rod is fixedly connected with a blade. The shearing machine is convenient for adjusting the cutting size. When the cutting size needs to be adjusted, slide the telescopic rod on the inner wall of the telescopic tube through the adjusting bolt, observe the first scale and the second scale, and adjust the baffle to a suitable position. One end of the plate to be cut is docked with the surface of the baffle to achieve the effect of controlling the shearing size of the plate, thus effectively solving the lack of measurement settings of the general shearing machine, and there are often dimensional errors during the cutting process. To a certain extent Issues affecting product quality.

Owner:王之韵

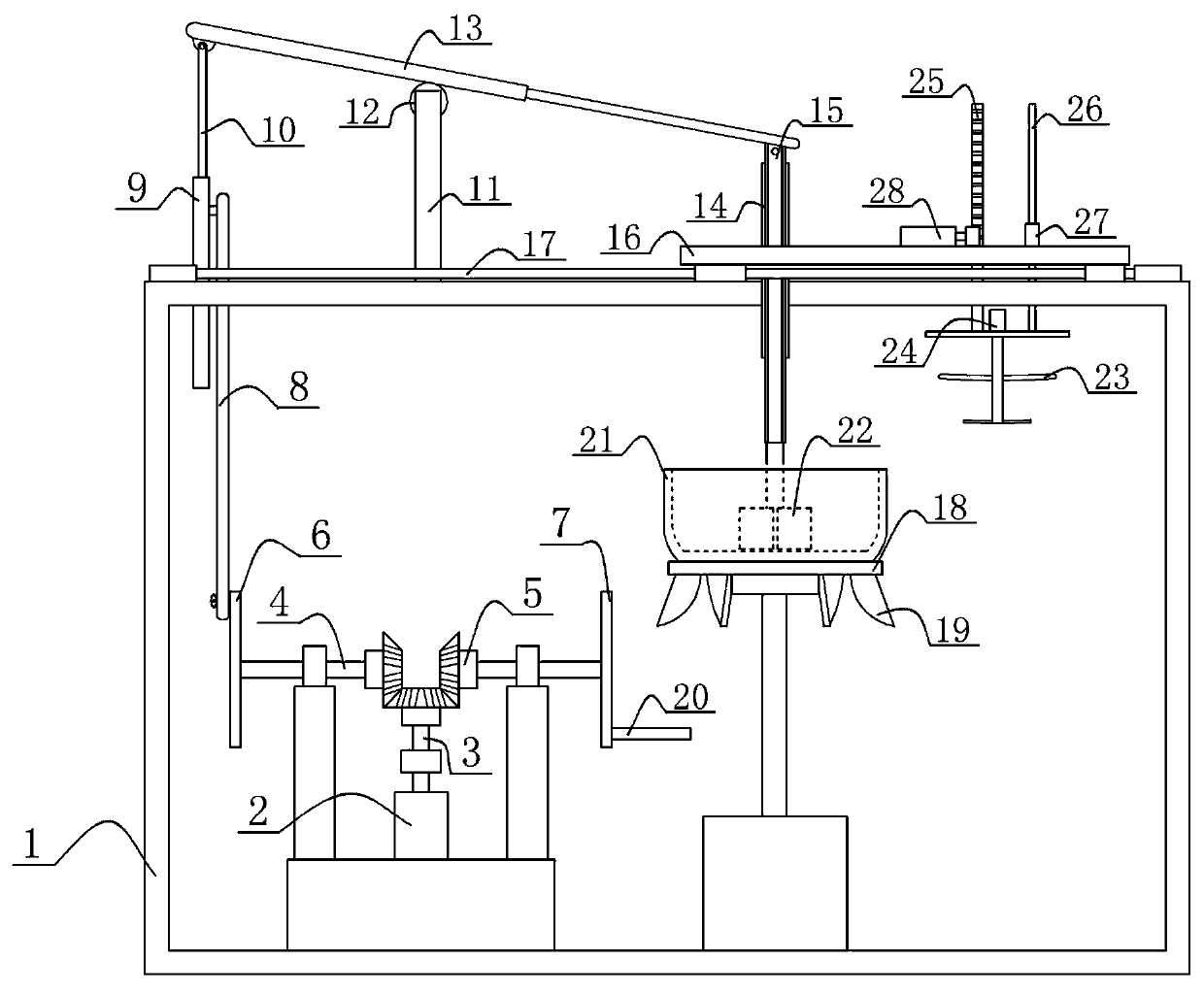

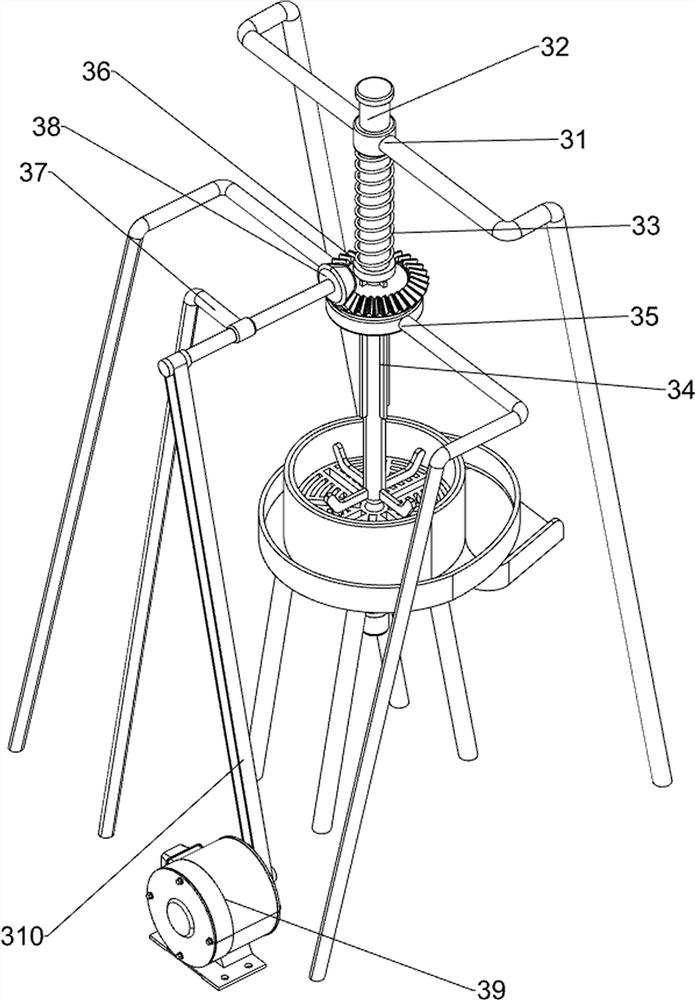

Automatic fried chicken cutlet making machine for food processing

ActiveCN112753722ARealize the effect of frying and salvageAchieve stirring effectTransportation and packagingRotary stirring mixersProcess engineeringBevel gear

The invention relates to a making machine, in particular to an automatic fried chicken cutlet making machine for food processing. The automatic fried chicken cutlet making machine for food processing is convenient to operate and capable of achieving automatic cutting and automatic discharging. The automatic fried chicken cutlet making machine for food processing comprises a bottom plate and an intermittent stirring mechanism, wherein a frying and fishing mechanism is arranged in the middle of the bottom plate; and the intermittent stirring mechanism is arranged on the bottom plate. By pushing a screening lifting frame upwards, a first spring is compressed, so that chicken cutlets fall onto a material receiving plate, and the frying and fishing effects are achieved; and a first bevel gear drives a rotating stirring rod to rotate, therefore, the rotating stirring rod stirs the chicken cutlets in a feeding pot, and the stirring effect is achieved.

