Automatic fried chicken cutlet making machine for food processing

A food processing and frying technology, which is applied in the field of automatic production machines for fried chicken chops for food processing, can solve the problems of inability to realize automatic cutting, inconvenient operation of chicken chop cutting, and inability to automatically discharge materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

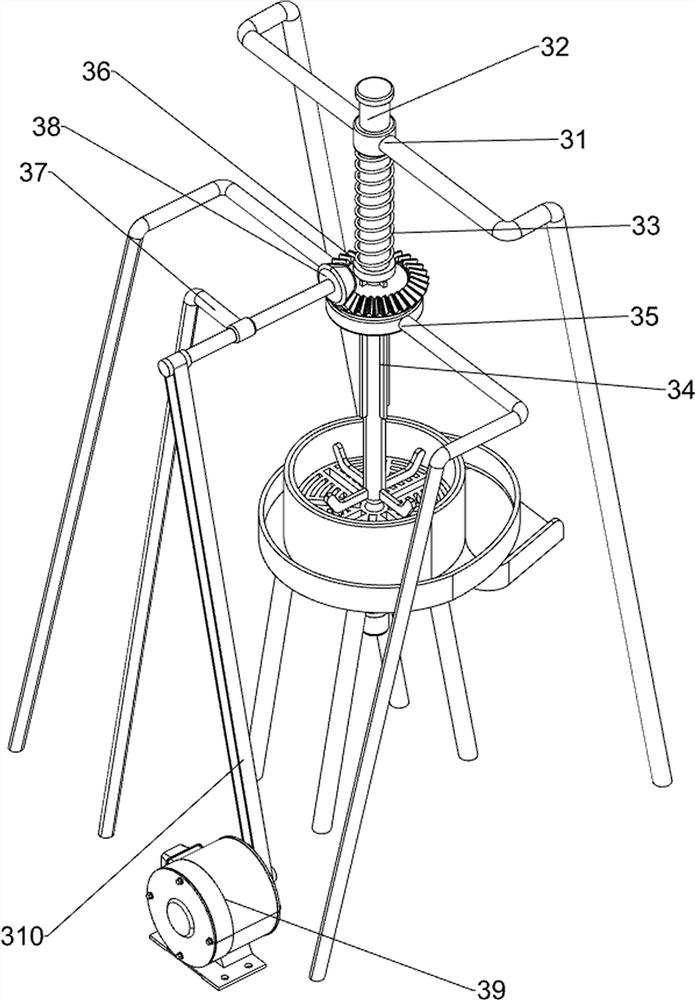

[0075] A kind of machine for making fried chicken cutlets automatically for food processing, such as figure 1 As shown, it includes a base plate 1, a frying and fishing mechanism 2 and an intermittent stirring mechanism 3. The upper and middle part of the bottom plate 1 is provided with a frying and fishing mechanism 2, and the base plate 1 is provided with an intermittent stirring mechanism 3.

[0076] When people want to make chicken cutlets, they can use this automatic fried chicken cutlet machine for food processing. First, the user pours hot oil into the frying and fishing mechanism 2, and then puts the chicken cutlets into the frying and fishing mechanism 2. Mechanism 2 starts the intermittent stirring mechanism 3, and the intermittent stirring mechanism 3 stirs the chicken chops in the frying and salvage mechanism 2, and after the stirring of the chicken chops is completed, the intermittent stirring mechanism 3 is closed.

Embodiment 2

[0078] On the basis of Example 1, such as Figure 2-Figure 4 As shown, the frying salvage mechanism 2 includes a discharge pot 21, a material receiving plate 22, a screening lifting frame 23 and a first spring 24, the bottom plate 1 is provided with a discharge pot 21 in the upper middle, and the discharge pot 21 is provided with a material receiving pot 21. The plate 22 and the middle part of the discharging pot 21 are slidingly provided with a screening lifting frame 23, and a first spring 24 is connected between the screening lifting frame 23 and the discharging pot 21.

[0079] The user pours hot oil into the feeding pot 21, and then puts the chicken steaks into the feeding pot 21. After the chicken steaks are made, the user pushes the screening lifting frame 23 upwards, and the first spring 24 is compressed, so that the chickens are discharged. Fall onto the material receiving plate 22 to realize the effect of frying and fishing, unclamp the screening lifting frame 23, an...

Embodiment 3

[0083] On the basis of Example 2, such as figure 1 and Figure 5-Figure 9 As shown, it also includes a pick-up mechanism 4, the base plate 1 is provided with a pick-up mechanism 4, and the pick-up mechanism 4 includes a winding wheel 41, a first spur gear 42, a second fixed sliding sleeve 43, a missing gear 44, a first Three bevel gears 45 and the first fixed rod 46, the left and right sides on the base plate 1 are all rotatably provided with winding wheels 41, and the first spur gear 42 is all provided on the two winding wheels 41, the left and right sides of the rear side on the base plate 1 Both are equipped with second fixed sliding sleeves 43, and the two second fixed sliding sleeves 43 are equipped with missing gears 44 in rotation, and the two missing gears 44 and the rotating connecting disc 35 are all provided with a third bevel gear 45. The three bevel gears 45 are rotatably connected with the rotating connection plate 35, and the rotating stirring rod 34 slides on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com