Owner:安徽汉韵生物科技有限公司

Plate cutting equipment

InactiveCN107378128AFlexible adjustmentReasonable settingFeeding apparatusPositioning apparatusPulp and paper industry

The invention discloses a plate cutting equipment, which comprises a table top, the lower surface of the table top is connected with a group of supporting columns located on the ground, the upper surface of the table top is provided with a chute, and a supporting device is arranged in the chute, and the left end of the table top is connected with a second One support rod, the right end is connected to the second support rod, the head ends of the first support rod and the second support rod are connected to the top plate of the equipment, the tail end of the screw passes through the first support rod and connected to the second support rod, and the head end of the screw is connected to the screw motor , the screw motor is connected to the first support rod through the connecting rod. There is a nut body set on the screw rod under the top plate of the equipment. The head end of the side of the nut body is equipped with a motor. The belt is attached to the mounting shaft of the cutting knife. The invention has the advantages of more reasonable setting, the size of the working table surface can be adjusted, adapting to the different sizes of the required cutting boards, and the limitation is small.

Owner:贵州恒力源林业科技有限公司

Yam cutting device for medicinal material processing

ActiveCN109049023AAchieve cutting effectImprove cutting efficiencyMetal working apparatusDrive shaftEngineering

The invention discloses a yam cutting device for medicinal material processing. A supporting frame is vertically and fixedly installed on a bottom plate. A top plate is horizontally and fixedly installed at the upper end of the supporting frame. A driven shaft is rotationally and vertically arranged on the bottom plate. The driven shaft is fixedly provided with a sheave and a rotating disc in a sleeved manner. Yams are inserted in containing sleeves, and a cutting blade is horizontally arranged below a limiting disc. The vertical downward projection of the end, close to the limiting disc, of the cutting blade is located on the limiting disc, and a collecting groove located under the cutting blade is fixedly installed in the bottom plate. The yam cutting device is ingenious in structure andreasonable in design, the sheave is used for driving the yams on the containing sleeves to rotate in a stepping manner, the cutting effect of the cutting blade on the yams is achieved, due to the fact that the multiple containing sleeves are arranged, the cutting efficiency of the yams is greatly improved, abutting springs can upwards push the yams so that the upper ends of the yams can abut against the lower bottom face of the limiting disc, the upward feeding amount of the yams is ensured, next-time cutting is ensured, the automation degree is high, and the cutting efficiency is greatly improved.

Owner:JIANGSU VOCATIONAL COLLEGE OF MEDICINE

Cutting device for energy-saving warming plate of building

InactiveCN109203001ATo achieve the mobile effectAchieve the effect of rotationMetal working apparatusMotor driveArchitectural engineering

The invention discloses a cutting device for an energy-saving warming plate of a building. The cutting device comprises a pedestal, first support bars are fixedly connected to the two sides of the topof the pedestal respectively, a second support bar is fixedly connected to the tops of the first support bars, a cutting disk is arranged in the bottom of the second support bar, a first fixed plateis arranged in the top of the pedestal, and a second fixed plate is in sliding connection to the top of the first fixed plate; and a first electric telescoping rod is in sliding connection to the bottom of the second support bar. The second fixed plate is arranged to accommodate the warming plate, a second electric telescoping rod is arranged to drive the second fixed plate to move, the first electric telescoping rod drives a motor to move, the motor drives the cutting disc to rotate, the cutting disc cuts the warming plate in different positions, and convenience is provided for use.

Owner:郑州谓凡智能科技有限公司

Full-automatic mechanical household minitype seedling separating device

InactiveCN108293379AEasy to fillTo achieve the effect of seedling separationTransplantingEngineeringSingle chip

The invention discloses a full-automatic mechanical household minitype seedling separating device. The device comprises a box body, the left side of the top of the box body is communicated with a filling tube, and the left side of the bottom of the box body is communicated with a discharge tube; the bottom of the right side of the inner cavity of the box body is fixedly connected with an electrictelescopic rod, the left side of the electric telescopic rod is fixedly connected with a cutting blade, and the right side of the top of the inner cavity of the box body is fixedly connected with a storage battery. Through the arrangement of the filling tube, sugar canes are conveniently filled in the box body, the effect of controlling the electric telescopic rod operation is achieved through a single chip microcomputer, and the effect of driving the cutting blade to move is achieved through the electric telescopic rod; the effect of separating sugar cane seedlings is achieved through the cutting blade, the effect of discharging the sugar canes is achieved through the discharge tube, and the effect of collecting the sugar canes is achieved through a collecting box; the device can automatically carry out the seedling separation and sugar cane collection on the sugar canes, the labor force is reduced, the efficiency is also increased, and it is convenient for people to use the device.

Owner:佛山市翔桂农机科技有限公司

Dust removing device for wood cutting

PendingCN108544603AAchieve cutting effectAchieve the effect of absorbingProfiling/shaping machinesBark-zones/chip/dust/waste removalPhysical healthPulp and paper industry

The invention discloses a dust removing device for wood cutting. The dust removing device for wood cutting comprises a machine body, a vertical plate is welded to the left side of the top of the machine body, a transverse plate is movably connected to the top of the vertical plate through a rotating shaft, a motor is fixedly connected with the bottom of the transverse plate through a fixing block,an output shaft of the motor is fixedly connected with a cutting disc, a plastic cover is fixedly connected with the center of the top of the machine body, and a through hole is formed in the centerof the top of the plastic cover. Due to the arrangement and matching of the plastic cover, a first guide pipe, an air blower, an air inlet pipe, a second guide pipe, a suction fan, an air outlet pipeand a water tank, the effect of dust suction is achieved; due to the arrangement and matching of a first connecting block, an electric telescopic rod, a second connecting block and a movable partitionplate, the effect of collecting and treating wood chips is achieved; and thus the advantage of a good dust removing effect is achieved, convenience is brought to wood processing personnel, and the physical health of the wood processing personnel is guaranteed.

Owner:JIANGSU MINGLE FLOOR

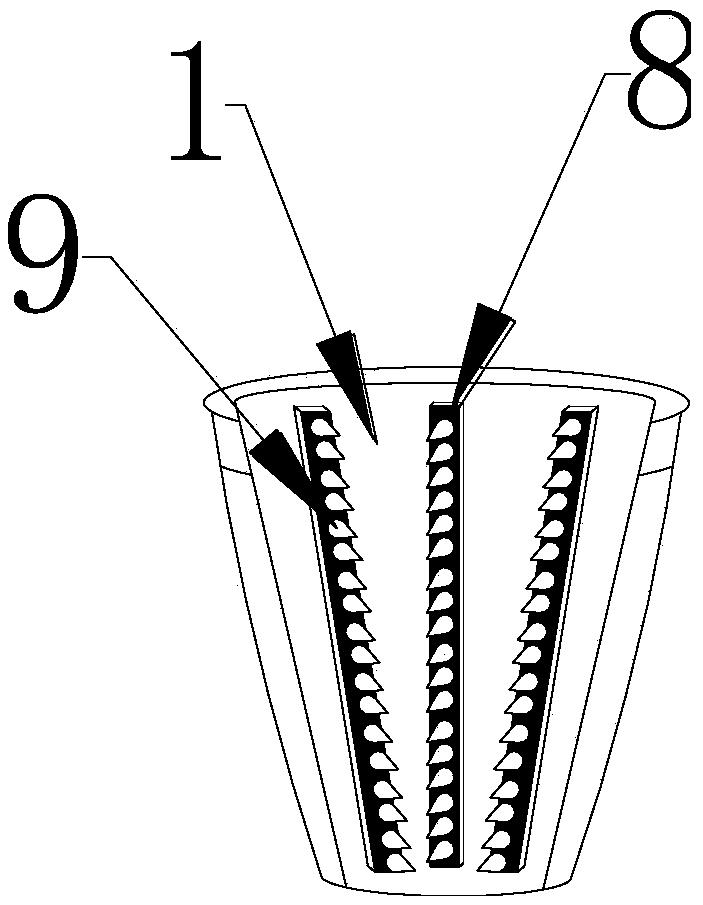

Conveniently-used wall-breaking processer

The invention provides a conveniently-used wall-breaking processer, and relates to the field of processing. The wall-breaking processer comprises a transparent shell, a top cover, a holding column, ahandle, a bottom circuit base and a display screen, wherein wall-breaking plates are fixedly connected to the surface of the inner side of the transparent shell; wall-breaking conical columns are fixedly connected to the surfaces of the wall-breaking plates; a linkage shaft is movably connected to the bottom end of the inner part of the bottom circuit base; four-blade cutter heads are movably connected to the bottom end and the top end of the linkage shaft; an auxiliary column is movably connected to the middle part of the linkage shaft; a blade slot is fixedly inlaid into the surface of the auxiliary column; triangular cones are fixedly connectedto the surface of the auxiliary column. A plurality of wall-breaking conical columns are provided and are symmetrical to one another, the wall-breaking conical columns are uniformly arranged on the surfaces of the wall-breaking plates and the wall-breaking conical columns are fixedly connected with the inner side of the transparent shell through the wall-breaking plates, so that when a user puts objects into the transparent shell, the effects of cutting the objects and breaking the walls of the objects are achieved through contact betweenthe wall-breaking conical columns and the objects.

Owner:肖安豪

Industrial automatic dicing device for plywood

ActiveCN112743637ARealize the driving effectAchieve cutting effectProfiling/shaping machinesSupport planeManufacturing engineering

The invention relates to a dicing device, in particular to an industrial automatic dicing device for plywood, and aims to provide the industrial automatic dicing device which is used for the plywood and is convenient to operate, complete in cutting surface and relatively high in cutting quality. The industrial automatic dicing device for the plywood comprises a base, first fixing frames, a pushing mechanism and a cutting mechanism; a supporting frame is arranged on the base; the two first fixing frames are arranged on one side of the base and are connected with the supporting frame; the pushing mechanism is arranged at the top of the supporting frame; and the cutting mechanism is arranged between the two first fixing frames. An air cylinder telescopic rod extends backwards and drives a first pushing frame to move backwards, the first pushing frame pushes the plywood backwards, and the pushing effect is achieved.

Owner:临沂汇丰木业有限公司

Titanium alloy plate laser cutting device for aerospace

PendingCN113751864ASave human effortAchieve cutting effectLaser beam welding apparatusPhysicsElectric machinery

The invention relates to a cutting device, in particular to a titanium alloy plate laser cutting device for aerospace. The titanium alloy plate laser cutting device for aerospace comprises a supporting frame, first connecting plates and first guide rods, wherein the two sides of the supporting frame are each connected with a mounting plate and a first fixing plate; the first connecting plates are connected to the sides of the tops of the first fixing plates at the two sides; and the first guide rods are connected to the tops of the first connecting plates. According to the device, push plates in material pushing mechanisms are driven by double-shaft motors in driving mechanisms to push titanium alloy plates to move, and in the process of pushing the titanium alloy plates to move, the titanium alloy plates are cut through laser cutters, so that the effect of automatically cutting the titanium alloy plates is achieved.

Owner:深圳市华丰泽电子有限公司

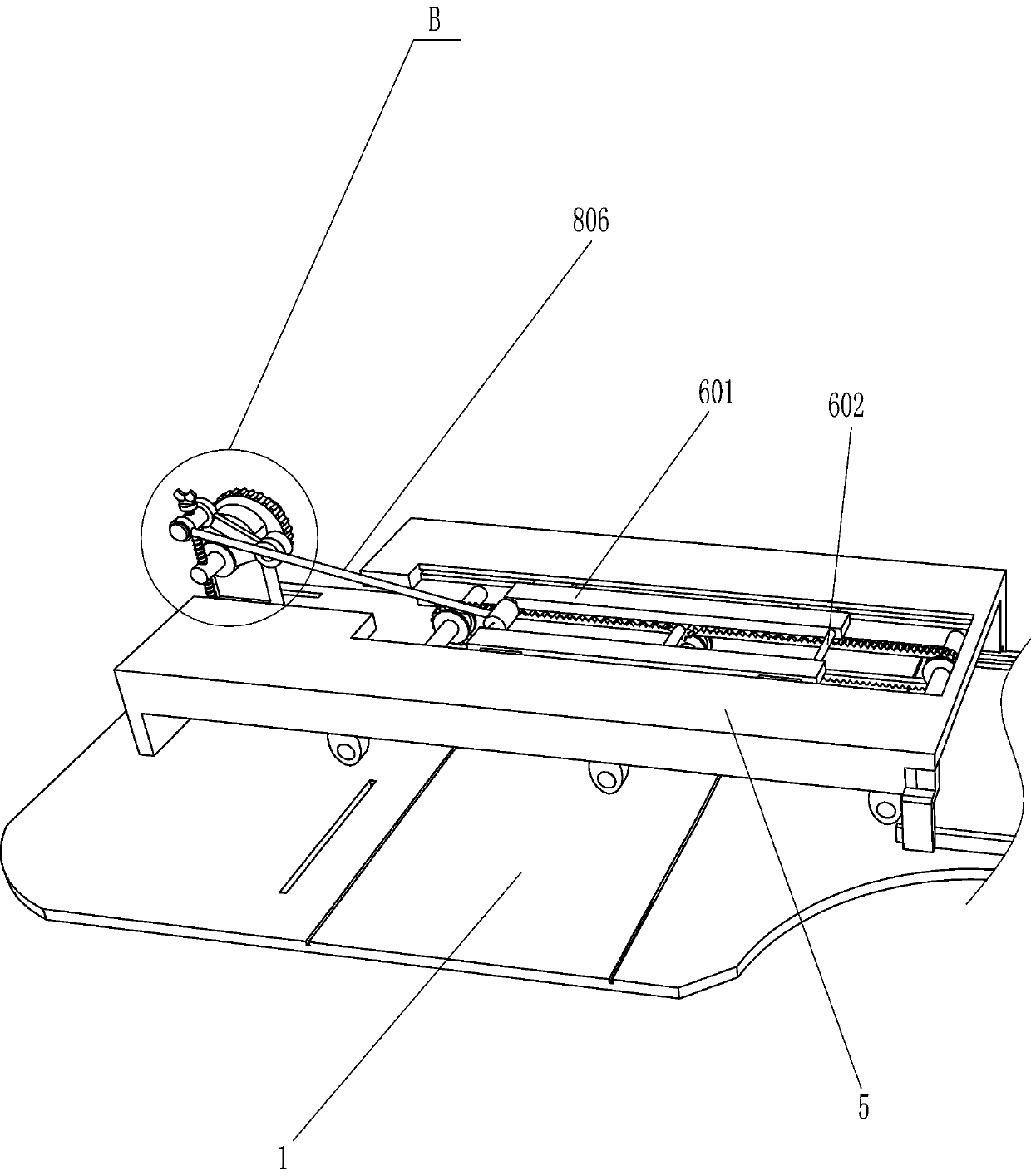

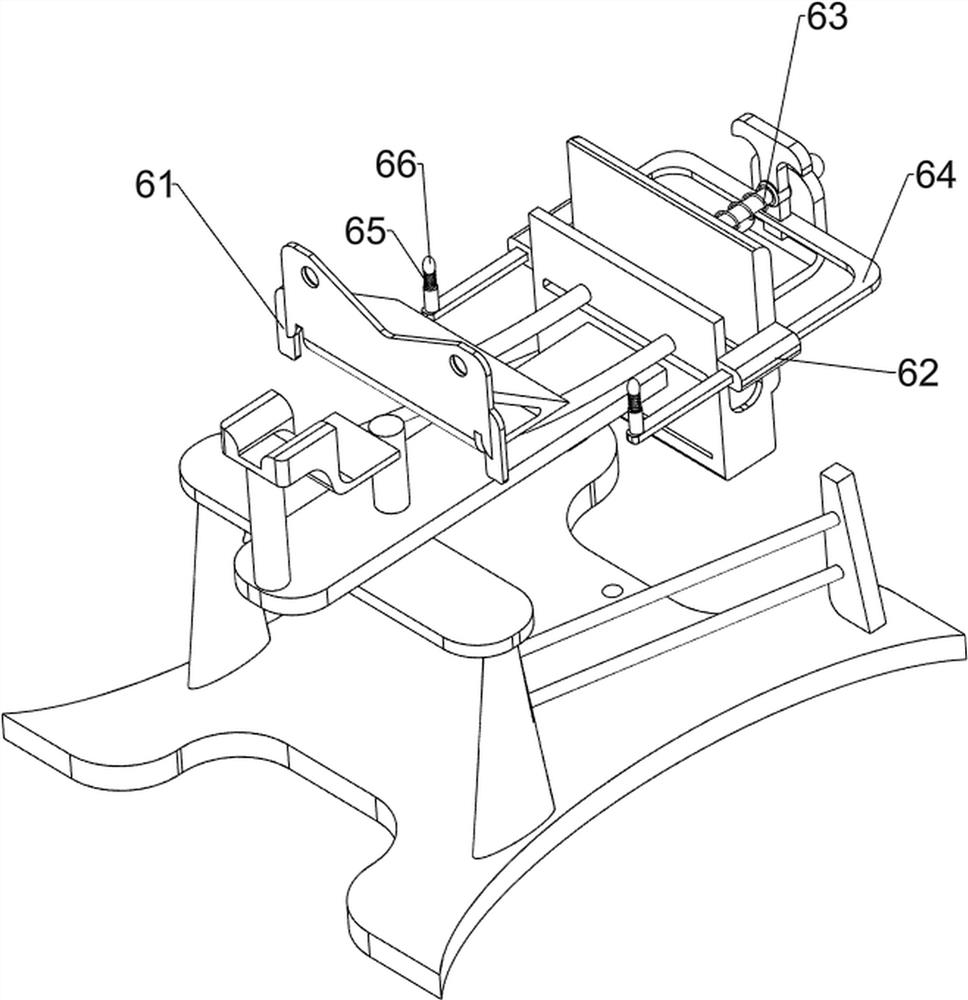

Adjustable cloth chair wood leg cutting device

InactiveCN111633743AAchieve cutting effectSave human effortFeeding devicesCircular sawsElectric machineryEngineering

The invention relates to a cutting device, in particular to an adjustable cloth chair wood leg cutting device. The technical problem to be solved is how to design an adjustable cloth chair wood leg cutting device capable of guaranteeing use safety of operators during operation and capable of saving manpower. The adjustable cloth chair wood leg cutting device comprises a bottom plate, a motor, a transmission device and a limiting device. The two sides of the bottom of the bottom plate are connected with landing legs, and a fixed clamp ring is connected to the middle of the bottom of the bottomplate. The motor is mounted on the fixed clamp ring, a saw blade is connected to an output shaft of the motor, a material falling opening is formed on the rear side of the top of the bottom plate, andthe upper portion of the saw blade penetrates through the material falling opening. The transmission device is arranged at the top of the bottom plate. The limiting device is arranged at the top of the bottom plate. According to the adjustable cloth chair wood leg cutting device, logs are cut into wood legs through cooperative running of the saw blade and the transmission device, and therefore the effect of cutting wood legs is achieved.

Owner:王封山

Wood cutting method

InactiveCN107553600AControl liftPrevent fallingCircular sawsBark-zones/chip/dust/waste removalCircular sawEngineering

The invention discloses a wood cutting method, which comprises cutting machine equipment, the bottom of the cutting machine equipment is fixedly connected with a support leg, the right side of the support leg is fixedly connected with a control box, and the outer front of the control box is fixed A switch is connected, the inner bottom of the control box is fixedly connected with a motor, the upper side of the left wall of the motor is fixedly connected with a dust suction pipe, the left side of the dust suction pipe is fixedly connected with a vacuum cleaner, and the bottom of the vacuum cleaner is movable A rotary handle switch is connected, and a sawdust leak is opened at the bottom of the rotary handle switch. In the present invention, through the cooperation of the cylinder, the circular twist and two circular saws, the bottom of the clamping block is fixedly connected to the first circular saw, so that the lifting of the cylinder can be controlled by the first pusher connected to the top of the cylinder, thereby controlling The lifting of the two circular saws can cut panels of different thicknesses, and then connect them through a circular twist, which avoids the problem of the two circular saws falling during cutting.

Owner:王铁龙

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com